Kungani Kufanele Ukhethe Isikhumba Esiqopha Nge-Laser?

Ukwenza ngokwezifiso, Ukunemba, Ukusebenza Kahle

Isikhumba sokusika nge-laser sesibe ithuluzi elibalulekile kumabhizinisi nakubantu abangochwepheshe, sinikeza ukunemba okungenakuqhathaniswa kanye nokwenza ngokwezifiso. Kungakhathaliseki ukuthi usebenza kuma-patches esikhumba aqoshiwe nge-laser noma ukwenza izesekeli zesikhumba zibe ngezakho, izinzuzo zokusebenzisa umshini wokusika nge-laser yesikhumba azinakubalwa. Nasi isizathu sokuthi kufanele ukhethe ukusika nge-laser esikhumbeni kuphrojekthi yakho elandelayo.

1. Ukunemba Okungalingani kanye Nemininingwane

Siyazi ukuthi kunezindlela eziningi zokuqopha nokuqopha izinto zakho zesikhumba, njengokuqopha nokunamathisela, ukusika imimese, ukuqopha nge-laser, ukutshisa, kanye nokuqopha nge-CNC, zinhle kakhulu kwezinye izici. Kodwa uma kukhulunywa ngokunemba kanye nokuceba kwemininingwane namaphethini, ukuqopha nge-laser ngokungangabazeki kuyinombolo 1.

Okumangalisayoukunemba okuphezulu kanye nohlelo lokulawula lwedijithalikusuka kumshini wobuciko we-laser wesikhumba ochwepheshe, unikeza umsebe we-laser omuhle kakhulu othinta isikhumba ngeUbubanzi obungu-0.5mm.

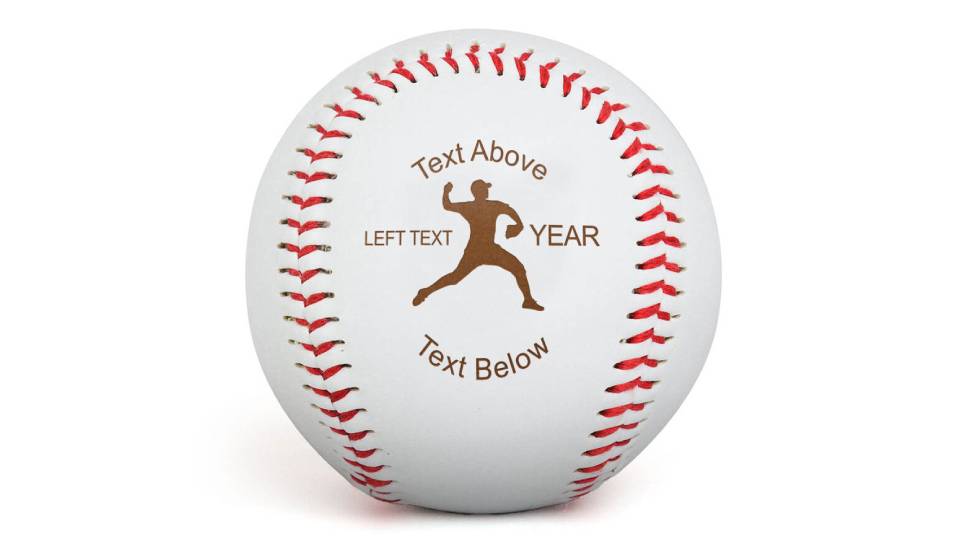

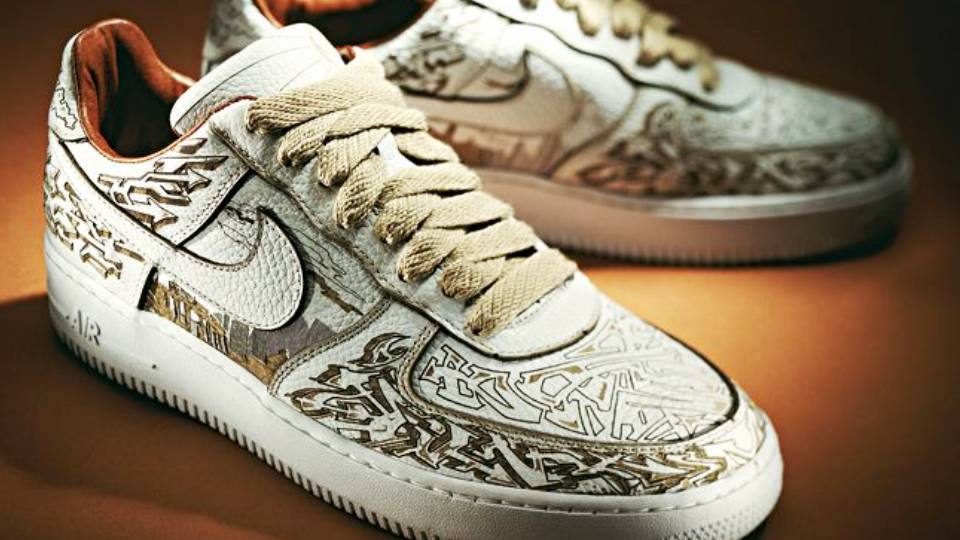

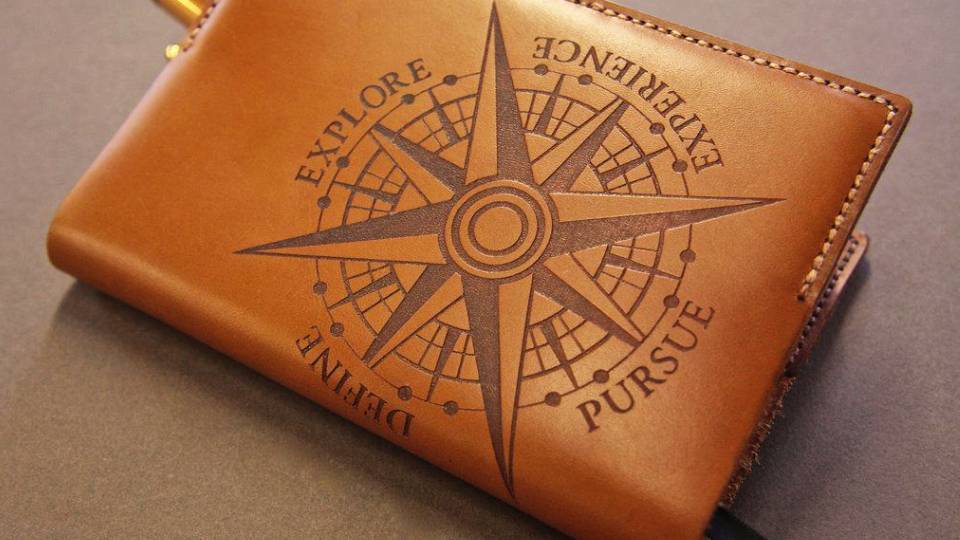

Ungasebenzisa leli thuba ukuqopha amaphethini amahle futhi ayinkimbinkimbi ezintweni zakho zesikhumba njengezikhwama zemali, izikhwama, amapheshi, amajakethi, izicathulo, imisebenzi yezandla, njll.

Ngesikhumba esiqoshwa nge-laser, ungafinyelela izinga elimangalisayo lokunemba. Umsebe we-laser ungaqopha amaphethini nemiklamo eyinkimbinkimbi, okuholela ekuqoshweni nge-laser okunemininingwane eminingi. imikhiqizo yesikhumba.

Lokhu kwenza isikhumba se-laser etch siphelele ekudaleni ubuciko obungokwezifiso, uphawu, noma amaphethini ezimpahleni zesikhumba.

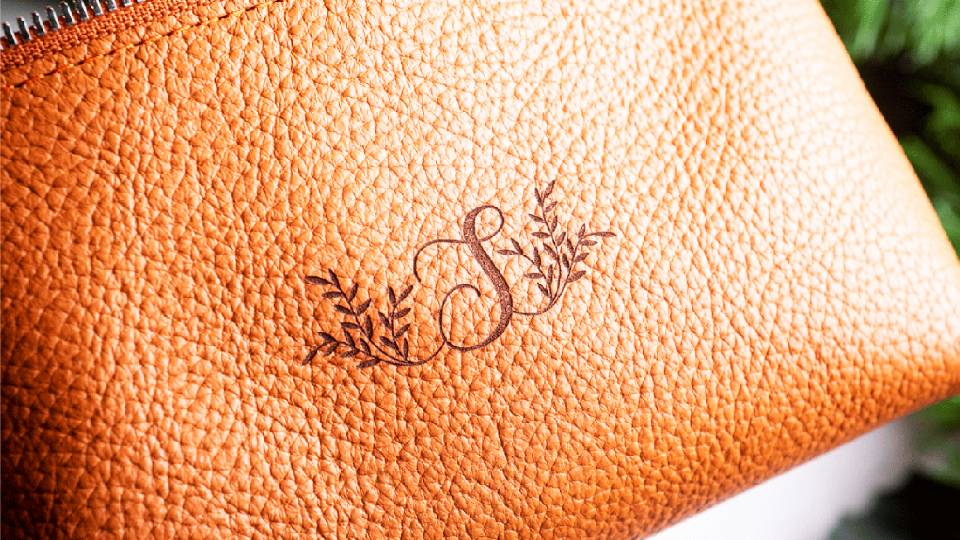

Isibonelo:Ama-logo enziwe ngokwezifiso kanye namaphethini ayinkimbinkimbi aqoshwe ezikhwameni noma emabhandeni.

Icala lokusetshenziswa:Amabhizinisi adinga ukufaka ama-logo anembile kuma-patches esikhumba aqoshwe nge-laser ukuze afake uphawu.

2. Ukwenza ngokwezifiso ngesilinganiso

Enye yezinto ezinhle kakhulu mayelanaukuqoshwa nge-laser esikhumbeniyikhono lokushintsha kalula phakathi kwemiklamo ehlukene ngaphandle kwamathuluzi engeziwe.Lokhu kuvumela ukwenza ngokwezifiso okuphelele, kungakhathaliseki ukuthi usebenza entweni eyodwa noma izimpahla zesikhumba ezikhiqiza ngobuningi.

Ukwenziwa ngokwezifiso okuguquguqukayo kwesikhumba esiqoshwa nge-laser, ngakolunye uhlangothi, kuvela emsebeni we-laser omuhle, kufana nechashazi, futhi kungadweba noma yiliphi iphethini kufaka phakathi ihluzo ze-vector kanye ne-pixel, okushiya izimpawu eziqoshiwe noma eziqoshwe zesitayela esiyingqayizivele.

Ngakolunye uhlangothi, kuvela emandleni kanye nesivinini se-laser esilungisekayo, lawa mapharamitha anquma ukujula kwesikhumba kanye nesikhala, futhi athinta izitayela zakho zesikhumba.

Isibonelo, uma usebenzisa umshini wokuqopha wesikhumba we-laser ongu-100W, bese usetha amandla e-laser abe ngu-10%-20%, ungathola umbhalo ocacile nongajulile noma omaka ebusweni besikhumba. Lokho kuhambisana nama-logo okuqopha, izinhlamvu, umbhalo, namagama okubingelela.

Uma ukhulisa iphesenti lamandla, uzothola uphawu lokuqopha olujulile, oluyisikhathi esidlule, njengokufaka isitembu nokuqopha.

Okokugcina kodwa okungabalulekile, isofthiwe yokuqopha nge-laser enobungane ingahlelwa nganoma yisiphi isikhathi, uma uhlola umklamo wakho esikhumbeni sesikhumba futhi ungalungile, ungashintsha isithombe somklamo kusofthiwe, bese uya kohlola uze uthole umphumela ophelele.

Ukugcaba isikhumba nge-laser kuguquguqukayo futhi kungokwezifiso, kufaneleka kubaklami abazimele kanye nalabo abenza ibhizinisi elenziwe ngokwezifiso.

Inzuzo:Ivumela amabhizinisi ukuthi anikeze imikhiqizo yesikhumba eyenzelwe wena ngaphandle kwezindleko ezengeziwe zokusetha.

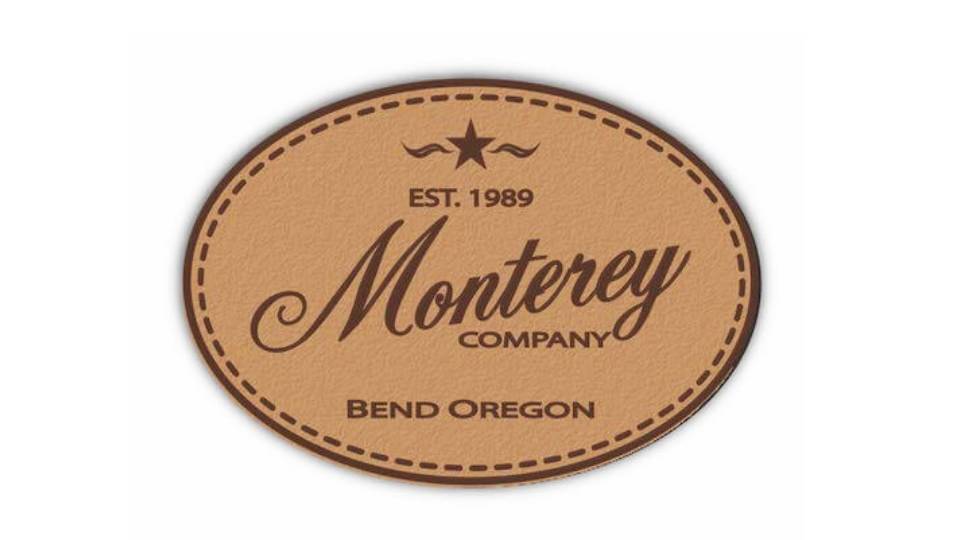

Isibonelo:Inikeza amapheshi esikhumba aqoshwe nge-laser kumajakethi nasezikhwameni ezenziwe ngokwezifiso ukuze kube nokuthinta komuntu siqu.

Ukuboniswa Kwevidiyo: Amathuluzi Ama-3 Okusika Isikhumba

3. Ukuguquguquka Kuzo Zonke Izicelo

Ukugoba nge-laser kufaneleka kakhulu emikhiqizweni eminingi yesikhumba kanye nezinhlobo zesikhumba okuhlanganisa isikhumba esishukwe ngemifino, i-nubuck, isikhumba esigcwele okusanhlamvu, isikhumba se-PU, i-suede, ngisho ne-Alcantara efana nesikhumba.

Phakathi kwama-laser amaningi, i-laser ye-CO2 ifaneleka kakhulu futhi ingakha isikhumba esihle nesithambile esiqoshwe nge-laser.

Imishini yokuqopha isikhumba nge-laserziyasebenziseka ngezindlela eziningi futhi zingasetshenziswa emikhiqizweni ehlukahlukene yesikhumba.

Ngaphandle kwezinto zokwenza isikhumba nsuku zonke, amapheshi esikhumba, amagilavu, kanye nezinto zokuzivikela, isikhumba sokusika nge-laser singasetshenziswa emikhakheni yezimoto njengegama lomkhiqizo lokusika nge-laser esiteringini, amaphethini okumaka nge-laser esivalweni sesihlalo.

Ngendlela, i-laser ingasika izimbobo ngisho nezimbobo ezincane esembozweni sesihlalo sesikhumba ukuze yengeze umoya nokubukeka. Okuningi ngalokho ongakwenza ngesikhumba esiqoshwa nge-laser, ngena ezindabeni ukuze uthole:imibono yesikhumba yokuqopha nge-laser

Eminye Imibono Yesikhumba Esiqoshwe Nge-Laser >>

4. Isivinini Esiphezulu Nokusebenza Kahle

Umshini wokuqopha isikhumba nge-laser unikeza isivinini kanye nokunemba, okwenza ube muhle kakhulu kumabhizinisi anezidingo ezinkulu zokukhiqiza.

Ngokuhlelwa nokusebenza okufanele, uchwephesheUmqophi wesikhumba we-Galvo nge-laseringafinyelela ku-isivinini sokumaka esiphakathi kuka-1 no-10,000mm/sFuthi uma isikhumba sakho sisesigoqweni, sincoma ukuthi ukhethe umshini we-laser wesikhumba one-i-auto-feederfuthiithebula lokuhambisa, ezisiza ukusheshisa ukukhiqizwa.

Kungakhathaliseki ukuthi udinga ukudala izingcezu ezikhiqizwa kanye noma izinto ezikhiqizwa ngobuningi, inqubo yesikhumba esikhishwa nge-laser iqinisekisa izikhathi zokukhiqiza ezisheshayo ngaphandle kokubeka ikhwalithi engcupheni.

Ividiyo Yesiboniso: Ukusika Nokuqopha Izicathulo Zesikhumba Nge-Laser Okusheshayo

Inzuzo:Ilungele amabhizinisi afuna ukukhiqiza inani elikhulu lezinto zesikhumba eziqoshwe nge-laser ngokushesha.

Isibonelo:Ukukhiqizwa okusheshayo kwamabhande esikhumba nezesekeli ngemidwebo eyenziwe ngokwezifiso.

5. Okunobungani Nemvelo

Ngokungafani nezindlela zokuqopha zendabuko,imishini yokuqopha isikhumba nge-laserakudingi ukuthintana ngokomzimba, amakhemikhali, noma udayi. Lokhu kwenza inqubo ibe sesimweni esizinzile futhi ibe nobungane nemvelo, futhi kukhiqizwe imfucuza encane.

Umthelela:Ukukhiqizwa kwesikhumba okuhlala isikhathi eside okunomthelela omncane emvelweni.

Inzuzo:Amabhizinisi aqaphela imvelo angavumelanisa imikhuba yawo nezinqubo ezinobungani nemvelo.

6. Imiklamo Ehlala Njalo Nehlala Isikhathi Eside

Imiklamo ekhiqizwe ngesikhumba esigoqwa nge-laser ihlala isikhathi eside futhi ayigugi. Kungakhathaliseki ukuthi ingama-patches esikhumba noma ukuqoshwa okuningiliziwe ezintweni zesikhumba, isikhumba esigoqwe nge-laser siqinisekisa ukuthi imiklamo izohlala isikhathi eside, ngisho nokusetshenziswa okuqhubekayo.

Unentshisekelo ngesikhumba esiqoshwe nge-laser?

Umshini we-laser olandelayo ungaba usizo kuwe!

• Indawo Yokusebenza: 400mm * 400mm (15.7” * 15.7”)

• Amandla e-Laser: 180W/250W/500W

• Ishubhu Le-laser: Ishubhu Le-laser Lensimbi le-CO2 RF

• Isivinini Esiphezulu Sokusika: 1000mm/s

• Isivinini Esiphezulu Sokuqopha: 10,000mm/s

• Indawo Yokusebenza: 1600mm * 1000mm (62.9” * 39.3”)

• Amandla e-Laser: 100W/150W/300W

• Isivinini Esiphezulu Sokusika: 400mm/s

• Ithebula Lokusebenza: Ithebula Lokuthutha

• Uhlelo Lokulawula Okwenziwa Ngemishini: Ukudluliselwa Kwebhande Nokushayela Kwemoto Yesinyathelo

Imibuzo Evame Ukubuzwa Ngesikhumba Sokuqopha Nge-Laser

1. Yisiphi isikhumba esingcono kakhulu sokuqopha nge-laser?

Isikhumba esingcono kakhulu sokusika nge-laser yisikhumba esifakwe umbala wemifino ngenxa yendawo yaso yemvelo, engakaphathwa esabela kahle ekusikeni. Sikhiqiza imiphumela ehlanzekile neqondile ngaphandle kwamabala okusha ngokweqile.

Ezinye izinketho ezinhle zifaka isikhumba esinsundu nge-chrome kanye ne-suede, kodwa zingadinga izilungiselelo eziqaphile ukuze kugwenywe imiphumela engathandeki njengokushintsha kombala noma ukusha. Gwema izikhumba eziphathwe kakhulu noma ezenziwe ngokwenziwa ngoba zingase zikhiphe umusi oyingozi futhi zingabangela ukugqwala okungalingani.

Ukuhlola izingcezu ezilahliwe kuhlale kunconywa ukuze ulungise izilungiselelo zakho.

2. Yimuphi umshini we-laser ofanele ukuqopha nokuqopha isikhumba?

I-laser ye-CO2 kanye ne-laser ye-diode ziyakwazi ukuqopha nokuqopha isikhumba. Kodwa kukhona umehluko emphumeleni wokuqopha ngenxa yokusebenza komshini kanye namandla awo.

Umshini we-laser we-CO2 unamandla futhi usebenza kanzima, ungaphatha ukuqoshwa kwesikhumba okujulile ngesikhathi esisodwa. Ngokusobala, umshini wesikhumba we-CO2 laser etching uza nokusebenza kahle kokukhiqiza kanye nemiphumela ehlukahlukene yokuqoshwa. Kodwa unezindleko eziphakeme kancane kune-diode laser.

Umshini we-laser we-diode mncane, ungasebenza ngezinto zesikhumba ezincane ezinombala wokuqopha okhanyayo kanye namamaki okuqopha, uma ufuna ukuthola ukuqopha okujulile, ayikho indlela ngaphandle kokusebenza amaphasi amaningi. Futhi ngenxa yendawo yawo encane yokusebenza kanye namandla aphansi, awukwazi ukuhlangabezana nokukhiqizwa kwekhwalithi yemboni kanye nokusebenza kahle okuphezulu.

Isiphakamiso

Ukusetshenziswa Kobungcweti:I-laser ye-CO2 ebangeni le-100W-150W ilungele ukuqoshwa kwesikhumba nokuqoshwa. Lokhu kuzokunikeza inhlanganisela engcono kakhulu yokunemba nokusebenza kahle.

Kwabathandi bezinto zokuzilibazisa noma amaphrojekthi amancane:I-laser ye-CO2 enamandla aphansi (cishe i-40W-80W) noma i-laser ye-diode ingasebenza emisebenzini yokuqopha elula.

3. Ungayisetha kanjani isikhumba esigoqa nge-laser?

• Amandla:Ngokuvamile kuphansi kunokusika. Qala ngamandla angaba ngu-20-50%, kuye ngomshini wakho we-laser kanye nokujula kokuqopha okufunayo.

•Isivinini: Ijubane eliphansi livumela ukugqwala okujulile. Indawo enhle yokuqala ingama-100-300 mm/s. Futhi, lungisa ngokusekelwe ezivivinyweni zakho kanye nokujula okufisayo.

•I-DPI: Ukusetha i-DPI ephezulu (cishe i-300-600 DPI) kungasiza ekufezeni ukuqoshwa okuningiliziwe, ikakhulukazi kumiklamo eyinkimbinkimbi. Kodwa akuzona zonke izimo, izilungiselelo ezithile sicela uxhumane nochwepheshe we-laser ochwepheshe.

• Gxila ku-Laser:Qiniseka ukuthi i-laser igxile kahle ebusweni besikhumba ukuze kuhlanzwe kahle. Ukuze uthole umhlahlandlela onemininingwane, ungabheka isihloko mayelanaindlela yokuthola ubude obufanele bokugxila.

•Ukubekwa Kwesikhumba: Vikela isikhumba embhedeni we-laser ukuze uvimbele ukunyakaza ngesikhathi senqubo yokuqopha.

4. Uyini umehluko phakathi kokuqopha nge-laser kanye nokuqopha isikhumba?

• Ukuqoshwa Nge-Laserinqubo lapho ugongolo lwe-laser lushisa noma lushintsha ubuso besikhumba ukuze kudalwe izimpawu ezihlala njalo nezinembile. Le ndlela ivumela imiklamo enemininingwane, okuhlanganisa umbhalo omncane, amaphethini ayinkimbinkimbi, noma izithombe. Umphumela uba uphawu olubushelelezi nolunezimbobo ebusweni besikhumba.

•Ukudweba nge-embossingKuhilela ukucindezela idayisi elishisayo noma isitembu esikhumbeni, okudala umklamo ophakanyisiwe noma ogobile. Lokhu kwenziwa ngomshini, futhi umphumela uba nobukhulu obuthathu. Ukudweba nge-embossing kuvame ukumboza izindawo ezinkulu zesikhumba futhi kungadala ukuthungwa okuthintekayo, kodwa akuvumeli izinga elifanayo lokunemba njengokuqopha nge-laser.

5. Ungawusebenzisa kanjani umshini wokuqopha wesikhumba nge-laser?

Kulula ukusebenzisa umshini we-laser. Uhlelo lwe-CNC luwunikeza ukuzenzekela okuphezulu. Udinga nje ukuqedela izinyathelo ezintathu, kanti kwabanye umshini we-laser ungaziqeda.

Isinyathelo 1. Lungisa isikhumba bese usibeka phezuithebula lokusika nge-laser.

Isinyathelo sesi-2. Ngenisa ifayela lakho lomklamo wesikhumba kuisofthiwe yokuqopha nge-laser, bese usetha amapharamitha e-laser njengejubane namandla.

(Ngemva kokuthenga umshini, uchwepheshe wethu we-laser uzoncoma amapharamitha afanele kuwe ngokwezidingo zakho zokuqopha nezinto zokwakha.)

Isinyathelo 3. Cindezela inkinobho yokuqala, bese umshini we-laser uqala ukusika nokuqopha.

Uma unemibuzo mayelana nesikhumba esinqunywa nge-laser, khuluma nathi!

Uma unesifiso somshini wokuqopha we-laser wesikhumba, landela izincomo ⇨

Ungayikhetha kanjani umshini ofanele wokusika isikhumba nge-laser?

Izindaba Ezihlobene

Isikhumba esiqoshwe nge-laser siyindlela entsha kumaphrojekthi esikhumba!

Imininingwane eqoshiwe eyinkimbinkimbi, ukuqoshwa kwephethini okuguquguqukayo nokwenziwe ngokwezifiso, kanye nesivinini sokuqoshwa esisheshayo ngokuqinisekile kuyakumangaza!

Udinga umshini owodwa wokuqopha nge-laser kuphela, asikho isidingo sanoma yiziphi izinhlayiya ezifile, asikho isidingo sezingcezu zommese, inqubo yokuqopha isikhumba ingabonakala ngesivinini esikhulu.

Ngakho-ke, isikhumba esiqoshwe nge-laser asigcini nje ngokwandisa kakhulu umkhiqizo wokukhiqiza imikhiqizo yesikhumba, kodwa futhi siyithuluzi le-DIY eliguquguqukayo lokuhlangabezana nazo zonke izinhlobo zemibono yokudala yabathandi bokuzijabulisa.

Ukusebenza ngokhuni okusikiwe nge-laser sekuthole ukuthandwa emikhakheni eyahlukahlukene, kusukela emisebenzini yezandla nemihlobiso kuya kumamodeli okwakha, ifenisha, nokuningi.

Ngenxa yokwenza ngokwezifiso kwayo okungabizi kakhulu, amakhono okusika nokuqopha anembe kakhulu, kanye nokuhambisana nezinto eziningi zokhuni, imishini yokusika i-laser yokhuni ilungele ukudala imiklamo yokhuni enemininingwane ngokusika, ukuqopha, nokumaka.

Kungakhathaliseki ukuthi ungumuntu othanda izinto zokuzilibazisa noma uchwepheshe wokusebenza ngokhuni, le mishini inikeza ukulula okungenakuqhathaniswa.

I-Lucite iyinto ethandwayo esetshenziswa kabanzi empilweni yansuku zonke kanye nasezinhlelweni zezimboni.

Nakuba abantu abaningi bejwayelene ne-acrylic, i-plexiglass, kanye ne-PMMA, i-Lucite ivelele njengohlobo lwe-acrylic esezingeni eliphezulu.

Kunezinhlobo ezahlukene ze-acrylic, ezihlukaniswa ngokucaca, amandla, ukumelana nokuklwebheka, kanye nokubukeka.

Njenge-acrylic esezingeni eliphezulu, i-Lucite ivame ukuza nentengo ephezulu.

Njengoba ama-laser angasika i-acrylic ne-plexiglass, ungase uzibuze: ungakwazi yini ukusika i-Lucite nge-laser?

Ake singene ukuze sithole okwengeziwe.

Thola Umshini Owodwa Wokuqopha Nge-Laser Webhizinisi Lakho Lesikhumba Noma Umklamo?

Isikhathi sokuthunyelwe: Septhemba-19-2024