I-CO2 Laser Cutting Machine yesikhumba

▶ Umsiki we-laser ojwayelekile wesikhumba

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Ukudlulisa Ibhande & Isinyathelo Motor Drive |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Conveyor |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Usayizi Wephakheji | 2350mm * 1750mm * 1270mm |

| Isisindo | 650kg |

* Ukuthuthukiswa Kwezimoto Ze-Servo Kuyatholakala

I-Giant Leap in Productivity

◆ Ukusebenza Okuphezulu

Ngokukhetha wonke amaphethini ofuna ukuwasika futhi usethe izinombolo zesiqeshana sesikhumba ngasinye, isofthiwe izofaka lezi zingcezu ngezinga lokusetshenziswa kakhulu ukuze wonge isikhathi sokusika nezinto zokwakha.

II-Auto feederkuhlanganiswe neIthebula le-Conveyorikhambi ekahle roll materials ukubona ukondla okuqhubekayo futhi ukusika. Akukho ukuhlanekezela okuphathekayo ngokuphakelayo okungenangcindezi.

◆ Ukukhipha Okuphezulu

Amakhanda amabili / amane / ama-Laser amaningi

Ukucutshungulwa Okuningi Ngasikhathi sinye

Ukuze kunwetshwe okukhiphayo nokusheshisa ukukhiqizwa, i-MimoWork inikeza amakhanda e-laser amaningi ukuze azikhethele ukusika iphethini efanayo ngesikhathi esisodwa. Lokhu akuthathi indawo eyengeziwe noma umsebenzi.

◆ Ukuvumelana nezimo

I-laser cutter eguquguqukayo ingasika kalula amaphethini wokuklama ahlukahlukene kanye nokwakheka ngokusika kwejika elifanele. Ngaphandle kwalokho, ukubhoboza kahle nokusika kungafinyelelwa emkhiqizweni owodwa.

◆ Isakhiwo Esiphephile Futhi Esiqinile

Idizayini Efakiwe

Ukucutshungulwa kwe-Laser okuhlanzekile nokuphephile

Idizayini evalekile ihlinzeka ngendawo yokusebenza ephephile nehlanzekile ngaphandle kokuvuza kwentuthu nephunga. Ungasebenzisa umshini we-laser futhi uqaphe isimo sokusika ngefasitela le-acrylic.

▶ Umsiki we-laser ojwayelekile wesikhumba

Izinketho Zokuthuthukisa I-Leather Laser Cutting

I-Servo Motor

Yiziphi izidingo zakho eziqondile?

Sazise futhi sikunikeze izixazululo ezenziwe ngezifiso ze-laser!

I-Laser Cutting & Engraving Isikhumba: Ikhwalithi Nokwenza Okuthandwa Nguwe

I-Laser Engraving Isikhumba: Inika Amandla Ubuciko

(Amacici Esikhumba Esika I-Laser, Ijakhethi Lesikhumba Le-Laser Cut, Isikhwama Sesikhumba Se-Laser Cut…)

Isikhumba Amasampula Laser Cutting

Izinhlelo zokusebenza ezijwayelekile

• Izicathulo zesikhumba

• Isembozo Sesihlalo Semoto

• Izingubo

• Isiqephu

• Izesekeli

• Amacici

• Amabhande

• Izikhwama

• Amasongo

• Imisebenzi yezandla

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Ukubuka kwevidiyofor laser cutting izicathulo design

- laser cutting

✔ onqenqemeni oluhlanzekile

✔ ukusikwa okubushelelezi

✔ ukusika iphethini

- laser perforating

✔ Ngisho nezimbobo

✔ Ukubhoboza okuhle

Noma yimiphi imibuzo ye-Leather Laser Cutting?

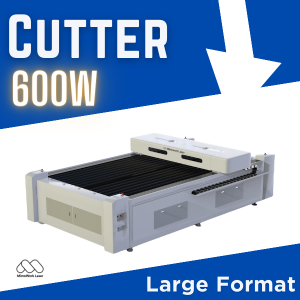

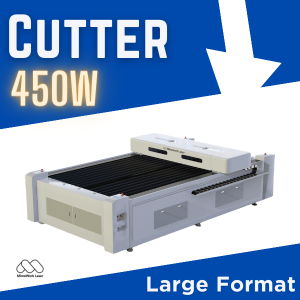

Isincomo somshini we-Laser

umshini wesikhumba we-laser cut

• Amandla eLaser: 100W/150W/300W

• Indawo yokusebenza: 1600mm * 1000mm

•Indawo Enwetshiwe: 1600mm * 500mm

umshini wokuqopha we-laser wesikhumba

• Amandla eLaser: 180W/250W/500W

• Indawo yokusebenza: 400mm * 400mm