Mutane da yawa suna ruɗani dadaidaita tsawon mai da hankalilokacin amfani da injin laser.

Domin amsa tambayoyin abokan ciniki, a yau za mu yi bayani kan takamaiman matakai da kuma kulawa da ake bayarwa gayadda ake samun madaidaicin tsawon ruwan tabarau na CO2 na laser da kuma daidaita shi.

Teburin Abubuwan da ke Ciki:

Menene Tsawon Hankali Ga Injin Laser na CO2

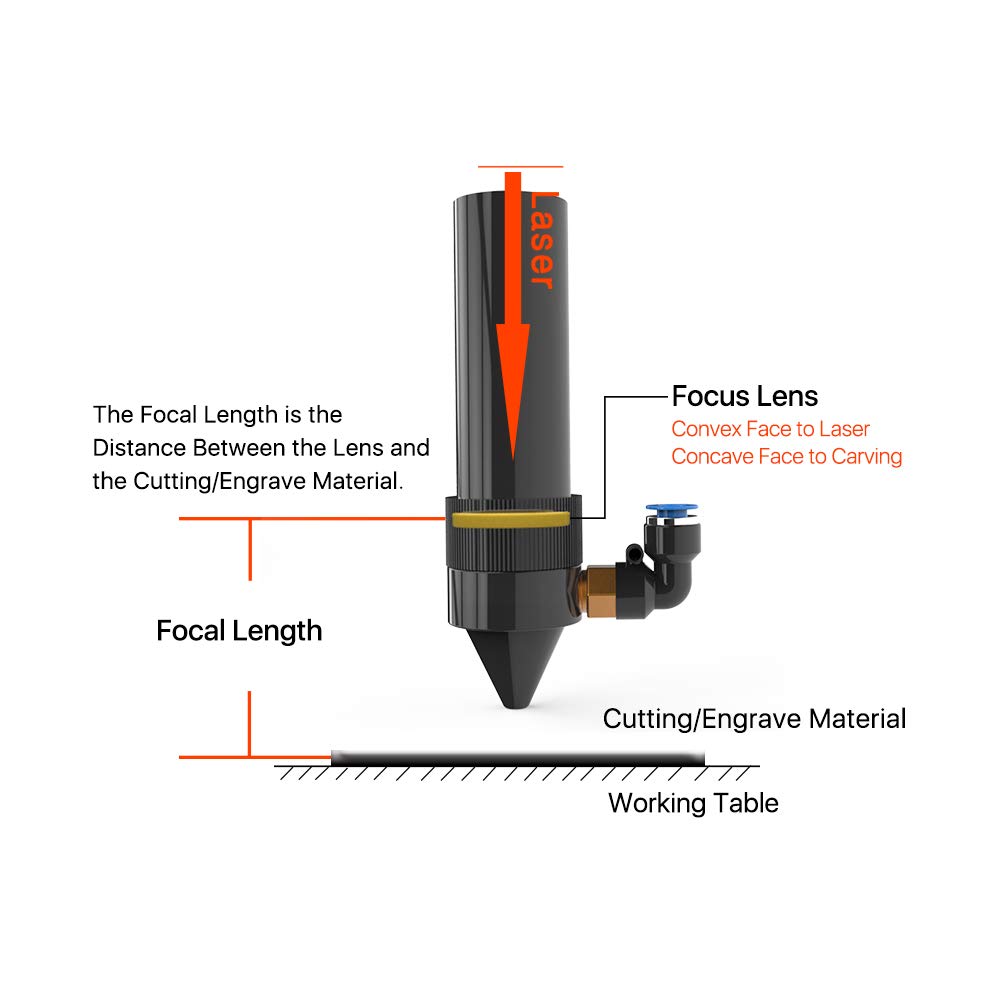

Ga injin laser, kalmar "tsawon mai da hankali"yawanci yana nufinnisantsakaninruwan tabaraukumakayanana sarrafa shi ta hanyar laser.

Wannan nisa yana ƙayyade ma'aunin hasken laser wanda ke tattara kuzarin laser dayana da tasiri mai mahimmanciakan inganci da daidaiton yanke ko sassaka na Laser.

Hanyar Aiki - Tantance tsawon CO2 na laser mai hankali

Mataki na 1: Shirya Kayan Aiki

Bari mu ci gaba da aikin injin sassaka na laser mu fara zaman koyarwa na yau.

Don daidaita yanayin laser, za ku buƙaci sarari biyu kawai na kwali.

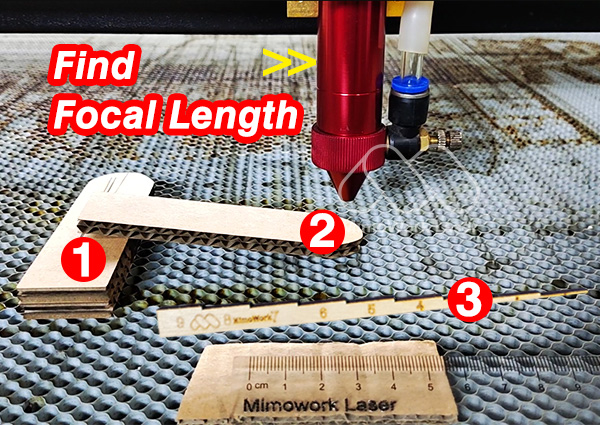

Mataki na 2: Nemo Tsawon CO2

Tsarin ruwan tabarau na gani da ke kan zanen laser ɗinku yana mai da hankali kan hasken laser da aka watsa zuwa wani wuri mai ma'aunin micron (wanda yake da siffar ma'auni). Wannan yankin mai ma'ana yana samun ƙarfin kololuwa, wanda ke ba da damar ingantaccen aikin sarrafa kayan.

Bayanin Fasaha:

Sigogi masu mayar da hankali sun dogara da ruwan tabarau. Koyaushe tabbatar da ƙayyadaddun bayanai don ruwan tabarau da aka shigar.

Tsarin Daidaitawa:

Tsarin daidaitawa mai aminci:

• Juya kwalin gwaji a zafin 15-30° ta amfani da madaurin injina

• Tabbatar da an ɗaura tauri don hana girgiza

Yi zane-zanen bincike:

• Fara sassaka vector mai kusurwa ɗaya

• Kula da saitunan gudu/ƙarfi daidai gwargwado

Binciken da aka mayar da hankali:

• Duba alamar sassaka ta hanyar amfani da na'urar microscopic

• Nemo mafi ƙarancin faɗin kerf (yana nuna matakin mai da hankali)

Tabbatar da girma:

• Amfani da na'urorin auna sigina na dijital:

a) Auna nisan bututun ƙarfe zuwa wurin aiki a matakin farko

b) Yi rikodin azaman ƙimar daidaitawar axis na Z

• Shigar da wannan siga a cikin tsarin sarrafa CNC ɗinku

Ga mai kula da hankali, koyaushe zaka iya yin naka da injin sassaka na laser ɗinka.

Idan kana son samun fayil ɗin ƙira na mai ruler mai ƙarfi kyauta, aiko mana da imel.

Mataki na 3: Tabbatar da Tsawon Mayar da Hankali Biyu

Harba laser zuwa kwali atsayi daban-daban, kuma kwatantaainihin alamun ƙonewadon nemomadaidaicin tsayin daka.

Sanya tarkacen kwalidaidaia kan teburin aiki kuma motsa kan laser a kai a tsayin milimita 5.

Na gaba, danna "bugun jini"Maɓallin da ke kan allon sarrafawa don barin alamun ƙonewa.

Maimaita wannan tsari, canza kan laser zuwatsayi daban-daban, kuma danna maɓallin bugun jini.

Yanzu, kwatanta alamun ƙonewa kuma samimafi ƙanƙantaan sassaka tabo.

Za ka iya zaɓako daihanyar samun madaidaicin tsawon mai da hankali.

Nunin Bidiyo | Ta Yaya Ake Ƙayyade Tsawon Hasken Haske

Wasu Shawarwari

Yadda Ake Yanke Kauri Plywood | Injin Laser na CO2

Don Yanke Laser

Lokacin yanke kayan, yawanci muna ba da shawarar daidaita wurin mayar da hankaliƙasa kaɗankayan don samun mafi kyawun yankewa.

Misali, zaka iya daidaita kan laser zuwa4mmko ma3mmsama da kayan(Lokacin da Tsawon Hankali ya kai 5mm).

Ta wannan hanyar, za a tattara makamashin laser mafi ƙarfia cikikayan, ya fi kyau a yanke kayan da suka yi kauri.

Don Zane-zanen Laser

Amma don zane-zanen laser, zaku iya motsa kan laser ɗinsama da kayansaman ya ɗan yi sama kaɗan.

Lokacin da Tsawon Hankali ya kai 5mm, tura shi zuwa6mm or 7mm.

Ta wannan hanyar, zaku iya samun sakamakon zane mai blur kuma ƙara bambanci tsakanin tasirin sassaka da kayan aiki.

Yadda Ake Zaɓar Lens ɗin Laser Mai Daidai?

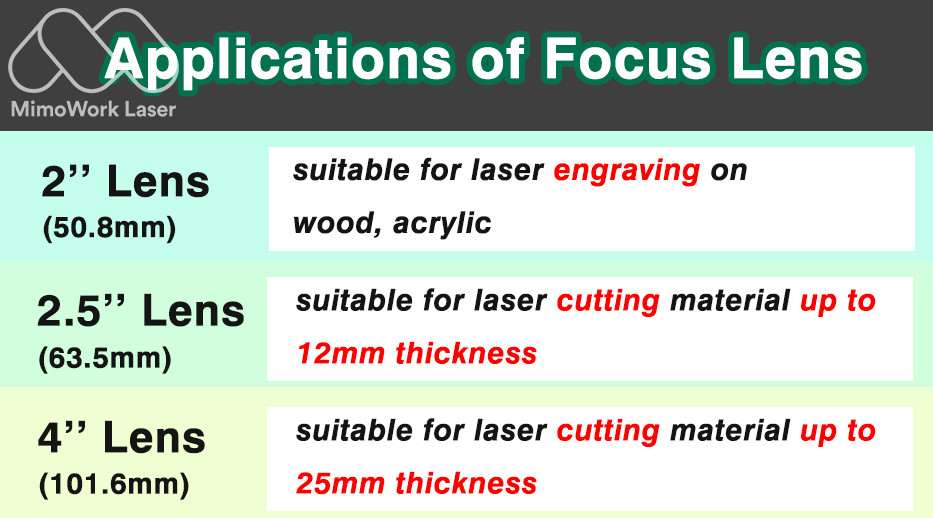

Muna kuma ba da shawarar zaɓar ruwan tabarau mai dacewabisa ga kayan aiki da buƙatu.

Gajeren tsawon mai da hankali kamar2.0"yana nufin ƙaramin wurin mai da hankali da haƙurin mai da hankali, wanda ya dace daHotunan ɗaukar hoto na laser mai girman DPI.

Don yanke laser,tsawon mai da hankalizai iya tabbatar da ingancin yankewa tare da gefen da ya yi kauri da lebur.

2.5" da 4.0"su ne mafi dacewa zaɓuɓɓuka.

Tsawon tsayin daka yana dazurfin nisa mai yankewa.

Na lissafa tebur a nan game da zaɓin ruwan tabarau mai ma'ana.

Duk wata tambaya game da yadda ake zaɓar ruwan tabarau na CO2 Laser da ya dace da aikace-aikacenku

Na'urar Laser ta CO2 da aka ba da shawarar:

Domin Laser Yankan Kauri Material

Wata Hanya Don Nemo CO2 Laser Focus

Don acrylic mai kauri ko itace, muna ba da shawarar cewa ya kamata a mayar da hankali kana tsakiyana kayan.

Gwajin Laser shinedoledonkayan daban-daban.

Yaya kauri acrylic za a iya yankewa ta laser?

Babban ƙarfi da ƙarancin gudu yawanci zaɓi ne mai kyau, don ƙarin bayani, za ku iyatambaye mu!

Ƙara Koyo Game da Yadda Ake Ƙayyade Tsawon Hasken Ruwan Ido

Lokacin Saƙo: Satumba-04-2023