Mashiinka Laydhka ee Acrylic (PMMA)

Haddii aad rabto inaad jarto xaashida acrylic (PMMA, Plexiglass, Lucite) si aad u sameyso calaamado acrylic ah, abaalmarinno, qurxin, alaab guri, xitaa dashboards-ka baabuurta, qalabka ilaalinta, ama kuwa kale? Qalabkee ayaa ah doorashada ugu fiican?

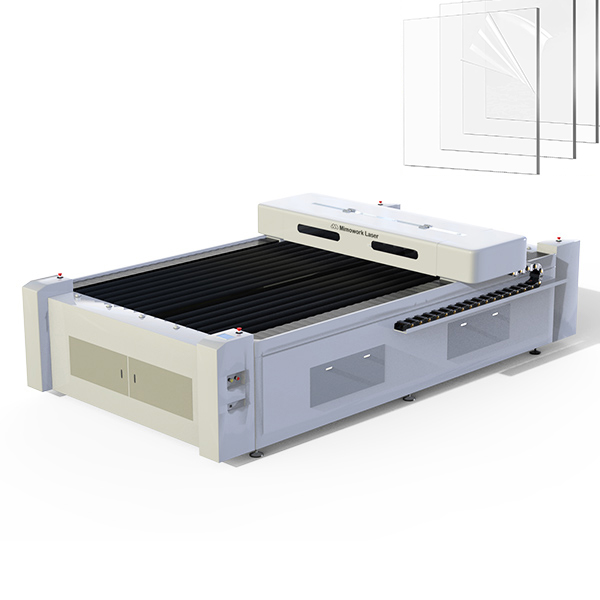

Waxaan kugula talineynaa mashiinka laser-ka acrylic-ga oo leh heer warshadeed iyo heer hiwaayadeed.

Xawaaraha goynta degdega ah iyo saamaynta goynta aadka u fiicanwaa faa'iidooyin aad u fiican oo ka mid ah mashiinnada jarista laser-ka acrylic ee aad jeclaan doonto.

Intaa waxaa dheer, mashiinka laser-ka acrylic sidoo kale waa qalab sawira laser-ka acrylic, kaas oo awood u leh inuu wax ka beddelo qaabka laser-ka acrylic.Ku xardh qaabab iyo sawirro jilicsan oo qurux badan xaashiyaha akrilik-kaWaxaad ganacsi gaar ah ku samayn kartaa farshaxan yar oo laser acrylic ah, ama waxaad ballaarin kartaa wax soo saarkaaga acrylic adoo maalgelinaya mashiin jarista laser acrylic sheet layser oo warshadeed oo weyn, kaas oo qaban kara xaashiyo acrylic ah oo waaweyn oo dhumuc weyn leh oo leh xawaare sare, oo aad ugu fiican wax soo saarkaaga ballaaran.

Maxaad ku samayn kartaa jarista laysarka ugu fiican ee acrylic-ga? Sii wad sahaminta wax badan!

Fur Awoodda Buuxda ee Mashiinka Jarjaridda Laydhka Acrylic Laser

Tijaabada Agabka: Goynta Laser-ka 21mm dhumucda Acrylic

Natiijada Imtixaanka:

Mashiinka Laser-ka ee Akrilik ee Awoodda Sare leh wuxuu leeyahay awood jaritaan oo cajiib ah!

Waxay jari kartaa xaashida acrylic ee dhumucdeedu tahay 21mm, waxayna abuuri kartaa badeeco acrylic ah oo tayo sare leh oo leh saameyn jaritaan olol leh.

Xaashiyaha acrylic-ga khafiifka ah ee ka yar 21mm, mashiinka goynta laysarka ayaa si fudud u maareeya!

| Goobta Shaqada (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Barnaamijka | Barnaamijka MimoCUT |

| Awoodda Laydhka | 100W/150W/300W/450W |

| Isha laysarka | Tube Laser-ka Galaaska ee CO2 ama Tube Laser-ka Birta ee CO2 RF |

| Nidaamka Xakamaynta Farsamada | Xakamaynta Suunka Matoorka Tallaabada |

| Miiska Shaqada | Miiska Shaqada ee Malabka ama Miiska Shaqada ee Strip Mindi |

| Xawaaraha ugu Badan | 1~400mm/s |

| Xawaaraha Dardargelinta | 1000~4000mm/s2 |

Faa'iidooyinka laga helo jarista iyo xardhista laysarka akrilik

La safeeyey & gees kiristaalo ah

Goynta qaab dabacsan

Qaab-dhismeedka qaabaysan ee adag

✔Cidhifyada jarista nadiifka ah oo si fiican loo safeeyey hal hawlgal

✔Looma baahna in la xiro ama la hagaajiyo acrylic-ka sababtoo ah farsamaynta aan la taaban karin

✔Habayn dabacsan oo loogu talagalay qaab kasta ama qaab kasta

✔Ma jiro wax wasakh ah sida shiididda oo ay taageerto soo-saaraha qiiqa

✔Goynta qaabka saxda ah oo leh nidaamyada aqoonsiga indhaha

✔Hagaajinta waxtarka laga bilaabo quudinta, jarista ilaa qaadashada iyadoo la adeegsanayo miiska shaqada ee basaska

Mashiinnada Jarida Laser-ka ee loo yaqaan 'acrylic laser'

• Awoodda laysarka: 100W/150W/300W

• Goobta Shaqada: 1300mm * 900mm (51.2” * 35.4”)

• Awoodda laysarka: 150W/300W/450W

• Goobta Shaqada: 1300mm * 2500mm (51” * 98.4”)

Xiiseynaya

MAKIINADDA JARJARIDA LAASARKA EE ACRYLIC

Qiimo lagu daray MimoWork Laser Options

✦Kamarada CCDWaxay siisaa mashiinka shaqada aqoonsiga ee jarista acrylic-ga daabacan ee ku teedsan qaabka.

✦Hawlgal degdeg ah oo xasilloon ayaa lagu xaqiijin karaa iyadoo la adeegsanayomatoorka servo iyo matoor aan burush lahayn.

✦Dhererka diiradda ugu fiican waxaa si toos ah looga heli karaa iyadoo la adeegsanayodiiradda otomaatiga ahmarka la jarayo agab si kala duwan u qaro weyn, looma baahna hagaajin gacanta ah.

✦Soo-saaraha Qiiqawaxay kaa caawin kartaa in laga saaro gaasaska sii jira, urta daran ee laga yaabo inay soo baxdo marka laysarka CO2 uu farsamaynayo agab gaar ah, iyo haraaga hawada ku jira.

✦MimoWork waxay leedahay noocyo kala duwan ooMiisaska Jarida Laser-kaagabyo iyo codsiyo kala duwan.sariirta goynta laser malab malabwaxay ku habboon tahay jarista iyo xardhida walxaha yaryar ee akrilik, iyoMiiska jarista xarigga mindiwaa ka fiican in la jaro acrylic qaro weyn.

Acrylic-ka lagu sameeyay UV-printed oo leh midab iyo qaab qani ah ayaa si isa soo taraysa caan u noqday.Sidee loo gooyaa acrylic-ga daabacan si sax ah oo dhakhso leh? CCD Laser Cutter waa doorashada ugu fiican.

Waxa uu leeyahay kamarad CCD ah oo caqli badan iyoBarnaamijka Aqoonsiga Indhaha, kaas oo aqoonsan kara oo meelayn kara qaababka, isla markaana u jiheyn kara madaxa laysarka inuu si sax ah u jaro qaabka.

Silsiladaha furaha ee akrilik, looxyada xayaysiinta, qurxinta, iyo hadiyadaha xusuusta leh ee laga sameeyay akrilik sawir lagu daabacay, way fududahay in lagu dhammaystiro mashiinka jarista laser-ka acrylic ee daabacan.

Waxaad isticmaali kartaa laysarka si aad u jarto acrylic daabacan si aad u sameyso naqshadayntaada gaarka ah iyo wax soo saarka ballaaran, taas oo ku habboon oo aad waxtar u leh.

Sida si otomaatig ah loogu jaro walxaha la daabacay | Acrylic & Wood

Codsiyada loo isticmaalo jarista iyo xardho laser loo yaqaan 'acrylic laser'

• Bandhigyada Xayeysiinta

• Dhismaha Qaab-dhismeedka Naqshadaha

• Calaamadaynta Shirkadda

• Koobab Fudud

• Acrylic Daabacan

• Alaabta guriga ee casriga ah

• Boodhadhka Dibadda

• Meesha Badeecada

• Calaamadaha Tafaariiqda

• Ka saarista buufinta

• Qaybta

• Qalabka Dukaamaysiga

• Iridda Qurxinta

Isticmaalka Mashiinka Jarjaraha Laser-ka ee Acrylic

Waxaan Sameynay Calaamad iyo Qurxin Akrilik ah

Sida loo sameeyo Laser Goo Cake Topper

Sida loo jaro laysarka qurxinta acrylic (barafka barafka)

Ganacsiga Jarida iyo Qorista Laser-ka ee Acrylic

Mashruuckee Acrylic ah ayaad ka shaqaynaysaa?

Talooyin La Wadaago: Loogu talagalay Jarida Laser Acrylic ee Fiican

◆Sare u qaad saxanka akrilik si uusan u taaban miiska shaqada inta uu jarayo

◆ Xaashi acrylic ah oo saafi ah oo sarreeya ayaa gaari kara saameyn goyn oo wanaagsan.

◆ Dooro gooyaha laysarka leh awoodda saxda ah ee geesaha ololka lagu safeeyey.

◆Afuufiddu waa inay noqotaa mid yar intii suurtogal ah si looga fogaado faafitaanka kulaylka taasoo sidoo kale horseedi karta gees gubanaya.

◆Ku xardho looxa akriliga dhinaca dambe si aad u soo saarto saameyn muuqaal ah oo ka timid dhinaca hore.

Casharka Fiidiyowga: Sidee loo gooyaa oo loo xareeyaa akrilik-ka laser-ka?

Su'aalaha Inta Badan La Isweydiiyo ee ku saabsan Laser-ka Goynta Acrylic (PMMA, Plexiglass, Lucite)

1. Ma ku jari kartaa acrylic-ga laysarka jarjaraha?

Xaashida acrylic-ka ee goynta laysarka waa hab caadi ah oo caan ah oo lagu sameeyo wax soo saarka acrylic-ka. Laakiin noocyada kala duwan ee xaashida acrylic-ka sida acrylic-ka la soo saaray, acrylic-ka la shubay, acrylic-ka la daabacay, acrylic-ka cad, acrylic-ka muraayadda, iwm., waxaad u baahan tahay inaad doorato mashiin laysar ah oo ku habboon noocyada acrylic-ka badankood.

Waxaan kugula talineynaa CO2 Laser, kaas oo ah isha laysarka ee acrylic-ku-habboon, wuxuuna soo saaraa saameyn goyn iyo saameyn xardho weyn xitaa iyadoo la isticmaalayo acrylic cad.Waan ognahay in diode laser uu awood u leeyahay inuu gooyo acrylic khafiif ah laakiin kaliya loogu talagalay acrylic madow iyo madow. Markaa CO2 Laser cutter waa doorasho ka wanaagsan jarista iyo xardhida acrylic.

2. Sidee loo laysarka u gooyaa acrylic?

Habka jarista laysarka ee loo yaqaan 'laser acrylic' waa hab fudud oo otomaatig ah. Kaliya 3 tallaabo, waxaad heli doontaa badeeco acrylic ah oo aad u fiican.

Tallaabada 1aad. Saar xaashida akrilik-ka miiska jarista laysarka.

Tallaabada 2. Ku rakib awoodda iyo xawaaraha laysarka barnaamijka laysarka.

Tallaabada 3. Bilow jarista iyo xardhida laysarka.

Ku saabsan hagaha faahfaahsan ee hawlgalka, khabiirkayaga laser-ka ayaa ku siin doona cashar xirfadeed oo dhammaystiran ka dib markaad iibsato mashiinka laser-ka. Markaa wixii su'aalo ah, xor u noqo inaad la xiriirtola hadal khabiirkayaga laysarka.

@ Email: info@mimowork.com

☏ WhatsApp: +86 173 0175 0898

3. Goynta iyo Qorista Acrylic: CNC VS. Laser?

Routers-yada CNC waxay isticmaalaan qalab goyn wareegaya si ay si muuqaal ah uga saaraan walxaha, oo ku habboon acrylic-ga qaro weyn (ilaa 50mm) laakiin badanaa waxay u baahan yihiin nadiifin.

Jarista laysarka waxay isticmaalaan fallaadho laysar ah si ay u dhalaaliyaan ama u uumi saaraan agabka, iyagoo bixinaya saxnaan sare iyo geeso nadiif ah iyada oo aan loo baahnayn in la nadiifiyo, ugu fiican acrylic-ga khafiifka ah (ilaa 20-25mm).

Ku saabsan saameynta jarista, sababtoo ah iftiinka laser-ka ee gooyaha laser-ka, jarista acrylic-ka ayaa ka saxsan oo ka nadiifsan jarista router-ka cnc.

Xawaaraha jarista, router-ka CNC wuxuu ka dhaqso badan yahay laser-ka jarista marka la jarayo acrylic. Laakiin marka la qorayo acrylic, laser-ku wuxuu ka fiican yahay CNC router-ka.

Markaa haddii aad xiisaynayso mowduuca, oo aad ku wareersan tahay sida loo kala doorto cnc iyo laser cutter, fiiri fiidiyowga ama bogga si aad wax badan uga barato:CNC VS Laser loogu talagalay jarista iyo xardhida acrylic

4. Sidee loo doortaa acrylic ku habboon jarista iyo xaraashka laysarka?

Acrylic-gu wuxuu ku yimaadaa noocyo kala duwan. Waxay dabooli kartaa baahiyo kala duwan iyadoo ay ku kala duwan yihiin waxqabadka, midabada, iyo saameynta bilicda.

In kasta oo dad badan ay og yihiin in xaashida acrylic-ka ee la shubay iyo kuwa la sii daayay ay ku habboon yihiin habka laysarka, haddana dad yar ayaa yaqaan hababka ugu wanaagsan ee loo isticmaalo laysarka.

Xaashiyaha acrylic-ga ee la shubay waxay muujiyaan saameyn xardho oo ka wanaagsan marka loo eego xaashida la sii daayay, taasoo ka dhigaysa kuwo ku habboon codsiyada xardho laysarka. Dhanka kale, xaashida la sii daayay way ka kharash yar yihiin waxayna si fiican ugu habboon yihiin ujeeddooyinka jarista laysarka.

5. Ma laysarka ku jari kartaa calaamadaha akrilik ee waaweyn?

Haa, waxaad ku jari kartaa calaamadaha acrylic-ga ee waaweyn adigoo isticmaalaya qalabka laysarka lagu jaro, laakiin waxay ku xiran tahay cabbirka sariirta mashiinka. Qalabkayaga yar yar ee laysarka lagu jaro waxay leeyihiin awoodo marin loo maro, taasoo kuu oggolaanaysa inaad la shaqeyso agabyo ka weyn cabbirka sariirta.

Iyo xaashida acrylic-ga ee ballaaran iyo kuwa dheer, waxaan haysannaa mashiinka jarista laser-ka ee qaabka weyn leh oo leh aag shaqo oo 1300mm * 2500mm ah, kaas oo si fudud loo maarayn karo calaamadaha acrylic-ga ee waaweyn.

Ma haysaa wax su'aalo ah oo ku saabsan jarista laysarka iyo xaraashka laysarka ee acrylic?

Aan ogaano oo aan ku siino talooyin iyo xalal dheeraad ah!

Iyadoo la horumarinayo tiknoolajiyada iyo horumarinta awoodda laysarka, tiknoolajiyada laysarka CO2 ayaa sii xoogaysanaysa marka la eego farsamaynta acrylic-ga.

Iyadoo aan loo eegin inay tahay muraayad la shubay (GS) ama muraayad acrylic ah oo la soo saaray (XT),laser-ka waa qalabka ugu habboon ee lagu jaro laguna xardho acrylic (plexiglass) iyadoo kharashyo farsameedku si weyn hoos ugu dhacayaan marka la barbar dhigo mashiinnada wax lagu shiido ee dhaqanka.

Awood u leh inuu farsameeyo qoto dheer oo kala duwan oo maaddo ah,Makiinadaha Laysarka ee MimoWorkIyada oo leh naqshado habaysan oo loo habeeyay iyo awood sax ah ayaa dabooli karta shuruudaha kala duwan ee farsamaynta, taasoo keentay shaqooyin acrylic ah oo qummangeesaha la gooyay oo siman oo kiristaalo ahhawlgal keli ah, uma baahna dhalaalin olol dheeraad ah.

Jarida Laser-ka ee Xirfadeed iyo Aqoonta leh ee Acrylic

Mashiinka laysarka acrylic wuxuu jari karaa xaashiyo acrylic ah oo khafiif ah oo qaro weyn leh oo leh gees goyn nadiif ah oo la safeeyey wuxuuna ku xarri karaa qaabab iyo sawirro qurux badan oo faahfaahsan oo ku yaal looxyada acrylic.

Iyada oo leh xawaaraha sare ee habaynta iyo nidaamka xakamaynta dhijitaalka ah, mashiinka goynta laser-ka CO2 ee acrylic wuxuu gaari karaa wax soo saar tiro badan oo tayo qumman leh.

Haddii aad leedahay ganacsi yar ama mid gaar ah oo loogu talagalay alaabada acrylic, mashiinka yar ee laser-ka ee loogu talagalay acrylic waa doorasho ku habboon. Si fudud ayaa loo shaqayn karaa waana mid kharash-ool ah!