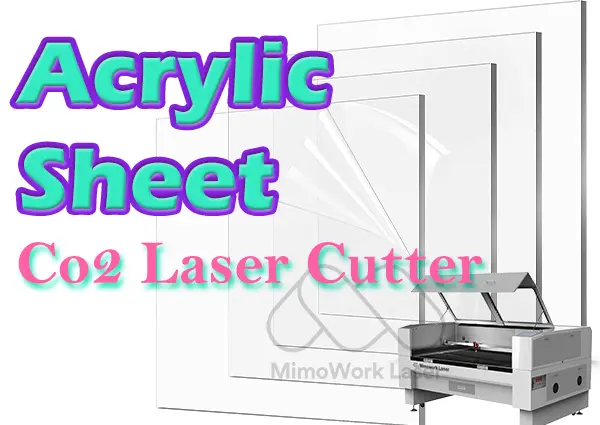

Laser-ku wuxuu u qalmaa kan ugu habboon ee lagu jari karo Acrylic! Maxaan sidaas u leeyahay? Sababtoo ah waafaqiddiisa ballaaran ee noocyada iyo cabbirrada acrylic-ga kala duwan, saxnaan aad u sarreysa iyo xawaare degdeg ah oo lagu jari karo acrylic-ga, si fudud loo baran karo loona shaqayn karo, iyo waxyaabo kaloo badan. Hadday tahay hiwaayad, jarista alaabada acrylic-ga ganacsiga, ama isticmaalka warshadaha, acrylic-ga jarista laser-ka wuxuu buuxiyaa ku dhawaad dhammaan shuruudaha. Haddii aad raadinayso tayo aad u wanaagsan iyo dabacsanaan sare, oo aad rabto inaad si dhakhso ah u barato, jarista acrylic-ga laser-ka ayaa noqon doonta doorashadaada koowaad.

Faa'iidooyinka Laser-ka Jarida Acrylic

✔ Cidhifka Jaritaanka Siman

Tamarta laysarka ee xoogga badan ayaa si degdeg ah ugu jari karta xaashida acrylic-ga jihada toosan. Kulaylku wuxuu shaabadaynayaa oo uu dhalaalinayaa geeska si uu u noqdo mid siman oo nadiif ah.

✔ Jarista Aan Taabashada Lahayn

Qalabka jarista laysarka wuxuu leeyahay habayn aan taabasho lahayn, kaas oo ka takhalusaya welwelka ku saabsan xoqidda iyo dildilaaca walxaha sababtoo ah ma jiro cadaadis farsamo. Looma baahna in la beddelo qalabka iyo qaybaha.

✔ Saxnaan Sare

Saxnaan aad u sareysa ayaa ka dhigaysa jarista laser-ka acrylic-ka inay u jarto qaabab adag sida ku cad faylka loogu talagalay. Ku habboon qurxinta acrylic-ga gaarka ah iyo agabka warshadaha iyo caafimaadka.

✔ Xawaaraha iyo Hufnaanta

Tamarta laysarka oo xooggan, cadaadis farsamo oo aan lahayn, iyo xakamaynta otomaatiga ah ee dhijitaalka ah, waxay si weyn u kordhisaa xawaaraha jarista iyo hufnaanta wax soo saarka oo dhan.

✔ Kala duwanaansho

Goynta laysarka CO2 waa mid aad u habboon in lagu jaro xaashida acrylic-ga ee dhumucdoodu kala duwan tahay. Waxay ku habboon tahay labadaba agabka acrylic-ga khafiifka ah iyo kuwa qaro weyn, taasoo siinaysa dabacsanaan codsiyada mashruuca.

✔ Qashinka Agabka Ugu Yar

Laydhka diiradda saaraya ee laysarka CO2 wuxuu yareeyaa qashinka agabka isagoo abuuraya ballaca kerf ee cidhiidhiga ah. Haddii aad la shaqeyneyso wax soo saarka tirada badan, barnaamijka laysarka ee caqliga leh ayaa hagaajin kara waddada jarista, wuxuuna kordhin karaa heerka isticmaalka agabka.

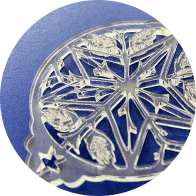

Cidhif cad oo kiristaal ah

Qaabka jarista ee adag

Sawirro lagu xardhay akrilik

▶ Si dhow u eeg: Waa maxay Laser-ka Acrylic-ga la jarayo?

Jarista Laser-ka ee loo yaqaan 'Acrylic Snowflake'

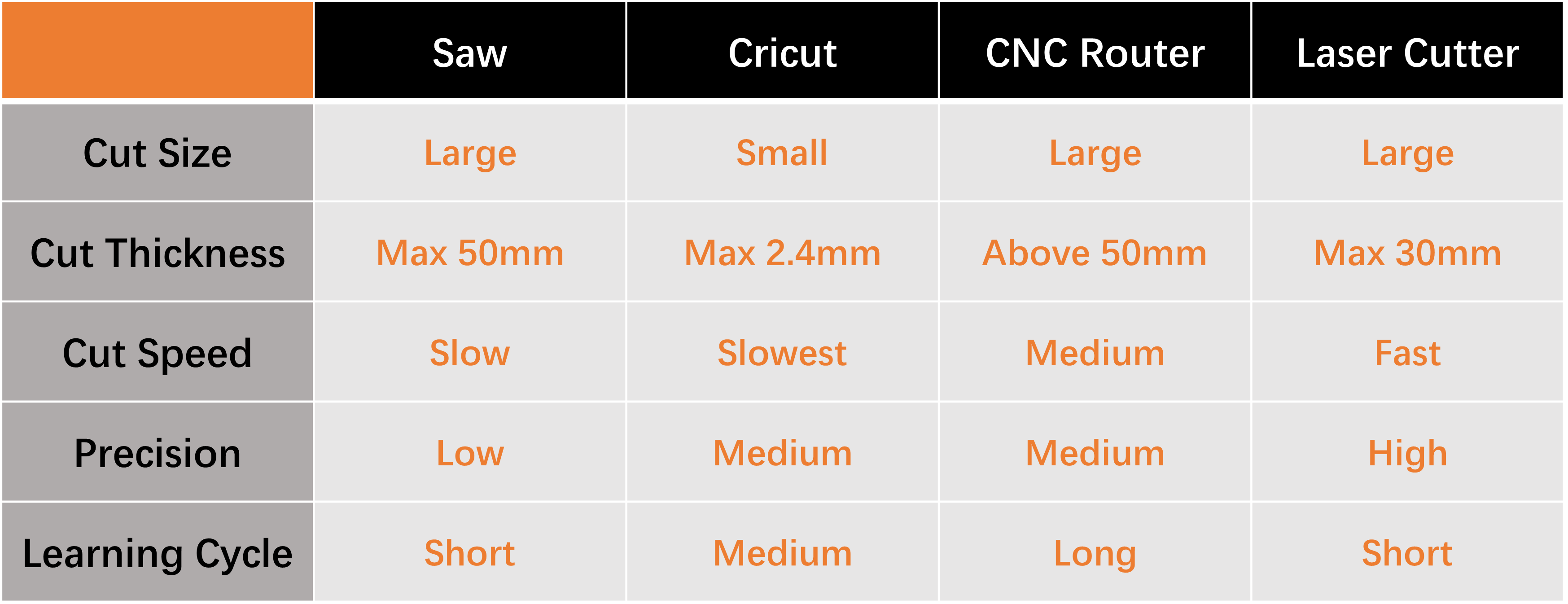

4 Qalabka Jarida - Sidee loo Jaraa Acrylic?

Jigsaw & Mishiinka Wareega

Miinshaar, sida miinshaar wareegsan ama jigsaw, waa qalab jarid oo badan oo loo isticmaalo acrylic. Waxay ku habboon tahay jarista toosan iyo kuwa qaloocan, taasoo ka dhigaysa mid loo heli karo mashaariicda DIY iyo codsiyada baaxadda weyn.

Cricut

Mashiinka Cricut waa qalab jarista saxda ah oo loogu talagalay farsamaynta iyo mashaariicda DIY. Waxay isticmaashaa daab fiican si ay u jarto agabyo kala duwan, oo ay ku jiraan acrylic, si sax ah oo fudud.

Router-ka CNC

Mashiin jaris oo kombiyuutarku maamulo oo leh qaybo kala duwan oo jaris ah. Waa mid aad u kala duwan, awoodna u leh inuu maareeyo agabyo kala duwan, oo ay ku jiraan acrylic, labadaba jarista adag iyo tan ballaaran.

Mashiinka jarista laysarka

Qalabka jarista laysarka wuxuu adeegsadaa laambad laysar ah si uu u jaro acrylic-ga si sax ah. Waxaa badanaa loo isticmaalaa warshadaha u baahan naqshado adag, faahfaahin fiican, iyo tayo goyn joogto ah.

Sidee loo doortaa jarista akrilik ee adiga kugu habboon?

sababtoo ah

Kala duwanaansho, Dabacsanaan, Hufnaan…

☻Awood u leh Laser-ka jarista Acrylic-ka oo aad u fiican:

Qaar ka mid ah Muunado ka mid ah Laser-ka Goynta Acrylic

• Bandhigga Xayeysiisyada

• Sanduuqa Kaydinta

• Calaamado

• Koob

• Moodel

• Silsilad Fure

• Dusha Keegga

• Hadyad iyo Qurxin

• Alaabta guriga

• Dahab

▶ Ma sun baa jarista laysarka ee loo yaqaan 'acrylic'?

▶ Sidee Loogu Jartaa Laser-ka Nadiifka ah ee Acrylic?

▶ Waa maxay laser-ka ugu fiican ee loo isticmaalo jarista akrilik?

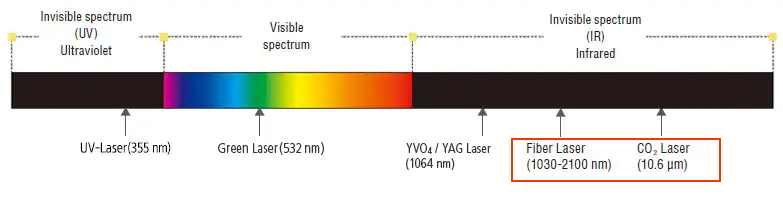

Gaar ahaan jarista acrylic-ga, laysarka CO2 waxaa badanaa loo arkaa doorashada ugu fiican sababtoo ah astaamaha hirarka, isagoo bixinaya jaritaanno nadiif ah oo sax ah oo ka yimaada dhumucda acrylic-ga kala duwan. Si kastaba ha ahaatee, shuruudaha gaarka ah ee mashaariicdaada, oo ay ku jiraan tixgelinta miisaaniyadda iyo agabka aad qorsheyneyso inaad la shaqeyso, waa inay sidoo kale saameeyaan doorashadaada. Had iyo jeer hubi tilmaamaha nidaamka laysarka oo hubi inuu la jaan qaadayo codsiyadaada loogu talagalay.

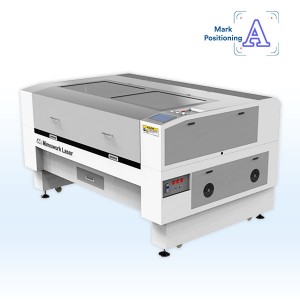

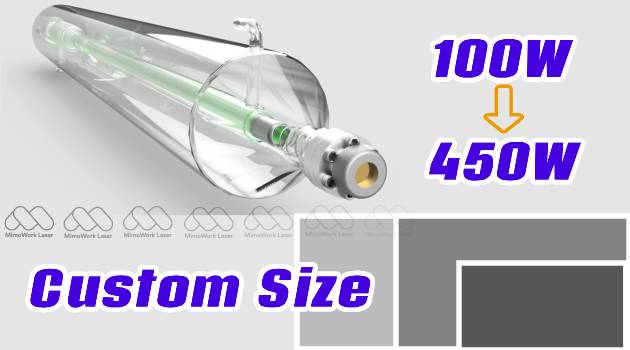

▶ Qalabka lagu goynayo Laser-ka CO2 ee lagu taliyay Acrylic

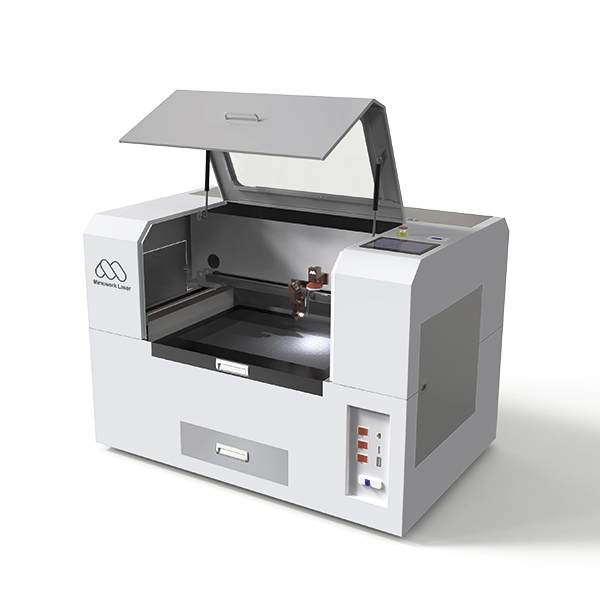

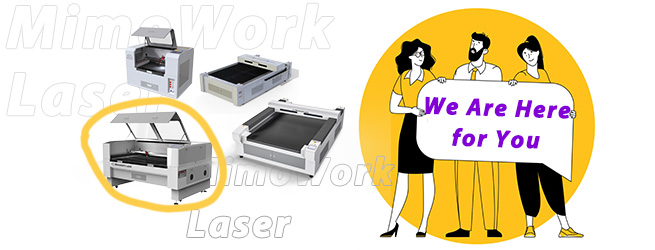

Laga soo bilaabo Taxanaha Laser-ka MimoWork

Cabbirka Miiska Shaqada:600mm * 400mm (23.6” * 15.7”)

Ikhtiyaarada Awoodda Laydhka:65W

Dulmar guud oo ku saabsan Mashiinka Laysarka ee Desktop-ka ah 60

Moodeelka Desktop-ka - Flatbed Laser Cutter 60 wuxuu ku faanaa naqshad yar oo si wax ku ool ah u yaraynaysa baahida booska ee qolkaaga. Si fudud ayuu ugu fadhiyaa miiska dushiisa, isagoo isu soo bandhigaya doorasho heer-gelis ah oo ku habboon shirkadaha cusub ee ku hawlan abuurista alaabada yaryar ee gaarka loo leeyahay, sida abaalmarinta acrylic, qurxinta, iyo dahabka.

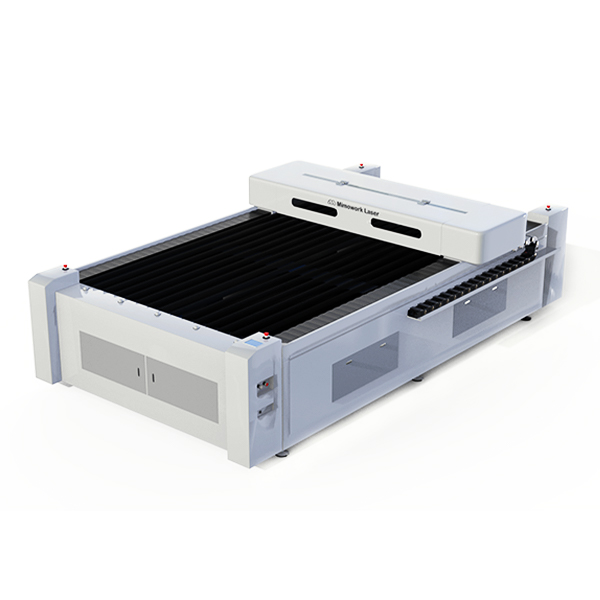

Cabbirka Miiska Shaqada:1300mm * 900mm (51.2” * 35.4”)

Ikhtiyaarada Awoodda Laydhka:100W/150W/300W

Dulmar guud oo ku saabsan Mashiinka Laser-ka ee Flatbed 130

Qalabka Laser-ka ee Flatbed bed 130 waa doorashada ugu caansan ee jarista acrylic. Naqshadeynta miiska shaqada ee dhex marta ayaa kuu sahlaysa inaad jarjarto cabbirka weyn ee xaashida acrylic ka dheer aagga shaqada. Intaa waxaa dheer, waxay bixisaa kala duwanaansho iyadoo lagu qalabeynayo tuubooyin laysar ah oo leh qiimeyn kasta oo awood ah si loo daboolo baahiyaha jarista acrylic oo leh dhumuc kala duwan.

Cabbirka Miiska Shaqada:1300mm * 2500mm (51.2” * 98.4”)

Ikhtiyaarada Awoodda Laydhka:150W/300W/500W

Dulmar guud oo ku saabsan Mashiinka Laydhka ee Flatbed 130L

Mashiinka weyn ee Flatbed Laser Cutter 130L ayaa si fiican ugu habboon jarista go'yaal acrylic ah oo waaweyn, oo ay ku jiraan looxyada 4ft x 8ft ee inta badan la isticmaalo ee laga heli karo suuqa. Mashiinkan waxaa si gaar ah loogu talagalay inuu daboolo mashaariicda waaweyn sida calaamadaha xayaysiinta dibadda, qaybaha gudaha, iyo qalab ilaalin gaar ah. Natiijo ahaan, wuxuu u muuqdaa mid ka mid ah ikhtiyaarrada la doorbido warshadaha sida xayeysiinta iyo soo saarista alaabta guriga.

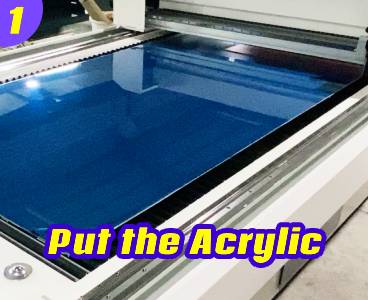

▶ Tilmaamaha Hawlgalka: Sidee loo gooyaa laysarka akrilik?

Iyada oo ku xidhan nidaamka CNC iyo qaybaha saxda ah ee mashiinka, mashiinka jarista laysarka acrylic waa mid otomaatig ah oo si fudud loo shaqayn karo. Waxa kaliya ee aad u baahan tahay inaad faylka naqshadda ku geliso kombiyuutarka, oo aad dejiso xuduudaha iyadoo loo eegayo sifooyinka agabka iyo shuruudaha jarista. Inta soo hartayna waxaa loo dayn doonaa laysarka. Waa waqtigii aad gacmahaaga xorayn lahayd oo aad maskaxda ku dhaqaajin lahayd hal-abuurka iyo male-awaalka.

Tallaabada 1. Diyaari mashiinka iyo acrylic-ga

Diyaarinta Acrylic:Ku hay acrylic-ga fidsan oo nadiif ah miiska shaqada, waana ka wanaagsan in la tijaabiyo iyadoo la isticmaalayo qashinka ka hor goynta laser-ka dhabta ah.

Mashiinka laysarka:go'aami cabbirka acrylic-ga, cabbirka qaabka jarista, iyo dhumucda acrylic-ga, si aad u doorato mashiinka ku habboon.

▶

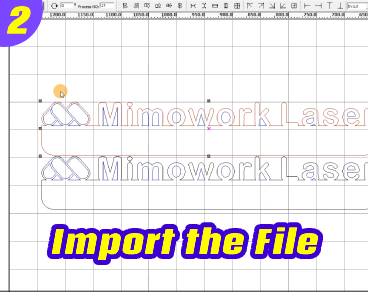

Tallaabada 2. dejinta software-ka

Faylka Naqshadeynta:soo dejinta faylka goynta barnaamijka.

Dejinta laysarka: La hadal khabiirkayaga laysarka si aad u hesho cabbirrada guud ee jarista. Laakiin agabyo kala duwan waxay leeyihiin dhumuc, daahirnimo, iyo cufnaan kala duwan, markaa tijaabinta kahor waa doorashada ugu fiican.

▶

Tallaabada 3. acrylic-ka laysarka lagu jaro

Bilow Jarida Laysarka:Laysarku si toos ah ayuu u jari doonaa qaabka iyadoo loo eegayo wadada la bixiyay. Xasuuso inaad furto hawo-qaadashada si aad u nadiifiso qiiqa, oo aad hoos u dhigto afuufidda hawada si aad u hubiso in geesku siman yahay.

Casharka Fiidiyowga: Jarida iyo Qorista Laser-ka ee Acrylic

▶ Sidee loo Doortaa Mashiinka laysarka?

Waxaa jira dhowr tixgelin marka aad dooranayso gooye laser acrylic ah oo ku habboon mashruucaaga. Marka hore waxaad u baahan tahay inaad ogaato macluumaadka agabka sida dhumucda, cabbirka, iyo sifooyinka. Iyo go'aaminta shuruudaha jarista ama qorista sida saxnaanta, xallinta xaraashka, hufnaanta jarista, cabbirka qaabka, iwm. Marka xigta, haddii aad leedahay shuruudo gaar ah oo ku saabsan wax soo saarka aan qiiqa lahayn, qalabaynta soo saaraha qiiqa ayaa diyaar ah. Intaa waxaa dheer, waxaad u baahan tahay inaad tixgeliso miisaaniyaddaada iyo qiimaha mashiinka. Waxaan kugula talineynaa inaad doorato bixiye mashiin laser xirfad leh si aad u hesho kharash-ool ah, adeeg dhammaystiran, iyo tignoolajiyada wax soo saarka ee la isku halleyn karo.

Waa inaad ka fikirtaa

> Macluumaad noocee ah ayaad u baahan tahay inaad bixiso?

> Macluumaadka xiriirkayaga

> Qiimaha mashiinka jarista laysarka akrilik

> Hadday tahay inaad doorato xulashooyinka mashiinka laysarka

▶ Isticmaalka Mashiinka

> Intee in le'eg oo dhumuc ah oo acrylic ah ayaa laser-ku jari karaa?

Dhumucda acrylic-ga ee laysarka CO2 uu jari karo waxay ku xiran tahay awoodda gaarka ah ee laysarka iyo astaamaha nidaamka jarista laysarka. Guud ahaan, laysarka CO2 waxay awood u leeyihiin inay jaraan xaashida acrylic-ga oo leh dhumuc kala duwan ilaa 30mm. Intaa waxaa dheer, arrimo ay ka mid yihiin diiradda iftiinka laysarka, tayada indhaha, iyo naqshadda gaarka ah ee laysarka jarjaraya ayaa saameyn ku yeelan kara waxqabadka jarista.

Kahor intaadan isku dayin inaad jarto xaashida acrylic-ka ee qaro weyn, waxaa lagugula talinayaa inaad hubiso tilmaamaha uu bixiyay soo saaraha qalabkaaga laysarka CO2. Samaynta tijaabooyinka jajabyada acrylic-ka ee dhumucdoodu kala duwan tahay waxay kaa caawin kartaa go'aaminta dejimaha ugu habboon ee mashiinkaaga gaarka ah.

Caqabad: Goynta Laser-ka 21mm dhumucda Acrylic

> Sidee looga fogaan karaa qiiqa acrylic-ka ee laysarka lagu jaro?

> Casharka jarista laysarka acrylic

Sidee loo ogaadaa heerka lenska laser-ka ee isha?

Sidee loo rakibaa tuubada laysarka?

Sidee loo nadiifiyaa muraayadda laysarka?

Baro wax badan oo ku saabsan Laser-ka Jarida Acrylic,

Halkan guji si aad noola hadasho!

Qalabka Laser-ka ee CO2 ee loo yaqaan Acrylic waa mashiin caqli badan oo otomaatig ah iyo lammaane lagu kalsoonaan karo shaqada iyo nolosha. Si ka duwan habaynta farsamada dhaqameed ee kale, qalabka laser-ka ayaa isticmaala nidaamka xakamaynta dhijitaalka ah si loo xakameeyo waddada jarista iyo saxnaanta jarista. Qaab-dhismeedka mashiinka deggan iyo qaybaha ayaa dammaanad qaadaya hawlgal siman.

Jahawareer ama su'aalo kasta oo ku saabsan qalabka gooyaha laser-ka acrylic, na weydii wakhti kasta

Waqtiga boostada: Diseembar-11-2023