I-Laser ifanelwe yeyona ifanelekileyo yokusika i-Acrylic! Kutheni nditsho njalo? Ngenxa yokuhambelana kwayo ngokubanzi neentlobo ezahlukeneyo ze-acrylic kunye nobukhulu, ukuchaneka okuphezulu kakhulu kunye nesantya esikhawulezayo ekusikeni i-acrylic, kulula ukuyifunda nokusebenza, nokunye. Nokuba ungumntu othanda izinto zokuzonwabisa, ukusika iimveliso ze-acrylic zeshishini, okanye zokusetyenziswa kwimizi-mveliso, i-acrylic yokusika i-laser ihlangabezana phantse nazo zonke iimfuno. Ukuba ufuna umgangatho ogqwesileyo kunye nokuguquguquka okuphezulu, kwaye ufuna ukuba yingcaphephe ngokukhawuleza, i-acrylic laser cutter iya kuba lukhetho lwakho lokuqala.

Iingenelo zeLaser Cutting Acrylic

✔ Umphetho oGuqukileyo oLula

Amandla e-laser anamandla anokusika ngoko nangoko iphepha le-acrylic liye kwicala elithe nkqo. Ubushushu buyayivala kwaye buyipolisha imiphetho ibe bushelelezi kwaye icocekile.

✔ Ukusika Okungenazo Iintambo

Isisiki selaser sinenkqubo yokucubungula ngaphandle kokuthinta, ukususa ixhala malunga nokukrweleka kwezinto kunye nokuqhekeka kuba akukho xinzelelo loomatshini. Akukho mfuneko yokutshintsha izixhobo kunye neebhithi.

✔ Ubuchule obuphezulu

Ukuchaneka okuphezulu kakhulu kwenza i-acrylic laser cutter isikwe ibe ziipateni ezintsonkothileyo ngokwefayile eyilelweyo. Ifanelekile kwimihombiso ye-acrylic eyenziwe ngokwezifiso kunye nezixhobo zoshishino kunye nezonyango.

✔ Isantya kunye nokusebenza kakuhle

Amandla e-laser aqinileyo, akukho xinzelelo loomatshini, kunye nolawulo oluzenzekelayo lwedijithali, kwandisa kakhulu isantya sokusika kunye nokusebenza kakuhle kwemveliso.

✔ Ukuguquguquka kwezinto

Ukusika nge-laser ye-CO2 kunokusetyenziswa ngeendlela ezahlukeneyo ukusika amaphepha e-acrylic anobukhulu obahlukeneyo. Ifanelekile kwizinto ezibhityileyo nezityebileyo ze-acrylic, nto leyo enika ukuguquguquka kwizicelo zeprojekthi.

✔ Inkunkuma encinci yezinto eziphathekayo

Umqadi ogxile kwi-laser ye-CO2 unciphisa inkunkuma yezinto ngokudala ububanzi obuncinci be-kerf. Ukuba usebenza ngokuvelisa ngobuninzi, isoftware ekrelekrele yokwenza i-laser nesting ingenza ngcono indlela yokusika, kwaye inyuse izinga lokusetyenziswa kwezinto.

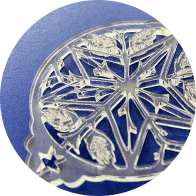

Umphetho ocacileyo wekristale

Ipateni yokusika entsonkothileyo

Iifoto eziqoshiweyo kwi-acrylic

▶ Jonga ngokusondeleyo: Yintoni i-Laser Cutting Acrylic?

Ukusika ngeLaser I-Acrylic Snowflake

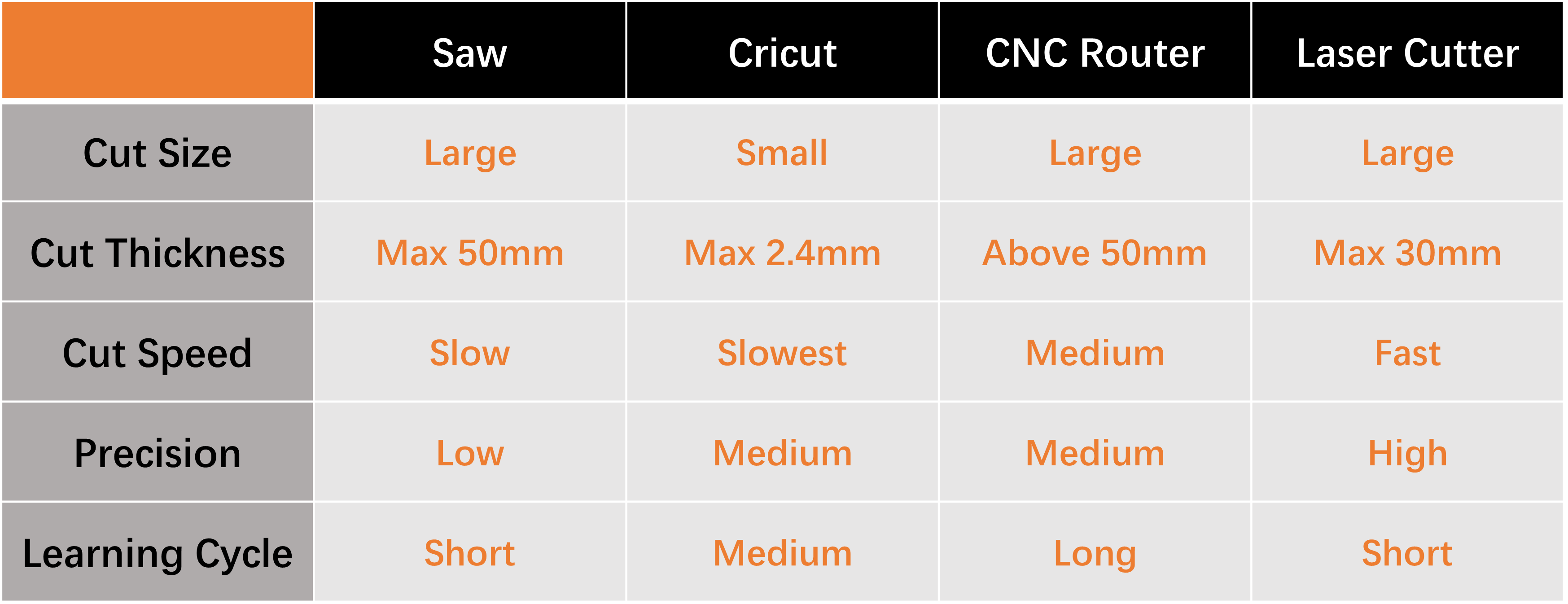

Izixhobo zokusika ezi-4 - Ungayisika njani i-Acrylic?

I-Jigsaw kunye ne-Circular Saw

Isarha, njengesarha ejikelezayo okanye ijigsaw, sisixhobo sokusika esisebenziseka lula esisetyenziswa kakhulu kwi-acrylic. Sifanelekile kwiindlela ezithe tye nezigobileyo, nto leyo eyenza ukuba ifikeleleke kwiiprojekthi ze-DIY kunye nezicelo ezinkulu.

I-Cricut

Umatshini weCricut sisixhobo sokusika ngokuchanekileyo esenzelwe ukwenza izinto zobugcisa kunye neeprojekthi ze-DIY. Usebenzisa i-blade encinci ukusika izinto ezahlukeneyo, kuquka i-acrylic, ngokuchanekileyo nangokulula.

I-CNC Router

Umatshini wokusika olawulwa yikhompyutha oneentlobo ngeentlobo zeenxalenye zokusika. Uyakwazi ukuguquguquka kakhulu, unako ukuphatha izinto ezahlukeneyo, kuquka i-acrylic, ukusika okuntsonkothileyo nokukhulu.

Umsiki weLaser

Umsiki welaser usebenzisa umqadi welaser ukusika i-acrylic ngokuchanekileyo okuphezulu. Isetyenziswa rhoqo kumashishini afuna uyilo oluntsonkothileyo, iinkcukacha ezincinci, kunye nomgangatho wokusika ohambelanayo.

Ungakhetha njani i-acrylic cutter efanela wena?

yimbangela yayo

Ukuguquguquka, Ukuguquguquka, Ukusebenza kakuhle…

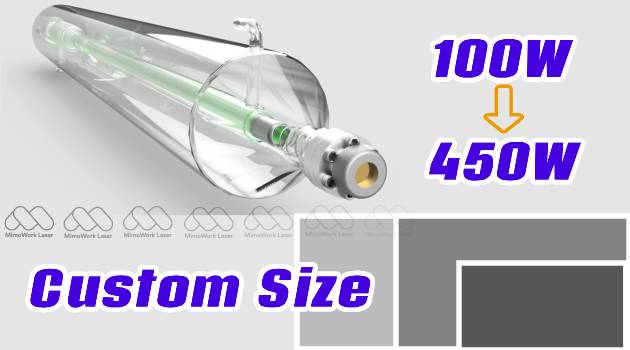

☻Amandla eLaser aBalaseleyo okusika iAcrylic:

Ezinye iisampuli ze-Laser Cutting Acrylic

• Umboniso weeNtengiso

• Ibhokisi yokugcina izinto

• Imiqondiso

• Indebe

• Imodeli

• Isitshixo

• Isigqubuthelo sekhekhe

• Isipho kunye nokuhombisa

• Ifenitshala

• Ubucwebe

▶ Ngaba i-Laser Cutting Acrylic inetyhefu?

▶ Ungayisika njani i-acrylic ecacileyo nge-laser?

▶ Yeyiphi eyona laser ilungileyo yokusika i-acrylic?

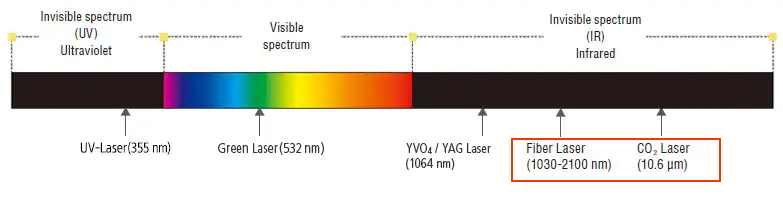

Ngokukodwa xa kusikwa i-acrylic, i-laser ye-CO2 idla ngokuthathwa njengolona khetho lubalaseleyo ngenxa yeempawu zayo zobude be-wavelength, inika ukusika okucocekileyo nokuchanekileyo kuzo zonke iintlobo zobukhulu be-acrylic. Nangona kunjalo, iimfuno ezithile zeprojekthi zakho, kubandakanya ukuqwalaselwa kohlahlo lwabiwo-mali kunye nezixhobo oceba ukusebenza ngazo, nazo kufuneka zichaphazele ukhetho lwakho. Soloko ujonga iinkcukacha zenkqubo ye-laser kwaye uqinisekise ukuba ihambelana nezicelo zakho.

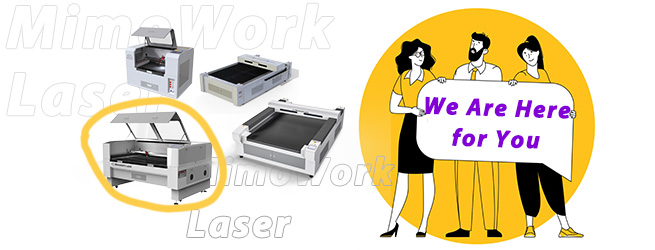

▶ Isisiki se-CO2 Laser esicetyiswayo kwi-Acrylic

Ukusuka kwiMimoWork Laser Series

Ubungakanani beTheyibhile yokuSebenza:600mm * 400mm (23.6” * 15.7”)

Iinketho zamandla eLaser:65W

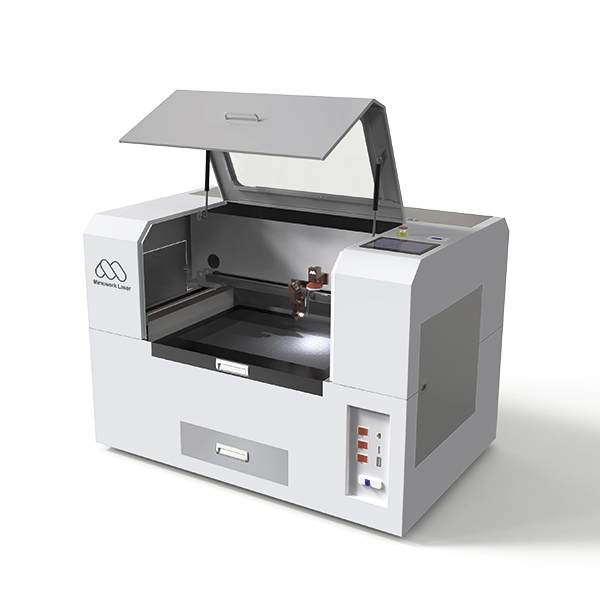

Isishwankathelo seDesktop Laser Cutter 60

Imodeli yeDesktop - Flatbed Laser Cutter 60 inesakhiwo esincinci esinciphisa ngokufanelekileyo iimfuno zendawo kwigumbi lakho. Ihlala kakuhle phezu kwetafile, iziveza njengokhetho olufanelekileyo lwamashishini amatsha abandakanyeka ekudalweni kweemveliso ezincinci ezenziwe ngokwezifiso, ezinje ngamabhaso e-acrylic, imihombiso, kunye nobucwebe.

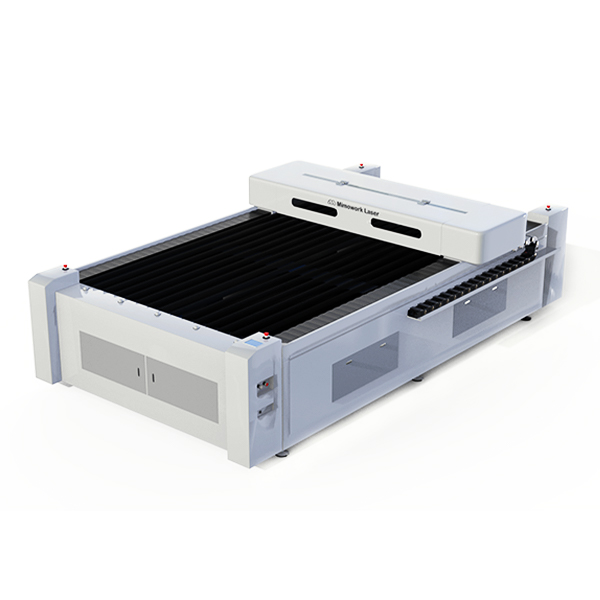

Ubungakanani beTheyibhile yokuSebenza:1300mm * 900mm (51.2” * 35.4”)

Iinketho zamandla eLaser:100W/150W/300W

Isishwankathelo seFlatbed Laser Cutter 130

I-Flatbed Laser Cutter 130 yeyona ndlela idumileyo yokusika i-acrylic. Uyilo lwayo lwetafile yokusebenza oludlulayo lukuvumela ukuba usike ubungakanani obukhulu bamashiti e-acrylic amade kunendawo yokusebenza. Ngaphezu koko, inika ukuguquguquka ngokuxhobisa ngeetyhubhu ze-laser zalo naluphi na umlinganiselo wamandla ukuhlangabezana neemfuno zokusika i-acrylic enobukhulu obahlukeneyo.

Ubungakanani beTheyibhile yokuSebenza:1300mm * 2500mm (51.2” * 98.4”)

Iinketho zamandla eLaser:150W/300W/500W

Isishwankathelo seFlatbed Laser Cutter 130L

I-Flatbed Laser Cutter 130L enkulu ifanelekile ukusika amaphepha amakhulu e-acrylic, kuquka neebhodi ezisetyenziswa rhoqo ze-4ft x 8ft ezikhoyo kwimarike. Lo matshini wenzelwe ngokukodwa ukwamkela iiprojekthi ezinkulu ezifana neempawu zentengiso zangaphandle, izahlulo zangaphakathi, kunye nezixhobo ezithile zokukhusela. Ngenxa yoko, ivelele njengokhetho olukhethwayo kumashishini afana nentengiso kunye nemveliso yefenitshala.

▶ Isikhokelo sokuSebenza: Ungayisika njani i-Acrylic ngeLaser?

Ngokuxhomekeke kwinkqubo ye-CNC kunye nezinto ezichanekileyo zomatshini, umatshini wokusika i-acrylic laser uyazenzekela kwaye kulula ukuwusebenzisa. Udinga nje ukulayisha ifayile yoyilo kwikhompyutha, kwaye usete iiparameter ngokweempawu zezinto kunye neemfuno zokusika. Okunye kuya kushiyelwa kwi-laser. Lixesha lokukhulula izandla zakho kwaye usebenzise ubuchule kunye nokucinga engqondweni.

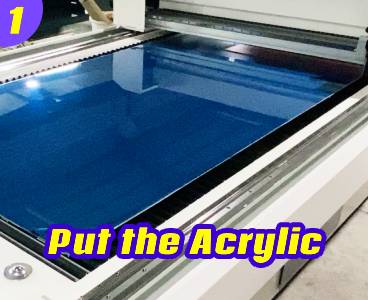

Inyathelo 1. lungiselela umatshini kunye ne-acrylic

Ukulungiswa kwe-Acrylic:Gcina i-acrylic icocekile kwaye ithambile etafileni yokusebenza, kwaye kungcono ukuvavanya usebenzisa ii-scrap ngaphambi kokusika nge-laser yokwenyani.

Umatshini weLaser:misela ubungakanani be-acrylic, ubungakanani bepateni yokusika, kunye nobukhulu be-acrylic, ukuze ukhethe umatshini ofanelekileyo.

▶

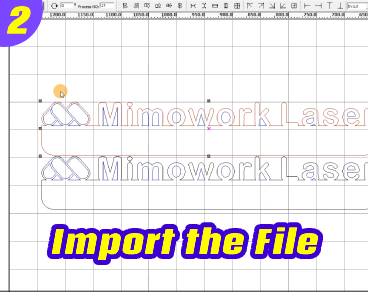

Inyathelo lesi-2. seta isoftware

Ifayile yoYilo:ngenisa ifayile yokusika kwisoftware.

Useto lweLaser: Thetha nengcali yethu yeleza ukuze ufumane iiparameter zokusika ngokubanzi. Kodwa izixhobo ezahlukeneyo zinobukhulu obahlukeneyo, ubumsulwa, kunye noxinano, ngoko ke ukuvavanya ngaphambi kovavanyo lolona khetho lufanelekileyo.

▶

Inyathelo lesi-3. i-acrylic esikiweyo nge-laser

Qalisa ukusika ngeLaser:I-laser iza kuyisika ngokuzenzekelayo ipatheni ngokwendlela enikiweyo. Khumbula ukuvula umoya ukuze ususe umsi, kwaye wehlise umoya ovuthuzayo ukuqinisekisa ukuba umphetho uthambile.

Isifundo sevidiyo: Ukusika ngeLaser kunye nokukrola iAcrylic

▶ Ungayikhetha njani iLaser Cutter?

Kukho izinto ezimbalwa ekufuneka uziqwalasele xa ukhetha isixhobo sokusika i-laser se-acrylic esifanelekileyo kwiprojekthi yakho. Okokuqala kufuneka wazi ulwazi lwezinto ezinje ngobukhulu, ubungakanani, kunye neempawu. Kwaye Chonga iimfuno zokusika okanye zokukrola ezifana nokuchaneka, isisombululo sokukrola, ukusebenza kakuhle kokusika, ubungakanani bepateni, njl. Okulandelayo, ukuba uneemfuno ezikhethekileyo zemveliso engeyiyo i-fume, kufumaneka isixhobo sokukhupha i-fume. Ngaphezu koko, kufuneka uqwalasele uhlahlo lwabiwo-mali lwakho kunye nexabiso lomatshini. Sicebisa ukuba ukhethe umthengisi womatshini we-laser oqeqeshiweyo ukuze ufumane iindleko ezingabizi kakhulu, inkonzo epheleleyo, kunye nobuchwepheshe bokuvelisa obuthembekileyo.

Ufanele Ucinge

> Loluphi ulwazi ekufuneka ulunike?

> Ulwazi lwethu loqhagamshelwano

> Iindleko zomatshini wokusika i-laser ye-acrylic

> Nokuba ukhetha ukhetho lomatshini we-laser

▶ Ukusebenzisa umatshini

> Ingakanani ubukhulu be-acrylic enokunqunyulwa nge-laser?

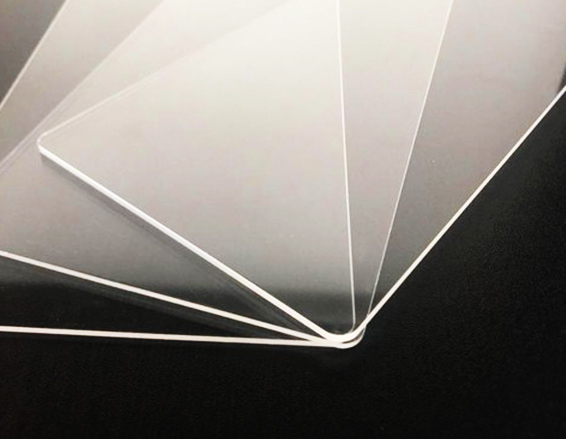

Ubukhulu be-acrylic obunokunqunyulwa yi-laser ye-CO2 buxhomekeke kumandla athile e-laser kunye neempawu zenkqubo yokusika nge-laser. Ngokubanzi, ii-laser ze-CO2 ziyakwazi ukusika amaphepha e-acrylic anobukhulu obahlukeneyo ukuya kuthi ga kwi-30mm. Ukongeza, izinto ezifana nokugxila kwe-laser beam, umgangatho we-optics, kunye noyilo oluthile lwe-laser cutter zinokuchaphazela ukusebenza kokusika.

Ngaphambi kokuba uzame ukusika amaphepha e-acrylic atyebileyo, kuyacetyiswa ukuba ujonge iinkcukacha ezibonelelwe ngumvelisi we-CO2 laser cutter yakho. Ukwenza uvavanyo kwiziqwenga ze-acrylic ezilahliweyo ezinobukhulu obahlukeneyo kunokunceda ekumiseleni useto olufanelekileyo kumatshini wakho othile.

Umngeni: Ukusikwa kweLaser okuyi-21mm ye-Acrylic etyebileyo

> Ungayiphepha njani i-acrylic cutting impumlo nge-laser?

> Isifundo somsiki we-laser we-acrylic

Ungayifumana njani ingqwalasela yelensi yelaser?

Ungayifakela njani ityhubhu yelaser?

Indlela yokucoca iilensi ze-laser?

Funda Okungakumbi malunga nokuSika ngeLaser Acrylic,

Cofa apha ukuze uthethe nathi!

I-CO2 Laser Cutter ye-Acrylic ngumatshini okrelekrele nozenzekelayo kunye neqabane elithembekileyo ekusebenzeni nasekuphileni. Ngokungafaniyo nezinye iindlela zokucubungula oomatshini zemveli, abasiki be-laser basebenzisa inkqubo yolawulo lwedijithali ukulawula indlela yokusika kunye nokuchaneka kokusika. Kwaye ulwakhiwo lomatshini oluzinzileyo kunye nezinto ezisetyenziswayo ziqinisekisa ukusebenza kakuhle.

Ilebhu yoMatshini weLaser yeMimoWork

Nakuphi na ukudideka okanye imibuzo malunga nomsiki we-acrylic laser, buza nje kuthi nangaliphi na ixesha

Ixesha lokuthumela: Disemba-11-2023