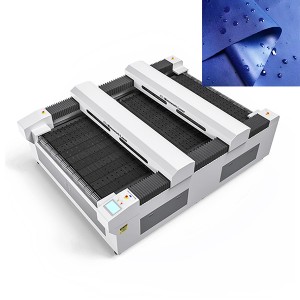

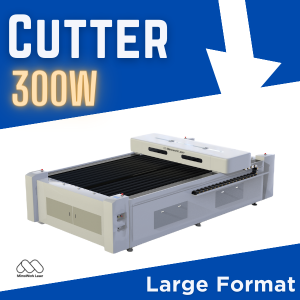

Sehahi sa Laser ea Lehong la Indasteri bakeng sa Lehong le Leholo le Letenya (Ho fihlela ho 30mm)

▶ Sehahi se seholo sa laser bakeng sa patsi

Lintlha tsa Tekheniki

| Sebaka sa Mosebetsi (W * L) | 1300mm * 2500mm (51" * 98.4") |

| Software | Offline Software |

| Matla a Laser | 150W/300W/450W |

| Mohloli oa Laser | CO2 Glass Laser Tube |

| Sistimi ea Taolo ea Mechini | Ball Screw & Servo Motor Drive |

| Tafole ea Mosebetsi | Lehare la Thipa kapa Tafole e Sebetsang ea khekhe ea linotsi |

| Lebelo le Leholo | 1 ~ 600mm/s |

| Ho Potlakisa Lebelo | 1000 ~ 3000mm/s2 |

| Ho Nepaha ha Boemo | ≤± 0.05mm |

| Boholo ba Mochini | 3800 * 1960 * 1210mm |

| Voltage e sebetsang | AC110-220V ± 10%, 50-60HZ |

| Mokhoa oa ho Pholisa | Mokhoa oa ho futhumatsa metsi le ts'ireletso ea metsi |

| Tikoloho ea Mosebetsi | Mocheso:0—45℃ Mongobo:5%—95% |

| Boholo ba Sephutheloana | 3850mm * 2050mm * 1270mm |

| Boima ba 'mele | 1000kg |

▷Likarolo tsa 1325 Laser Cutter

Phetoho e Kholo ea Tlhahiso

◾ Boleng bo tsitsitseng le bo Botle ba ho Seha

Moralo oa kamehla oa Tsela ea Optical

Ka bolelele bo nepahetseng ba tsela ea optical e hlahisoang, lebone la laser le sa fetoheng sebakeng sefe kapa sefe mofuteng oa tafole ea ho itšeha le ka fella ka ho seha thepa eohle, ho sa tsotelehe botenya. Ka lebaka la seo, o ka fumana phello e ntle ea ho itšeha bakeng sa acrylic kapa lehong ho feta tsela ea laser e fofang halofo.

◾ Sebetsa se Phahameng le se Nepahetseng

Mokhoa o Sebetsang oa Phetiso

X-axis precision screw module, Y-axis unilateral ball screw e fana ka botsitso bo babatsehang le ho nepahala bakeng sa motsamao o phahameng oa lebelo la gantry. Ha e kopantsoe le servo motor, sistimi ea phetisetso e theha katleho e phahameng haholo ea tlhahiso.

◾ Tšebeletso e tšoarellang le e telele

Sebopeho se tsitsitseng sa Mechini

'Mele oa mochini o cheselitsoe ka tube ea lisekoere tsa 100mm mme o tsofala ka ho sisinyeha le kalafo ea botsofali ea tlhaho. Gantry le ho itšeha hlooho li sebelisa aluminium e kopantsoeng. Tlhophiso e akaretsang e netefatsa boemo bo tsitsitseng ba ho sebetsa.

◾ Ho sebetsa ka lebelo le phahameng

Lebelo le Phahameng la ho Seha le ho Beba

1300 * 2500mm laser cutter ea rona e ka finyella 1-60,000mm / min ho betla lebelo le 1-36,000mm / min ho itšeha lebelo.

Ka nako e ts'oanang, ho nepahala ha maemo ho boetse ho netefalitsoe ka hare ho 0.05mm, e le hore e khone ho khaola le ho ngola linomoro kapa litlhaku tse 1x1mm, ho hang ha ho bothata.

Hobaneng u khetha MimoWork Laser

130250 lintlha tsa mochini oa laser papiso

|

| Tse ling tsa moetsi | Mochine oa laser oa MimoWork |

| Ho poma lebelo | 1-15,000mm/min | 1-36,000mm/min |

| Ho nepahala ha boemo | ≤± 0.2mm | ≤± 0.05mm |

| Matla a laser | 80W/100W/130W/150W | 100W/130W/150W/300W/500W |

| Mokhoa oa laser | Tsela ea laser e fofang halofo | Tsela ea kamehla ea optical |

| Sistimi ea phetiso | Lebanta la phetiso | Servo motor + ball screw |

| Tsamaiso ea ho khanna | Mokhanni oa mohato | Servo motor |

| Tsamaiso ea taolo | Tsamaiso ea khale, ha e rekisoe | Sistimi e ncha e tsebahalang ea taolo ea RDC |

| Moqapi oa motlakase oa boikhethelo | No | CE/UL/CSA |

| 'Mele o ka sehloohong | Traditional welding fuselage | Bethe e matlafalitsoeng, sebopeho sa kakaretso se cheselitsoe ka 100mm square tube, 'me se tsofala ka ho sisinyeha le kalafo ea botsofali ea tlhaho. |

Mehlala ea ho tloha Wood Laser Cutter

Lisebelisoa tsa lehong tse loketseng

MDF, Basswood, White Pine, Alder, Cherry, Oak, Baltic Birch Plywood, Balsa, Cork, Cedar, Balsa, Solid Wood, Plywood, Timber, Teak, Veneers, Walnut, Hardwood, Laminated Wood le Multiplex

Lisebelisoa tse pharaletseng

• Lisebelisoa

• Lebokose la polokelo

• Mehlala ea Mehaho

• Ho khabisa li-Inlays tsa fatše

Lifitio | Ke eng se sehang laser se ka u etsetsang sona?

Laser Engraving Photo on Wood

Fumana Lepolanka Laser Cutter ho Ntlafatsa Khoebo ea Hao

Natefeloa ke monate oa lehong la laser!

▶ Sehahi se seholo sa laser bakeng sa patsi

Ntlafatsa Likhetho tseo u ka li khethang

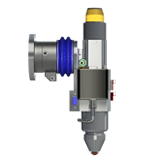

Hlooho ea Laser e Kopantsoeng

Auto Focus

TheKhamera ea CCDe khona ho lemoha le ho beha mohlala holim'a acrylic e hatisitsoeng, ho thusa laser cutter ho hlokomela ho itšeha ho nepahetseng ka boleng bo holimo. Moralo ofe kapa ofe o hlophisitsoeng oa litšoantšo o hatisitsoeng o ka sebetsoa ka mokhoa o bonolo ho latela kemiso ka sistimi ea optical, ea bapala karolo ea bohlokoa papatsong le indastering e meng.

Lipotso Tse Amanang le Ena: U ka 'na ua Thahasella

1. Na nka sebelisa mofuta ofe kapa ofe oa lehong bakeng sa ho itšeha ka laser, kapa ho na le mefuta e itseng ea patsi e sebetsang hantle ka ho fetisisa?

2. Ke botenya bofe ba lehong boo mochini oa ho itšeha oa CO2 o ka sebetsanang le ona ka katleho?

E, polokeho ke ea bohlokoa ha u sebetsa ka li-laser. Etsa bonnete ba hore ho na le moea o nepahetseng sebakeng sa hau sa mosebetsi ho tlosa mosi o hlahisoang nakong ea ho itšeha. Kamehla u roale thepa e loketseng ea ho itšireletsa (PPE), ho kenyeletsoa le likhalase tsa tšireletso. Ho ekelletsa moo, etsa bonnete ba hore patsi ha e na lintho tse koahetsoeng, lithapo, kapa lik'hemik'hale tse ka 'nang tsa hlahisa mosi o kotsi ha o pepeselitsoe laser.

Ho rema Lehong: CNC Routers VS Laser

1. Melemo ea CNC Routers

Ho latela nalane, o mong oa melemo ea mantlha ea ho khetha router ho fapana le laser e ne e le bokhoni ba eona ba ho fihlela botebo bo nepahetseng ba ho itšeha. Routa ea CNC e fana ka boiketlo ba liphetoho tse otlolohileng (haufi le Z-axis), e lumellang taolo e otlolohileng holim'a botebo ba sehiloeng. Ka mantsoe a bonolo, o ka fetola bolelele ba sehahi ho tlosa karolo e itseng feela ea bokaholimo ba patsi.

2. Mefokolo ea CNC Routers

Li-routers li sebetsa hantle ho sebetsana le li-curve butle butle empa li na le meeli ha ho tluoamahlakore a bohale. Ho nepahala ha bona ho hatelloa ke radius ea sekhahla sa ho itšeha. Ka mantsoe a bonolo,bophara ba sehiloeng bo tsamaellana le boholo ba kotopo ka boeona. Li-router tse nyane ka ho fetesisa li na le radius ea hoo e ka bang1 limilimithara.

Kaha li-routers li fokotsa likhohlano, ho bohlokoa ho tiisa thepa ka mokhoa o sireletsehileng sebakeng se sehang. Ntle le ho lokisa hantle, torque ea router e ka fella ka hore thepa e bilike kapa e fetohe ka tšohanyetso. Ka tloaelo, patsi e kenngoa sebakeng sa eona ho sebelisoa li-clamp. Leha ho le joalo, ha "router bit" ea lebelo le phahameng e sebelisoa ho thepa e koetsoeng ka thata, ho hlahisoa tsitsipano e kholo. Tension ena e na le monyetla oa hosotha kapa ho senya patsi, ho hlahisa mathata ha ho seha thepa e tšesaane haholo kapa e bonojoana.

3. Melemo & Go tlhoka mesola ea Laser

Ho tšoana le li-routers tse iketsetsang, li-cutters tsa laser li laoloa ke tsamaiso ea CNC (Computer Numerical Control). Leha ho le joalo, phapang e ka sehloohong ke mokhoa oa bona oa ho itšeha. Lisebelisoa tsa laseru se ke ua itšetleha ka khohlano; ho e-na le hoo, ba seha thepa ba sebelisamocheso o matla. Lebone le nang le matla a phahameng le chesa ka katleho ka lehong, ho fapana le mokhoa o tloaelehileng oa ho betla kapa oa ho etsa mechine.

Joalokaha ho boletsoe pejana, bophara ba sehiloeng bo khethoa ke boholo ba sesebelisoa sa ho itšeha. Le ha li-router tse nyane li na le radius e ka tlase ho 1 mm, lebone la laser le ka fetoloa hore le be le radius e nyane joalo ka0.1 limilimithara. Bokhoni bona bo lumella ho theoa ha likotoana tse rarahaneng haholo kanepahalo e makatsang.

Kaha ba sehang ka laser ba sebelisa mokhoa oa ho chesa ho rema lehong, baa kotulae bohale ka tsela e ikhethang. Le hoja ho chesoa hona ho ka lebisa ho 'mala o mong, mehato e ka kenngoa ts'ebetsong ho thibela matšoao a sa batloeng. Ho feta moo, ts'ebetso ea ho chesa e tiisa mapheo, ka honaho fokotsa ho hola le ho honyelaea lehong le rehiloeng.

Mochini oa Laser o Amanang

bakeng sa ho itšeha ka lehong le acrylic laser

• Fast & e nepahetseng fatiloeng bakeng sa thepa e tiileng

• Mokhoa oa ho kenella ka litsela tse peli o lumella lisebelisoa tsa nako e telele tse behiloeng le ho khaola

bakeng sa lehong le acrylic laser fatling

• Moralo o bobebe le o kopaneng

• Ho bonolo ho sebetsa bakeng sa ba qalang