Litafole tsa Laser

Litafole tse sebetsang tsa Laser li etselitsoe lisebelisoa tse bonolo tsa ho fepa le ho tsamaisa nakong ea ho itšeha ka laser, ho betla, ho penta le ho tšoaea.MimoWork e fana ka litafole tse latelang tsa cnc laser ho matlafatsa tlhahiso ea hau.Khetha sutu ho latela tlhoko ea hau, ts'ebeliso, thepa le tikoloho ea ho sebetsa.

Mokhoa oa ho kenya le ho theola thepa ho tloha tafoleng ea ho itšeha ka laser e ka ba mosebetsi o sa sebetseng.

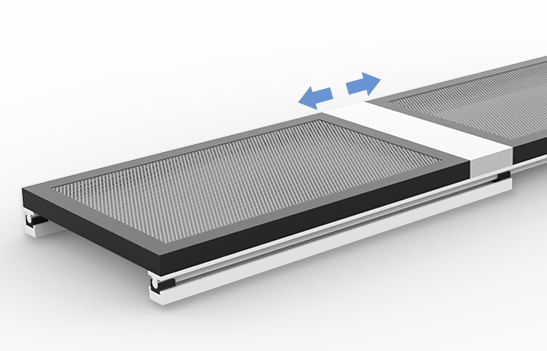

Ho fanoe ka tafole e le 'ngoe ea ho itšeha, mochine o tlameha ho emisa ka ho feletseng ho fihlela lits'ebetso tsena li phethiloe.Nakong ena ea ho se sebetse, u senya nako le chelete e ngata.E le ho rarolla bothata bona le ho eketsa tlhahiso ka kakaretso, MimoWork e khothalletsa tafole ea shuttle ho felisa nako ea nako pakeng tsa ho fepa le ho itšeha, ho potlakisa ts'ebetso eohle ea ho itšeha ka laser.

Tafole ea shuttle, eo hape e bitsoang pallet changer, e hlophisitsoe ka moralo oa ho feta e le hore e tsamaee ka litsela tse peli.Ho thusa ho kenya le ho laolla thepa e ka fokotsang kapa ea felisa nako ea ho theoha le ho kopana le lisebelisoa tsa hau tse khethehileng tsa ho itšeha, re hlophisitse boholo bo fapaneng ho lumellana le boholo bo bong le bo bong ba mechine ea laser ea MimoWork.

Likarolo tsa mantlha:

E loketse bakeng sa lisebelisoa tsa lakane tse tenyetsehang le tse tiileng

| Melemo ea litafole tsa li-shuttle tsa ho feta | Mefokolo ea litafole tsa ho feta |

| Libaka tsohle tsa mosebetsi li tsitsitse ka bophahamo bo lekanang, kahoo ha ho na phetoho e hlokahalang ho Z-axis | Eketsa mohato oa maoto oa tsamaiso ea laser ka kakaretso ka lebaka la sebaka se eketsehileng se hlokahalang mahlakoreng ka bobeli a mochine |

| Sebopeho se tsitsitseng, se tšoarellang le se ka tšeptjoang, liphoso tse fokolang ho feta litafole tse ling tsa shuttle | |

| Tlhahiso e tšoanang ka theko e theko e tlaase | |

| Sepalangoang se tsitsitseng ka ho feletseng le se sa sisinyeheng | |

| Ho kenya le ho sebetsa ho ka etsoa ka nako e le 'ngoe |

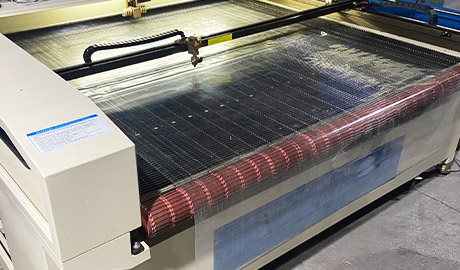

Letlapa la Conveyor bakeng sa Mochini oa ho Seha Laser

Tafole ea conveyor e entsoe katepo ea tšepe e sa hloekange loketseng bakeng salisebelisoa tse tšesaane le tse tenyetsehang joalo kafilimi, leselaleletlalo. Ka sistimi ea conveyor, ho seha ka laser ho sa feleng hoa khoneha.Ho sebetsa hantle ha lisebelisoa tsa laser tsa MimoWork ho ka eketsoa le ho feta.

Likarolo tsa mantlha:

• Ha ho ho otlolla masela

• Automatic bohale taolo

• Customized saese ho kopana mong le e mong tlhoko, tšehetsa e khōlō sebopeho

Melemo ea Tsamaiso ea Tafole ea Conveyor:

• Phokotso ea litšenyehelo

Ka thuso ea tsamaiso ea conveyor, ho itšeha ka mokhoa o itekanetseng le ho tsoelang pele ho ntlafatsa haholo katleho ea tlhahiso.Ka nako eo, nako e nyane le mosebetsi o sebelisoa, ho fokotsa litšenyehelo tsa tlhahiso.

• Tlhahiso e phahameng

Tlhahiso ea batho e na le moeli, kahoo ho hlahisa tafole ea conveyor ho e-na le hoo ke boemo bo latelang bakeng sa hau ho eketsa boholo ba tlhahiso.E lumellana lee fepang ka koloi, Tafole ea conveyor ea MimoWork e thusa ho fepa le ho seha khokahano e se nang moeli le boiketsetso bakeng sa ts'ebetso e phahameng.

• Ho nepahala le ho pheta-pheta

Kaha ntho e ka sehloohong e hlolehang tlhahisong e boetse e le lebaka la motho - ho nkela mosebetsi oa matsoho sebaka ka mochini o nepahetseng, o hlophisitsoeng o nang le tafole ea conveyor o tla fana ka liphetho tse nepahetseng haholoanyane.

• Ho eketsa polokeho

Bakeng sa ho theha tikoloho e bolokehileng ea ts'ebetso, tafole ea conveyor e eketsa sebaka sa ts'ebetso seo kantle ho sona se sireletsehileng kapa ho beha leihlo ho bolokehile.

Bed Laser ea mahe a linotsi bakeng sa Mochini oa Laser

Tafole ea ho sebetsa e bitsoa ka sebopeho sa eona se tšoanang le khekhe ea linotši.E etselitsoe hore e lumellane le boholo bo bong le bo bong ba mechine ea laser ea MimoWork.

Foil ea aluminium e lumella beam ea laser hore e fete ka mokhoa o hloekileng ka har'a thepa eo u e sebetsanang le ho fokotsa maikutlo a ka tlaase ho tloha ho chesa bokamorao ba thepa hape e sireletsa haholo hlooho ea laser hore e se ke ea senyeha.

Bethe ea khekhe ea linotsi ea laser e lumella moea o bonolo oa mocheso, lerōle le mosi nakong ea ts'ebetso ea laser.

Likarolo tsa mantlha:

• E loketse lits'ebetso tse hlokang likhakanyo tse fokolang tsa morao le ho bata haholo

• Tafole e sebetsang ea khekhe ea linotši e matla, e tsitsitseng, e tšoarellang e ka tšehetsa lisebelisoa tse boima

• 'Mele oa tšepe oa boleng bo holimo o u thusa ho lokisa thepa ea hau ka limakete

Letlapa la Knife Strip bakeng sa Mochini oa ho Seha Laser

Tafole ea thipa ea thipa, eo hape e bitsoang tafole ea aluminium slat seha e etselitsoe ho ts'ehetsa thepa le ho boloka sebaka se bataletseng.Tafole ena ea laser cutter e loketse ho seha lisebelisoa tse teteaneng (8 mm botenya) le likarolo tse bophara ho feta 100 mm.

Haholo-holo ke bakeng sa ho khaola ka har'a lisebelisoa tse teteaneng moo u ka ratang ho qoba ho khutlela morao laser.Li-bar tse otlolohileng li boetse li u lumella ho phalla hantle ka ho fetisisa ha u ntse u khaola.Lamellas e ka behoa ka bomong, ka lebaka leo, tafole ea laser e ka fetoloa ho latela kopo ea motho ka mong.

Likarolo tsa mantlha:

• Tlhophiso e bonolo, mefuta e mengata ea likopo, ts'ebetso e bonolo

• E loketse ho seha li-substrates tsa laser tse kang acrylic, lehong, polasetiki, le thepa e tiileng haholoanyane

Lipotso life kapa life mabapi le boholo ba bethe ea laser cutter, lisebelisoa tse tsamaellanang le litafole tsa laser le tse ling

Re mona bakeng sa hau!

Litafole tse ling tse ka sehloohong tsa Laser bakeng sa ho itšeha le ho ngola ka Laser

Letlapa la Vacuum ea Laser

Tafole ea laser cutter vacuum e lokisa lisebelisoa tse fapaneng tafoleng e sebetsang e sebelisa vacuum e bobebe.Sena se tiisa ho tsepamisa maikutlo ho nepahetseng holim'a bokaholimo bohle 'me ka lebaka leo liphetho tse betliloeng tse betere lia tiisetsoa.E kopantsoe le fene ea ho tima, moea o monyang o ka fefola masalla le sekhechana sa thepa e tsitsitseng.Ho phaella moo, e fokotsa boiteko ba ho tšoara bo amanang le ho kenngoa ha mechine.

Tafole ea vacuum ke tafole e nepahetseng bakeng sa lisebelisoa tse tšesaane le tse bobebe, joalo ka pampiri, lifoile, le lifilimi tseo ka kakaretso li sa beheng fatše.

Tafole ea Ferromagnetic

Mohaho oa ferromagnetic o lumella ho kenya lisebelisoa tse tšesaane joalo ka pampiri, lifilimi kapa foil tse nang le limatlase ho netefatsa sebaka se bataletseng le se bataletseng.Esita le ho sebetsa ho bohlokoa bakeng sa ho fumana liphetho tse nepahetseng bakeng sa ho betla ka laser le ho tšoaea lits'ebetso.

Acrylic Cutting Grid Table

Ho kenyeletsoa le tafole ea ho itšeha ea laser e nang le grid, grid e khethehileng ea laser engraver e thibela ho nahana ka morao.Ka hona e loketse ho seha li-acrylics, laminates, kapa lifilimi tsa polasetiki tse nang le likarolo tse nyane ho feta 100 mm, kaha tsena li lula sebakeng se bataletseng ka mor'a ho khaola.

Acrylic Slat Cutting Table

Tafole ea laser slats e nang le acrylic lamellas e thibela ho thuisa nakong ea ho itšeha.Tafole ena e sebelisoa ka ho khetheha bakeng sa ho seha lisebelisoa tse teteaneng (botenya ba 8 mm) le likarolo tse bophara ho feta 100 mm.Palo ea lintlha tse tšehetsang e ka fokotsoa ka ho tlosa tse ling tsa lamellas ka bomong, ho itšetlehile ka mosebetsi.

Tataiso ea Tlatsetso

MimoWork e fana ka tlhahiso ⇨

Ho hlokomela moea o boreleli le litšila tse khathatsang, tlase kapa lehlakorengexhaust blowerli kenngoa ho etsa hore khase, mosi le masala li fete tafoleng ea ho sebetsa, ho sireletsa thepa hore e senyehe.Bakeng sa mefuta e fapaneng ea mochini oa laser, ho hlophisoa le kopano bakeng satafole e sebetsang, sesebelisoa sa ventilationlemosi oa mosili fapane.Tlhahiso ea laser ea litsebi e tla u fa tiiso e ka tšeptjoang tlhahisong.MimoWork e teng ho emela potso ea hau!