60W CO2 Laser Engraver

Technical Data

60W CO2 Laser Engraver - Best laser engraving machine to get started

|

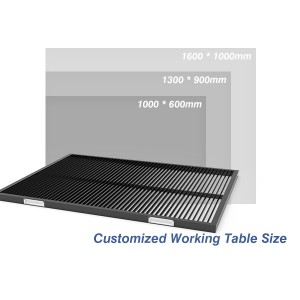

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

60W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

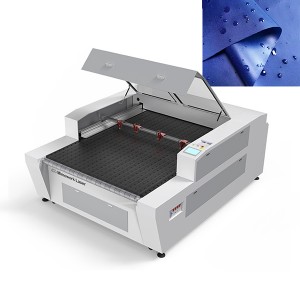

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

* Higher Power Output Laser Tube Upgrades Available

Upgrade options for you to choose

Rotary Device

Servo Motors

CCD Camera

Brushless DC Motors

Have specific needs for your machine?

Tell us your requirements

Video Display

▷ Laser Cutting & Engraving Paper

Ultra-fast engraving speed makes intricate patterns engraving come true in a short time. Laser engraving on paper can deliver brownish burning effects, which creates a retro feeling on the paper products like business cards. Besides paper crafts, laser engraving can be used in text and log marking and scoring to create brand value.

✔ High repetition due to digital control and auto-processing

✔ Flexible shape engraving in any directions

✔ Clean and intact surface with contactless processing

▷ Laser Engraving Characters on Wood

The 60W CO2 Laser Engraver can achieve wood laser engraving and cut in one pass. That is convenient and highly efficient for woodcraft making or industrial production. Hope the video can help you have a great understanding of wood laser engraver machines.

Simple workflow:

1. process the graphic and upload

2. put the wood board on the laser table

3. start the laser engraver

4. get the finished craft

Find more videos about our laser cutters at our Video Gallery