Iimfihlo zokuWelda ngeLaser: Lungisa iingxaki eziqhelekileyo ngoku!

Intshayelelo:

Isikhokelo esipheleleyo sokusombulula iingxaki

Oomatshini bokuWelda beLaser abaphathwa ngesandla

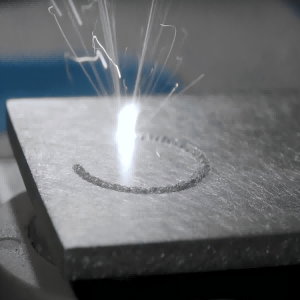

Umatshini wokuwelda we-fiber laser ophathwa ngesandla ufumene udumo olukhulu kumashishini ahlukeneyo ngenxa yokuchaneka kwawo nokusebenza kakuhle.

Nangona kunjalo, njengayo nayiphi na enye indlela yokuwelda, ayikhuselekanga kwimingeni kunye neengxaki ezinokuvela ngexesha lenkqubo yokuwelda.

Oku kupheleleyoukusombulula ingxaki yokuwelda nge-laserIjolise ekusombululeni iingxaki eziqhelekileyo ezidibana noomatshini bokuwelda nge-laser abaphathwa ngesandla, iingxaki ezinxulumene nokuwelda, kunye nemiba enxulumene nomgangatho wokuwelda.

Uluhlu Lomxholo:

Iimpazamo kunye nezisombululo zoMatshini wokuWelda weLaser ngaphambi kokuba uqalise

1. Izixhobo azikwazi ukuqala (Amandla)

Isisombululo: Jonga ukuba iswitshi yentambo yombane iyasebenza na.

2. Izibane azinakukhanya

Isisombululo: Jonga ibhodi engaphambi komlilo ine-voltage ye-220V okanye engenayo, jonga ibhodi yokukhanyisa; i-fuse ye-3A, isibane se-xenon.

3. Isibane Sikhanyisiwe, Akukho Laser

Isisombululo: Qaphela ukuba inxalenye yomatshini wokuwelda welaser ophathwa ngesandla kwisibonisi ngaphandle kokukhanya iqhelekile. Okokuqala, jonga ukuba inxalenye ye-CNC yeqhosha lelaser ivaliwe, ukuba ivaliwe, uze uvule iqhosha lelaser. Ukuba iqhosha lelaser liqhelekile, vula ujongano lolawulo lwamanani ukuze ubone ukuba useto lokukhanya okuqhubekayo, ukuba akunjalo, uze utshintshele ekukhanyeni okuqhubekayo.

Iingxaki kunye nokulungiswa kweWelder yeLaser Phase Welding Phase

Umthungo weWeld umnyama

Igesi ekhuselayo ayivulekanga, logama nje igesi yenitrogen ivuliwe, ingasombululwa.

Icala lokuhamba komoya legesi ekhuselayo alilunganga, icala lokuhamba komoya legesi ekhuselayo kufuneka lenziwe ngokuchaseneyo necala lokuhamba kwesixhobo somsebenzi.

Ukunqongophala kokungena kwiWelding

Ukungabikho kwamandla e-laser kunokuphucula ububanzi be-pulse kunye nomsinga.

Ilensi yokugxila ayilonani lifanelekileyo, ukuze ilungelelanise inani lokugxila kufutshane nendawo yokugxila.

Ukubuthathaka kweLaser Beam

Ukuba amanzi okupholisa angcolisiwe okanye akatshintshwanga ixesha elide, angasombululwa ngokutshintsha amanzi okupholisa kunye nokucoca ityhubhu yeglasi ye-UV kunye nesibane se-xenon.

Ilensi egxile okanye i-diaphragm ye-resonant cavity ye-laser yonakele okanye ingcolisiwe, kufuneka itshintshwe okanye icocwe ngexesha.

Hambisa i-laser kwindlela ephambili ye-optical, lungisa i-diaphragm ye-total reflection kunye ne-semi-reflection kwindlela ephambili ye-optical, jonga kwaye ujikeleze indawo ngephepha lomfanekiso.

I-laser ayiphumi kwi-nozzle yobhedu engaphantsi kwentloko egxile kuyo. Lungisa i-diaphragm ebonakalisayo engama-45-degree ukuze i-laser iphume embindini we-nozzle yegesi.

Ukusombulula iingxaki zoMgangatho wokuWelda ngeLaser

1. Ukutshiza

Emva kokuba kugqityiwe ukuwelda nge-laser, amasuntswana amaninzi esinyithi avela kumphezulu wento okanye umsebenzi, enamathele kumphezulu wento okanye umsebenzi.

Isizathu sokuchaphaza: umphezulu wezinto ezicutshungulweyo okanye umsebenzi awucocekanga, kukho ioyile okanye ungcoliseko, oku kunokubangelwa kukuguquguquka komaleko we-galvanized.

1) Nika ingqalelo ekucoceni izinto okanye umsebenzi ngaphambi kokuba welding nge-laser;

2) I-Spatter inxulumene ngokuthe ngqo noxinano lwamandla. Ukunciphisa ngokufanelekileyo amandla okuwelda kunokunciphisa i-spatter.

2. Iintanda

Ukuba isantya sokupholisa sesixhobo sokusebenza sikhawuleza kakhulu, ubushushu bamanzi okupholisa kufuneka bulungiswe kwisixhobo ukuze kwandiswe ubushushu bamanzi.

Xa umsantsa wokulingana kwesixhobo somsebenzi mkhulu kakhulu okanye kukho i-burr, ukuchaneka komatshini wesixhobo somsebenzi kufuneka kuphuculwe.

Isixhobo sokusebenza asicocwanga. Kwimeko enjalo, isixhobo sokusebenza kufuneka sicocwe kwakhona.

Izinga lokuhamba kwegesi ekhuselayo likhulu kakhulu, nto leyo enokulungiswa ngokunciphisa izinga lokuhamba kwegesi ekhuselayo.

3. Imbobo Kumphezulu Weld

Izizathu zokuveliswa kwe-porosity:

1) Ichibi elinyibilikisiweyo eliwelding nge-laser linzulu kwaye limxinwa, kwaye izinga lokuphola likhawuleza kakhulu. Igesi eveliswa kwichibi elinyibilikisiweyo isemva kwexesha ukuba ingaphuphuma, nto leyo enokukhokelela ngokulula ekwakhiweni kwe-porosity.

2) Umphezulu we-weld awucocwanga, okanye umphunga we-zinc wephepha le-galvanized uyaguquguquka.

Coca umphezulu wento yokusebenza kunye nomphezulu we-weld ngaphambi kokuwelda ukuze kuphuculwe ukuguquguquka kwe-zinc xa ishushu.

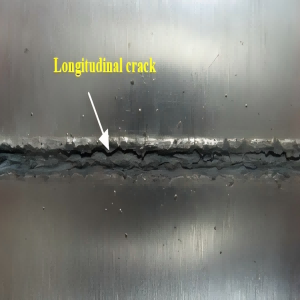

4. Ukuphambuka kokuWelding

Isinyithi esijijelweyo asiyi kuqina embindini wesakhiwo esidibeneyo.

Isizathu sokuphambuka: Ukubekwa ngendlela engachanekanga ngexesha lokuwelda, okanye ixesha lokuzalisa elingachanekanga kunye nokulungelelaniswa kweengcingo.

Isisombululo: Lungisa indawo yokuwelda, okanye ixesha lokugcwalisa kunye nendawo yentambo, kunye nendawo yesibane, ucingo kunye ne-weld.

5. Ukuvalelwa kweSlag kumphezulu, okubonakala kakhulu phakathi kweeLeya

Izizathu zokubamba i-slag kumphezulu:

1) Xa kudityaniswa ii-multi-layer multi-pass welding, i-coating phakathi kwee-layer ayicocekanga; okanye umphezulu we-weld yangaphambili awuthe tyaba okanye umphezulu we-weld awuhlangabezani neemfuno.

2) Iindlela ezingalunganga zokusebenza kwe-welding, ezifana namandla aphantsi okufaka i-welding, isantya se-welding sikhawuleza kakhulu.

Isisombululo: Khetha umsinga wokufaka welding ofanelekileyo kunye nesantya sokufaka welding, kwaye i-interlayer coating kufuneka icocwe xa kudityaniswa i-multi-layer multi-pass welding. Gaya uze ususe i-weld nge-slag phezu komphezulu, kwaye wenze i-weld ukuba kuyimfuneko.

Ezinye Izixhobo – I-Handheld Laser Welder Iingxaki Eziqhelekileyo Nezisombululo

1. Ukusilela kwesixhobo soKhuseleko

Izixhobo zokukhusela ukhuseleko zomatshini wokuwelda nge-laser, ezifana nocango lwegumbi lokuwelda, isenzi sokuhamba kwegesi, kunye nesenzi sobushushu, zibalulekile ekusebenzeni kakuhle. Ukusilela kwezi zixhobo akunakuphazamisa kuphela ukusebenza kwesixhobo okuqhelekileyo kodwa kukwabeka nomngcipheko wokwenzakala kumqhubi.

Ukuba izixhobo zokukhusela ukhuseleko azisebenzi kakuhle, kubalulekile ukuba kumiswe ukusebenza ngoko nangoko kwaye kuqhagamshelwane neengcali ukuze zilungiswe kwaye zitshintshwe.

2. Ukuxinana kwesixhobo sokuhambisa ucingo

Ukuba kukho i-wire feeder jam kule meko, into yokuqala ekufuneka siyenze kukujonga ukuba umlomo wesibhamu uvalekile na, inyathelo lesibini kukujonga ukuba i-wire feeder ivalekile na kwaye kukho ukujikeleza kwediski yesilika okuqhelekileyo.

Shwankathela

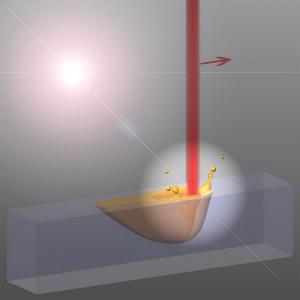

Ngobuchule obungenakuthelekiswa nanto, isantya kunye nokuguquguquka, ukuwelda nge-laser bubuchwepheshe obuxabisekileyo kumashishini afana neemoto, i-aerospace kunye ne-elektroniki.

Nangona kunjalo, iziphene ezahlukeneyo zinokwenzeka ngexesha lenkqubo yokuwelda, kubandakanya ukuqhekeka, ukuqhekeka, ukuqhekeka, ukurhawuzelelwa kwentsimbi, ukutsha, ukuguquka kwesakhiwo, kunye nokuxinana kwentsimbi.

Isiphene ngasinye sinesizathu esithile, njengoSeto lwelaser olungafanelekanga, ukungcola kwezinto, iigesi zokukhusela ezinganeleyo, okanye amalungu angalungelelananga kakuhle.

Ngokuqonda ezi ziphene kunye nezizathu zazo eziphambili, abavelisi banokusebenzisa izisombululo ezijolise kuzo, ezinje ngokuphucula iiparameter zelaser, ukuqinisekisa ukulingana kakuhle kwamalungu, ukusebenzisa iigesi zokukhusela ezisemgangathweni ophezulu, kunye nokusebenzisa unyango lwangaphambi nasemva kokuwelda.

Uqeqesho olufanelekileyo lwabaqhubi, ukugcinwa kwezixhobo zemihla ngemihla kunye nokubeka esweni inkqubo ngexesha langempela kuphucula umgangatho wokuwelda kwaye kunciphise iziphene.

Ngendlela ebanzi yokuthintela iziphene kunye nokwenza ngcono inkqubo, ukuwelda nge-laser kuhlala kubonelela ngee-welds eziqinileyo, ezithembekileyo nezisemgangathweni ophezulu ezihlangabezana nemigangatho engqongqo yoshishino.

Awazi ukuba loluphi uhlobo lomatshini wokuwelda nge-laser omawukhethe?

Kufuneka wazi: Indlela yokukhetha umatshini we-laser ophathwa ngesandla

Umthamo ophezulu kunye nombane osetyenziswa kwiindlela ezahlukeneyo zokuWelda

Umatshini wokuwelda we-laser ophathwa ngesandla we-2000W ubonakala ngobukhulu bomatshini obuncinci kodwa umgangatho wokuwelda oqaqambileyo.

Umthombo we-laser yefayibha ozinzileyo kunye nentambo yefayibha edibeneyo zibonelela ngokuhanjiswa komqadi we-laser okhuselekileyo nozinzileyo.

Ngamandla aphezulu, isitshixo se-laser welding sigqibelele kwaye sivumela ukuba i-welding joint iqine ngakumbi nakwintsimbi etyebileyo.

Ukuthwaleka ukuze kube lula ukuguquguquka

Njengoko ibukeka incinci kwaye incinci, umatshini wokuwelda welaser ophathwayo uxhotyiswe ngesibhamu sokuwelda selaser esiphathwayo esinokuhanjiswa esikhaphukhaphu kwaye silungele ukusetyenziswa kwe-multi-laser welding kuyo nayiphi na i-engile kunye nomphezulu.

Iindidi ezahlukeneyo zee-nozzles ze-laser welder kunye neenkqubo zokutyisa ngocingo oluzenzekelayo zenza kube lula ukusebenza kwe-laser welding kwaye oko kulungele abaqalayo.

Ukuwelda nge-laser ekhawulezayo kwandisa kakhulu ukusebenza kakuhle kwemveliso yakho kunye nemveliso ngelixa kuvumela isiphumo esihle kakhulu sokuwelda nge-laser.

Izinto ekufuneka uzazi malunga: Ukuwelda ngeLaser ephathwayo

Ukuba uyithandile le vidiyo, kutheni ungacingi ngayoubhalisela kwiChannel yethu yeYoutube?

Izicelo ezinxulumene noko onokuba nomdla kuzo:

Yonke into oyithengileyo kufuneka inolwazi oluhle

Singakunceda ngolwazi oluneenkcukacha kunye neengcebiso!

Ixesha leposi: Jan-16-2025