Umsiki we-Laser we-Acrylic (PMMA)

Uma ufuna ukusika amashidi e-acrylic (PMMA, Plexiglass, Lucite) ukuze wenze izimpawu ze-acrylic, imiklomelo, imihlobiso, ifenisha, ngisho namadeshibhodi ezimoto, imishini yokuzivikela, noma okunye? Yiliphi ithuluzi lokusika elingcono kakhulu?

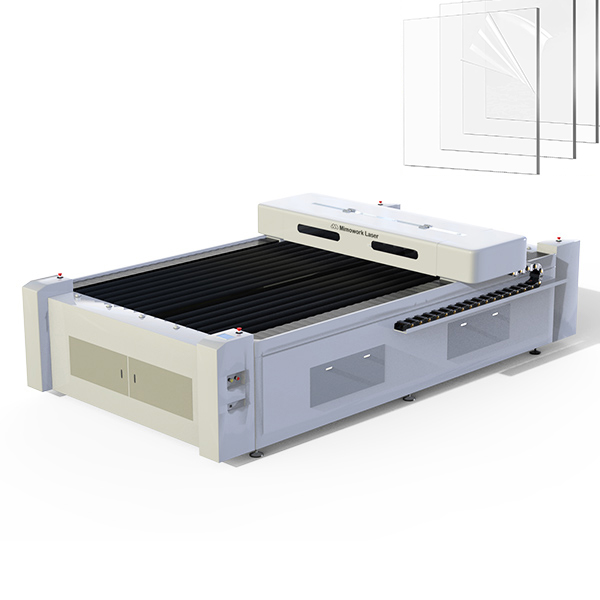

Sincoma umshini we-laser we-acrylic onezinga lezimboni kanye nezinga lokuzijabulisa.

Isivinini sokusika esisheshayo kanye nomphumela omuhle kakhulu wokusikaizinzuzo ezinhle kakhulu zemishini yokusika i-laser ye-acrylic ozoyithanda.

Ngaphandle kwalokho, umshini we-laser we-acrylic ubuye ube ngumqophi we-laser we-acrylic, ongakwaziqopha amaphethini nezithombe ezithambile nezinhle kakhulu kumashidi e-acrylicUngenza ibhizinisi lakho ngokwezifiso ngomshini omncane wokuqopha i-laser we-acrylic, noma wandise umkhiqizo wakho we-acrylic ngokutshala imali emshinini wokusika i-laser we-acrylic sheet omkhulu wezimboni, ongaphatha amashidi e-acrylic amakhulu futhi ajiyile ngesivinini esiphezulu, okuhle kakhulu ekukhiqizeni kwakho ngobuningi.

Yini ongayenza nge-laser cutter engcono kakhulu ye-acrylic? Qhubeka uhlole okwengeziwe!

Vula Amandla Aphelele E-Acrylic Laser Cutter

Ukuhlolwa Kwezinto Ezibalulekile: Ukusika Nge-Laser Okuyi-Acrylic Okujiyile okungu-21mm

Umphumela Wokuhlola:

I-Higher Power Laser Cutter ye-Acrylic inekhono elihle kakhulu lokusika!

Ingasika ishidi le-acrylic elingu-21mm ubukhulu, futhi idale umkhiqizo we-acrylic oqediwe wekhwalithi ephezulu onomphumela wokusika opholishwe ngelangabi.

Kumashidi e-acrylic amancane angaphansi kuka-21mm, umshini wokusika nge-laser nawo uyawaphatha kalula!

| Indawo Yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Isofthiwe | Isofthiwe ye-MimoCUT |

| Amandla e-Laser | 100W/150W/300W/450W |

| Umthombo We-Laser | Ishubhu ye-CO2 Glass Laser noma i-CO2 RF Metal Laser Tube |

| Uhlelo Lokulawula Okwenziwa Ngemishini | Ukulawula Ibhande Lemoto Yesinyathelo |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Honey Comb noma Ithebula Lokusebenza Le-Knife Strip |

| Isivinini Esiphezulu | 1 ~ 400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinzuzo Zokusika Nokuqopha Nge-Acrylic Laser

Umphetho opholishiwe nocwebezelayo

Ukusika okuguquguqukayo kwesimo

Ukuqoshwa kwephethini eyinkimbinkimbi

✔Imiphetho yokusika ehlanzekile epholishiwe kahle ngesikhathi esisodwa

✔Asikho isidingo sokubopha noma ukulungisa i-acrylic ngenxa yokucubungula okungenakuthinta

✔Ukucubungula okuguquguqukayo kwanoma yisiphi isimo noma iphethini

✔Akukho ukungcola njengoba kwenzeka ngokugaya okusekelwa yi-fume extractor

✔Ukusika iphethini okunembile ngezinhlelo zokuqashelwa kokukhanya

✔Ukuthuthukisa ukusebenza kahle kusukela ekudleni, ukusika kuya ekwamukeleni ngetafula lokusebenza le-shuttle

Imishini Yokusika I-Laser Edumile Ye-Acrylic

• Amandla e-Laser: 100W/150W/300W

• Indawo Yokusebenza: 1300mm * 900mm (51.2” * 35.4”)

• Amandla e-Laser: 150W/300W/450W

• Indawo Yokusebenza: 1300mm * 2500mm (51” * 98.4”)

Unentshisekelo ku-

UMSHINI WOKUSIKELA I-ACRYLIC LASER

Inani Elingeziwe Elivela Kuzinketho Ze-MimoWork Laser

✦Ikhamera ye-CCDinikeza umshini umsebenzi wokuqaphela wokusika i-acrylic ephrintiwe eceleni kwe-contour.

✦Ukucubungula okusheshayo nokuzinzile kungenziwa ngeimoto ye-servo kanye nemoto engenamabhulashi.

✦Ukuphakama kokugxila okungcono kakhulu kungatholakala ngokuzenzakalelayo ngeukugxila okuzenzakalelayolapho usika izinto ezijiyile ngendlela ehlukile, asikho isidingo sokulungiswa ngesandla.

✦Isikhiphi Sokuthuthumelakungasiza ekususeni amagesi ahlala isikhathi eside, iphunga elibi elingase livele lapho i-laser ye-CO2 icubungula izinto ezithile ezikhethekile, kanye nezinsalela eziphuma emoyeni.

✦I-MimoWork inezinhlobo ezahlukeneAmathebula Okusika Nge-Laserngezinto ezahlukene kanye nezinhlelo zokusebenza.umbhede wokusika we-laser wezinyosiifanele ukusika nokuqopha izinto ezincane ze-acrylic, kanyeitafula lokusika imichilo yommesekungcono ukusika i-acrylic ejiyile.

I-acrylic ephrintiwe nge-UV enombala ocebile kanye nephethini iye yathandwa kakhulu.Ungayisika kanjani i-acrylic ephrintiwe ngokunembe kangaka nangokushesha kangaka? I-CCD Laser Cutter iyisinqumo esifanele.

Ifakwe ikhamera ye-CCD ehlakaniphile futhiIsofthiwe Yokuqashelwa Kokubona, engakwazi ukubona nokubeka amaphethini, futhi iqondise ikhanda le-laser ukuze lisike ngokunembile eceleni komugqa.

Amaketanga okhiye e-Acrylic, amabhodi okukhangisa, imihlobiso, kanye nezipho ezingasoze zalibaleka ezenziwe nge-acrylic ephrintiwe ngezithombe, kulula ukuqedela ngomshini wokusika we-laser we-acrylic ophrintiwe.

Ungasebenzisa i-laser ukusika i-acrylic ephrintiwe yomklamo wakho owenziwe ngokwezifiso kanye nokukhiqizwa ngobuningi, okuyinto elula futhi esebenza kahle kakhulu.

Indlela yokusika izinto eziphrintiwe ngokuzenzakalelayo | I-Acrylic kanye Nokhuni

Izicelo Zokusika Nokuqopha Nge-Acrylic Laser

• Izibonisi Zezikhangiso

• Ukwakhiwa Kwemodeli Yezakhiwo

• Ukulebula Kwenkampani

• Izindebe Ezithambile

• I-Acrylic Ephrintiwe

• Ifenisha Yesimanje

• Amabhodi Okukhangisa Angaphandle

• Indawo Yomkhiqizo

• Izimpawu Zomthengisi

• Ukususwa kwe-Sprue

• Ibhulakhethi

• Ukulungisa izinto ezitolo

• Indawo Yokumisa Izimonyo

Ukusebenzisa i-Acrylic Laser Cutter

Senze Izimpawu Nokuhlobisa Okuthile Kwe-Acrylic

Indlela Yokusika Ikhekhe Nge-Laser

Indlela yokusika imihlobiso ye-acrylic nge-laser (i-snowflake)

Ibhizinisi Lokusika Nokuqopha Nge-Laser Acrylic

Yimuphi Umsebenzi We-Acrylic Osebenza Nawo?

Amathiphu Okwabelana: Ukuze Ukwazi Ukusika I-Laser Ephelele ye-Acrylic

◆Phakamisa ipuleti le-acrylic ukuze lingathinti itafula lokusebenza ngenkathi usika

◆ Ishidi le-acrylic elihlanzekile kakhulu lingafeza umphumela omuhle wokusika.

◆ Khetha umsiki we-laser onamandla afanele emiphethweni epholishwe ngomlilo.

◆Ukufutha kufanele kube kuncane ngangokunokwenzeka ukuze kugwenywe ukusabalala kokushisa okungaholela nasekushiseni.

◆Gqopha ibhodi le-acrylic ngemuva ukuze udale umphumela wokubuka phambili.

Ividiyo Yokufundisa: Ungasika Kanjani Futhi Uqophe I-Acrylic Nge-Laser?

Imibuzo Evame Ukubuzwa mayelana ne-Laser Cutting Acrylic (PMMA, Plexiglass, Lucite)

1. Ungakwazi yini ukusika i-acrylic nge-laser cutter?

Ishidi le-acrylic lokusika nge-laser liyindlela evamile nethandwayo ekukhiqizweni kwe-acrylic. Kodwa ngezinhlobo ezahlukene zamashidi e-acrylic njenge-acrylic extruded, i-acrylic ehlanganisiwe, i-acrylic ephrintiwe, i-acrylic ecacile, i-acrylic yesibuko, njll., udinga ukukhetha umshini we-laser ofanele izinhlobo eziningi ze-acrylic.

Sincoma i-CO2 Laser, ewumthombo we-laser ohambisana ne-acrylic, futhi ikhiqiza umphumela omuhle wokusika kanye nomphumela wokuqopha ngisho noma i-acrylic ecacile.Siyazi ukuthi i-diode laser iyakwazi ukusika i-acrylic encane kodwa kuphela nge-acrylic emnyama nemnyama. Ngakho-ke i-CO2 Laser cutter iyindlela engcono yokusika nokuqopha i-acrylic.

2. Ungasika kanjani i-acrylic nge-laser?

Ukusika i-acrylic nge-laser kuyinqubo elula nezenzakalelayo. Ngezinyathelo ezintathu kuphela, uzothola umkhiqizo omuhle kakhulu we-acrylic.

Isinyathelo 1. Beka ishidi le-acrylic etafuleni lokusika nge-laser.

Isinyathelo sesi-2. Setha amandla nesivinini se-laser kusofthiwe ye-laser.

Isinyathelo sesi-3. Qala ukusika nokuqopha nge-laser.

Mayelana nomhlahlandlela wokusebenza onemininingwane, uchwepheshe wethu we-laser uzokunikeza isifundo sobungcweti nesiphelele ngemuva kokuthenga umshini we-laser. Ngakho-ke noma yimiphi imibuzo, zizwe ukhululekile ukukhuluma nochwepheshe wethu we-laser.

@ Email: info@mimowork.com

☏ I-WhatsApp: +86 173 0175 0898

3. Ukusika Nokuqopha i-Acrylic: I-CNC Vs. I-Laser?

Ama-router e-CNC asebenzisa ithuluzi lokusika elijikelezayo ukuze asuse izinto ezibonakalayo, ezifanele i-acrylic ejiyile (kufika ku-50mm) kodwa ngokuvamile zidinga ukupholishwa.

Abasiki be-laser basebenzisa umsebe we-laser ukuncibilikisa noma ukufutha impahla, okunikeza ukunemba okuphezulu kanye nemiphetho ehlanzekile ngaphandle kwesidingo sokupholisha, okungcono kakhulu kuma-acrylic amancane (kufika ku-20-25mm).

Mayelana nomphumela wokusika, ngenxa yogongolo oluhle lwe-laser lomsiki we-laser, ukusika kwe-acrylic kunembile futhi kuhlanzekile kunokusika kwe-cnc router.

Ukuze kusheshiswe ukusika, i-CNC router ishesha kakhulu kune-laser cutter ekusikeni i-acrylic. Kodwa uma kuqoshwa i-acrylic, i-laser ingcono kune-CNC router.

Ngakho-ke uma unesithakazelo kulesi sihloko, futhi udidekile ngokuthi ungakhetha kanjani phakathi kwe-cnc kanye ne-laser cutter, hlola ividiyo noma ikhasi ukuze ufunde kabanzi:I-CNC VS Laser yokusika nokuqopha i-acrylic

4. Ungayikhetha kanjani i-acrylic efanelekile yokusika nokuqopha nge-laser?

I-acrylic iza ngezinhlobo ezahlukene. Ingahlangabezana nezidingo ezahlukahlukene ngomehluko ekusebenzeni, imibala, kanye nemiphumela yobuhle.

Nakuba abantu abaningi bazi ukuthi amashidi e-acrylic ahlanganisiwe nakhishwe ngaphandle afanele ukucutshungulwa nge-laser, bambalwa abajwayelene nezindlela zabo ezihlukile zokusebenzisa i-laser.

Amashidi e-acrylic ahlanganisiwe abonisa imiphumela yokuqopha engcono kakhulu uma kuqhathaniswa namashidi akhishwe, okwenza afaneleke kakhulu ekusetshenzisweni kokuqopha nge-laser. Ngakolunye uhlangothi, amashidi akhishwe asebenza kahle kakhulu futhi afaneleka kangcono ngezinjongo zokusika nge-laser.

5. Ungakwazi yini ukusika izimpawu ze-acrylic ezinkulu nge-laser?

Yebo, ungasika izimpawu ze-acrylic ezinkulu kakhulu usebenzisa i-laser cutter, kodwa kuya ngosayizi wombhede womshini. Izicucu zethu ezincane ze-laser zinezici zokudlula, ezikuvumela ukuthi usebenze ngezinto ezinkulu ezingaphezu kosayizi wombhede.

Futhi ngamashidi e-acrylic abanzi nande, sinomshini wokusika we-laser omkhulu onefomethi enkulu onendawo yokusebenza engu-1300mm * 2500mm, okulula ukuyiphatha ngezimpawu ezinkulu ze-acrylic.

Unemibuzo mayelana nokusika nge-laser kanye nokuqoshwa nge-laser ku-acrylic?

Sazise futhi sikunikeze izeluleko ezengeziwe kanye nezixazululo!

Ngokuthuthuka kobuchwepheshe kanye nokuthuthukiswa kwamandla e-laser, ubuchwepheshe be-laser ye-CO2 buya ngokuya buqina ekusetshenzisweni kwe-acrylic.

Kungakhathaliseki ukuthi ingilazi ye-acrylic eyenziwe ngensimbi (GS) noma ekhishwe (XT),I-laser iyithuluzi elifanele lokusika nokuqopha i-acrylic (plexiglass) ngezindleko zokucubungula eziphansi kakhulu uma kuqhathaniswa nemishini yokugaya yendabuko.

Iyakwazi ukucubungula ukujula okuhlukahlukene kwezinto ezibonakalayo,Izisiki Ze-Laser ze-MimoWorkngomklamo wokucushwa okwenziwe ngokwezifiso kanye namandla afanele kungahlangabezana nezidingo ezahlukene zokucubungula, okuholela ekusebenzeni okufanelekile kwe-acrylic ngeimiphetho esikiwe ecacile, ebusheleleziekusebenzeni okukodwa, asikho isidingo sokwengezwa kokupholisha ilangabi.

Ukusika nge-Laser okuchwepheshile nokufanelekayo ku-Acrylic

Umshini we-acrylic laser ungasika amashidi e-acrylic amancane namakhulu ngomphetho osezingeni ohlanzekile nocwebezelayo bese uqopha amaphethini nezithombe ezinhle kakhulu nezinemininingwane kumaphaneli e-acrylic.

Ngesivinini sokucubungula esiphezulu kanye nohlelo lokulawula lwedijithali, umshini wokusika we-laser we-CO2 we-acrylic ungafeza ukukhiqizwa okukhulu ngekhwalithi ephelele.

Uma unebhizinisi elincane noma elenzelwe wena imikhiqizo ye-acrylic, umqophi omncane we-laser we-acrylic uyisinqumo esifanele. Kulula ukuyisebenzisa futhi ingabizi kakhulu!