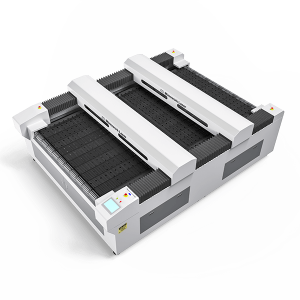

Laser Cutter for Foam Board

Sinomunye wamadivayisi okukhiqiza athuthuke kakhulu, onjiniyela abanolwazi nabaqeqeshiwe kanye nabasebenzi, izinhlelo zokubamba zekhwalithi enhle kanye neqembu elinobungane elinesipiliyoni sokuthola imali yokwesekwa kwangaphambili/ngemuva kokuthengisa le-Laser Cutter for Foam Board, Izisebenzi zenhlangano yethu kanye ukusetshenziswa kobuchwepheshe besimanje kulethwa okuthengiswayo kwekhwalithi ephezulu okukhonzwe kakhulu futhi kwaziswa abathengi bethu emhlabeni wonke.

Sinomunye wamadivayisi okukhiqiza athuthuke kakhulu, onjiniyela abanolwazi nabaqeqeshiwe kanye nabasebenzi, izinhlelo zokubamba zekhwalithi enhle kanye neqembu elinobungane elinolwazi lokusekela imali ngaphambi/ngemuva kokuthengisaumsiki wegwebu ngokwezifiso, igwebu elinqunyiwe le-laser, i-foam yokusika i-laser, I-Foam Laser Cutter, umshini wokusika we-laser foam, isevisi yokusika i-laser foam, I-Laser Cut Foam, i-laser cut foam ukufaka, i-laser cut polyurethane foam, ibhodi legwebu le-laser cutter, umsiki we-laser webhodi legwebu, Igwebu lokusika i-laser, umshini wokusika i-laser foam, ukusika i-laser foam, ukusika i-polyurethane foam laser, sithemba ngobuqotho ukusungula ubudlelwano bebhizinisi obuhle nobesikhathi eside nenkampani yakho oyihloniphayo ngaleli thuba, elisekelwe ekulinganeni, ekuzuzeni inzuzo kanye nokuwina ibhizinisi kusukela manje kuya esikhathini esizayo."Ukwaneliseka kwakho kuyinjabulo yethu".

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Ukusebenza okuningi emshinini owodwa

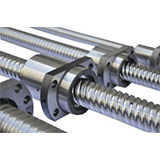

Ibhola & Isikulufa

Isikulufu sebhola i-actuator yomugqa ongumshini ehumusha ukunyakaza okuzungezayo kuya ekunyakazeni komugqa okunokungqubuzana okuncane.I-shaft enentambo ihlinzeka ngomzila we-helical wamabhering amabhola osebenza njengesikulufu esinembayo.Kanye nokukwazi ukufaka noma ukumelana nemithwalo ye-thrust ephezulu, bangenza kanjalo ngokungqubuzana okuncane kwangaphakathi.Zenziwa ukuvala ukubekezelelana ngakho-ke zifanele ukusetshenziswa ezimweni lapho ukunemba okuphezulu kuyadingeka.Ukuhlanganiswa kwebhola kusebenza njengenadi kuyilapho i-shaft enentambo iyisikulufu.Ngokuphambene nezikulufu zokuhola ezivamile, izikulufu zebhola zivamise ukuba nkulu, ngenxa yesidingo sokuba nendlela yokuzungeza kabusha amabhola.Isikulufu sebhola siqinisekisa isivinini esikhulu kanye nokusikwa kwe-laser ngokunemba okuphezulu.

I-Servo Motors

I-servomotor iyi-servomotor evaliwe esebenzisa impendulo yendawo ukuze ilawule ukunyakaza kwayo kanye nendawo yokugcina.Okokufaka ekulawuleni kwayo isignali (kungaba i-analog noma idijithali) emele indawo eyalwe kushafti okukhiphayo.Injini ibhangqwe nohlobo oluthile lwesifaki khodi ukuze inikeze impendulo yesikhundla nesivinini.Esimweni esilula, kulinganiswa isikhundla kuphela.Indawo elinganisiwe yokuphumayo iqhathaniswa nendawo yomyalo, okokufaka kwangaphandle kusilawuli.Uma indawo yokuphumayo ihluka kulokho okudingekayo, kukhiqizwa isignali yephutha ebangela ukuthi injini ijikeleze kunoma iyiphi indlela, njengoba kudingekile ukuletha shaft yokukhipha endaweni efanele.Njengoba izikhundla zisondela, isignali yephutha iyancipha ibe yiziro, futhi injini iyama.Ama-Servo motors aqinisekisa isivinini esiphezulu nokunemba okuphezulu kokusika nokuqoshwa kwe-laser.

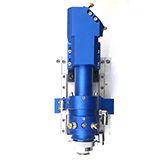

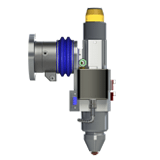

I-Mix Laser Head

Ikhanda le-laser elixubile, elaziwa nangokuthi i-metal non-metallic laser cutting head, liyingxenye ebaluleke kakhulu yomshini wokusika we-laser wensimbi ne-non-metal.Ngaleli khanda le-laser elichwepheshile, ungakwazi ukusika kokubili izinto zensimbi nezingezona ezensimbi.Kukhona ingxenye ye-Z-Axis yokudlulisa yekhanda le-laser ehamba phezulu naphansi ukuze ilandelele indawo okugxilwe kuyo.Isakhiwo sayo sekhabethe eliphindwe kabili sikwenza ukwazi ukubeka amalensi okugxila amabili ahlukene ukuze usike izinto zogqinsi oluhlukene ngaphandle kokulungiswa kwebanga lokugxila noma ukuqondanisa kwe-beam.Ikhulisa ukuguquguquka kokusika futhi yenza ukusebenza kube lula kakhulu.Ungasebenzisa igesi yokusiza ehlukene emisebenzini ehlukene yokusika.

I-Auto Focus

Ngokuyinhloko isetshenziselwa ukusika insimbi.Kungase kudingeke ukuthi usethe ibanga elithile lokugxila kusofthiwe lapho izinto zokusika zingekho flat noma ezinobukhulu obuhlukile.Khona-ke inhloko ye-laser izokwehla naphezulu ngokuzenzakalelayo, igcine ubude obufanayo & nebanga lokugxila ukuze lifane nalokho okusetha ngaphakathi kwesofthiwe ukuze uzuze ikhwalithi yokusika ephezulu ngokungaguquki.

Ividiyo ye-Laser Cutting Acylic (PMMA)

Ividiyo ye-Laser Engraving Wood Board

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Izinkambu Zokusebenza

I-Laser Cutting Yemboni Yakho

Ukuphrinta Kwedijithali

I-edge ehlanzekile futhi ebushelelezi ngokwelashwa okushisayo

Ukukhangisa Nezipho

Izinzuzo eziyingqayizivele zezimpawu zokusika ze-laser nemihlobiso

Izinto ezivamile kanye nezicelo

ye-Flatbed Laser Cutter 130

Buka izinto zokusebenza ezengeziwe

Senze amasistimu e-laser enqwaba yamakhasimende

Zingeze ohlwini!

I-Laser Cutting Foam

Isixazululo esisebenzayo nesifanelekayo sokusika i-Laser se-Foam

Ukusetshenziswa kwezimboni kwegwebu kubuyekezwa njalo.Imakethe yegwebu yanamuhla yakhiwe ngezinto eziningi ezahlukahlukene ezisetshenziswa ezinhlobonhlobo zezicelo.Ukuze kucutshungulwe amagwebu, imboni iya ngokuya ithola ukuthi i-laser cutter ifaneleka kakhulu ukusika nokuqopha amagwebu enziwe nge-polyester (PES), i-polyethylene (PE) noma i-polyurethane (PUR).Kwezinye izinhlelo zokusebenza, ama-laser anganikeza enye indlela emangazayo ezindleleni zokucubungula zendabuko.Ngaphezu kwalokho, igwebu elicutshungulwe nge-laser libuye lisetshenziswe ezinhlelweni zobuciko, njengezikhumbuzo noma ozimele bezithombe.

Izinzuzo ze-Laser Cutting on Foam

Unqenqema oluhlanzekile noluhlanzekile

Ukusika okuhle nokunembayo

Ukusika okuguquguqukayo kokwakheka okuningi

Lapho usika igwebu lezimboni, izinzuzo ze-laser cutter ngaphezu kwamanye amathuluzi wokusika ziyabonakala.Nakuba umsiki wendabuko enza ingcindezi eqinile kugwebu, okuholela ekuwohlokeni kwempahla kanye nemiphetho yokusika engahlanzekile, i-laser ingakha amakhonco amahle kakhulu ngenxa yokusikwa okunembayo nokungathinteki.

Uma usebenzisa ukusika ijethi yamanzi, amanzi azomuncwa kugwebu elimuncayo phakathi nenqubo yokuhlukanisa.Ngaphambi kokuqhubeka nokucutshungulwa, impahla kumele yomiswe, okuyinqubo edla isikhathi.Ukusika i-laser kushiya le nqubo futhi ungaqhubeka nokucubungula izinto ngokushesha.Ngokuphambene, i-laser iyakholisa kakhulu futhi ngokusobala iyithuluzi lokuqala lokucubungula igwebu.

Ukucubungula i-Laser ye-Foam

1. I-Laser Cutting on Foam

Ikhanda le-laser eliguquguqukayo elinogongolo olucolisekile lwe-laser ukuncibilikisa igwebu ngokuphazima kweso ukuze kunqandwe igwebu ukuze kufinyelelwe emaphethelweni okuvala.

2. I-Laser Engraving ku-Foam

I-laser ugongolo oluhle lunamathisela ubuso begwebu ngokulinganayo ukuze kuzuzwe umphumela oqoshwe kahle.

Izicelo ezijwayelekile ze-Laser Cutting Foam

• I-gasket yegwebu

• Iphedi legwebu

• Isigcwalisi sezihlalo zemoto

• I-foam liner

• Umcamelo wezihlalo