Inayiloni Indwangu Laser Umsiki

Ukudala inzuzo ethe xaxa kubathengi ifilosofi yenkampani yethu;ukukhula kwamakhasimende kuwukujaha kwethu iNylon Fabric Laser Cutter, Izinto zethu ezithengiswayo zingamathemba amasha namadala okuqashelwa okuhambisanayo nokwethenjwa.Samukela amathemba amasha namadala okusibizela ubudlelwano benkampani besikhathi eside, inqubekelaphambili efanayo.Ake sigijime ngesivinini ngenkathi kumnyama!

Ukudala inzuzo ethe xaxa kubathengi ifilosofi yenkampani yethu;ukukhula kwamakhasimende kuwujaha lwethu lokusebenzaI-Co2 laser stippling, indlela yokusika inayiloni, indlela yokuqopha i-polymer nge-laser, laser ukusika inayiloni ishidi, Inayiloni yokusika i-laser, Laser ukusika pa, umsiki wenayiloni, Umshini wokusika inayiloni, ukusika inayiloni, Umshini wokusika inayiloni, ukusika inayiloni laser, ishidi lenayiloni lisikwe ngosayizi, Sihlinzeka ngezinto zekhwalithi kuphela futhi sikholelwa ukuthi lena ukuphela kwendlela yokugcina ibhizinisi liqhubeka.Singahlinzeka ngensizakalo yangokwezifiso efana ne-Logo, usayizi wangokwezifiso, noma izimpahla zangokwezifiso njll ezingavumelana nemfuneko yekhasimende.

Izinzuzo Industrial Laser Cutter for Indwangu

Ukugxuma Okukhulu Ekukhiqizeni

Idatha Yezobuchwepheshe

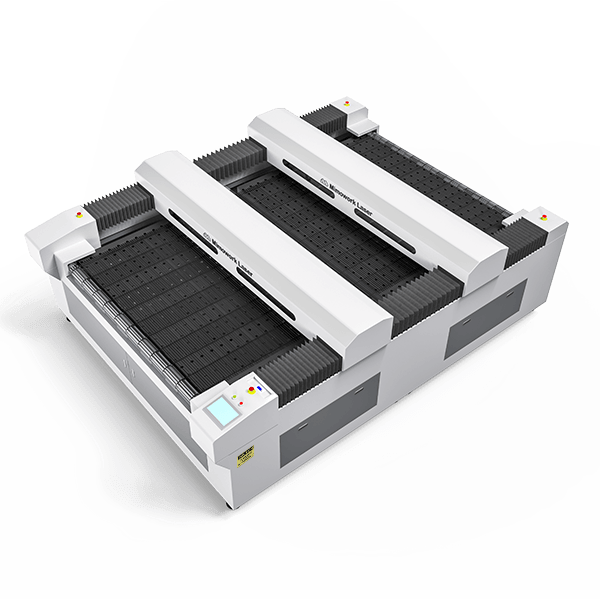

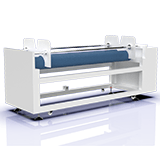

| Indawo yokusebenza (W * L) | 1600mm * 3000mm (62.9'' *118'') |

| Max Ububanzi Bezinto | 1600mm (62.9'') |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 150W/300W/500W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | I-Rack & Pinion Transmission kanye ne-Servo Motor Driven |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Conveyor |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~6000mm/s2 |

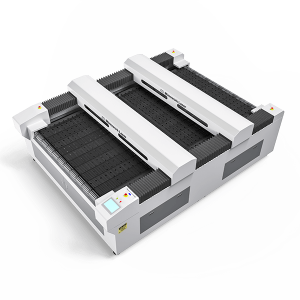

* Ama-laser gantries amabili azimele ayatholakala ukuze aphinde kabili ukusebenza kahle kwakho.

(Thuthukisa Amandla omshini wakho wokusika we-laser wezimboni, umshini wokusika we-laser wengubo)

I-R&D yokusika i-Fabric Laser

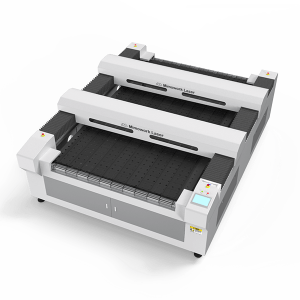

I-Auto feeder

I-Auto feederiyunithi yokudla egijima ngokuhambisana nomshini wokusika we-laser.I-feeder izodlulisela izinto zokugoqa etafuleni lokusika ngemva kokubeka ama-rolls ku-feeder.Isivinini sokudla singasethwa ngokuya ngesivinini sakho sokusika.Inzwa ihlonyiselwe ukuqinisekisa ukuma kahle kwempahla kanye nokunciphisa amaphutha.I-feeder iyakwazi ukunamathisela amadayamitha e-shaft ahlukene emiqulu.Irola ye-pneumatic ingakwazi ukuzivumelanisa nezindwangu ngokushuba okuhlukahlukene nokuqina.Le yunithi ikusiza ukuthi ubone inqubo yokusika ezenzakalelayo ngokuphelele.

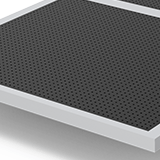

I-Vacuum Suction

II-Vacuum Suctionilele ngaphansi kwetafula lokusika.Ngezimbobo ezincane nezijulile endaweni yetafula lokusika, umoya 'ubopha' izinto ezisetafuleni.Ithebula le-vacuum alingeni endleleni ye-laser beam ngenkathi isika.Ngokuphambene nalokho, kanye nefeni enamandla yokukhipha umoya, ithuthukisa umphumela wokuvimbela intuthu nothuli ngesikhathi sokusika.

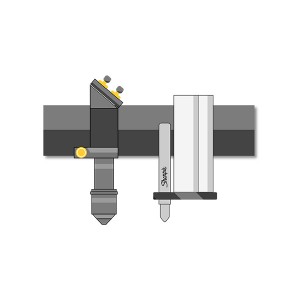

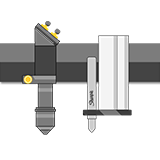

Ipeni Lomaka - Inketho

Kubakhiqizi abaningi, ikakhulukazi ukucubungula izindwangu zobuchwepheshe, izingcezu zidinga ukuthungwa ngemva kwenqubo yokusika.Siyabonga kuIpeni Lokumaka, ungenza amamaki afana nenombolo yesiriyali yomkhiqizo, usayizi womkhiqizo, idethi yokwenziwa komkhiqizo, njll ukuze kwandiswe ukusebenza kahle kukonke.Ungakhetha imibala ehlukene ngokwezidingo zakho.

Umthombo we-CO2 RF Laser - Inketho

Ihlanganisa amandla, ikhwalithi ye-beam enhle kakhulu, kanye nama-pulses amagagasi acishe abe isikwele (9.2 / 10.4 / 10.6μm) ngokusebenza kahle okuphezulu kanye nesivinini.Ngendawo encane ethinteke ekushiseni, kanye nokwakhiwa okuhlangene, okuvalwe ngokugcwele, kokukhipha ama-slab ukuze kube nokuthembeka okuthuthukisiwe.Kwezinye izindwangu ezikhethekile zezimboni, i-RF Metal Laser Tube izoba inketho engcono.

Ukuboniswa kwevidiyo kwe-Laser Cutting Cordura® Vest

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Izinkambu Zokusebenza

Laser Cutting Non-Metal Izicelo

Izingubo Nezindwangu Zasekhaya

I-edge ehlanzekile futhi ebushelelezi ngokwelashwa okushisayo

Imboni yokuhlunga

Imfihlo yokusika iphethini enhle

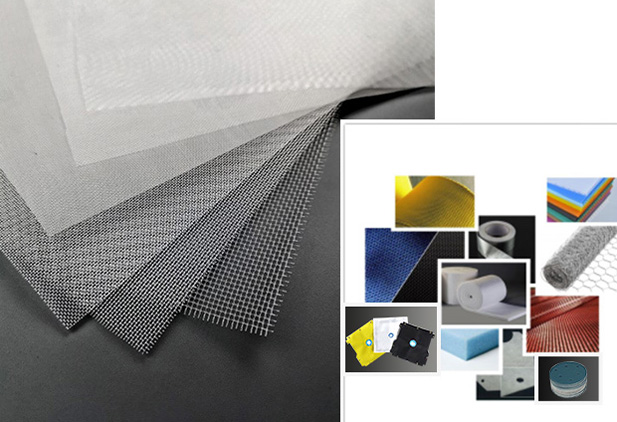

Ukukhethwa kwesihlungi semidiya esifanele kunquma ikhwalithi nomnotho wayo yonke inqubo yokuhlunga, okuhlanganisa ukuhlukaniswa koketshezi oluqinile kanye nokuhlunga komoya.I-Laser ibhekwa njengobuchwepheshe obungcono kakhulu bokusika imidiya yokuhlunga (Hlunga Indwangu,Igwebu Lokuhlunga,Uboya, Isikhwama Sokuhlunga, I-Filter Mesh, nezinye izinhlelo zokusebenza zokuhlunga)

Izinto Ezihlanganisiwe

High Power Laser Cutting

Ukusika i-laser kungaletha ukunemba okuphezulu nemiphumela yekhwalithi engaguquki ngogongolo oluhle lwe-laser.Ukucutshungulwa kwemvelo okushisayo kuqinisekisa imiphetho evaliwe futhi ebushelelezi ngaphandle kokuphazamiseka nokuphukaizinto ezihlanganisiwe.

I-Outdoor Upholstery & Gear

Indwangu engenamthungo ye-laser yokusika i-laminated

Izidingo zokusebenza ziphakeme kakhulu ngendwangu yangaphandle.Ukuvikela ilanga, ukuphefumula, ukungangeni kwamanzi, ukumelana nokugqoka, yonke le misebenzi ivamise ukudinga izendlalelo eziningi zezinto.I-laser cutter yethu yezimboni iyithuluzi elifaneleka kakhulu lokusika izindwangu ezinjalo.

Izinto ezivamile kanye nezicelo

ye-Flatbed Laser Cutter 160L

Buka izinto zokusebenza ezengeziwe

Umsiki we-laser wezohwebo, umshini wokusika izindwangu zezimboni uyathengiswa

Zingeze ohlwini!

Ukudala inzuzo ethe xaxa kubathengi ifilosofi yenkampani yethu;ukukhula kwamakhasimende wukujaha kwethu okusebenzayo komshini wokusika welebula wokufa wase-China othengiswayo oshisayo wase-China, okuthengiswayo kwethu kungamathemba amasha namadala okuqashelwa okufanayo nokwethenjwa.Samukela amathemba amasha namadala okusibizela ubudlelwano benkampani besikhathi eside, inqubekelaphambili efanayo.Ake sigijime ngesivinini ngenkathi kumnyama!

Inayiloni Laser Cutting

Isixazululo esiqeqeshiwe nesifanelekayo sokusika iLaser seNyiloni

inayiloni-04

Amapharashuthi, izingubo ezisebenzayo, ivesti ye-ballistic, izingubo zamasosha, imikhiqizo ejwayelekile eyenziwe inayiloni konke kungasikwa nge-laser ngendlela yokusika eguquguqukayo nenembile.Ukusikwa ongathintwanga inayiloni kugwema ukuhlanekezela kanye nokulimala.Ukwelashwa okushisayo namandla e-laser anembile kuletha imiphumela yokuzisika ezinikele yokusika ishidi lenayiloni, iqinisekisa ukuthi ihlanzekile, iqeda inkinga yokucubungula i-burr yesibili.Izinhlelo ze-laser ze-MimoWork zinikeza amakhasimende izixazululo ezifanele ze-laser ezenziwe ngezifiso ngezidingo ezahlukene (izinhlobonhlobo ezihlukahlukene zenayiloni, osayizi abahlukene, nobujamo).

Ungayisika kanjani inayiloni ngomshini wokusika i-Fabric Laser?

Umthombo we-laser we-CO2 onobude beza beza be-micron obungu-9.3 no-10.6 uthambekele ekumuncweni ngokwengxenye izinto zenayiloni ukuze uncibilike okokusebenza ngokuguqulwa kwe-photothermal.Ukwengeza, izindlela eziguquguqukayo nezihlukahlukene zokucubungula zingakha amathuba amaningi ezindatshana zenayiloni, okuhlanganisa ukusika kwe-laser nokuqoshwa kwe-laser.Isici sokucubungula esingokwemvelo sohlelo lwe-laser bekungavimbi ijubane lokusungula izinto ezintsha ezifunwa ngamakhasimende.

Ukucutshungulwa kwe-Laser yeNayiloni

i-laser-cutting-nylon-01

1. Inayiloni yokusika iLaser

Ukusika amashidi enayiloni abe usayizi phakathi kwezinyathelo ezi-3, umshini we-laser we-CNC ungahlanganisa ifayela lokuklama libe ngamaphesenti angu-100.

1. Beka indwangu enayiloni etafuleni lokusebenza;

2. Layisha ifayela lokusika noma dweba indlela yokusika kusofthiwe;

3. Qala umshini ngesilungiselelo esifanele.

2. I-Laser Engraving Kunayiloni

Emkhiqizweni wezimboni, ukumaka kuyisidingo esivamile sokuhlonza uhlobo lomkhiqizo, ukuphathwa kwedatha, nokuqinisekisa indawo elungile yokuthunga ishidi lezinto ezilandelayo ukuze kwenziwe inqubo yokulandelela.Ukuqoshwa kwe-laser ezintweni zenayiloni kungaxazulula inkinga ngokuphelele.Ukungenisa ifayela eliqoshiwe, ukusetha ipharamitha ye-laser, ucindezela inkinobho yokuqala, umshini wokusika we-laser bese uqopha amamaki embobo yokubhoboza engutsheni, ukumaka ukubekwa kwezinto ezifana nezicucu ze-Velcro, ezizothungwa kamuva phezu kwendwangu.

i-laser-perforating-nylon-01

3. I-Laser Perforating Inayiloni

I-laser izacile kodwa enamandla ingabhoboza inayiloni ngokushesha okuhlanganisa izindwangu ezihlanganisiwe, eziyinhlanganisela ukuze ziqhube izimbobo eziminyene nezihlukene zobukhulu nezimbobo, kuyilapho kungekho ukunamathela kwempahla.Icocekile futhi ihlanzekile ngaphandle kokucubungula.

Kunganilaser ukusika inayiloni ishidi?

clean-aage-cutting-01

Hlanza umphetho wanoma yimaphi ama-engeli

izimbobo ezincane-ezincane

Izimbobo ezincane ezinhle ezinokuphindaphinda okuphezulu

ukusika-ifomethi enkulu

Ukusika ifomethi enkulu yamasayizi abenziwe ngokwezifiso

✔ Ukuvala imiphetho kuqinisekisa ukuhlanzeka nokuyisicaba

✔ Noma iyiphi iphethini nesimo singasikwa nge-laser

✔ Akukho ukuguqulwa kwendwangu kanye nokulimala

✔ Izinga lokusika eliqhubekayo neliphindaphindekayo

✔ Akukho ukuhuzuka kwethuluzi nokushintshwa

✔ Ithebula elenziwe ngokwezifiso lanoma yimuphi usayizi wezinto zokwakha

Ukusetshenziswa kwe-Laser Cutting Nylon

• Ibhade lesihlalo semoto

• Izisetshenziswa zeBallistic

• Izingubo Nemfashini

• Izingubo Zamasosha

• Izindwangu Zokwenziwa

• Idivayisi yezokwelapha

• I-Interior Design

• Amatende

• Amapharashuthi

• Iphakheji