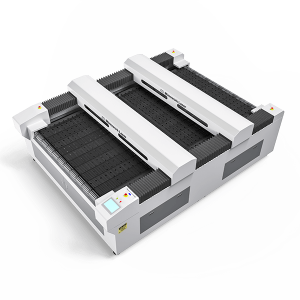

I-Plastiki Laser Cutter kanye ne-Engraver

Ikhwalithi iza kuqala;isevisi ihamba phambili;ibhizinisi ukubambisana" ifilosofi yethu yebhizinisi ehlala ibhekwa futhi ilandelwa inkampani yethu ye-Plastic Laser Cutter kanye ne-Engraver, Sigxila ekukhiqizeni umkhiqizo wethu futhi sihambisana nemisho embalwa enolwazi kanye nemishini yezinga lokuqala. Izimpahla zethu okufanele ube nazo.

Ikhwalithi iza kuqala;isevisi ihamba phambili;ibhizinisi liwukubambisana" yifilosofi yethu yebhizinisi ehlala ibonwa futhi ilandelwa inkampani yethuubucwebe be-laser cut ngokwezifiso, ukusika ipulasitiki ngokwezifiso, laser ukusika amashidi epulasitiki, i-laser cut polyethylene, i-laser cut polypropylene, laser cutter for plastic, laser ukusika ipulasitiki, qopha i-laser kupulasitiki, laser engraver for plastic, laser engraving abs, I-Laser Engraving Plastic, ukufakwa kwe-laser kupulasitiki, ipulasitiki yokumaka laser, umqophi wepulasitiki we-laser, Njengendlela yokusebenzisa insiza olwazini olukhulayo namaqiniso ekuhwebeni kwamazwe ngamazwe, siyawamukela amathemba avela yonke indawo kuwebhu nokungaxhunyiwe ku-inthanethi.Naphezu kwezinto ezisezingeni eliphezulu esizihlinzekayo, insizakalo yokubonisana ephumelelayo nenelisayo ihlinzekwa yiqembu lethu lenkonzo yochwepheshe ngemva kokuthengisa.Uhlu lwezixazululo kanye nemingcele ejulile kanye nanoma yimiphi eminye imininingwane etholakalayo izothunyelwa kuwe ngesikhathi ukuze uthole imibuzo.Ngakho-ke qiniseka ukuthi uyasithinta ngokusithumelela ama-imeyili noma usithinte uma kukhona okukukhathazayo mayelana nefemu yethu.futhi ungathola imininingwane yekheli lethu kuwebhusayithi yethu futhi uze ebhizinisini lethu.noma inhlolovo yendawo yezixazululo zethu.Siyaqiniseka ukuthi besihlela ukwabelana ngemiphumela futhi sakhe ubudlelwano obuqinile bokusebenzisana nabalingani bethu kule makethe.Sibheke ngabomvu imibuzo yakho.

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Ukusebenza okuningi emshinini owodwa

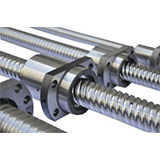

Ibhola & Isikulufa

Isikulufu sebhola i-actuator yomugqa ongumshini ehumusha ukunyakaza okuzungezayo kuya ekunyakazeni komugqa okunokungqubuzana okuncane.I-shaft enentambo ihlinzeka ngomzila we-helical wamabhering amabhola osebenza njengesikulufu esinembayo.Kanye nokukwazi ukufaka noma ukumelana nemithwalo ye-thrust ephezulu, bangenza kanjalo ngokungqubuzana okuncane kwangaphakathi.Zenziwa ukuvala ukubekezelelana ngakho-ke zifanele ukusetshenziswa ezimweni lapho ukunemba okuphezulu kuyadingeka.Ukuhlanganiswa kwebhola kusebenza njengenadi kuyilapho i-shaft enentambo iyisikulufu.Ngokuphambene nezikulufu zokuhola ezivamile, izikulufu zebhola zivamise ukuba nkulu, ngenxa yesidingo sokuba nendlela yokuzungeza kabusha amabhola.Isikulufu sebhola siqinisekisa isivinini esikhulu kanye nokusikwa kwe-laser ngokunemba okuphezulu.

I-Servo Motors

I-servomotor iyi-servomotor evaliwe esebenzisa impendulo yendawo ukuze ilawule ukunyakaza kwayo kanye nendawo yokugcina.Okokufaka ekulawuleni kwayo isignali (kungaba i-analog noma idijithali) emele indawo eyalwe kushafti okukhiphayo.Injini ibhangqwe nohlobo oluthile lwesifaki khodi ukuze inikeze impendulo yesikhundla nesivinini.Esimweni esilula, kulinganiswa isikhundla kuphela.Indawo elinganisiwe yokuphumayo iqhathaniswa nendawo yomyalo, okokufaka kwangaphandle kusilawuli.Uma indawo yokuphumayo ihluka kulokho okudingekayo, kukhiqizwa isignali yephutha ebangela ukuthi injini ijikeleze kunoma iyiphi indlela, njengoba kudingekile ukuletha shaft yokukhipha endaweni efanele.Njengoba izikhundla zisondela, isignali yephutha iyancipha ibe yiziro, futhi injini iyama.Ama-Servo motors aqinisekisa isivinini esiphezulu nokunemba okuphezulu kokusika nokuqoshwa kwe-laser.

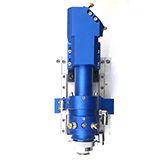

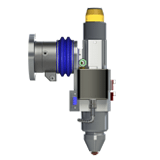

I-Mix Laser Head

Ikhanda le-laser elixubile, elaziwa nangokuthi i-metal non-metallic laser cutting head, liyingxenye ebaluleke kakhulu yomshini wokusika we-laser wensimbi ne-non-metal.Ngaleli khanda le-laser elichwepheshile, ungakwazi ukusika kokubili izinto zensimbi nezingezona ezensimbi.Kukhona ingxenye ye-Z-Axis yokudlulisa yekhanda le-laser ehamba phezulu naphansi ukuze ilandelele indawo okugxilwe kuyo.Isakhiwo sayo sekhabethe eliphindwe kabili sikwenza ukwazi ukubeka amalensi okugxila amabili ahlukene ukuze usike izinto zogqinsi oluhlukene ngaphandle kokulungiswa kwebanga lokugxila noma ukuqondanisa kwe-beam.Ikhulisa ukuguquguquka kokusika futhi yenza ukusebenza kube lula kakhulu.Ungasebenzisa igesi yokusiza ehlukene emisebenzini ehlukene yokusika.

I-Auto Focus

Ngokuyinhloko isetshenziselwa ukusika insimbi.Kungase kudingeke ukuthi usethe ibanga elithile lokugxila kusofthiwe lapho izinto zokusika zingekho flat noma ezinobukhulu obuhlukile.Khona-ke inhloko ye-laser izokwehla naphezulu ngokuzenzakalelayo, igcine ubude obufanayo & nebanga lokugxila ukuze lifane nalokho okusetha ngaphakathi kwesofthiwe ukuze uzuze ikhwalithi yokusika ephezulu ngokungaguquki.

Ividiyo ye-Laser Cutting Acylic (PMMA)

Ividiyo ye-Laser Engraving Wood Board

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Izinkambu Zokusebenza

I-Laser Cutting Yemboni Yakho

Ukuphrinta Kwedijithali

I-edge ehlanzekile futhi ebushelelezi ngokwelashwa okushisayo

Ukukhangisa Nezipho

Izinzuzo eziyingqayizivele zezimpawu zokusika ze-laser nemihlobiso

Izinto ezivamile kanye nezicelo

ye-Flatbed Laser Cutter 130

Buka izinto zokusebenza ezengeziwe

Senze amasistimu e-laser enqwaba yamakhasimende

Zingeze ohlwini!

I-China OEM China Cutter, I-Digital Cutter, Njengendlela yokusebenzisa insiza olwazini olwandayo namaqiniso ekuhwebeni kwamazwe ngamazwe, siyawamukela amathemba avela yonke indawo kuwebhu nokungaxhunyiwe ku-inthanethi.Naphezu kwezinto ezisezingeni eliphezulu esizihlinzekayo, insizakalo yokubonisana ephumelelayo nenelisayo ihlinzekwa yiqembu lethu lenkonzo yochwepheshe ngemva kokuthengisa.Uhlu lwezixazululo kanye nemingcele ejulile kanye nanoma yimiphi eminye imininingwane etholakalayo izothunyelwa kuwe ngesikhathi ukuze uthole imibuzo.Ngakho-ke qiniseka ukuthi uyasithinta ngokusithumelela ama-imeyili noma usithinte uma kukhona okukukhathazayo mayelana nefemu yethu.futhi ungathola imininingwane yekheli lethu kuwebhusayithi yethu futhi uze ebhizinisini lethu.noma inhlolovo yendawo yezixazululo zethu.Siyaqiniseka ukuthi besihlela ukwabelana ngemiphumela futhi sakhe ubudlelwano obuqinile bokusebenzisana nabalingani bethu kule makethe.Sibheke ngabomvu imibuzo yakho.

I-Laser Cutting Plastic

Professional Laser Cutting Isixazululo Plastic

Uzuza ekusebenzeni kwe-laser ye-premium kanye nokuhambisana phakathi kwe-laser wavelength kanye nokumunca ipulasitiki, umshini we-laser ugqama kubuchwepheshe bemishini obuvamile obunesivinini esiphezulu kanye nekhwalithi enhle kakhulu.Kufakwe ukucubungula okungathinteki futhi okungaphoqiwe, izinto zepulasitiki zingaguqulwa zibe unqenqema olubushelelezi nendawo ecwebezelayo ngaphandle kokulimala kwengcindezi.Ngenxa yalokho kanye namandla anamandla emvelo, ukusika nge-laser kuba yindlela ekahle ekwenzeni i-prototype eyenziwe ngepulasitiki kanye nokukhiqizwa kwevolumu.

Izinzuzo ze-Laser Cutting Plastic

I-Edge ehlanzekile futhi ebushelelezi

i-inter-laser-cut

Ukusikwa kwangaphakathi okuguquguqukayo

Ukusika i-contour yephethini

✔ Ukushisa okuncane endaweni ethintekile kuphela ngokusikwa

✔ Indawo ekhazimulayo ngenxa yokucubungula okungaxhunywanga nokungaphoqeleli

✔ Hlanza futhi unqenqemeni oluyisicaba ngogongolo lwe-laser oluqinile futhi oluqinile

✔ Ukusika okuqondile kwekhonta yepulasitiki enephethini

✔ Isivinini esisheshayo nohlelo oluzenzakalelayo luthuthukisa kakhulu ukusebenza kahle

✔ Ukunemba okuphezulu okuphindaphindiwe kanye nendawo ye-laser enhle kuqinisekisa izinga eliphezulu elingaguquki

✔ Akukho ukushintshwa kwethuluzi lomumo owenziwe ngezifiso

✔ Umshini Womaka weLaser uletha amaphethini ayinkimbinkimbi nokumaka okuningiliziwe

Ukusika kwe-Laser kungahlangabezana nokukhiqizwa kwamapulasitiki ahlukahlukene anezakhiwo ezahlukahlukene, osayizi, nobujamo.Usekelwa umklamo wokudlula kanye namathebula okusebenza enziwe ngokwezifiso avela ku-MimoWork, ungakwazi ukusika futhi uqophe kupulasitiki ngaphandle komkhawulo wamafomethi wezinto ezibonakalayo.Ngaphandle kwe-Plastic Laser Cutter, Umshini Wokumaka Nge-Laser we-UV kanye Nomshini Womaka we-Fiber Laser usiza ukubona ukumaka kwepulasitiki, ikakhulukazi ukuhlonza izingxenye ze-elekthronikhi namathuluzi anembile.

Izicelo ezijwayelekile ze-Laser Cutting Plastic

◾ Ubucwebe

◾ Amafilimu

◾ I-foil

◾ Imihlobiso

◾ Amakhibhodi

◾ Ukupakisha

◾ Amamodeli

◾ Amakesi efoni angokwezifiso

◾ Amabhodi esekethe aphrintiwe (PCB)

◾ Izingxenye zezimoto

◾ Amathegi okuhlonza

◾ Shintsha bese inkinobho

◾ Ukuqinisa ipulasitiki

◾ Izingxenye ze-elekthronikhi

◾ Ukuhlanza ipulasitiki

◾ Inzwa