Indlela Engcono Kakhulu Yokusika I-Fiberglass: Ukusika Nge-CO2 Laser

Isingeniso

I-fiberglass

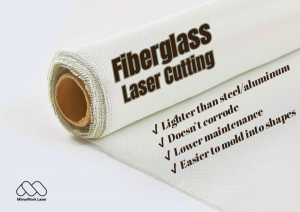

I-Fiberglass, into ene-fiber eyenziwe ngengilazi, eyaziwa ngamandla ayo, isisindo sayo esincane, kanye nokumelana okuhle kakhulu nokugqwala kanye nokuvikela ukuguga. Isetshenziswa kabanzi emikhakheni eyahlukahlukene, kusukela ezintweni zokuvikela ukuguga kuya kumaphaneli okwakha.

Kodwa ukuqhekeka kwe-fiberglass kunzima kakhulu kunalokho ongakucabanga. Uma uzibuza ukuthi ungazithola kanjani izicucu ezihlanzekile neziphephile,ukusika nge-laserIzindlela zifanele ukubhekisiswa kahle. Eqinisweni, uma kukhulunywa nge-fiberglass, amasu okusika nge-laser ashintshe indlela esisingatha ngayo le nto, okwenza ukusika nge-laser kube yisisombululo esithandwa ochwepheshe abaningi. Ake sichaze ukuthi kungani ukusika nge-laser kuvelele nokuthi kunganiUkusika nge-laser ye-CO2iyindlela engcono kakhulu yokusika i-fiberglass.

Ukuhluka Kokusika kwe-CO2 nge-Laser kwe-Fiberglass

Emkhakheni wokusika i-fiberglass, izindlela zendabuko, ezithiywe yimingcele yokunemba, ukuguguleka kwamathuluzi, kanye nokusebenza kahle, ziyazabalaza ukuhlangabezana nezidingo zokukhiqiza okuyinkimbinkimbi.

Ukusika kwe-CO₂ nge-laserNokho, yakha indlela entsha yokusika enezinzuzo ezine eziyinhloko. Isebenzisa umsebe we-laser ogxile ukudabula imingcele yesimo nokunemba, igwema ukuguguleka kwamathuluzi ngemodi yokungathintani, ixazulula izingozi zokuphepha ngokungenisa umoya okufanele kanye nezinhlelo ezihlanganisiwe, futhi ikhulisa umkhiqizo ngokusika okusebenzayo.

▪Ukunemba Okuphezulu

Ukunemba kokusikwa kwe-laser CO2 kuyashintsha izinto.

Umsebe we-laser ungagxila endaweni encane kakhulu, okuvumela ukusika okunezimo ezibekezelela okunzima ukukufeza ngezinye izindlela. Kungakhathaliseki ukuthi udinga ukudala ukusika okulula noma iphethini eyinkimbinkimbi ku-fiberglass, i-laser ingakwenza kalula. Isibonelo, lapho usebenza ezingxenyeni ze-fiberglass zezingxenye ze-elekthronikhi eziyinkimbinkimbi, ukunemba kokusika kwe-laser CO2 kuqinisekisa ukulingana nokusebenza okuphelele.

▪Akukho ukuthintana ngokomzimba, akukho ukugqokwa kwamathuluzi

Enye yezinzuzo ezinkulu zokusika nge-laser ukuthi inqubo yokungathintani.

Ngokungafani namathuluzi okusika ngomshini aguga ngokushesha lapho usika i-fiberglass, i-laser ayinayo le nkinga. Lokhu kusho ukuthi izindleko zokulungisa ziphansi ngokuhamba kwesikhathi. Ngeke kudingeke ukuthi ushintshe njalo ama-blade noma ukhathazeke ngokuguguleka kwamathuluzi okuthinta ikhwalithi yokusikwa kwakho.

▪Kuphephile Futhi Kuhlanzekile

Nakuba ukusika nge-laser kukhiqiza umusi lapho kusikwa i-fiberglass, ngezinhlelo zokungenisa umoya ezifanele, kungaba inqubo ephephile nehlanzekile.

Imishini yokusika nge-laser yesimanje ivame ukuza nezinhlelo zokukhipha intuthu ezakhelwe ngaphakathi noma ezihambisanayo. Lokhu kuyintuthuko enkulu kunezinye izindlela, ezikhiqiza umusi omningi oyingozi futhi ezidinga izinyathelo zokuphepha ezibanzi.

▪Ukusika Okusheshayo Okuphezulu

Isikhathi siyimali, akunjalo? Ukusika i-CO2 nge-laser kuyashesha.

Ingasika i-fiberglass ngesivinini esisheshayo kakhulu kunezindlela eziningi zendabuko. Lokhu kuzuzisa kakhulu uma unomsebenzi omningi. Endaweni yokukhiqiza ematasa, ikhono lokusika izinto ngokushesha lingakhuphula kakhulu umkhiqizo.

Ekuphetheni, uma kukhulunywa ngokusika i-fiberglass, ukusika i-laser CO2 kuyimpumelelo ecacile. Kuhlanganisa ukunemba, isivinini, ukusebenza kahle kwezindleko, kanye nokuphepha ngandlela thile. Ngakho-ke, uma usabhekene nezindlela zokusika zendabuko, kungase kube yisikhathi sokushintshela ekusikeni i-laser CO2 bese uzibonele umehluko.

I-Fiberglass Yokusika Nge-Laser Ngomzuzu O-1 [Imbozwe Nge-Silicone]

Ukusetshenziswa Kokusika kwe-CO2 nge-Laser ku-Fiberglass

Izicelo ze-Fiberglass

I-fiberglass ikhona yonke indawo ekuphileni kwethu kwansuku zonke, kusukela ezintweni esizisebenzisayo zokuzilibazisa kuya ezimotweni esizishayelayo.

Ukusika kwe-CO2 nge-laseriyimfihlo yokuvula amandla ayo aphelele!

Kungakhathaliseki ukuthi wenza into esebenzayo, ehlobisayo, noma elungiselelwe izidingo ezithile, le ndlela yokusika iguqula i-fiberglass ibe yinto eqinile ukuze isebenze ngayo ibe yindwangu eguquguqukayo.

Ake sibheke ukuthi kwenza kanjani umehluko ezimbonini nasemaphrojekthini ansuku zonke!

▶ Ukuhlobisa Ekhaya kanye Nemisebenzi Yokuzenzela

Kulabo abathanda ukuhlobisa ikhaya noma ukwenza izinto ngokwakho, i-fiberglass eqoshiwe nge-laser CO2 ingaguqulwa ibe izinto ezinhle neziyingqayizivele.

Ungakha ubuciko bodonga obenziwe ngokwezifiso ngamashidi e-fiberglass asikwe nge-laser, aqukethe amaphethini ayinkimbinkimbi aphefumulelwe yimvelo noma ubuciko besimanje. I-fiberglass ingasikwa futhi ibe yizimo zokwenza ama-lampshade anesitayela noma ama-vase okuhlobisa, okwengeza ubuhle kunoma yiliphi ikhaya.

▶Enkundleni Yezinto Zokudlala Ezemidlalo Zasemanzini

I-fiberglass iyinto ebaluleke kakhulu ezikebheni, kuma-kayak, nasemabhodini okugwedla ngoba ayingeni manzi futhi ihlala isikhathi eside.

Ukusika nge-laser CO2 kwenza kube lula ukwenza izingxenye ezenziwe ngokwezifiso zalezi zinto. Isibonelo, abakhi bezikebhe bangasika izimbobo ze-fiberglass noma izindawo zokugcina ezilingana kahle, okugcina amanzi engangeni. Abenzi be-kayak bangakha ozimele bezihlalo ezi-ergonomic kusuka ku-fiberglass, ezenzelwe izinhlobo ezahlukene zomzimba ukuze kube nenduduzo engcono. Ngisho nezinto ezincane zamanzi ezifana namaphiko e-surfboard ziyazuza—amaphiko e-fiberglass anqunywe nge-laser anezimo eziqondile ezithuthukisa ukuzinza kanye nesivinini emagagasini.

▶Embonini Yezimoto

I-Fiberglass isetshenziswa kabanzi embonini yezimoto ezingxenyeni ezifana namaphaneli omzimba kanye nezingxenye zangaphakathi ngenxa yamandla ayo kanye nokukhanya kwayo.

Ukusikwa kwe-CO2 nge-laser kwenza kube lula ukukhiqizwa kwezingxenye ze-fiberglass ezenziwe ngokwezifiso nezinembile kakhulu. Abakhiqizi bezimoto bangakha imiklamo yephaneli yomzimba eyingqayizivele enama-curve ayinkimbinkimbi kanye nama-cutout ukuze kube ne-aerodynamics engcono. Izingxenye zangaphakathi ezifana nama-dashboard enziwe nge-fiberglass nazo zingasikwa nge-laser ukuze zivumelane kahle nomklamo wemoto, okuthuthukisa kokubili ubuhle kanye nokusebenza.

Imibuzo Evame Ukubuzwa mayelana ne-Laser Cutting Fiberglass

I-fiberglass kunzima ukuyisika ngoba iyinto egugulekayo eguga imiphetho ye-blade ngokushesha. Uma usebenzisa ama-blade ensimbi ukusika ama-insulation batts, uzogcina uwashintsha njalo.

Ngokungafani namathuluzi okusika ngomshini aguga ngokushesha lapho kusikwa i-fiberglass,umsiki we-laserayinayo le nkinga!

Izindawo ezinomoya omuhle kanye nezisiki ze-laser ze-CO₂ ezinamandla aphezulu zilungele umsebenzi.

I-fiberglass imunca kalula ubude bamaza obuvela kuma-laser e-CO₂, futhi umoya ofanele uvimbela umusi onobuthi ukuthi ungahlali endaweni yokusebenza.

YEBO!

Imishini yesimanje ye-MimoWork iza nesofthiwe elula ukuyisebenzisa kanye nezilungiselelo ezilungiselelwe kusengaphambili ze-fiberglass. Siphinde sinikeze izifundo, futhi ukusebenza okuyisisekelo kungaqedwa ngezinsuku ezimbalwa—yize ukulungisa kahle imiklamo eyinkimbinkimbi kuthatha ukuzijwayeza.

Ukutshalwa kwezimali kokuqala kuphakeme, kodwa ukusika nge-laserkusindisa imali isikhathi eside: akukho ukushintshwa kwezinsika, ukuchithwa kwezinto ezincane, kanye nezindleko eziphansi zokucubungula ngemuva kokusetshenziswa.

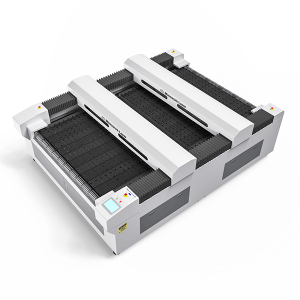

Ncoma Imishini

| Indawo Yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Isofthiwe | Isofthiwe Engaxhunyiwe Ku-inthanethi |

| Amandla e-Laser | 100W/150W/300W |

| Isivinini Esiphezulu | 1 ~ 400mm/s |

| Indawo Yokusebenza (W * L) | 1600mm * 3000mm (62.9” * 118”) |

| Isofthiwe | Isofthiwe Engaxhunyiwe Ku-inthanethi |

| Amandla e-Laser | 150W/300W/450W |

| Isivinini Esiphezulu | 1 ~ 600m/s |

Uma Unemibuzo mayelana ne-Laser Cutting Fiberglass, Xhumana Nathi!

Ungase ube nentshisekelo ku-

Ingabe unemibuzo mayelana ne-Laser Cutting Fiberglass Sheet?

Isikhathi sokuthunyelwe: Agasti-01-2025