Best Way to Cut Fiberglass: CO2 Laser Cutting

Introduction

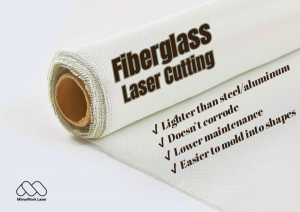

Fiberglass

Fiberglass,a fibrous material made from glass,known for its strength,light weight,and excellent resistance to corrosion and insulation.It’s widely used in various fields,from insulation materials to building panels.

But cracking fiberglass is trickier than you might think.If you’re wondering how to get clean, safe cuts, laser cut methods are worth a close look. In fact, when it comes to fiberglass, laser cut techniques have revolutionized how we handle this material, making laser cut the go-to solution for many professionals. Let’s break down why laser cut stands out and why CO2 laser cutting is the best way to cut fiberglass.

The Uniqueness of Laser CO2 Cutting for Fiberglass

In the field of fiberglass cutting, traditional methods, hampered by limitations in precision, tool wear, and efficiency, struggle to meet the demands of complex production.

Laser CO₂ cutting, however, builds a brand-new cutting paradigm with four core advantages. It uses a focused laser beam to break through the boundaries of shape and precision, avoids tool wear through a non-contact mode, resolves safety hazards with proper ventilation and integrated systems, and boosts productivity via efficient cutting.

▪High Precision

The precision of laser CO2 cutting is a game-changer.

The laser beam can be focused to an incredibly fine point, allowing for cuts with tolerances that are difficult to achieve by other means. Whether you need to create a simple cut or a complex pattern in fiberglass, the laser can execute it with ease. For instance, when working on fiberglass parts for intricate electronic components, the precision of laser CO2 cutting ensures a perfect fit and functionality.

▪No Physical Contact, No Tool Wear

One of the biggest advantages of laser cutting is that it's a non-contact process.

Unlike mechanical cutting tools that wear out quickly when cutting fiberglass, the laser doesn't have this problem. This means lower maintenance costs in the long run. You won't have to constantly replace blades or worry about tool wear affecting the quality of your cuts.

▪Safe and Clean

While laser cutting does produce fumes when cutting fiberglass, with proper ventilation systems in place, it can be a safe and clean process.

Modern laser cutting machines often come with built-in or compatible fume extraction systems. This is a big improvement over other methods, which produce a lot of harmful fumes and require more extensive safety measures.

▪High-Speed Cutting

Time is money, right? Laser CO2 cutting is fast.

It can cut through fiberglass at a much quicker rate than many traditional methods. This is especially beneficial if you have a large volume of work. In a busy manufacturing environment, the ability to cut materials quickly can significantly increase productivity.

In conclusion, when it comes to cutting fiberglass, laser CO2 cutting is a clear winner. It combines precision, speed, cost-effectiveness, and safety in a way. So, if you're still struggling with traditional cutting methods, it might be time to make the switch to laser CO2 cutting and see the difference for yourself.

Laser Cutting Fiberglass in 1 Minute [Silicone-Coated]

Applications of Laser CO2 Cutting in Fiberglass

Fiberglass Applications

Fiberglass is everywhere in our daily lives, from the gear we use for hobbies to the cars we drive.

Laser CO2 cutting is the secret to unlocking its full potential!

Whether you’re crafting something functional, decorative, or tailored to specific needs, this cutting method turns fiberglass from a tough material to work with into a versatile canvas.

Let’s dive into how it’s making a difference in everyday industries and projects!

▶In Home Decor and DIY Projects

For those into home decor or DIY, laser CO2 cut fiberglass can be transformed into beautiful and unique items.

You can create custom-made wall art with laser cut fiberglass sheets, featuring intricate patterns inspired by nature or modern art. Fiberglass can also be cut into shapes for making stylish lampshades or decorative vases, adding a touch of elegance to any home.

▶In the Water Sports Gear Field

Fiberglass is a staple in boats, kayaks, and paddleboards because it’s water-resistant and durable.

Laser CO2 cutting makes it easy to craft custom parts for these items. For example, boat builders can laser-cut fiberglass hatches or storage compartments that fit snugly, keeping water out. Kayak makers can create ergonomic seat frames from fiberglass, tailored to different body types for better comfort. Even smaller water gear like surfboard fins benefit—laser-cut fiberglass fins have precise shapes that improve stability and speed on the waves.

▶In the Automotive Industry

Fiberglass is widely used in the automotive industry for parts like body panels and interior components due to its strength and lightweight nature.

Laser CO2 cutting enables the production of custom, high-precision fiberglass parts. Car manufacturers can create unique body panel designs with complex curves and cutouts for better aerodynamics. Interior components such as dashboards made of fiberglass can also be laser-cut to fit perfectly with the vehicle's design, enhancing both aesthetics and functionality.

FAQs about Laser Cutting Fiberglass

Fiberglass is tough to cut because it’s an abrasive material that wears down blade edges quickly. If you use metal blades to cut insulation batts, you’ll end up changing them frequently.

Unlike mechanical cutting tools that wear out quickly when cutting fiberglass, the laser cutter doesn't have this problem!

Well-ventilated areas and high-power CO₂ laser cutters are ideal for the job.

Fiberglass easily absorbs the wavelengths from CO₂ lasers, and proper ventilation keeps toxic fumes from lingering in the workspace.

YES!

MimoWork's modern machines come with user-friendly software and preset settings for fiberglass.We also offer tutorials, and basic operation can be mastered in a few days—though fine-tuning for complex designs takes practice.

Initial investment is higher, but laser cutting saves money long-term: no blade replacements, less material waste, and lower post-processing costs.

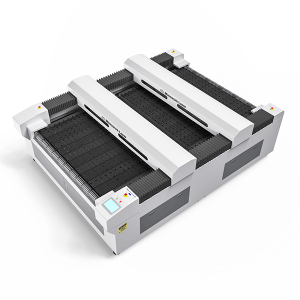

Recommend Machines

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Max Speed | 1~400mm/s |

| Working Area (W * L) | 1600mm * 3000mm (62.9” * 118 ”) |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Max Speed | 1~600m/s |

If You Have Questions about Laser Cutting Fiberglass, Contact Us!

You may be interested in

Got any Doubts about Laser Cutting Fiberglass Sheet?

Post time: Aug-01-2025