Indlela yokusika i-Laser Sula i-Acrylic

Amathiphu Namasu Okuzuza Imiphumela Ephelele

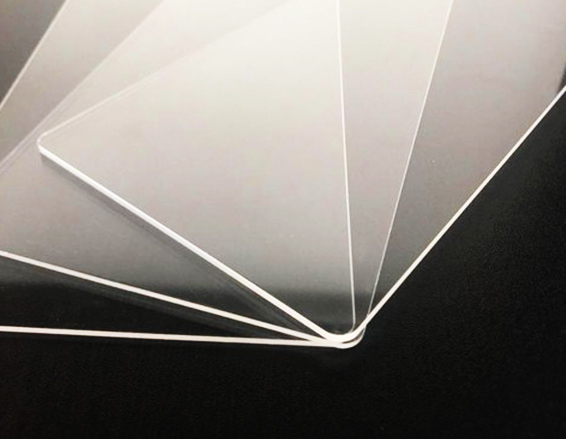

I-laser-cutting acrylic ecacile iyi-ainqubo evamileesetshenziswa ezimbonini ezahlukene ezifanaukwenza izimpawu, ukumodela kwezakhiwo, kanye ne-prototyping yomkhiqizo.

Inqubo ihilela ukusebenzisa i-laser cutter yeshidi le-acrylic enamandla kakhulusika, qopha, noma usikeumklamo phezu kocezu lwe-acrylic ecacile.

Ukusika okuwumphumela kunguihlanzekile futhi inembile, enonqenqema olupholishiwe oludinga ukucutshungulwa okuncane kwangemuva.

Kulesi sihloko, sizofaka izinyathelo eziyisisekelo zokusika i-acrylic ecacile ye-laser futhi sinikeze amathiphu namasu okukufundisaindlela yokusika i-acrylic ecacile nge-laser.

Isinyathelo 1: Lungiselela I-Acrylic Ecacile

Ngaphambi kokusika i-acrylic ecacile nge-laser, kubalulekile ukwenza isiqiniseko sokuthi impahla injaloilungiswe kahle.

Amashidi e-acrylic acacile ngokuvamile afika nefilimu evikelayo nhlangothi zombili ukuvimbela imihuzuko nokulimala ngesikhathi sokuthutha nokuphatha.

Kubalulekile ukususa le filimungaphambi kwe-CO2 laser acrylic cutting, njengoba kungabangelaukusika okungalingani kanye nokuncibilika.

Uma ifilimu yokuzivikela isusiwe, i-acrylic kufanele ihlanzwe nge-aokokuhlanza okuncaneukususa noma yikuphi ukungcola, uthuli, noma imfucumfucu.

Isinyathelo sesi-2: Setha Umshini Wokusika I-Acrylic Sheet Laser

Uma i-acrylic ecacile isilungisiwe, sekuyisikhathi sokusetha umshini wokusika we-laser.

Umshini osika i-acrylic kufanele ufakwe i-CO2 laser enobude obungamazacishe 10.6 micrometers.

I-laser kufanele futhi ilinganiswe ku-amandla alungile nezilungiselelo zesivinini, ezingase zihluke kuye ngokuthiukujiya kwe-acrylic nokujula okufunayo kokusika.

I-laser kufanele ibeigxile ebusweni be-acrylicukuqinisekisa ukusika okunembile.

Isinyathelo sesi-3: Dizayina Iphethini Yokusika

Ngaphambi kokuqala inqubo yokusika i-CO2 laser acrylic, kubalulekile ukuklama iphethini yokusika.

Lokhu kungenziwa kusetshenziswa isoftware ye-computer-aid design (CAD) efanaI-Adobe Illustrator noma i-AutoCAD.

Iphethini yokusika kufanele igcinwenjengefayela le-vector, engalayishwa emshinini wokusika we-laser ukuze icutshungulwe.

Iphethini yokusika kufanele futhi ifakenoma yimiphi imiklamo eqoshiwe noma e-etching efiswayo.

Isinyathelo sesi-4: Sika i-Laser i-Acrylic ecacile

Lapho i-laser yokusika i-acrylic isimisiwe futhi iphethini yokusika yaklanywa, sekuyisikhathi sokuqala inqubo yokusika i-CO2 laser acrylic.

I-acrylic ecacile kufanele ibekwe ngokuphepha embhedeni wokusika womshini,ukuqinisekisa ukuthi isezingeni futhi iphansi.

I-laser cutter acrylic sheets kufanele ivulwe, futhi iphethini yokusika kufanele ilayishwe emshinini.

Umshini wokusika we-laser uzolandela iphethini yokusika, usebenzisa i-laser ukusika i-acrylic ngokunemba nokunemba.

Amathiphu namasu we-Laser Cutting Sula i-Acrylic

• Sebenzisa Isilungiselelo Samandla Aphansi

Sula i-acrylic canncibilika futhi ushintshe umbalakuzilungiselelo zamandla aphezulu.

Ukuze ugweme lokhu, kungcono ukusebenzisaukulungiselelwa kwamandla aphansifuthiyenza amaphasi amaningiukufeza ukujula okufunayo kokusika.

• Sebenzisa i-High-Speed Setting

Sula i-acrylic can futhiqhekezakuzilungiselelo zesivinini esiphansi.

Ukuze ugweme lokhu, kungcono ukusebenzisa aukusetha ngesivinini esikhulu futhi wenze amaphasi amaningiukufeza ukujula okufunayo kokusika.

• Sebenzisa Umthombo Womoya Ocindezelwe

Umthombo womoya ocindezelwe ungasiza ukuphephula udoti futhi uvimbele ukuncibilika phakathi nenqubo yokusika i-laser.

• Sebenzisa Umbhede Wokusika Izinyosi

Umbhede wokusika ikhekheba lezinyosi ungasiza ukusekela i-acrylic ecacile futhi uvimbele ukulwa phakathi nenqubo yokusika i-laser.

• Sebenzisa i-Masking Tape

Ukusebenzisa i-masking tape ebusweni be-acrylic ecacile ngaphambi kokusika kwe-laser kungasiza ekuvimbeleni ukuguga nokuncibilika.

Laser Cutting Acrylic Isiphetho

I-Laser yokusika i-acrylic ecacile iyinqubo eqondile engenziwa ngokunemba nokunemba kusetshenziswa imishini namasu afanele.Ngokulandela izinyathelo ezichazwe kulesi sihloko futhi usebenzisa amathiphu namasu anikeziwe, ungafinyelela imiphumela engcono kakhulu lapho usika i-acrylic ecacile ye-laser yephrojekthi yakho elandelayo.

Isibonisi Sevidiyo |Isebenza kanjani i-Laser Cut Acrylic

I-Laser Cut Acrylic Signage

I-Laser Cut Thick Acrylic ifika ku-21mm

I-Laser Cut & Uqophe ku-Acrylic

Thatha Imibono Yakho, Woza ne-Laser Acrylic ukuze Ujabule!

I-Laser Cut Ephrintiwe Acrylic?Kulungile!

Hhayi kuphela ukusika amashidi e-acrylic acacile, i-CO2 Laser ingasika i-acrylic ephrintiwe.Ngosizo lweIkhamera ye-CCD, i-acrylic laser cutter izwa sengathi inamehlo, futhi iqondise ikhanda le-laser ukuthi linyakaze futhi lisike eduze komkhonto ophrintiwe.Funda kabanzi mayelanaIkhamera ye-CCD laser cutter >>

Umshini Wokusika we-Acrylic Laser odumile

Noma yimiphi imibuzo mayelana nokusebenza kwe-Laser Cut Acrylic?

Isikhathi sokuthumela: Mar-16-2023