Izimfihlo Zokushisela Nge-Laser: Lungisa Izinkinga Ezivamile Manje!

Isingeniso:

Umhlahlandlela Ophelele Wokuxazulula Izinkinga

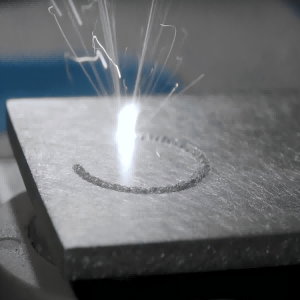

Imishini Yokushisela Ye-Laser Ephathwayo

Umshini wokushisela we-fiber laser ophathwa ngesandla uthole ukuthandwa okukhulu ezimbonini ezahlukahlukene ngenxa yokunemba kwawo kanye nokusebenza kahle kwawo.

Kodwa-ke, njenganoma iyiphi enye indlela yokushisela, ayivikelekile ezinkingeni nezinkinga ezingase ziphakame ngesikhathi senqubo yokushisela.

Lokhu kupheleleukuxazulula izinkinga zokushisela nge-laserihlose ukubhekana nezinkinga ezivamile ezibhekene nemishini yokushisela nge-laser ephathwa ngesandla, izinkinga ezihlobene nokushisela, kanye nezinkinga eziphathelene nekhwalithi yokushisela.

Uhlu Lokuqukethwe:

Amaphutha Nezixazululo Zomshini Wokushisela We-Laser Ngaphambi Kokuqala

1. Imishini Ayikwazi Ukuqala (Amandla)

Isixazululo: Hlola ukuthi iswishi yentambo kagesi iyasebenza yini.

2. Izibani azikwazi ukukhanyisa

Isixazululo: Hlola ibhodi langaphambi komlilo nge-voltage engu-220V noma ngaphandle kwayo, hlola ibhodi lokukhanyisa; i-fuse engu-3A, isibani se-xenon.

3. Ukukhanya Kukhanyiswe, Akukho Laser

Isixazululo: Qaphela ukuthi ingxenye yesibonisi esiphathwa ngesandla somshini wokuwelda we-laser ngaphandle kokukhanya ijwayelekile. Okokuqala, hlola ukuthi ingxenye ye-CNC yenkinobho ye-laser ivaliwe, uma ivaliwe, bese uvula inkinobho ye-laser. Uma inkinobho ye-laser ijwayelekile, vula isikhombikubona sokubonisa ukulawula kwezinombolo ukuze ubone ukuthi ngabe ukusethwa kokukhanya okuqhubekayo, uma kungenjalo, bese ushintshela ekukhanyeni okuqhubekayo.

Izinkinga Nokulungiswa Kwe-Welder Yesigaba Sokushisela Nge-Laser

Umthungo Wokushisela Umnyama

Igesi evikelayo ayivulekile, inqobo nje uma igesi ye-nitrogen ivuliwe, ingaxazululeka.

Isiqondiso sokuhamba komoya segesi evikelayo asilungile, isiqondiso sokuhamba komoya segesi evikelayo kufanele senziwe siphambene nesiqondiso sokuhamba kwengxenye yokusebenza.

Ukuntuleka Kokungena Kokushisela

Ukuntuleka kwamandla e-laser kungathuthukisa ububanzi be-pulse kanye nomsinga.

Ilensi yokugxila akuyona inani elifanele, ukulungisa inani lokugxila eduze nendawo yokugxila.

Ubuthakathaka Bomsebe We-Laser

Uma amanzi okupholisa engcolisiwe noma engakashintshwa isikhathi eside, angaxazululwa ngokushintsha amanzi okupholisa nokuhlanza ishubhu lengilazi ye-UV kanye nesibani se-xenon.

Ilensi yokugxila noma i-diaphragm ye-laser yonakele noma ingcolile, kufanele ishintshwe noma ihlanzwe ngesikhathi.

Hambisa i-laser endleleni eyinhloko yokukhanya, lungisa i-diaphragm yokukhanya okuphelele kanye ne-diaphragm yokukhanya okuncane endleleni eyinhloko yokukhanya, hlola bese uzungeza indawo ngephepha lesithombe.

I-laser ayikhiphi i-nozzle yethusi ngaphansi kwekhanda eliqondisayo. Lungisa i-diaphragm ebonakalisayo engama-degree angu-45 ukuze i-laser ikhiphe i-nozzle yegesi maphakathi.

Ukuxazulula Izinkinga Zekhwalithi Yokushisela Nge-Laser

1. Ukuphalaza

Ngemva kokushiswa nge-laser, izinhlayiya eziningi zensimbi ziyavela ebusweni bento noma ingxenye yomsebenzi, zinamathele ebusweni bento noma ingxenye yomsebenzi.

Isizathu sokufafaza: ubuso bezinto ezicutshunguliwe noma ingxenye yokusebenza ayihlanzekile, kukhona uwoyela noma ukungcola, kungase kubangelwe nokuwohloka kwesendlalelo se-galvanized.

1) Naka ukuhlanza izinto noma umsebenzi ngaphambi kokushisela nge-laser;

2) I-Spatter ihlobene ngqo nobuningi bamandla. Ukunciphisa okufanele amandla okushisela kunganciphisa i-spatter.

2. Imifantu

Uma ijubane lokupholisa le-workpiece lishesha kakhulu, izinga lokushisa lamanzi okupholisa kufanele lilungiswe ku-fixture ukuze kwandiswe izinga lokushisa lamanzi.

Uma igebe lokulingana kwezingxenye zokusebenza likhulu kakhulu noma kukhona i-burr, ukunemba komshini wezingxenye zokusebenza kufanele kuthuthukiswe.

I-workpiece ayihlanzwanga. Kulokhu, i-workpiece idinga ukuhlanzwa futhi.

Izinga lokugeleza kwegesi evikelayo likhulu kakhulu, okungaxazululwa ngokunciphisa izinga lokugeleza kwegesi evikelayo.

3. Imbobo Ebusweni Bokushisela

Izizathu zokuvela kwe-porosity:

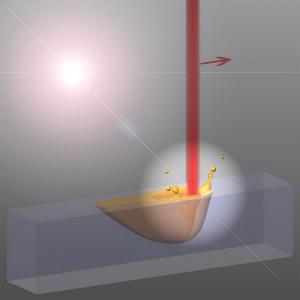

1) Ichibi elicibilikisiwe elishibilikisiwe nge-laser lijulile futhi lincane, futhi izinga lokupholisa lishesha kakhulu. Igesi ekhiqizwa echibini elicibilikisiwe sekwephuze kakhulu ukuthi ingachichima, okungaholela kalula ekwakhekeni kwama-porosity.

2) Ubuso be-weld abuhlanzwa, noma umhwamuko we-zinc weshidi elihlanganisiwe uyashintshashintsha.

Hlanza ubuso bento yokusebenza kanye nobuso be-weld ngaphambi kokushisela ukuze uthuthukise ukuguquguquka kwe-zinc uma ishiswa.

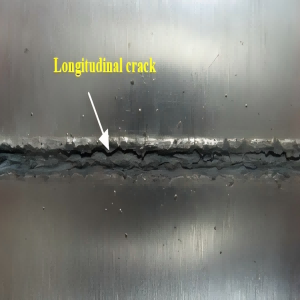

4. Ukuphambuka kokushisela

Insimbi ehlanganisiwe ngeke iqine phakathi kwesakhiwo esihlanganisiwe.

Isizathu sokuphambuka: Ukuma okunganembile ngesikhathi sokushisela, noma isikhathi sokugcwalisa esinganembile kanye nokulungiswa kwentambo.

Isixazululo: Lungisa indawo yokushisela, noma isikhathi sokugcwalisa kanye nendawo yentambo, kanye nendawo yesibani, intambo kanye nentambo yokushisela.

5. Ukuvaleka Kwe-Slag Engaphezulu, Okubonakala Kakhulu Phakathi Kwezendlalelo

Izimbangela zokubamba i-slag ebusweni:

1) Uma kushiselwa nge-multi-layer multi-pass, ungqimba oluphakathi kwezingqimba aluhlanzekile; noma ubuso be-weld yangaphambilini abuyisicaba noma ubuso be-weld abuhlangabezani nezidingo.

2) Amasu okusebenza ngokushisela angafanele, njengamandla okufaka aphansi okushisela, isivinini sokushisela sishesha kakhulu.

Isixazululo: Khetha amandla okushisela afanele kanye nesivinini sokushisela, futhi ungqimba oluphakathi kwezingqimba kumele luhlanzwe lapho kushiselwa nge-multi-layer multi-pass. Gaya bese ususa i-weld nge-slag ebusweni, bese wenza i-weld uma kudingeka.

Ezinye Izesekeli – I-Handheld Laser Welder Izinkinga Ezivamile Nezixazululo

1. Ukwehluleka kwedivayisi yokuvikela ukuphepha

Amadivayisi okuvikela ukuphepha omshini wokushisela nge-laser, njengomnyango wegumbi lokushisela, inzwa yokugeleza kwegesi, kanye nenzwa yokushisa, abalulekile ekusebenzeni kwawo kahle. Ukwehluleka kwala madivayisi akugcini nje ngokuphazamisa ukusebenza okuvamile kwemishini kodwa futhi kungabeka engcupheni yokulimala kumqhubi.

Uma kwenzeka ukungasebenzi kahle kwamadivayisi okuvikela ukuphepha, kubalulekile ukumisa ukusebenza ngokushesha bese uthintana nochwepheshe ukuze balungise futhi bashintshe.

2. Ukujima Kwesitsha Sokuphakela Izintambo

Uma kukhona i-wire feeder jam kulesi simo, into yokuqala okudingeka siyenze ukuhlola ukuthi umlomo wesibhamu uvalekile yini, isinyathelo sesibili ukuhlola ukuthi i-wire feeder ivalekile yini nokuthi kukhona ukujikeleza kwediski yesilika kuvamile.

Fingqa

Ngokunemba okungenakuqhathaniswa, isivinini kanye nokuguquguquka, ukushisela nge-laser kuwubuchwepheshe obuwusizo ezimbonini ezifana nezimoto, izindiza kanye ne-elekthronikhi.

Kodwa-ke, kungase kube namaphutha ahlukahlukene ngesikhathi senqubo yokushisela, okuhlanganisa ukubhoboka, ukuqhekeka, ukuchaphaza, ubhontshisi obungajwayelekile, ukusha, ukuguquka, kanye nokushiswa.

Iphutha ngalinye linembangela ethile, njengezilungiselelo ze-laser ezingafanele, ukungcola kwezinto ezibonakalayo, amagesi avikelayo anganele, noma amalunga angahlelekile kahle.

Ngokuqonda la maphutha kanye nezimbangela zawo eziyinhloko, abakhiqizi bangafaka izixazululo eziqondiwe, njengokuthuthukisa amapharamitha e-laser, ukuqinisekisa ukulingana okufanele kwamalunga, ukusebenzisa amagesi okuvikela asezingeni eliphezulu, kanye nokusebenzisa ukwelashwa kwangaphambi nangemuva kokushiswa.

Ukuqeqeshwa okufanele komqhubi, ukugcinwa kwemishini nsuku zonke kanye nokuqapha inqubo ngesikhathi sangempela kuthuthukisa ikhwalithi yokushisela futhi kunciphise amaphutha.

Njengoba kunendlela ephelele yokuvimbela amaphutha kanye nokwenza ngcono izinqubo, ukushisela nge-laser kunikeza njalo ukushisela okuqinile, okuthembekile kanye nekhwalithi ephezulu okuhlangabezana nezindinganiso eziqinile zemboni.

Awazi ukuthi hlobo luni lomshini wokushisela nge-laser okufanele uwukhethe?

Udinga ukwazi: Indlela yokukhetha umshini we-laser ophathwa ngesandla

Amandla aphezulu kanye ne-Wattage yezicelo ezahlukahlukene zokushisela

Umshini wokushisela we-laser ophathwa ngesandla ongu-2000W ubonakala ngobukhulu bomshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-laser yefayibha ozinzile kanye nekhebula lefayibha elixhunyiwe linikeza ukulethwa kwe-laser beam okuphephile nokuzinzile.

Ngamandla aphezulu, imbobo yokhiye yokushisela ye-laser iphelele futhi ivumela ijoyinti lokushisela ukuthi liqine ngisho nasensimbini ejiyile.

Ukuthwaleka Kokuguquguquka

Njengoba ibukeka incane futhi incane ngomshini, umshini wokushisela we-laser ophathwayo ufakwe isibhamu sokushisela se-laser esiphathwa ngesandla esinyakaziswayo esilula futhi esilungele ukusetshenziswa kokushisela kwe-laser eminingi kunoma iyiphi i-engeli kanye nobuso.

Izinhlobo ezahlukene zokuzikhethela zama-nozzle okushisela nge-laser kanye nezinhlelo zokuphakela ngocingo okuzenzakalelayo zenza ukusebenza kokushisela nge-laser kube lula futhi lokho kuyabasiza abaqalayo.

Ukushisela nge-laser okusheshayo kukhulisa kakhulu ukusebenza kahle kokukhiqiza kwakho kanye nomphumela ngenkathi kuvumela umphumela omuhle kakhulu wokushisela nge-laser.

Izinto Okufanele Uzazi Ngazo: Ukushisela Nge-Laser Ephathwa Ngesandla

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisele isiteshi sethu se-Youtube?

Izicelo Ezihlobene Ongase Ube Nentshisekelo Kuzo:

Konke Ukuthenga Kufanele Kube Nolwazi Oluhle

Singasiza ngolwazi oluningiliziwe kanye nokubonisana!

Isikhathi sokuthunyelwe: Jan-16-2025