Izinto Ezibalulekile Okufanele Uzicabangele Nge-Laser Cutting Plywood

Umhlahlandlela Wokuqopha Nge-Laser Yokhuni

I-plywood esikiwe nge-laser inikeza ukunemba okungenakuqhathaniswa kanye nokuguquguquka, okwenza ibe yindawo ekahle kakhulu kuyo yonke into kusukela emisebenzini yobuciko kuya kumaphrojekthi amakhulu. Ukuze ufeze imiphetho ehlanzekile futhi ugweme umonakalo, kubalulekile ukuqonda izilungiselelo ezifanele, ukulungiswa kwezinto, kanye namathiphu okulungisa. Lo mhlahlandlela wabelana ngezinto ezibalulekile ezizokusiza uthole imiphumela emihle kakhulu uma usebenzisa umshini wokusika izinkuni nge-laser ku-plywood.

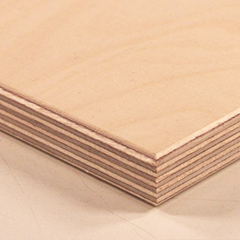

Ukukhetha i-Plywood Efanele

Izinhlobo zePlywood zokusika nge-Laser

Ukukhetha i-plywood efanele kubalulekile ukuze kutholakale imiphumela ehlanzekile neqondile ngei-plywood esikiwe nge-laseramaphrojekthi. Izinhlobo ezahlukene ze-plywood zinikeza izinzuzo ezihlukile, futhi ukukhetha efanele kuqinisekisa ukusebenza okungcono kanye nekhwalithi yokuqeda.

I-Plywood Esikiwe Nge-Laser

I-Birch Plywood

Okusanhlamvu okuhle, okulinganayo okunezikhala ezincane, kuhle kakhulu ekuqopheni okunemininingwane kanye nemiklamo eyinkimbinkimbi.

I-Poplar Plywood

Ilula, kulula ukuyisika, ilungele amaphaneli okuhlobisa kanye nemiklamo emikhulu.

I-Plywood Ebhekene Ne-Veneer

Ubuso be-veneer yokhuni obuhlotshisiwe bamaphrojekthi aphezulu, bunikeza ukuqedwa kokhuni lwemvelo.

I-Plywood Encane Ekhethekile

Amashidi amancane kakhulu okwenza amamodeli, imisebenzi yezandla, kanye namaphrojekthi adinga ukusikwa okubucayi.

I-Plywood ye-MDF-Core

Imiphetho yokusika ebushelelezi kanye nobukhulu obuhambisanayo, ilungele ukuqedwa okupendiwe noma okufakwe i-laminate.

Yimuphi ukhuni okufanele ngiwukhethe ngokuya ngezidingo zokusika nge-laser?

| Ukusetshenziswa Kokusika Nge-Laser | Uhlobo lwePlywood olunconyiwe | Amanothi |

|---|---|---|

| Ukuqoshwa Okunemininingwane Emihle | I-Birch | Uhlamvu olubushelelezi kanye nezikhala ezincane zemiphetho eqinile |

| Ukusika Okusheshayo Okunemininingwane Ephakathi | I-Poplar | Ilula futhi kulula ukuyisika ukuze isebenze kahle |

| Ukusika Indawo Enkulu | I-MDF-Core | Ubuningi obuhambisanayo bokusika okufanayo |

| Kudingeka Ukuqeda Unqenqema Olusezingeni Eliphezulu | Ubuso obuyi-Veneer | Indawo yokuhlobisa idinga izilungiselelo eziqondile |

| Ukusika Okuncane, Okuthambile | Okukhethekile Okuncane | Incane kakhulu kumamodeli nemisebenzi yobuciko eyinkimbinkimbi |

I-Baltic Birch Plywood

Ubukhulu bePlywood

Ubukhulu be-plywood bungathinta nekhwalithi yokusikwa kwe-laser yokhuni. I-plywood ejiyile idinga amandla aphezulu e-laser ukuze isike, okungabangela ukuthi ukhuni lushise noma lushe. Kubalulekile ukukhetha amandla e-laser afanele kanye nesivinini sokusika ngokujiya kwe-plywood.

Amathiphu Okulungiselela Izinto Ezibalulekile

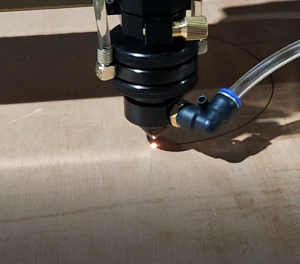

Isivinini Sokusika

Ijubane lokusika lisho ukuthi i-laser ihamba ngokushesha kangakanani phezu kwe-plywood. Ijubane lokusika eliphakeme lingandisa umkhiqizo, kodwa futhi linganciphisa ikhwalithi yokusika. Kubalulekile ukulinganisela ijubane lokusika nekhwalithi yokusika oyifunayo.

Amandla e-Laser

Amandla e-laser anquma ukuthi i-laser ingasika ngokushesha kangakanani i-plywood. Amandla aphezulu e-laser angasika i-plywood ejiyile ngokushesha kakhulu kunamandla aphansi, kodwa futhi angabangela ukuthi ukhuni lushise noma lushe. Kubalulekile ukukhetha amandla e-laser afanele ngokobukhulu be-plywood.

Ibhodi Yokusika I-Laser Die Steps2

Ibhodi Yokusika Izinkuni Ye-Laser

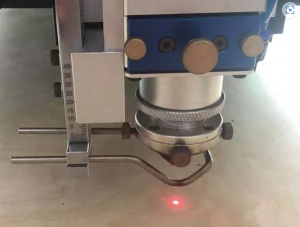

Ilensi Yokugxila

Ilensi yokugxila inquma usayizi womsebe we-laser kanye nokujula kokusikwa. Usayizi womsebe omncane uvumela ukusikwa okunembe kakhudlwana, kuyilapho usayizi womsebe omkhulu ungasika izinto ezijiyile. Kubalulekile ukukhetha ilensi yokugxila efanele ukuze ilingane nobukhulu be-plywood.

Usizo Lomoya

Usizo lomoya luvuthela umoya ku-plywood yokusika nge-laser, okusiza ukususa udoti futhi kuvimbele ukusha noma ukusha. Kubaluleke kakhulu ekusikeni i-plywood ngoba ukhuni lungakhiqiza udoti omningi ngesikhathi sokusika.

Usizo Lomoya

Isiqondiso Sokusika

Indlela imishini yokusika izinkuni nge-laser eqondisa ngayo i-plywood ingathinta ikhwalithi yokusikwa. Ukusika ngokumelene nokusanhlamvu kungabangela ukuthi ukhuni luqhekeke noma ludabuke, kanti ukusika ngokusanhlamvu kungaveza ukusika okuhlanzekile. Kubalulekile ukucabangela indlela okusanhlamvu kwezinkuni okuqondiswe ngayo lapho uklama ukusikwa.

Ukusika Izinkuni Nge-Laser Die Doard 3

Ukubuka ividiyo ye-Laser Wood Cutter

Izinto Okucatshangwa Ngazo Ngokuklama

Lapho uklama ukusika nge-laser, kubalulekile ukucabangela ubukhulu be-plywood, ukwakheka okuyinkimbinkimbi, kanye nohlobo lwejoyinti elisetshenzisiwe. Eminye imiklamo ingadinga ukwesekwa okwengeziwe noma amathebhu ukuze ibambe i-plywood endaweni yayo ngesikhathi sokusika, kanti eminye ingadinga ukucatshangelwa okukhethekile ngohlobo lwejoyinti elisetshenzisiwe.

Izinkinga Ezivamile Nokuxazulula Izinkinga

Nciphisa amandla e-laser noma wandise isivinini sokusika; faka i-masking tape ukuvikela indawo engaphezulu.

Khulisa amandla e-laser noma wehlise isivinini; qiniseka ukuthi indawo egxile kuyo isethwe kahle.

Khetha i-plywood enomswakama omncane bese uyibopha ngokuqinile embhedeni we-laser.

Sebenzisa amandla aphansi ngamaphasi amaningi, noma lungisa izilungiselelo zokusika okuhlanzekile.

Ukuze uthole i-plywood esikwe nge-laser, khetha i-birch, i-basswood, noma i-maple enobuso obubushelelezi, i-glue ene-resin ephansi, kanye nezikhala ezincane. Amashidi amancane afanela ukuqoshwa, kuyilapho amashidi amakhulu edinga amandla engeziwe.

Ekuphetheni

Ukusika nge-laser ku-plywood kungakhiqiza ukusika kwekhwalithi ephezulu ngokunemba nangesivinini. Kodwa-ke, kunezici eziningana ezibalulekile okufanele uzicabangele lapho usebenzisa ukusika nge-laser ku-plywood, okuhlanganisa uhlobo lwe-plywood, ukujiya kwezinto, isivinini sokusika kanye namandla e-laser, ilensi yokugxila, usizo lomoya, isiqondiso sokusika, kanye nokucatshangelwa komklamo. Ngokucabangela lezi zici, ungafinyelela imiphumela emihle kakhulu ngokusika nge-laser ku-plywood.

Umshini Wokusika I-Laser Wokhuni Onconyiwe

| Indawo Yokusebenza (W *L) | 80mm * 80mm (3.15'' * 3.15'') |

| Umthombo We-Laser | I-Fiber Laser |

| Amandla e-Laser | 20W |

| Indawo Yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4”) |

| Umthombo We-Laser | Ishubhu ye-CO2 Glass Laser noma ishubhu ye-CO2 RF Metal Laser |

| Amandla e-Laser | 100W/150W/300W |

| Indawo Yokusebenza (W *L) | 1300mm * 2500mm (51” * 98.4”) |

| Umthombo We-Laser | Ishubhu ye-laser yengilazi ye-CO2 |

| Amandla e-Laser | 150W/300W/450W |

Ufuna Ukutshala Imali Kumshini We-Wood Laser?

Isikhathi sokuthunyelwe: Mashi-17-2023