Kedu ihe bụ ịgbado ọkụ laser?Mgbado ọkụ laser vs arc ịgbado ọkụ?Ị nwere ike laser weld aluminum (na igwe anaghị agba nchara)?Ị na-achọ welder laser maka ọrịre nke dabara gị mma?Edemede a ga-agwa gị ihe kpatara Welder Laser Handheld ji dị mma maka ngwa dị iche iche yana ego agbakwunyere maka azụmahịa gị, yana ndepụta ihe ndekọ zuru ezu iji nyere gị aka ime mkpebi.

Ọhụrụ na ụwa nke akụrụngwa laser ma ọ bụ onye nwere akụrụngwa laser, na-enwe obi abụọ banyere ịzụrụ ma ọ bụ nkwalite gị ọzọ?Enweghị nchekasị ọzọ n'ihi na Mimowork Laser nwetara azụ gị, na afọ 20+ nke ahụmahụ laser, anyị nọ ebe a maka ajụjụ gị ma dị njikere maka ajụjụ gị.

Kedu ihe bụ Welding Laser?

Aka eriri laser welder na-eme ihe n'ụzọ nke ịgbado ọkụ.Site ndọpụ na nnukwu okpomọkụ si laser doo, na ele mmadụ anya n'ihu metal na-agbaze ma ọ bụ ọbụna vaporized, nkwonkwo ndị ọzọ metal mgbe metal jụrụ na solidifying na-etolite ịgbado ọkụ nkwonkwo.

Ị maara?

Ihe mkpuchi laser ejiri aka dị mma karịa welder Arc ọdịnala ma nke a bụ ihe kpatara ya.

N'iji ya na welder Arc ọdịnala, welder laser na-enye:

•Alaike oriri

•OpekempeMpaghara Okpomọkụ metụtara

•Obere ma ọ bụ mbaNrụrụ ihe

•Mgbanwe na mmaebe ịgbado ọkụ

•Dị ọchawelding onu namba ozonhazi mkpa

•Nke dị mkpụmkpụoge ịgbado ọkụ -2 ruo 10ugboro ngwa ngwa

• na-eji ọkụ na-amụba ìhè Ir-radianceadịghị njọ

• gburugburu ebe obibienyi enyi

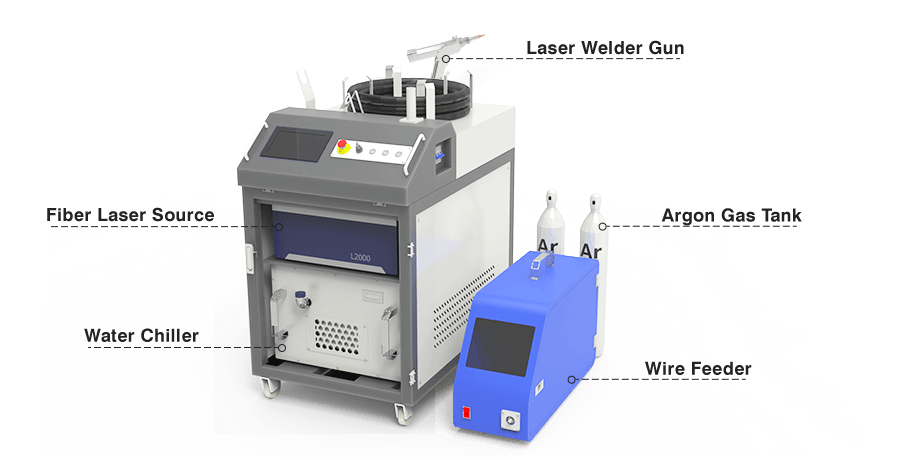

Isi njirimara nke igwe welder laser ejiri aka:

Kadị nchekwa

A na-ejikarị gas nchebe nke ịgbado ọkụ laser bụ N2, Ar, na He.Njirimara anụ ahụ na kemịkal ha dị iche, yabụ mmetụta ha na weld dịkwa iche iche.

Nnweta

A na-eji usoro ịgbado ọkụ nke ejiri aka rụọ ya na kọmpat laser welder, na-enye mma na mgbanwe na-enweghị nkwekọrịta, weld nwere ike ịrụ ọrụ ngwa ngwa yana ịrụ ọrụ ịgbado ọkụ bụ n'elu ahịrị.

Ọnụ dị irè

Dị ka ule ndị na-arụ ọrụ ubi mere, uru nke otu igwe ịgbado ọkụ laser ejiri aka ruru okpukpu abụọ nke ọnụ ahịa igwe ịgbado ọkụ ọdịnala.

Nkwekọrịta

Laser Welding Handheld dị mfe iji rụọ ọrụ, ọ nwere ike ịgbanye mpempe igwe anaghị agba nchara, mpempe akwụkwọ ígwè, mpempe akwụkwọ galvanized na ihe ọla ndị ọzọ.

Ọganihu

Ọmụmụ nke Handheld Laser Welder bụ nnukwu nkwalite teknụzụ, ọ bụkwa mmalite obi ọjọọ maka ngwọta ịgbado ọkụ laser ọdịnala dị ka ịgbado ọkụ argon arc, ịgbado ọkụ eletrik na ihe ndị ọzọ ga-eji ngwọta ịgbado ọkụ laser ọgbara ọhụrụ dochie ya.

Ngwa ndị a na-ejikarị maka ịgbado ọkụ laser - atụmatụ na ndụmọdụ:

Nke a bụ ndepụta nke ihe ndị a na-ejikarị maka ịgbado ọkụ Laser, na mgbakwunye ụfọdụ atụmatụ izugbe na njirimara nke ihe n'ụzọ zuru ezu yana ndụmọdụ ụfọdụ maka ị nweta nsonaazụ ịgbado ọkụ ka mma.

Igwe anaghị agba nchara

Ọnụ ọgụgụ mgbasawanye nke thermal nke igwe anaghị agba nchara dị elu ya mere mpempe ọrụ igwe anaghị agba nchara dị mfe ikpo ọkụ mgbe ị na-eji ngwọta ịgbado ọkụ ọdịnala, ebe okpomọkụ emetụtara dị ukwuu karịa ihe a na-emekarị ka ọ bụrụ na ọ ga-eduga ná nsogbu nrụrụ siri ike.Otú ọ dị, site n'iji igwe ịgbado ọkụ laser ejiri aka na-edozi ọtụtụ nsogbu dịka n'oge usoro ịgbado ọkụ dum, okpomọkụ a na-emepụta na-adị ala, tinyere eziokwu ahụ bụ na igwe anaghị agba nchara nwere obere okpomọkụ nke okpomọkụ, nnukwu ike absorption na agbaze arụmọrụ.Enwere ike nweta weld mara mma nke ọma ma ọ bụrụ na ịgbado ọkụ ahụ n'ụzọ dị mfe.

Carbon ígwè

A handheld laser welder nwere ike ozugbo na-eji na nkịtị carbon ígwè, n'ihi bụ tụnyere igwe anaghị agba nchara laser ịgbado ọkụ, mgbe okpomọkụ emetụtara ebe nke carbon ígwè bụ ọbụna obere, ma n'oge ịgbado ọkụ usoro, ndị fọdụrụ okpomọkụ bụ dịtụ elu, ya mere ọ. ka dị mkpa iji kpoo akụkụ ọrụ tupu ịgbado ọkụ na-esonyere ya na nchekwa ọkụ mgbe ịgbado ọkụ ga-ewepụ nchekasị iji zere mgbawa.

Aluminom na aluminom Alloys

Aluminom na aluminom alloy bụ ihe na-egosipụta nke ọma, na enwere ike inwe nsogbu porosity na ebe ịgbado ọkụ ma ọ bụ mgbọrọgwụ nke mpempe ọrụ.Tụnyere na gara aga ọtụtụ metal ihe, aluminum na aluminum alloy ga-enwe elu chọrọ maka parameters ntọala nke akụrụngwa, ma ọ bụrụhaala na ahọrọ ịgbado ọkụ parameters kwesịrị ekwesị, ị nwere ike nweta a weld na n'ibu Njirimara nke isi metal Ẹkot.

Ọla kọpa na ọla kọpa Alloys

Ọtụtụ mgbe, mgbe ị na-eji ngwọta ịgbado ọkụ ọdịnala, ihe ọla kọpa ga-ekpo ọkụ n'ime usoro ịgbado ọkụ iji nyere aka ịgbado ọkụ n'ihi ịdị elu thermal conductivity nke ihe ahụ, n'ihi ya, àgwà dị otú ahụ nwere ike ịkpata ịgbado ọkụ na-ezughị ezu, akụkụ na-abụghị ngwakọta na nsonaazụ ndị ọzọ na-achọghị n'oge ịgbado ọkụ.N'ụzọ megidere nke ahụ, enwere ike iji welder laser ejiri aka mee ihe maka ịgbado ọla kọpa na ọla kọpa na-enweghị nsogbu n'ihi ikike itinye uche dị ukwuu na ọsọ ịgbado ọkụ nke laser welder.

Die Steel

Enwere ike iji igwe ịgbado ọkụ laser ejiri aka mee maka ịgbado ụdị dị iche iche nke nchara anwụ anwụ, mmetụta ịgbado ọkụ na-ezute mgbe niile na-eju afọ.

Anyị na-atụ aro Welder Laser:

Welder Laser - gburugburu na-arụ ọrụ

◾ Okpomọkụ dị nso nke ebe ọrụ: 15 ~ 35 ℃

◾ Iru mmiri dị nso nke gburugburu ebe ọrụ: <70% Enweghị condensation

◾ Ntu oyi: mmiri na-ekpo ọkụ dị mkpa n'ihi ọrụ nke ikpo ọkụ ọkụ maka ihe ndị na-ekpochapụ ọkụ laser, na-eme ka welder laser na-agba ọsọ nke ọma.

(Ojiji zuru ezu na ntuziaka gbasara chiller mmiri, ị nwere ike ịlele:Usoro ihe nkpuchi ikuku maka sistemụ laser CO2)

Ị chọrọ ịmatakwu banyere Laser Welders?

Oge nzipu: Dec-09-2022