Yintoni i-laser welding?Ukuwelda kweLaser vs arc welding?Ngaba ungayenza i-laser weld aluminiyam (kunye nentsimbi engatyiwayo)?Ngaba ujonge i-laser welder ethengiswayo efanele wena?Eli nqaku liza kukuxelela ukuba kutheni i-Handheld Laser Welder ingcono kwizicelo ezahlukeneyo kunye nebhonasi yayo eyongeziweyo kwishishini lakho, kunye noluhlu oluneenkcukacha lwezixhobo zokukunceda ekwenzeni izigqibo.

Umtsha kwihlabathi lezixhobo zelaser okanye umsebenzisi osele enamava koomatshini belaser, ungathandabuzi malunga nokuthenga kwakho okulandelayo okanye uphuculo?Awusayi kuba nexhala kuba iMimowork Laser ifumene umqolo wakho, kunye ne-20+ yeminyaka yamava e-laser, silapha ngemibuzo yakho kwaye silungele imibuzo yakho.

Yintoni iLaser Welding?

I-fiber laser welder ephathwayo ephathwayo kwizinto eziphathekayo ngendlela yokudibanisa ukuwelda.Ngobushushu obugxininisiweyo kunye nobukhulu obusuka kumqadi welaser, inxenye yesinyithi iyanyibilika okanye ide ibe ngumphunga, idityaniswe enye isinyithi emva kokupholisa kwentsimbi kunye nokuqina ukwenza idibaniso yokuwelda.

Ubusazi?

I-laser welder ephathwa ngesandla ingcono kune-Arc welder yemveli kwaye nantsi isizathu.

Xa kuthelekiswa ne-arc welder yemveli, i-laser welder ibonelela:

•Ngasezantsiukusetyenziswa kwamandla

•UbuncinaneUbushushu beNdawo echaphazelekayo

•Ngokucacileyo okanye hayiUkuguqulwa kwezinto

•Iyalungiswa kwaye ilungileindawo yokuwelda

•Cocawelding edge ngeakukho okunyeukusetyenzwa okufunekayo

•Mfutshaneixesha welding -2 ukuya kwi-10amaxesha ngokukhawuleza

• Ikhupha ukukhanya kwe-Ir-radiance ngeakukho bungozi

• Ngokusingqongileyoubuhlobo

Iimpawu eziphambili zomatshini we-laser welder ophathwa ngesandla:

Ikhuselekile

Iigesi ezisetyenziswa ngokuqhelekileyo zokukhusela i-laser welding ikakhulu i-N2, i-Ar, kunye ne-He.Iimpawu zabo zomzimba kunye neekhemikhali zahlukile, ngoko ke iziphumo zazo kwi-welds nazo zahlukile.

Ukufikeleleka

Inkqubo ye-welding ye-handheld ixhotywe nge-laser welder compact, ibonelela ngokulula kunye nokuguquguquka ngaphandle kokuphazamiseka, i-weld inokwenziwa lula kwaye ukusebenza kwe-welding kuphezulu kumgca.

Isebenza kakuhle emalini

Ngokweemvavanyo ezenziwa ngabaqhubi bentsimi, ixabiso lomatshini omnye we-laser welding welding ulingana namaxesha amabini eendleko zomqhubi we-welding yendabuko.

Ukuguquguquka

I-Laser Welding Handheld ilula ukusebenza, inokuwelda ngokulula ishidi lensimbi engenasici, ishidi lentsimbi, iphepha elenziwe ngesinyithi kunye nezinye izinto zetsimbi.

Ukuqhubela phambili

Ukuzalwa kwe-Handheld Laser Welder luphuculo olukhulu lwetekhnoloji, kwaye sisiqalo esikhohlakeleyo sezisombululo ze-laser welding ezifana ne-argon arc welding, i-welding yombane kunye nokunye ukuze kuthathwe indawo yezisombululo ze-laser welding.

Izinto ezisetyenziswa ngokuqhelekileyo kwi-Laser Welding - Iimpawu kunye neeNgcebiso:

Olu luhlu lwezixhobo eziqhele ukusetyenziswa kwi-Laser Welding, kwezongezelelweyo ezinye iimpawu eziqhelekileyo kunye neempawu zemathiriyeli ngokweenkcukacha kunye neengcebiso ezithile zokufezekisa iziphumo ezingcono zokuwelda.

Yenziwe ngentsimbi eshayinayo

I-coefficient yokwandisa i-thermal yensimbi engenasici iphezulu ngoko ke i-stainless-steel workpiece ilula ukugqithiswa xa i-welding kunye nezisombululo ze-welding zendabuko, indawo echaphazelekayo yokushisa inkulu kunesiqhelo kunye nale nto iya kukhokelela kwiingxaki ezinzulu ze-deformation.Nangona kunjalo, ngokusebenzisa umatshini wokuwelda we-laser ophathwa ngesandla usombulula iingxaki ezininzi njengoko ngexesha lonke lenkqubo ye-welding ubushushu obuveliswayo buphantsi, kunye nenyaniso yokuba insimbi engenasici ine-conductivity ephantsi ye-thermal, ukufunxa amandla aphezulu kunye nokusebenza kakuhle kokunyibilika.I-weld eyenziwe kakuhle, i-weld egudileyo inokufumaneka emva kwe-welding ngokulula.

Intsimbi yeCarbon

I-laser welder ephathwa ngesandla ingasetyenziswa ngokuthe ngqo kwintsimbi eqhelekileyo yekhabhoni, umphumo uthelekiseka nentsimbi yensimbi engenasici, ngelixa indawo echaphazelekayo yobushushu bentsimbi yekhabhoni incinci nangakumbi, kodwa ngexesha lenkqubo yokuwelda, ubushushu obushiyekileyo buphezulu kakhulu, ngoko ke. kusekho imfuneko yokutshisa icwecwe lomsebenzi phambi kokuba ukuwelda kukhatshwe kunye nokugcinwa kobushushu emva kwe-welding ukuphelisa uxinzelelo ukuphepha iintanda.

I-Aluminiyam kunye ne-Aluminiyam i-alloys

I-aluminium kunye ne-aluminium alloy zizinto ezibonisa kakhulu, kwaye kunokubakho iingxaki ze-porosity kwindawo ye-welding okanye ingcambu yomsebenzi.Xa kuthelekiswa nezixhobo ezininzi zetsimbi zangaphambili, i-aluminium kunye ne-aluminium ingxubevange iya kuba neemfuneko eziphezulu zokuseta iiparamitha zesixhobo, kodwa nje ukuba iiparitha ezikhethiweyo ze-welding zifanelekile, unokufumana i-weld kunye neempawu zomatshini zesiseko sesinyithi esilinganayo.

Iingxube zeCopper kunye neCopper

Ngokuqhelekileyo, xa usebenzisa isisombululo se-welding yendabuko, izinto zobhedu ziya kutshiswa kwinkqubo ye-welding ukuncedisa i-welding ngenxa ye-conductivity ephezulu ye-thermal yezinto eziphathekayo, loo nto ingabangela ukuba i-welding ingaphelelanga, i-partial non-fusion kunye nezinye iziphumo ezingathandekiyo ngexesha lokudibanisa.Ngokuchasene noko, i-laser ebambe ngesandla inokusetyenziswa ngokuthe ngqo kwi-welding yobhedu kunye ne-alloys yobhedu ngaphandle kweengxaki ngenxa yamandla okuxininisa okugqithisileyo kunye nesantya esikhawulezayo se-welding ye-laser welder.

Die Steel

Umatshini we-laser welding obambe ngesandla ungasetyenziselwa ukudibanisa iintlobo ezahlukeneyo zentsimbi yokufa, kwaye umphumo we-welding uhlala udibana ngokwanelisayo.

Isityebi seLaser esicetyiswayo esixhaswe ngesandla:

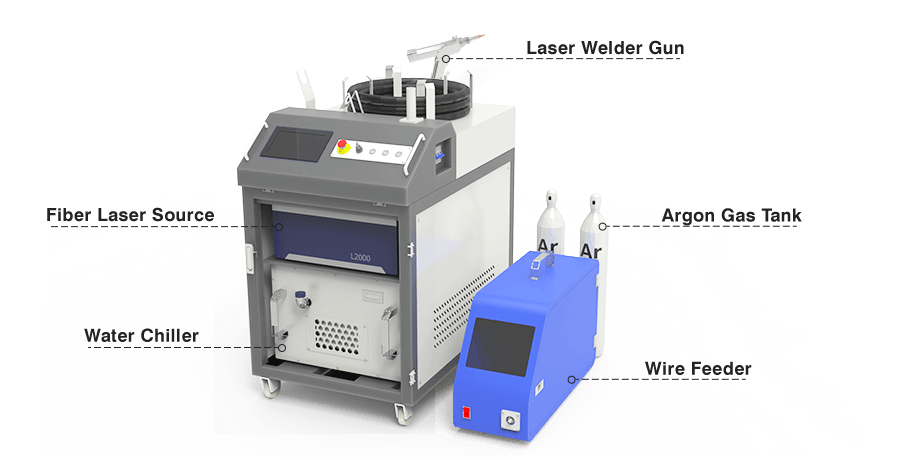

I-Laser Welder-iNdawo yokuSebenza

◾ Uluhlu lobushushu lwendawo yokusebenza: 15 ~ 35 ℃

◾ Uluhlu lokufuma lwemeko-bume yokusebenza: < 70% Akukho ukujiya

◾ Ukupholisa: i-chiller yamanzi iyimfuneko ngenxa yomsebenzi wokususa ubushushu kwi-laser-dissipating components, ukuqinisekisa ukuba i-laser welder isebenza kakuhle.

(Usetyenziso oluneenkcukacha kunye nesikhokelo malunga ne-chiller yamanzi, ungajonga:Amanyathelo okungqina umkhenkce kwiNkqubo yeLaser yeCO2)

Ngaba ufuna ukwazi ngakumbi malunga neLaser Welders?

Ixesha lokuposa: Dec-09-2022