Talooyin iyo Farsamooyin Toosinta Dharka ee Jarida Saxda ah

Wax kasta oo aad rabto oo ku saabsan dharka lasercutter

Toosinta dharka ka hor inta aan la jarin waa tallaabo muhiim ah oo ku saabsan habka wax soo saarka dharka. Dharka aan si habboon loo toosin wuxuu keeni karaa jaritaan aan sinnayn, walxo la khasaariyay, iyo dharka si liidata loo dhisay. Maqaalkan, waxaan ku sahamin doonnaa farsamooyinka iyo talooyinka lagu toosinayo dharka, iyadoo la hubinayo jarista laysarka saxda ah oo hufan.

Tallaabada 1: Dhaqidda Kahor

Kahor intaadan toosin dharkaaga, waa muhiim inaad hore u dhaqdo. Dharku wuu yaraan karaa ama wuu qalloocan karaa inta lagu jiro habka dhaqidda, sidaa darteed dhaqidda kahor waxay ka hortagi doontaa wax kasta oo aan loo baahnayn oo la yaab leh ka dib marka dharka la dhiso. Dhaqidda kahor waxay sidoo kale ka saari doontaa cabbir kasta ama dhammaystir kasta oo ku yaal dharka, taasoo sahlaysa in lala shaqeeyo.

Tallaabada 2: Isku-dubaridka Cidhifyada Selvage

Cidhifyada dharka ee laalaaban karo waa cidhifyada la dhammeeyay ee la siman dhererka dharka. Badanaa si adag ayay uga tolan yihiin dharka intiisa kale mana fidsana. Si aad u toosiso dharka, isku toosi cidhifyada dharka adigoo dharka ku laalaabanaya nus dherer ahaan, adigoo isku dhejinaya cidhifyada dharka. Simi laalaab kasta ama laablaab kasta.

Tallaabada 3: Kor u Qaadista Dhammaadka

Marka geesaha selvage-ka la isku dhejiyo, laba jibbaar dhinacyada dharka. Si aad tan u sameyso, dharka u laab si kala bar ah, adigoo isku dhejinaya geesaha selvage-ka. Simi laalaab kasta ama laablaab kasta. Kadib, jar cidhifyada dharka, adigoo abuuraya cidhif toosan oo ku toosan cidhifyada selvage-ka.

Tallaabada 4: Hubinta Toosnaanta

Ka dib markaad geesaha isku laabto, hubi in dharku toosan yahay adigoo mar kale labanlaabay dherer ahaan. Labada gees ee geesaha waa inay si fiican isugu ekaadaan, mana jiraan wax laalaab ama laalaab ah oo ku jira dharka. Haddii dharku aanu toosnayn, hagaaji ilaa uu ka noqdo.

Tallaabada 5: Kaawinta

Marka dharka la toosiyo, ku bir si aad uga saarto laalaabyada ama laablaabyada haray. Kaawintu waxay sidoo kale kaa caawin doontaa inaad dharka ku dejiso xaaladdiisa toosan, taasoo sahlaysa in lala shaqeeyo inta lagu jiro habka jarista. Hubi inaad isticmaasho habka kulaylka ee ku habboon nooca dharka aad la shaqaynayso.

Tallaabada 6: Jaritaanka

Ka dib marka aad toosiso oo aad kaawiso dharka, waa diyaar in la jaro. Isticmaal qalab laysar ah oo dharka lagu jaro si aad u jarto dharka sida waafaqsan qaabkaaga. Hubi inaad isticmaasho gogosha jarista si aad u ilaaliso dusha sare ee shaqadaada oo aad u hubiso jarista saxda ah.

Talooyin ku saabsan Toosinta Dharka

Isticmaal dusha sare oo ballaaran oo siman si aad u toosiso dharkaaga, sida miiska jarista ama looxa kaawinta.

Hubi in qalabkaaga jarista uu fiiqan yahay si loo hubiyo jarista nadiifka ah oo sax ah.

Isticmaal gees toosan, sida mastarad ama barkin, si aad u hubiso in si toos ah loo jaray.

Isticmaal miisaanno, sida miisaannada qaabka ama qasacadaha, si aad dharka ugu hayso meesha uu ku yaalo inta aad jarayso.

Hubso inaad xisaabiso xariiqda midhaha ee dharka marka aad jarayso. Xariiqda midhaha waxay la socotaa geesaha selvage-ka waana inay la jaanqaado qaabka ama naqshadda dharka.

Gunaanad

Toosinta dharka ka hor inta aan la jarin waa tallaabo muhiim ah oo ku saabsan habka wax soo saarka dharka. Adigoo horay u dhaqaya, isku hagaajinaya geesaha selvage-ka, kor u qaadaya darafyada, hubinaya toosanaanta, kaawiyaya, iyo jarista, waxaad hubin kartaa jarista saxda ah oo hufan. Iyada oo la adeegsanayo farsamooyinka iyo qalabka saxda ah, waxaad ku gaari kartaa jarista saxda ah oo aad dhisi kartaa dharka ku habboon oo u muuqda mid aad u fiican. Xusuusnow inaad qaadato waqtigaaga oo aad samir yeelato, maadaama toosinta dharka ay noqon karto geedi socod waqti badan qaata, laakiin natiijada kama dambaysta ah waxay u qalantaa dadaalka.

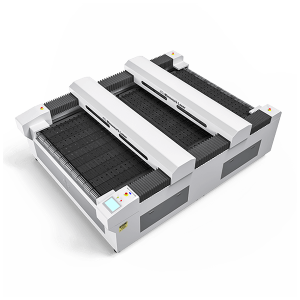

Bandhigga Muuqaalka | Muuqaalka Jarida Laser-ka Dharka

Maqaarka laser-ka dharka lagu taliyay

Su'aalaha Badiya La Weydiiyo

Toosinta saxda ah ee dharka waxay hubineysaa jarista laysarka oo sax ah oo joogto ah. Waa tan sababta:

Waxay ka fogaataa qallooca:Dharka aan la sixin (xariijimaha la qalloociyey) wuxuu sababaa in qaababka laysarka lagu jaro ay qalloocaan, taasoo burburisa isku dheelitirka - muhiim u ah dharka.

Waxay Kordhisaa Waxtarka:Dhar toosan ayaa si siman u fidsan, taasoo u oggolaanaysa jarista laysarka (sida MimoWork's) inay si sax ah u raacaan qaababka, taasoo yaraynaysa qashinka agabka.

Hubinta Goynta Nadiifka ah:Laalaab ama laablaab dharka aan toosnayn waxay qaban karaan kulaylka laysarka, taasoo horseedi karta cidhifyo guban ama xariiqyo aan sinnayn.

Dhaqidda kahor waa furaha jarista laysarka ee joogtada ah. Waa kan doorkeeda:

Joojinta Qandhada:Dharka aan la dhaqin ayaa laga yaabaa inuu libdho ka dib marka la jaro, taasoo leexata qaababka laysarka lagu jaro - taasoo muhiim u ah waxyaabaha ku habboon sida dharka ciyaaraha.

Waxay ka saartaa kiimikooyinka:Cabbirka dharka cusub wuxuu dhalaali karaa marka la kululeeyo laysarka, taasoo haraaga ka dhigaysa kuwa wax jabiya (sida MimoWork's) ama dharka.

Waxay jilcisaa Faybarrada:Waxay ka dhigtaa dharka mid siman, waxay hagaajisaa diiradda laysarka iyo jarista saxnaanta.

Qalab gaar ah ayaa xoojiya toosinta dharka, iyagoo si fiican ula jaanqaadaya gooyayaasha laysarka. Waa kan waxa shaqeeya:

Dusha sare ee Fidsan ee Weyn:Miisaska jarista (cabbirrada sariirta ee laysarka ee MimoWork) u daa dharka inuu si siman u jiifo, taasoo fududaynaysa isku-xidhka.

Miisaanka Qaabka:Dharka ku hay meesha, si looga hortago isbeddellada carqaladeeya waddooyinka laysarka.

Cidhifyada Toosan/Xakameeyayaasha:Hubi in khadadka hadhuudhku ay la jaanqaadaan tilmaamaha jarista laysarka, kuwaas oo muhiim u ah jarista qaababka joogtada ah.

Birta leh Kulayl Gaar ah oo Dhar ah:Waxay dejisaa dhar toosan, iyadoo ilaalinaysa fidsanaan inta lagu jiro farsamaynta laysarka.

Ma haysaa wax su'aalo ah oo ku saabsan shaqada Mashiinka Gooya Laser-ka ee Dharka?

Waqtiga boostada: Abriil-13-2023