Ke Eng e Etsang Hore ho Seha Laser ho Phethahetse Lesela la PCM?

Theknoloji ea lesela la laser e fana ka ho nepahala ho ikhethang le ho qeta ho hloekileng, ho etsa hore e lumellane hantle le lesela la pcm, le hlokang boleng bo tsitsitseng le taolo ea mocheso. Ka ho kopanya ho nepahala ha laser ho itšeha le thepa e tsoetseng pele ea lesela la pcm, bahlahisi ba ka fihlela ts'ebetso e phahameng ka masela a bohlale, lisebelisoa tse sireletsang, le lits'ebetso tse laolang mocheso.

▶ Kenyelletso ea Motheo ea Lesela la PCM

Lesela la PCM

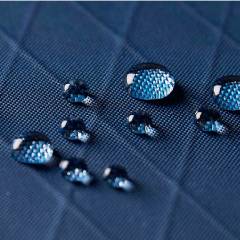

Lesela la PCM, kapa lesela la Phase Change Material, ke lesela le sebetsang hantle haholo le etselitsoeng ho laola mocheso ka ho monya, ho boloka le ho lokolla mocheso. E kopanya lisebelisoa tsa phetoho ea mokhahlelo ka har'a sebopeho sa lesela, se fetohang lipakeng tsa maemo a tiileng le a metsi ka mocheso o itseng.

Sena se lumellaLesela la PCMho boloka mmele o phodile ka ho etsa hore mmele o phole ha ho chesa le ho futhumala ha ho bata. Lesela la PCM le atisang ho sebelisoa lipapaling, liaparo tsa ka ntle le liaparo tse sireletsang, le fana ka matšeliso a ntlafetseng le matla a matla libakeng tse matla.

▶ Tlhahlobo ea Thepa ea Thepa ea PCM Fabric

Lesela la PCM le na le taolo e ntle ea mocheso ka ho monya le ho lokolla mocheso ka liphetoho tsa mekhahlelo. E fana ka phefumoloho, nako e telele, le taolo ea mongobo, e etsa hore e be e loketseng bakeng sa masela a bohlale le lits'ebetso tse baballang mocheso.

Mofuta oa Fiber & Mefuta

Lesela la PCM le ka etsoa ka ho kenya lisebelisoa tsa phetoho ea mokhahlelo ho kapa mefuteng e fapaneng ea fiber. Mefuta e tloaelehileng ea fiber e kenyelletsa:

Polyester:E tšoarella ebile e bobebe, hangata e sebelisoa e le lesela la motheo.

K'hothone:E bonolo ebile e phefumoloha, e loketse ho apara letsatsi le leng le le leng.

Nylon: E matla le elastic, e sebelisoang ka masela a ts'ebetso.

Li-Fibers tse kopantsoeng: E kopanya likhoele tsa tlhaho le tsa maiketsetso ho leka-lekanya boiketlo le ts'ebetso.

Thepa ea Mechini le Ts'ebetso

| Thepa | Tlhaloso |

|---|---|

| Matla a tšepe | E tšoarella, e hanela ho otlolla le ho taboha |

| Ho tenyetseha | E bonolo ebile e tenyetseha bakeng sa ho apara hamonate |

| Karabelo ea Mocheso | E monya/e lokolla mocheso ho laola mocheso |

| Hlatsoa Durability | E boloka ts'ebetso ka mor'a ho hlatsoa hangata |

| Matšeliso | E phefumolohang ebile e senya mongobo |

Melemo & Mefokolo

| Melemo | Mefokolo |

|---|---|

| Taolo e ntle ea mocheso | Theko e phahameng ha e bapisoa le masela a tloaelehileng |

| E ntlafatsa boiketlo ba bareki | Ts'ebetso e ka 'na ea fokotseha ka mor'a ho hlatsoa hangata |

| E boloka ho phefumoloha le ho feto-fetoha ha maemo | Mocheso o fokolang oa phetoho ea mohato |

| E tšoarella tlas'a potoloho ea mocheso o pheta-phetoang | Ho kopanya ho ka ama lesela la lesela |

| E loketse lits'ebetso tse fapaneng | E hloka mokhoa o khethehileng oa tlhahiso |

Sebopeho sa Sebopeho

Lesela la PCM le kopanya lisebelisoa tsa phetoho ea karolo ea microencapsulated kahare kapa holim'a likhoele tsa masela joalo ka polyester kapa k'hothone. E boloka ho phefumoloha le ho feto-fetoha ha maemo ha e ntse e fana ka taolo e sebetsang ea mocheso le nako e telele ka mekhahlelo e mengata ea mocheso.

▶ Lisebelisoa tsa PCM Fabric

Liaparo tsa lipapali

E boloka baatlelete ba pholile kapa ba futhumetse ho latela mosebetsi le tikoloho.

Lisebelisoa tsa Kantle

E laola mocheso oa 'mele ka lijase, mekotla ea ho robala le liatlana.

Liaparo tsa Bongaka

E thusa ho boloka mocheso oa 'mele oa mokuli nakong ea ho hlaphoheloa.

Liaparo tsa Sesole le Maqheka

E fana ka tekanyo ea mocheso maemong a leholimo a feteletseng.

Libethe le Liaparo tsa Lehae

E sebelisoa ka materase, mesamo, le likobo bakeng sa boiketlo ba boroko.

Smart and Wearable Tech

E kopantsoe le liaparo bakeng sa taolo ea mocheso e arabelang.

▶ Ho ipapisa le Lithapo Tse Ling

| Karolo | Lesela la PCM | K'hothone | Polyester | Boea |

|---|---|---|---|---|

| Molao oa Mocheso | E ntle (ka phetoho ea mohato) | Tlase | E itekanetseng | E ntle (insulation ea tlhaho) |

| Matšeliso | Holimo (ho ikamahanya le mocheso) | E bonolo ebile e phefumoloha | Ho hema hanyane | Mofuthu le bonolo |

| Taolo ea Mongobo | E ntle (ka lesela la motheo le phefumolohang) | E monya mongobo | Wicks mongobo | E monya empa e boloka mongobo |

| Ho tšoarella | E phahameng (ka kopanyo ea boleng) | E itekanetseng | Phahameng | E itekanetseng |

| Hlatsoa Ho hanyetsa | E mahareng ho isa hodimo | Phahameng | Phahameng | E itekanetseng |

| Litšenyehelo | E phahameng (ka lebaka la theknoloji ea PCM) | Tlase | Tlase | Mahareng ho isa holimo |

▶ Mochini oa Laser o khothalelitsoeng bakeng sa PCM

•Matla a Laser:100W/150W/300W

•Sebaka sa Mosebetsi:1600mm * 1000mm

•Matla a Laser:150W/300W/500W

•Sebaka sa Mosebetsi:1600mm * 3000mm

Re Tailor Customized Laser Solutions for Production

Litlhoko tsa hau = Litlhaloso tsa rona

▶ Mehato ea ho Seha Laser ea PCM

Mohato oa Pele

Tlhophiso

Beha lesela la PCM fatše holim'a bethe ea laser, ho etsa bonnete ba hore e hloekile ebile ha e sosobane.

Fetola matla a laser, lebelo, le maqhubu ho latela botenya le mofuta oa lesela.

Mohato oa Bobeli

Ho poma

Etsa tlhahlobo e nyane ho lekola boleng bo holimo le ho netefatsa hore li-PCM ha li lutle kapa ha li senyehe.

Etsa bonnete ba hore ho na le moea o nepahetseng ho tlosa mosi kapa likaroloana.

Mohato oa Boraro

Qetella

Sheba mahlakore a hloekileng le li-capsules tsa PCM tse tsitsitseng; tlosa masalla kapa likhoele ha ho hlokahala.

Vedio e amanang:

Tataiso ea Matla a Molemo ka ho Fetisisa a Laser bakeng sa ho Seha Masela

Videong ena, re ka bona hore masela a fapaneng a ho itšeha ka laser a hloka matla a fapaneng a ho itšeha ka laser mme o ithute ho khetha matla a laser bakeng sa lisebelisoa tsa hau ho fihlela maqeba a hloekileng le ho qoba matšoao a ho chesa.

Ithute Boitsebiso bo eketsehileng ka Laser Cutters & Options

▶ Lipotso tsa PCM Fabric

A PCM(Phase Change Material) ho masela e bolela ntho e kopantsoeng le lesela le monyang, ho boloka, le ho ntša mocheso ha o ntse o fetoha-hangata ho tloha ho tiileng ho ea ho metsi le ka tsela e fapaneng. Sena se lumella textile ho laola mocheso ka ho boloka microclimate e tsitsitseng haufi le letlalo.

Li-PCM hangata li na le li-microencapsulated 'me li kenngoa ka har'a likhoele, liaparo kapa masela. Ha mocheso o phahama, PCM e nka mocheso o feteletseng (ho qhibiliha); ha e pholile, thepa e tiisa le ho lokolla mocheso o bolokiloeng-ho fana kaboiketlo bo matla ba mocheso.

PCM ke thepa ea boleng bo phahameng e sebetsang e tsejoang ka taolo ea eona e ntle ea mocheso, e fanang ka matšeliso a tsoelang pele ka ho monya le ho lokolla mocheso. E tšoarella nako e telele, e boloka matla, 'me e sebelisoa haholo libakeng tse shebaneng le ts'ebetso joalo ka liaparo tsa lipapali, lisebelisoa tsa kantle, tsa bongaka le tsa sesole.

Leha ho le joalo, masela a PCM a batla a theko e boima, 'me liphetolelo tsa boleng bo tlaase li ka' na tsa senyeha ka mor'a ho hlatsoa khafetsa. Ka hona, ho bohlokoa ho khetha lihlahisoa tsa PCM tse kentsoeng hantle le tse entsoeng hantle.

Eseng haeba li-setting tsa laser li ntlafalitsoe. Ho sebelisa matla a tlaase ho isa ho a itekanetseng ka lebelo le phahameng ho fokotsa mocheso oa mocheso, ho thusa ho sireletsa botšepehi ba li-microcapsules tsa PCM nakong ea ho itšeha.

Ho itšeha ka laser ho fana ka likarolo tse hloekileng, tse tiisitsoeng ka ho nepahala ho phahameng, ho fokotsa litšila tsa lesela, le ho qoba khatello ea mochine e ka senyang likarolo tsa PCM-e etsa hore e be e loketseng bakeng sa masela a sebetsang.

E sebelisoa ka liaparo tsa lipapali, liaparo tsa ka ntle, libethe le masela a bongaka-sehlahisoa leha e le sefe moo sebopeho se nepahetseng le taolo ea mocheso li leng bohlokoa.