Yintoni eyenza ukusika kweLaser kugqibelele kwilaphu lePCM?

Itekhnoloji yelaphu yokusikwa kweLaser ibonelela ngokuchaneka okungaqhelekanga kunye nokugqitywa okucocekileyo, kuyenza ifanelane ngokugqibeleleyo ilaphu le-pcm, elifuna umgangatho ongaguqukiyo kunye nolawulo lobushushu. Ngokudibanisa ukuchaneka kokusika kwe-laser kunye neempawu eziphambili zelaphu le-pcm, abavelisi banokufikelela ekusebenzeni okuphezulu kwiingubo ezilumkileyo, izixhobo zokukhusela, kunye nezicelo zokulawula ubushushu.

▶ Intshayelelo esisiseko yelaphu lePCM

Ilaphu lePCM

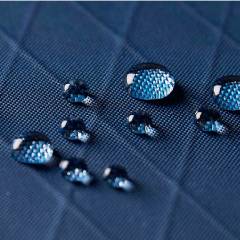

ilaphu lePCM, okanye ilaphu leMpahla yoTshintsho lweSigaba, lilaphu elisebenza ngokuphezulu elenzelwe ukulawula ubushushu ngokufunxa, ukugcina, nokukhulula ubushushu. Idibanisa izixhobo zokutshintsha kwesigaba kwisakhiwo selaphu, esitshintsha phakathi kwamazwe aqinileyo kunye nolwelo kumaqondo obushushu athile.

Oku kuvumelailaphu lePCMukugcina intuthuzelo yobushushu ngokugcina umzimba upholile xa kushushu kwaye kushushu xa kubanda. Idla ngokusetyenziswa kwimpahla yezemidlalo, izixhobo zangaphandle, kunye nempahla ekhuselayo, ilaphu lePCM libonelela ngentuthuzelo eyongeziweyo kunye nokusebenza kakuhle kwamandla kwiindawo eziguqukayo.

▶ Uhlalutyo lweePropati zeMathiriyeli kwilaphu lePCM

Ilaphu le-PCM libonisa ulawulo olubalaseleyo lobushushu ngokufunxa kunye nokukhulula ubushushu ngotshintsho lwesigaba. Inika ukuphefumla, ukuqina, kunye nolawulo lokufuma, iyenza ilungele amalaphu alumkileyo kunye nezicelo ezingevani nobushushu.

Ukuqulunqwa kweFayibha & Iintlobo

Ilaphu le-PCM linokwenziwa ngokufakela imathiriyeli yokutshintsha isigaba kwiintlobo ezahlukeneyo zefiber. Iintlobo zefiber eziqhelekileyo ziquka:

Ipolyester:Yomelele kwaye ilula, ihlala isetyenziswa njengelaphu lesiseko.

Umqhaphu:Ithambile kwaye iyaphefumla, ifanelekile ukunxiba kwansuku zonke.

Inayiloni: Inamandla kunye ne-elastic, isetyenziswe kwiingubo zokusebenza.

IiFayibha ezixutywe: Idibanisa imicu yendalo kunye neyokwenziwa ukulungelelanisa intuthuzelo kunye nokusebenza.

IiPropati zoomatshini kunye nokuSebenza

| Ipropati | Inkcazo |

|---|---|

| Tensile strength | Ihlala ixesha elide, ixhathisa ukolula kunye nokukrazula |

| Ukuba bhetyebhetye | Ithambile kwaye ibhetyebhetye ukunxiba kakuhle |

| Ukuphendula kweThermal | Ifunxa/ikhupha ubushushu ukulawula ubushushu |

| Hlamba Ukuqina | Igcina ukusebenza emva kokuhlamba okuninzi |

| Intuthuzelo | Ukuphefumla kunye nokukhupha umswakama |

Izinto eziluncedo kunye nemida

| Iingenelo | Ukulinganiselwa |

|---|---|

| Ummiselo obalaseleyo we-thermal | Iindleko eziphezulu xa kuthelekiswa neendwangu eziqhelekileyo |

| Yandisa intuthuzelo yabathengi | Ukusebenza kunokwehla emva kokuhlamba okuninzi |

| Igcina ukuphefumla kunye nokuguquguquka | Uluhlu lobushushu obuncinci bokutshintsha kwesigaba |

| Ihlala ixesha elide phantsi kwemijikelo ye-thermal ephindaphindiweyo | Ukudibanisa kunokuchaphazela ukuthungwa kwelaphu |

| Ifanelekile kwizicelo ezahlukeneyo | Ifuna inkqubo yokuvelisa ekhethekileyo |

Iimpawu zoLwakhiwo

Ilaphu le-PCM lidibanisa imathiriyeli yokutshintsha kwesigaba se-microencapsulated ngaphakathi okanye kwiintsinga ezilukiweyo ezifana nepolyester okanye umqhaphu. Igcina ukuphefumla kunye nokuguquguquka ngelixa ibonelela ngolawulo olusebenzayo lwe-thermal kunye nokuqina ngemijikelezo emininzi yobushushu.

▶ Ukusetyenziswa kwelaphu lePCM

Isinxibo sezemidlalo

Igcina iimbaleki zipholile okanye zifudumele ngokusekelwe kumsebenzi kunye nokusingqongileyo.

Isixhobo sangaphandle

Ilawula ubushushu bomzimba kwiibhatyi, iingxowa zokulala, kunye neeglavu.

Iimpahla zoNyango

Inceda ukugcina ubushushu bomzimba wesigulane ngexesha lokubuyisela.

Isinxibo saseMkhosini kunye nasoBuchule

Inika ibhalansi ye-thermal kwimozulu enzima.

Iimpahla zokulala kunye nezaseKhaya

Isetyenziswa kumatrasi, imiqamelo, kunye neengubo zokulala.

Ubuchwephesha obukrelekrele nobunxitywayo

Idityaniswe kwiingubo zolawulo oluphendulayo lwe-thermal.

▶ Ukuthelekisa nezinye iiFibers

| Umba | Ilaphu lePCM | Umqhaphu | Ipolyester | Uboya |

|---|---|---|---|---|

| Ulawulo lweThermal | Kugqwesileyo (ngokutshintsha kwesigaba) | Phantsi | Phakathi | Ilungile (i-insulation yendalo) |

| Intuthuzelo | Phezulu (iqondo lobushushu-liyaqhelanisa) | Ithambile kwaye iyaphefumla | Ukuphefumla kancinci | Ishushu kwaye ithambile |

| Ulawulo lokufuma | Ilungile (ngelaphu lesiseko eliphefumlayo) | Ifunxa ukufuma | Wicks ukufuma | Iyafunxa kodwa igcine ukufuma |

| Ukuqina | Phezulu (ngokudityaniswa komgangatho) | Phakathi | Phezulu | Phakathi |

| Hlamba Ukumelana | Phakathi ukuya phezulu | Phezulu | Phezulu | Phakathi |

| Iindleko | Phezulu (ngenxa yetekhnoloji yePCM) | Phantsi | Phantsi | Phakathi ukuya phezulu |

▶ Umatshini weLaser ocetyiswayo wePCM

•Amandla eLaser:100W/150W/300W

•Indawo yokusebenzela:1600mm * 1000mm

•Amandla eLaser:150W/300W/500W

•Indawo yokusebenzela:1600mm * 3000mm

Silungisa izisombululo zeLaser ezenzelwe iMveliso

Iimfuno zakho = IiNkcazo zethu

▶ ILaser Cutting PCM Fabric Steps

Inyathelo lokuqala

Misela

Beka ilaphu le-PCM emcaba phezu kwebhedi yelaser, uqinisekise ukuba icocekile kwaye ayinamibimbi.

Lungisa amandla e-laser, isantya, kunye nobuninzi obusekwe kubukhulu belaphu kunye nohlobo.

Inyathelo lesiBini

Ukusika

Yenza uvavanyo oluncinci ukujonga umgangatho wecala kwaye uqinisekise ukuba ii-PCM azivuzi okanye zonakaliswe.

Yenza uyilo olupheleleyo lokusika, uqinisekise ukungena komoya okufanelekileyo ukususa umsi okanye amasuntswana.

Inyathelo lesiThathu

Gqiba

Khangela imiphetho ecocekileyo kunye nee-capsules ze-PCM ezingaguqukiyo; susa intsalela okanye imisonto ukuba kuyimfuneko.

Irediyo enxulumeneyo:

Isikhokelo kuMmandla weLaser ogqwesileyo wokusika amalaphu

Kule vidiyo, sinokubona ukuba amalaphu ahlukeneyo okusika i-laser afuna amandla ahlukeneyo okusika i-laser kwaye ufunde indlela yokukhetha amandla e-laser kwizinto zakho ukuze ufezekise ukusika okucocekileyo kunye nokunqanda amanqaku okutshisa.

Funda ngakumbi Ulwazi malunga neLaser Cutters & Options

▶ Ii-FAQ ze-PCM Fabric

A PCM(Isixhobo soTshintsho lweSigaba) kwizinto ezilukiweyo zibhekisa kwinto edityaniswe kwilaphu elifunxa, ligcine, kwaye likhuphe ubushushu njengoko butshintsha isigaba-ngokuqhelekileyo ukusuka kokuqinileyo ukuya kulwelo ngokuphambanayo. Oku kuvumela i-textile ukuba ilawule ukushisa ngokugcina i-microclimate ezinzileyo kufuphi nesikhumba.

Ii-PCM zihlala zi-microencapsulated kwaye zifakwe kwiifiber, iingubo, okanye iileyiti zelaphu. Xa iqondo lokushisa liphakama, i-PCM ithatha ukushisa okugqithisileyo (i-melting); xa ipholile, i-material iqinisa kwaye ikhuphe ubushushu obugciniweyo-ukubonelelaintuthuzelo thermal enamandla.

I-PCM yinto ephezulu yokusebenza esemgangathweni eyaziwayo ngolawulo oluphezulu lweqondo lokushisa, inika induduzo eqhubekayo ngokufunxa kunye nokukhulula ukushisa. Yomelele, iyawonga amandla, kwaye isetyenziswa ngokubanzi kumasimi ajolise ekusebenzeni njengempahla yezemidlalo, izixhobo zangaphandle, ezonyango, kunye nempahla yasemkhosini.

Nangona kunjalo, amalaphu e-PCM abiza kakhulu, kwaye iinguqulelo ezikumgangatho ophantsi zinokufumana ukuthotywa kokusebenza emva kokuhlanjwa ngokuphindaphindiweyo. Ke ngoko, ukukhetha iimveliso zePCM ezifakwe kakuhle kwaye zenziwe ngokufanelekileyo kubalulekile.

Akunjalo ukuba useto lwelaser lulungiselelwe. Ukusebenzisa amandla aphantsi ukuya kumodareyitha kunye nesantya esiphezulu kunciphisa ukubonakaliswa kobushushu, kunceda ukukhusela ingqibelelo ye-PCM microcapsules ngexesha lokusika.

Ukusika i-Laser kunika imiphetho ecocekileyo, etywinwe ngokuchaneka okuphezulu, kunciphisa inkunkuma yelaphu, kwaye ugweme uxinzelelo lomatshini olungonakalisa iileyile ze-PCM-ezenza zilungele iilaphu ezisebenzayo.

Isetyenziswa kwiimpahla zemidlalo, iimpahla zangaphandle, iindawo zokulala, kunye neempahla zonyango-nayiphi na imveliso apho zombini imilo echanekileyo kunye nokulawulwa kwe-thermal kubalulekile.