What Makes Laser Cutting Perfect for PCM Fabric?

Laser cut fabric technology provides exceptional accuracy and clean finishes, making it the perfect match for pcm fabric, which requires consistent quality and thermal control. By combining the precision of laser cutting with the advanced properties of pcm fabric, manufacturers can achieve superior performance in smart textiles, protective gear, and temperature-regulating applications.

▶ The Basic Introduction Of PCM Fabric

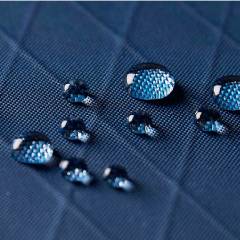

PCM Fabric

PCM fabric, or Phase Change Material fabric, is a high-performance textile designed to regulate temperature by absorbing, storing, and releasing heat. It integrates phase change materials into the fabric structure, which transition between solid and liquid states at specific temperatures.

This allows PCM fabric to maintain thermal comfort by keeping the body cooler when it's hot and warmer when it's cold. Commonly used in sportswear, outdoor gear, and protective clothing, PCM fabric offers enhanced comfort and energy efficiency in dynamic environments.

▶ Material Properties Analysis of PCM Fabric

PCM fabric features excellent thermal regulation by absorbing and releasing heat through phase changes. It offers breathability, durability, and moisture management, making it ideal for smart textiles and temperature-sensitive applications.

Fiber Composition & Types

PCM fabric can be made by embedding phase change materials into or onto various fiber types. Common fiber compositions include:

Polyester: Durable and lightweight, often used as the base fabric.

Cotton: Soft and breathable, suitable for everyday wear.

Nylon: Strong and elastic, used in performance textiles.

Blended Fibers: Combines natural and synthetic fibers to balance comfort and functionality.

Mechanical & Performance Properties

| Property | Description |

|---|---|

| Tensile Strength | Durable, resists stretching and tearing |

| Flexibility | Soft and flexible for comfortable wear |

| Thermal Responsiveness | Absorbs/releases heat to regulate temperature |

| Wash Durability | Maintains performance after multiple washes |

| Comfort | Breathable and moisture-wicking |

Advantages & Limitations

| Advantages | Limitations |

|---|---|

| Excellent thermal regulation | Higher cost compared to regular fabrics |

| Enhances wearer comfort | Performance may degrade after many washes |

| Maintains breathability and flexibility | Limited temperature range of phase change |

| Durable under repeated thermal cycles | Integration can affect fabric texture |

| Suitable for diverse applications | Requires specialized manufacturing process |

Structural Characteristics

PCM fabric integrates microencapsulated phase change materials within or on textile fibers like polyester or cotton. It maintains breathability and flexibility while providing effective thermal regulation and durability through multiple heat cycles.

▶ Applications of PCM Fabric

Sportswear

Keeps athletes cool or warm based on activity and environment.

Outdoor Gear

Regulates body temperature in jackets, sleeping bags, and gloves.

Medical Textiles

Helps maintain patient body temperature during recovery.

Military and Tactical Wear

Provides thermal balance in extreme climates.

Bedding and Home Textiles

Used in mattresses, pillows, and blankets for sleep comfort.

Smart and Wearable Tech

Integrated into garments for responsive thermal control.

▶ Comparison with Other Fibers

| Aspect | PCM Fabric | Cotton | Polyester | Wool |

|---|---|---|---|---|

| Thermal Regulation | Excellent (via phase change) | Low | Moderate | Good (natural insulation) |

| Comfort | High (temperature-adaptive) | Soft and breathable | Less breathable | Warm and soft |

| Moisture Control | Good (with breathable base fabric) | Absorbs moisture | Wicks moisture | Absorbs but retains moisture |

| Durability | High (with quality integration) | Moderate | High | Moderate |

| Wash Resistance | Moderate to high | High | High | Moderate |

| Cost | Higher (due to PCM technology) | Low | Low | Medium to high |

▶ Recommended Laser Machine for PCM

We Tailor Customized Laser Solutions for Production

Your Requirements = Our Specifications

▶ Laser Cutting PCM Fabric Steps

Step One

Setup

Place the PCM fabric flat on the laser bed, ensuring it is clean and wrinkle-free.

Adjust laser power, speed, and frequency based on fabric thickness and type.

Step Two

Cutting

Run a small test to check edge quality and ensure PCMs are not leaking or damaged.

Execute the full design cut, ensuring proper ventilation to remove fumes or particles.

Step Three

Finish

Check for clean edges and intact PCM capsules; remove residue or threads if needed.

Related vedio:

Guide to the Best Laser Power for Cutting Fabrics

In this video, we can see that different laser cutting fabrics require different laser cutting powers and learn how to choose laser power for your material to achieve clean cuts and avoid scorch marks.

Learn More Information about Laser Cutters & Options

▶ PCM Fabric's FAQs

A PCM (Phase Change Material) in textiles refers to a substance integrated into fabric that absorbs, stores, and releases heat as it changes phase—typically from solid to liquid and vice versa. This allows the textile to regulate temperature by maintaining a stable microclimate close to the skin.

PCMs are often microencapsulated and embedded in fibers, coatings, or fabric layers. When the temperature rises, the PCM absorbs excess heat (melting); when it cools, the material solidifies and releases stored heat—providing dynamic thermal comfort.

PCM is a high-quality functional material known for its excellent temperature regulation, providing continuous comfort by absorbing and releasing heat. It is durable, energy-efficient, and widely used in performance-oriented fields such as sportswear, outdoor gear, medical, and military clothing.

However, PCM fabrics are relatively expensive, and lower-quality versions may experience performance degradation after repeated washing. Therefore, choosing well-encapsulated and properly manufactured PCM products is essential.

Not if the laser settings are optimized. Using low to moderate power with high speed minimizes heat exposure, helping protect the integrity of PCM microcapsules during cutting.

Laser cutting offers clean, sealed edges with high precision, reduces fabric waste, and avoids mechanical stress that could damage PCM layers—making it ideal for functional fabrics.

It is used in sportswear, outdoor clothing, bedding, and medical textiles—any product where both precise shape and thermal control are critical.