Uyini Umshini We-Galvo Laser?

I-laser ye-Galvo, evame ukubizwa ngokuthi i-laser ye-Galvanometer, uhlobo lohlelo lwe-laser olusebenzisa izikena ze-galvanometer ukulawula ukunyakaza kanye nesiqondiso somsebe we-laser.

Lobu buchwepheshe buvumela ukubeka imisebe ye-laser ngendlela enembile futhi esheshayo, okwenza ifaneleke ezinhlelweni ezahlukahlukene, okuhlanganisa ukumaka nge-laser, ukuqopha, ukusika, nokuningi.

Igama elithi "Galvo" lisuselwa ku-"galvanometer," okuyithuluzi elisetshenziselwa ukukala nokuthola imisinga kagesi emincane. Emongweni wezinhlelo ze-laser, ama-scanner e-Galvo asetshenziselwa ukubonakalisa nokulawula umsebe we-laser.

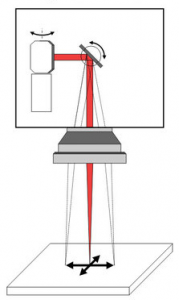

Lezi ziskena zakhiwe izibuko ezimbili ezifakwe kuma-motor e-galvanometer, angalungisa ngokushesha i-engeli yezibuko ukuze alawule indawo yomsebe we-laser.

Izici Eziyinhloko Zezinhlelo Ze-Galvo Laser Zifaka:

1. Umthombo We-Laser

2. Ukukhishwa Kwe-Laser Beam

3. Izikena zeGalvanometer

4. Ukuphambuka Kwemisebe

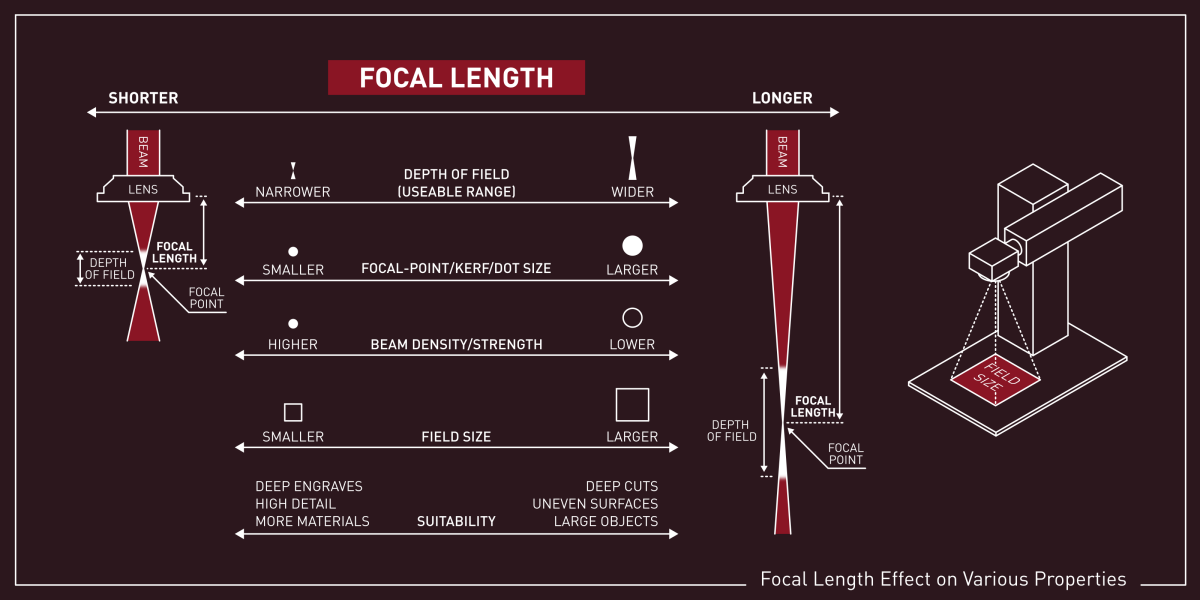

5. I-Focusing Optics

6. Ukusebenzisana Kwezinto Ezibalulekile

7. Ukuskena Okusheshayo

8. Ukulawulwa Kwekhompyutha

9. Ukupholisa Nokuphepha

10. Ukuphathwa Kokukhishwa Kwegesi Nokungcola

Indlela yokwenza: Iphepha Lokuqopha Le-Galvo Laser

Unemibuzo mayelana ne-Galvo Laser? Kungani ungaxhumani nathi?

1. Isicelo Sakho:

Chaza ngokucacile injongo ye-laser yakho. Ingabe uyasika, uyamaka, noma uyaqopha? Izonquma amandla e-laser kanye nobude besikhathi obudingekayo.

3. Amandla e-Laser:

Khetha amandla e-laser afanele ngokusekelwe kuhlelo lwakho lokusebenza. Ama-laser anamandla aphezulu afanele ukusika, kuyilapho ama-laser anamandla aphansi esetshenziselwa ukumaka nokuqopha.

5. Umthombo We-Laser:

Khetha phakathi kwe-CO2, i-fiber, noma ezinye izinhlobo zemithombo ye-laser. Ama-laser e-CO2 avame ukusetshenziselwa ukuqopha nokusika izinto eziphilayo.

7. Isofthiwe Nokulawula:

Isofthiwe elula ukuyisebenzisa enamakhono okwenza ngokwezifiso ibalulekile ekulungiseni kahle amapharamitha e-laser kanye nokwenza ngcono ukusebenza.

9. Ukugcinwa Nokusekelwa:

Cabangela izidingo zokunakekelwa kanye nokutholakala kokusekelwa kwamakhasimende. Ukufinyelela usizo lobuchwepheshe kanye nezingxenye ezishintshwayo uma kudingeka.

11. Isabelomali Nokuhlanganiswa:

Nquma isabelomali sakho sohlelo lwe-laser lwe-Galvo. Khumbula ukuthi izinhlelo ezisezingeni eliphezulu ezinezici ezithuthukisiwe zingabiza kakhulu. Uma uhlela ukuhlanganisa uhlelo lwe-laser lwe-Galvo emgqeni wokukhiqiza okhona, qiniseka ukuthi luyahambisana nezinhlelo zakho zokwenza izinto ngokuzenzakalelayo kanye nokulawula.

2. Ukuhambisana kwezinto ezibonakalayo:

Qinisekisa ukuthi uhlelo lwe-laser lwe-Galvo luyahambisana nezinto ozosebenza ngazo. Izinto ezahlukene zingadinga amaza athile e-laser noma amazinga wamandla.

4. Isivinini Seskena Se-Galvo:

Cabanga ngesivinini sokuskena sesithwebuli seGalvo. Amaskena asheshayo afaneleka kakhulu ezinhlelweni zokusebenza ezisebenzisa amandla amaningi, kuyilapho amaskena ahamba kancane engase abe nembe kakhulu emsebenzini onemininingwane.

6. Usayizi Wendawo Yomsebenzi:

Nquma usayizi wendawo yokusebenza edingekayo ekusetshenzisweni kwakho. Qinisekisa ukuthi uhlelo lwe-laser lwe-Galvo lungafanela ubukhulu bezinto zakho.

8. Uhlelo Lokupholisa:

Qinisekisa ukusebenza kahle kohlelo lokupholisa. Uhlelo lokupholisa oluthembekile lubalulekile ukuze kulondolozwe ukusebenza kwe-laser futhi kwandise isikhathi sokuphila kwemishini.

10. Izici Zokuphepha:

Beka phambili izici zokuphepha ezifana nezingidi ezixhumene, izihlangu zemishayo, nezinkinobho zokuma eziphuthumayo ukuze uvikele abaqhubi futhi uvimbele izingozi

12. Ukwanda Kwesikhathi Esizayo Nokubuyekezwa:

Cabanga ngezidingo ezingaba khona zesikhathi esizayo. Uhlelo lwe-laser lwe-Galvo olukwazi ukwandiswa lukuvumela ukuthi wandise amakhono akho njengoba ibhizinisi lakho likhula. Cwaninga futhi ufune izincomo kontanga noma ochwepheshe bemboni ukuze uthole ukuqonda ngezinhlelo ze-laser ze-Galvo ezifanele kakhulu.

13. Ukwenza ngokwezifiso:

Cabanga ukuthi udinga uhlelo olujwayelekile olutholakala ngokushesha noma ikhambi elenziwe ngokwezifiso elenzelwe uhlelo lwakho lokusebenza oluthile.

Ngokuhlola ngokucophelela lezi zici, ungakhetha uhlelo lwe-laser lwe-Galvo olufanele oluhambisana nemigomo yebhizinisi lakho, luthuthukise izinqubo zakho zokukhiqiza, futhi luqinisekise ukusebenza kahle kanye nekhwalithi ezinhlelweni zakho zokusebenza.

Umbukiso Wevidiyo: Ungawukhetha Kanjani Umshini Wokumaka We-Laser?

Uchungechunge lwe-MimoWork Laser

▶ Kungani Ungaqali Ngalezi Zindlela Ezinhle?

Usayizi Wethebula Lokusebenza:400mm * 400mm (15.7” * 15.7”)

Izinketho Zamandla E-Laser:180W/250W/500W

Ukubuka konke kweGalvo Laser Engraver & Marker 40

Umbono ophezulu wokusebenza walolu hlelo lwe-laser lwe-Galvo ungafinyelela ku-400mm * 400 mm. Ikhanda le-GALVO lingalungiswa liqonde phezulu ukuze ufinyelele osayizi abahlukene be-laser beam ngokuya ngobukhulu bezinto zakho. Ngisho nasendaweni yokusebenza ephezulu, usengathola i-laser beam engcono kakhulu engu-0.15 mm ukuze uthole ukusebenza okuhle kakhulu kokuqopha nokumaka kwe-laser. Njengezinketho ze-laser ze-MimoWork, i-Red-Light Indication System kanye ne-CCD Positioning System zisebenza ndawonye ukulungisa isikhungo sendlela yokusebenza endaweni yangempela yento ngesikhathi sokusebenza kwe-laser ye-galvo. Ngaphezu kwalokho, inguqulo yomklamo ogcwele ohlanganisiwe ingacelwa ukuze ihlangabezane nezinga lokuvikela ukuphepha lekilasi 1 lomqophi we-laser we-galvo.

Usayizi Wethebula Lokusebenza:1600mm * Okungapheli (62.9" * Okungapheli)

Izinketho Zamandla E-Laser:350W

Ukubuka konke kweGalvo Laser Engraver

Umqophi we-laser wefomethi enkulu ungowocwaningo nokuthuthukiswa kwezinto ezinkulu eziqoshwe nge-laser kanye nokumaka nge-laser. Ngohlelo lokuhambisa, umqophi we-laser we-galvo angaqopha futhi amake ezindwangu ezigoqekayo (izindwangu). Lokho kulula kulezi zinto ezicutshungulwa isikhathi eside kakhulu. Ukuqoshwa kwe-laser okuqhubekayo nokuguquguqukayo kunqoba kokubili ukusebenza kahle okuphezulu kanye nekhwalithi ephezulu ekukhiqizeni okusebenzayo.

Usayizi Wethebula Lokusebenza:70*70mm, 110*110mm, 175*175mm, 200*200mm (Kungenziwa ngezifiso)

Izinketho Zamandla E-Laser:20W/30W/50W

Ukubuka konke komshini wokumaka we-Fiber Galvo Laser

Umshini wokumaka i-fiber laser usebenzisa imisebe ye-laser ukwenza amamaki ahlala njalo ebusweni bezinto ezahlukahlukene. Ngokushintsha noma ukushisa ebusweni bezinto ngamandla okukhanya, ungqimba olujulile lwembula khona-ke ungathola umphumela wokusika emikhiqizweni yakho. Kungakhathaliseki ukuthi iphethini, umbhalo, ikhodi yebha, noma eminye imidwebo iyinkimbinkimbi kangakanani, uMshini Wokumaka I-Fiber Laser we-MimoWork ungawaqopha emikhiqizweni yakho ukuze uhlangabezane nezidingo zakho zokwenza ngokwezifiso.

Thumela Izidingo Zakho Kithi, Sizokunikeza Isixazululo Se-Laser Esingochwepheshe

Qala Umeluleki We-Laser Manje!

> Yiluphi ulwazi okudingeka ulunikeze?

> Ulwazi lwethu lokuxhumana

Imibuzo Evamile Mayelana ne-Galvo Laser

Uma zisetshenziswa kahle futhi ngezinyathelo zokuphepha ezifanele, izinhlelo ze-laser ze-Galvo ziphephile. Kufanele zifake izici zokuphepha ezifana nezingidi ezihlanganisiwe nezihlangu zemishayo. Landela njalo iziqondiso zokuphepha futhi unikeze ukuqeqeshwa komqhubi ukuqinisekisa ukusetshenziswa okuphephile.

Yebo, izinhlelo eziningi ze-laser ze-Galvo zenzelwe ukuhlanganiswa ezindaweni zokukhiqiza ezenzakalelayo. Qinisekisa ukuthi ziyahambisana nezinhlelo zakho zokulawula ezikhona kanye nemishini yokwenza ezenzakalelayo.

Izidingo zokulungisa ziyahlukahluka kuye ngomkhiqizi kanye nomodeli. Ukulungisa okuvamile kungafaka phakathi ukuhlanza ama-optics, ukuhlola izibuko, kanye nokuqinisekisa ukuthi uhlelo lokupholisa lusebenza kahle. Kubalulekile ukulandela izincomo zokulungisa zomkhiqizi.

Yebo, izinhlelo ze-laser ze-Galvo ziyakwazi ukudala imiphumela ye-3D ngokushintsha amandla nemvamisa ye-laser. Lokhu kungasetshenziswa ekwenzeni i-texture nokwengeza ukujula ezindaweni.

Isikhathi sokuphila kohlelo lwe-laser lwe-Galvo sincike ekusetshenzisweni, ekunakekelweni, kanye nasekhwalithini. Izinhlelo zekhwalithi ephezulu zingahlala amahora angamashumi ezinkulungwane zokusebenza, uma nje zinakekelwa kahle.

Nakuba izinhlelo zeGalvo ziphumelela kakhulu ekumakeni nasekuqopheni, zingasetshenziswa nasekusikeni izinto ezincane njengephepha, ipulasitiki, nezindwangu. Amandla okusika ancike emthonjeni we-laser kanye namandla.

Izinhlelo ze-laser ze-Galvo zibhekwa njengezinobungani nemvelo kunezindlela zokumaka zendabuko. Zikhiqiza imfucuza encane futhi azidingi izinto ezisetshenziswayo njengoyinki noma udayi.

Ezinye izinhlelo ze-laser ze-Galvo zingashintshwa ukuze zisetshenziswe ekuhlanzeni nge-laser, okwenza zibe amathuluzi asebenziseka kalula emisebenzini eyahlukahlukene.

Yebo, izinhlelo ze-laser ze-Galvo zingacubungula kokubili ihluzo ze-vector kanye ne-raster, okuzenza zikwazi ukwenza imisebenzi eminingi ngemiklamo namaphethini ayinkimbinkimbi.

Ungavumelani nanoma yini engaphansi kwehlukile

Tshala imali kokungcono kakhulu

Isikhathi sokuthunyelwe: Novemba-09-2023