Ungakwazi yini ukusika igwebu le-EVA nge-laser?

Uhlu Lokuqukethwe:

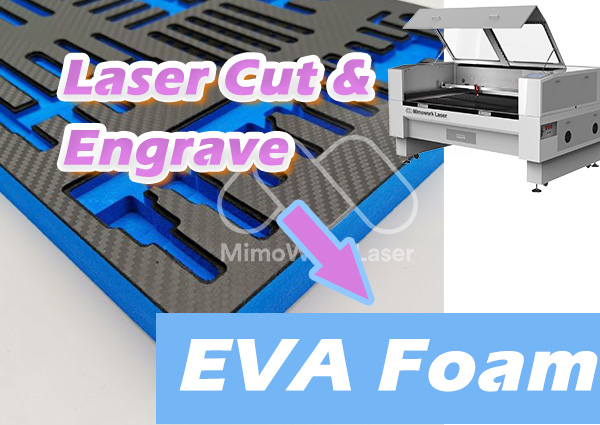

Kuyini i-EVA Foam?

I-foam ye-EVA, eyaziwa nangokuthi i-Ethylene-Vinyl Acetate foam, uhlobo lwezinto zokwenziwa ezisetshenziswa kakhulu ezinhlobonhlobo zezicelo. Yenziwa ngokuhlanganisa i-ethylene ne-vinyl acetate ngaphansi kokushisa nokucindezela, okuholela ezintweni ze-foam eziqinile, ezilula, neziguquguqukayo. I-foam ye-EVA yaziwa ngezakhiwo zayo zokunciphisa nokudonsa ukushaqeka, okwenza kube ukukhetha okuthandwayo kwemishini yezemidlalo, izicathulo, kanye nemisebenzi yezandla.

Izilungiselelo ze-Laser Cut Eva Foam

Ukusika nge-laser kuyindlela ethandwayo yokubumba nokusika i-foam ye-EVA ngenxa yokunemba kwayo kanye nokuguquguquka kwayo. Izilungiselelo zokusika nge-laser ezifanele ze-foam ye-EVA zingahluka kuye ngokuthi i-laser cutter ethile, amandla ayo, ukujiya kanye nobuningi be-foam, kanye nemiphumela yokusika oyifunayo. Kubalulekile ukwenza ukusika kokuhlola nokulungisa izilungiselelo ngokufanele. Kodwa-ke, nansi eminye imihlahlandlela evamile yokukuqalisa:

Amandla ▶

Qala ngokusetha amandla aphansi, cishe ngo-30-50%, bese uwakhuphula kancane kancane uma kudingeka. I-foam ye-EVA ejiyile futhi ebanzi ingadinga izilungiselelo zamandla aphezulu, kanti i-foam encane ingadinga amandla aphansi ukuze kugwenywe ukuncibilika noma ukusha ngokweqile.

Isivinini ▶

Qala ngesivinini esimaphakathi sokusika, ngokuvamile esicishe sibe ngu-10-30 mm/s. Futhi, kungadingeka ukuthi ulungise lokhu ngokusekelwe ekujiyeni nasekubuneni kwefoam. Isivinini esiphansi singabangela ukusikwa okuhlanzekile, kanti isivinini esisheshayo singase sifanele ifoam encane.

▶ Ukugxila

Qinisekisa ukuthi i-laser igxile kahle ebusweni be-foam ye-EVA. Lokhu kuzosiza ekutholeni imiphumela engcono yokusika. Landela imiyalelo enikezwe umenzi wokusika i-laser yokuthi ungalungisa kanjani ubude be-focal.

▶ Ukunciphisa Ukuhlolwa

Ngaphambi kokusika umklamo wakho wokugcina, yenza ukusika kokuhlola engxenyeni encane yesampula ye-foam ye-EVA. Sebenzisa izilungiselelo zamandla nesivinini ezahlukene ukuthola inhlanganisela efanele enikeza ukusika okuhlanzekile nokunembile ngaphandle kokusha noma ukuncibilika ngokweqile.

Ividiyo | Indlela Yokusika Igwebu Nge-Laser

Isiguqo Se-Laser Cut Foam Sesihlalo Semoto!

I-Laser Cut Foam ingakanani?

Noma yimiphi imibuzo mayelana nendlela yokusika i-eva foam nge-laser

Umshini Wokusika We-Laser Onconyiwe we-EVA Foam

Ingabe Kuphephile Ukusebenzisa I-Laser-Cut EVA Foam?

Uma umsebe we-laser uxhumana ne-foam ye-EVA, ufudumeza futhi ushise izinto, ukhulule amagesi kanye nezinto ezincane. Intuthu ekhiqizwa yi-foam ye-EVA esikwa nge-laser ivame ukuba nama-volatile organic compounds (ama-VOC) kanye nezinhlayiya ezincane noma udoti. Le ntuthu ingaba nephunga futhi ingaqukatha izinto ezifana ne-acetic acid, i-formaldehyde, kanye neminye imikhiqizo ephuma ekushiseni.

Kubalulekile ukuba nomoya ofanele lapho usika i-laser foam ye-EVA ukuze kususwe umusi endaweni yokusebenza. Umoya ofanele usiza ekugcineni indawo yokusebenza iphephile ngokuvimbela ukunqwabelana kwamagesi angaba yingozi nokunciphisa iphunga elihambisana nenqubo.

Ingabe Kukhona Isicelo Esibalulekile?

Uhlobo oluvame kakhulu lwe-foam olusetshenziswa ekusikeni nge-laser yi-igwebu le-polyurethane (igwebu le-PU)I-PU foam iphephile ukunqunywa nge-laser ngoba ikhiqiza umusi omncane futhi ayikhiphi amakhemikhali anobuthi uma ivezwa emsebeni we-laser. Ngaphandle kwe-PU foam, ama-foam enziwe nge-i-polyester (PES) kanye ne-polyethylene (PE)zilungele futhi ukusika, ukuqopha, kanye nokumaka nge-laser.

Kodwa-ke, igwebu elithile elisekelwe ku-PVC lingakhiqiza amagesi anobuthi uma usebenzisa i-laser. I-fume extractor ingaba inketho enhle ongayicabangela uma udinga ukusika amagwebu anjalo nge-laser.

Igwebu Lokusika: I-Laser Vs. CNC Vs. Die Cutter

Ukukhetha ithuluzi elingcono kakhulu kuncike kakhulu ekujiyeni kwefoam ye-EVA, ubunzima bokusika, kanye nezinga lokunemba elidingekayo. Imimese esetshenziswayo, izikele, izisiki zefoam ezishisayo, izisiki ze-laser ze-CO2, noma ama-router e-CNC konke kungaba izinketho ezinhle uma kukhulunywa ngokusika ifoam ye-EVA.

Ummese obukhali kanye nesikelo kungaba ukukhetha okuhle uma udinga kuphela ukwenza imiphetho eqondile noma elula egobile, futhi kuyabiza kakhulu. Kodwa-ke, amashidi e-foam e-EVA amancane kuphela angasikwa noma agobe ngesandla.

Uma Usebhizinisini, ukuzenzakalela, kanye nokunemba kuzoba yinto eza kuqala okufanele uyicabangele.

Esimweni esinjalo,umshini wokusika i-laser we-CO2, i-CNC router, kanye noMshini Wokusika I-Diekuzocatshangelwa.

▶ Umsiki We-Laser

I-laser cutter, njenge-desktop CO2 laser noma i-fiber laser, iyindlela enembile nephumelelayo yokusika i-EVA foam, ikakhulukaziimiklamo eyinkimbinkimbi noma eyinkimbinkimbi. Abasiki be-laser bahlinzekaimiphetho ehlanzekile, evaliwefuthi zivame ukusetshenziselwangezinga elikhuluamaphrojekthi.

▶ I-CNC Router

Uma unokufinyelela ku-router ye-CNC (Computer Numerical Control) enethuluzi lokusika elifanele (njengethuluzi elijikelezayo noma ummese), ingasetshenziswa ukusika i-foam ye-EVA. Ama-router e-CNC anikeza ukunemba futhi angakwazi ukusingathaamashidi e-foam ajiyile.

▶ Umshini Wokusika Idayi

I-laser cutter, njenge-desktop CO2 laser noma i-fiber laser, iyindlela enembile nephumelelayo yokusika i-EVA foam, ikakhulukaziimiklamo eyinkimbinkimbi noma eyinkimbinkimbi. Abasiki be-laser bahlinzekaimiphetho ehlanzekile, evaliwefuthi zivame ukusetshenziselwangezinga elikhuluamaphrojekthi.

Inzuzo Ye-Laser Cutting Foam

Uma usika igwebu lezimboni, izinzuzo zaloumsiki we-laserngaphezu kwamanye amathuluzi okusika kusobala. Kungakha ama-contour amahle kakhulu ngenxaukusika okunembile nokungathintani, nge-c eningi kakhuluunqenqema oluthambile noluyisicaba.

Uma usebenzisa ukusika ngejethi yamanzi, amanzi azomuncwa kwi-foam emuncayo ngesikhathi senqubo yokuhlukanisa. Ngaphambi kokucubungula okwengeziwe, izinto kumele zomiswe, okuyinqubo ethatha isikhathi. Ukusika nge-laser kuyayishiya le nqubo futhi ungakwaziqhubeka nokucubungulaizinto ezibonakalayo ngokushesha. Ngokuphambene nalokho, i-laser iyakholisa kakhulu futhi ngokusobala iyithuluzi elihamba phambili lokucubungula igwebu.

Isiphetho

Imishini yokusika nge-laser ye-MimoWork ye-foam ye-EVA ifakwe izinhlelo zokukhipha intuthu ezakhelwe ngaphakathi ezisiza ekubambeni nasekususeni intuthu ngqo endaweni yokusika. Ngaphandle kwalokho, izinhlelo ezengeziwe zokungenisa umoya, njengezifeni noma izihlanzi zomoya, zingasetshenziswa ukuqinisekisa ukususwa kwentuthu ngesikhathi senqubo yokusika.

Izinto Ezivamile Zokusika Nge-Laser

Imibuzo Evame Ukubuzwa

I-laser cutting foam ye-EVA ikhipha umusi oqukethe ama-VOC, i-acetic acid, kanye ne-formaldehyde, okuyingozi uma uphefumula. Sebenzisa i-fume extractor (isb., i-Fume Extractor 2000) nge-laser cutter yakho ukuze ususe lomusi. Qinisekisa ukuthi indawo yokusebenza inomoya omuhle ngamafeni noma amafasitela avuliwe. Gwema ukuvezwa isikhathi eside ngokugqoka umshini wokuphefumula uma kudingeka. Hlanza njalo uhlelo lokukhipha umoya lomsiki ukuze ugcine ukusebenza kahle, njengoba ukwakheka kwawo kunganciphisa ukususwa komusi futhi kube nezingozi zomlilo.

Ubukhulu obukhulu buxhomeke emandleni e-laser. Izisiki ze-laser ze-CO2 zedeskithophu (isb., Umshini Wokusika we-Laser we-Acrylic) zivame ukuphatha i-foam ye-EVA enobukhulu obufika ku-15-20mm. Amamodeli ezimboni afana ne-Extended Flatbed Laser Cutter 160, enamandla aphezulu, angasika i-foam enobukhulu obufika ku-50mm uma ehambisana nesivinini esisheshayo (5-10 mm/s) ukuqinisekisa ukuhwamuka okuphelele. I-foam enobukhulu ingadinga ukudlula kaningi, kodwa ukusika kokuhlola kubalulekile ukuze kugwenywe ukusika okungaphelele noma ukusha ngokweqile.

Ukusika kokuhlola kubalulekile ukuze kulungiswe izilungiselelo ze-foam yakho ethile. I-foam ye-EVA iyahlukahluka ngobukhulu kanye nobukhulu, ngakho-ke ngisho nangemihlahlandlela ejwayelekile, amandla afanele kanye nesivinini kungahluka. Ukusika kokuhlola engxenyeni encane ye-foam kusiza ukuhlonza ibhalansi efanele—amandla amaningi kakhulu abangela ukusha, kuyilapho amaqabunga amancane kakhulu ebanga imiphetho edabukile. Lokhu kuqinisekisa ukuthi iphrojekthi yakho yokugcina (isb., imicamelo yesihlalo semoto, imisebenzi yezandla) inemiphetho eqondile, evaliwe, esindisa isikhathi nezinto ngokugwema amaphutha ngomshini wokusika we-laser.

Isikhathi sokuthunyelwe: Meyi-18-2023