Nasihu da Dabaru don Samun Cikakkun Sakamako tare da Yanke Laser na Fabric

Yadin yanke Laser yana da sauƙin canzawa ga masu zane, yana ba da hanya madaidaiciya don kawo ra'ayoyi masu rikitarwa zuwa rayuwa.

Idan kana son samun sakamako mai kyau, samun saitunanka da dabarunka daidai shine mahimmanci.

A cikin wannan labarin, za mu yi muku bayani game da duk abin da kuke buƙatar sani game da yadin yanke laser. Daga mafi kyawun saitunan zuwa dabarun da aka gwada da gaske, muna da shawarwari don taimaka muku haɓaka ayyukanku da cimma sakamako mai ban mamaki. Bari mu nutse!

Teburin Abubuwan da ke Ciki:

Menene Laser Yankan Yanke?

Yadin Laser fasaha ce mai kawo sauyi wadda ke canza yanayin yadi da ƙira.

A taƙaice, yana amfani da hasken laser mai ƙarfi don yanke nau'ikan yadudduka daban-daban tare da daidaito mai ban mamaki.

Fa'idodin suna da ban sha'awa: za ku sami gefuna masu tsabta da aka rufe waɗanda ke daina lalacewa a cikin hanyarsa, ikon ƙirƙirar tsare-tsare masu rikitarwa da rikitarwa, da kuma iya aiki da komai daga siliki mai laushi zuwa zane mai ɗorewa. Hanya ce mai kyau don kawo wahayin kirkire-kirkire zuwa rayuwa!

>> Tsarin Gyaran Daidaito tare da Haske<<

Yadin da ake yankan Laser ba a iyakance shi ga ƙa'idodin kayan aikin yanka na gargajiya ba, wanda ke ba da damar ƙirƙirartsare-tsare masu rikitarwa kamar yadin da aka saka.

Zane-zane na musamman, har ma da tambari ko monogram na musamman akan tufafi da kayan haɗi.

Bugu da ƙari, tsari ne da ba ya hulɗa da juna, ma'ana akwaibabu hulɗa ta jiki kai tsayeda masana'anta,rage girmanhaɗarin lalacewa ko karkacewa.

Mafi kyawun Saitunan Laser don Yanke Laser akan Yadi

Samun saitunan laser masu dacewa yana da matuƙar muhimmanci don samun sakamako mai kyau yayin yanke yadi. Saitunan da suka fi dacewa na iya bambanta dangane da abubuwa da yawa, gami da kauri da nau'in yadi, ƙirar ku, da takamaiman na'urar yanke laser da kuke amfani da ita.

Ga wasu jagororin gabaɗaya don taimaka muku saita laser ɗinku don yankan masana'anta:

▶ Ƙarfin Laser don Yanke Laser:

Ƙarfin laser da ka zaɓa ya kamata ya dace da kauri na yadinka.

>> Ga masaku masu siriri da laushi, yi nufin samun ƙarancin ƙarfin da ke kusa da kashi 10-20%.

>> Don yadi mai kauri, ƙara ƙarfin zuwa kusan kashi 50-60%.

Ta wannan hanyar, za ku tabbatar da tsaftace yankewa ba tare da lalata kayan ku ba!

Laser Tube don Laser Cutter

Yanke Laser na CO2 hanya ce da ake amfani da ita sosai kuma mai inganci wacce ta dace da yadudduka daban-daban, gami da polyester, auduga, nailan, ji, Cordura, siliki, da sauransu.

Yawanci, bututun laser mai ƙarfin 100W yana aiki da kyau ga yawancin aikace-aikace.

Duk da haka, idan kuna da takamaiman buƙatu—kamar yanke yadudduka da yawa na yadi ko kayan haɗin gwiwa na musamman—yana da mahimmanci ku yi la'akari da waɗannan buƙatu.

Kullum muna ba da shawarar yin gwajin laser kafin fara samar da kayan masana'anta. Wannan yana taimakawa wajen tabbatar da cewa kun cimma sakamakon da ake so ba tare da wani abin mamaki ba!

Tuntube mudon ƙarin shawarwari na ƙwararru idan kuna da matsala da yadin yanke laser.

▶ Saurin Yanke Laser:

Saurin yanke laser wani muhimmin abu ne wanda ya bambanta dangane da kauri na masana'anta:

>> Ga masaku masu siriri da laushi, yi amfani da saurin gudu na kimanin mm 10-15/s.

>> Ga masaku masu kauri, za ku iya ƙara saurin zuwa kusan 20-25 mm/s.

Daidaita saurin yadda ya kamata yana tabbatar da tsaftace yankewa yayin da yake kiyaye mutuncin yadi!

▶ Yawan amfani:

Saita mitar laser zuwa babban darajar 1000-2000 Hz.

Wannan yana tabbatar da tsabta da daidaiton yankewa, yana rage haɗarin lalacewar gefuna masu kaifi.

▶ Taimakon Iska:

Amfani da fasahar taimakon iska yana da amfani.

Yana taimakawa wajen fitar da datti daga yankin da aka yanke,tsaftace shi da kuma hana lalacewar da zai iya faruwa ga masakar yayin yankewa.

▶ Mai Cire Tururi:

Tsaftace Laser na Mai Cire Fushi

Lokacin yanke wasu kayan haɗin gwiwa, za ku iya fuskantar wari mara daɗi.

Na'urar fitar da hayaki tana da matuƙar muhimmanci don kiyaye muhalli mai tsafta, musamman ga abokan ciniki da ke aiki a kan ayyuka masu mahimmanci, kamar jakunkunan iska.

Wannan yana taimakawa wajen tabbatar da yanayi mai aminci da jin daɗi na aiki.

Themai fitar da hayakizai iya taimaka maka wajen magance waɗannan.

Har yanzu ba ni da ra'ayin game da Saitin Yanke Laser, Tuntube mu don ƙarin Bayani mai zurfi

Dabaru da Nasihu don Yanke Laser

Don cimma mafi kyawun sakamako lokacin da masana'anta yanke laser,Yi la'akari da waɗannan dabaru da shawarwari:

1. Shirya Yadi

Wankewa da Baƙin ƙarfe:A wanke kuma a goge masakar don cire duk wani ƙura da datti.

Mai Daidaita Fuskar:A shafa mai daidaita mayafin a bayan yadi. Wannan yana taimakawa wajen hana juyawa yayin yankewa.

2. Abubuwan da Zane Ya Yi La'akari da su

Cikakkun Bayani da Bayani:Ka tuna da sarkakiyar tsarinka.

A guji ƙananan bayanai ko kusurwoyi masu kaifi, domin waɗannan na iya zama ƙalubale a yanke su daidai da injin yanke laser.

3. Yanke Gwaji

Yi Gwaji Yankewa:Koyaushe yi gwajin yankewa a kan wani yanki na yadi kafin yanke ƙirar ƙarshe.

Wannan zai taimaka maka gano saitunan laser mafi kyau don takamaiman masana'anta da ƙira.

4. Tsaftace Injin Yanke Laser na Yadi

Kulawa na Kullum:Bayan yankewa, tsaftace na'urar yanke laser don hana taruwar tarkace, wanda hakan ka iya lalata na'urar.

Kulawa akai-akai yana tabbatar da ingantaccen aiki da tsawon rai.

Nunin Bidiyo | Yadda Ake Yanke Masana'antar Zane ta Laser

Nunin Bidiyo | Shin Laser Zai Iya Yanke Yadi Mai Layi Da Yawa?

Me yasa Fabric Laser Cutter shine Mafi kyawun Kayan aiki don Yanke Fabric

Duk da cewa nau'ikan masu yanke laser daban-daban na iya yanke masana'anta, ƙwararren mai yanke laser shine mafi kyawun zaɓi saboda dalilai da yawa:

1. Daidaito da Daidaito

Tsarin da aka Keɓance: An ƙera na'urorin yanke laser na masana'anta musamman don yanke masaka, suna da software wanda ke ba da damar sarrafa tsarin yankewa daidai. Wannan yana tabbatar da cewa an yanke masakar daidai da takamaiman ƙirar ku.

2. Sifofi na Musamman

Taimakon Iska: Yawancin na'urorin yanke laser na masana'anta suna zuwa da kayan aikin taimakawa iska waɗanda ke fitar da tarkace daga yankin yankewa. Wannan yana kiyaye masakar tsabta kuma yana rage haɗarin lalacewa yayin aikin yankewa.

3. Ƙarfin Zane Mai Tsauri

Tsarin Yankewa Mai Hadari: Daidaiton yanke laser na masana'anta yana bawa masu zane damar ƙirƙirar ƙira masu rikitarwa da cikakkun bayanai waɗanda zasu yi wahalar cimmawa ta hanyar amfani da hanyoyin yankewa na gargajiya.

A ƙarshe,Laser yanke masana'antawani abu nemai ƙirƙira kuma daidaitaccehanyar yanke yadi wanda ke ba masu zane damar ƙirƙirartsare-tsare masu rikitarwa tare da daidaito da daidaito.

Ta hanyar amfaniLallaidamasaitunan laser, dabaru.

Duba | Injin Yanke Laser na Yadi

Zaɓi Wanda Ya Dace da Buƙatarku

Yadda ake yanke masana'anta ta Laser a gida ko masana'anta?

Kwanan nan mun sami buƙatu da yawa game da masu yanke laser na masana'anta don amfani a gida ko bita, mun yanke shawarar bayyana abubuwa a sarari kuma a miƙe.

Ee, masana'anta yanke laser a gidaabu ne mai yiwuwaamma kuna buƙatar la'akari da girman yadinku da girman gadon laser.

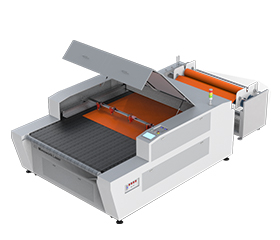

Yawanci, ƙaramin injin yanke laser zai yi kyau kamarna'urar yanke laser 6040, kumaInjin yanke laser 9060.

Kumaana buƙatar tsarin samun iska, zai fi kyau idan kuna da bututun iska ko kuma hanyar fita.

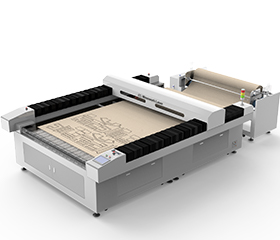

Ga masana'anta,Ana buƙatar samar da taro mai yawa, don haka muna ba da shawarar mizaninYanke Laser na masana'anta 1610, kumainjin yanke laser mafi girma1630.

Mai ciyarwa ta atomatikkumateburin jigilar kayaiya aiki tare, fahimtaratomatikyanke laser na masana'anta.

Ba wai kawai haka ba, mun yi bincike da kuma ƙirƙiro hanyoyin magance matsaloli daban-daban don samun ingantaccen aiki, ƙarancin aiki, da sauran buƙatu na musamman.

Misali: Kawuna da yawa na Laser don Yanke Yadi

◼Shugaban Laser tare da Alamar Tawada: Alama da Yankewa

Mai ciyarwa mai matakai biyu:Yanke Laser Layer 2

Yaya game da Laser Engraving akan Yadi?

A tsakiyar zanen laser na CO2 akwai laser na CO2 da kansa, wanda ke samar da hasken da ya fi ƙarfin gaske a wani takamaiman tsawon rai. Wannan tsawon rai yana da tasiri musamman wajen sassaka da yanke kayayyaki iri-iri, ciki har da yadi.

Idan hasken laser ya yi mu'amala da masakar, yana dumama saman, wanda ke haifar da tururi a cikin gida. Wannan tsari yana ƙirƙirar tsare-tsare masu inganci da rikitarwa, wanda ke ba da damar yin zane-zane dalla-dalla waɗanda ke da wahalar cimmawa ta hanyar hanyoyin gargajiya.

Amfanin sassaka Laser na CO2:

1. Daidaito:Ikon ƙirƙirar tsare-tsare masu rikitarwa da cikakkun bayanai tare da cikakken daidaito.

2. Sauƙin amfani:Ya dace da nau'ikan yadi iri-iri, ciki har da auduga, polyester, da gauraye.

3. Dorewa:Hanya mafi tsafta idan aka kwatanta da sassaka na gargajiya, rage sharar gida da amfani da sinadarai.

Ƙarfafa Ƙirƙira

Zane-zanen laser na CO2 wata fasaha ce mai sauyi wadda ke canza yadda ake tsara da kuma samar da yadi. Tana bayar da kayan aiki mai ƙarfi ga masu fasaha, 'yan kasuwa, da masu zane, wanda ke ba su damar tura iyakokin kerawa.

Bincika Saitin Yadi na Laser Engraving

1. Zaɓar Yadi Mai Dacewa

2. Tsarin Zane (Bitmap vs Vector)

3. Sigogi Mafi Kyau na Laser

4. Sanya Yadi sannan ka fara sassaka

Ko kai mai sha'awar kayan kwalliya ne, ko mai sana'a, ko kuma mai ƙirƙirar kayan da suka dace da muhalli, zane-zanen laser na CO2 a kan masana'anta yana buɗe duniyar damarmaki da ake jira a bincika. Daga ƙirƙirar masana'anta na musamman, zuwa aikace-aikacen ƙira na zamani, damar ba ta da iyaka!

Samfuran Masana'anta na Laser

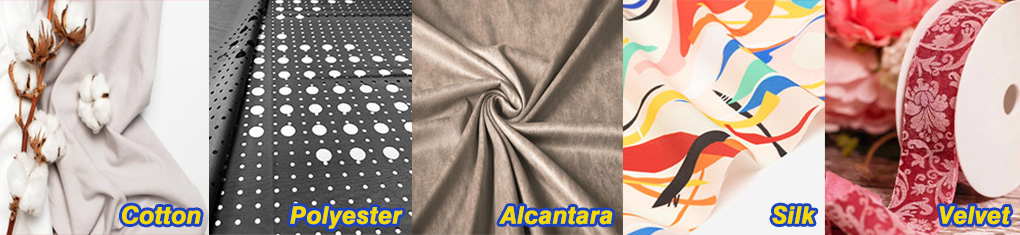

Ba duk masaku ne suka dace da zane-zanen laser ba. Ga taƙaitaccen bayani game da nau'ikan masaku da suka fi dacewa:

Mafi kyawun Yadi don Zane-zanen Laser

Polyester: Yadi mai yawan polyester shine mafi kyawun zaɓi don sassaka laser. Abubuwan polymer ɗin suna hulɗa da zafin laser yadda ya kamata, wanda ke ba da damar sassaka daidai kuma bayyananne. Ana amfani da polyester sosai a cikin kayan wasanni da kayan aiki saboda juriyarsa da kuma kaddarorinsa masu hana danshi.

Yadudduka Masu Ƙalubale

Kayan Halitta da na Halitta: Yadi da aka yi da auduga, siliki, ulu, ko wasu kayan halitta na iya zama da wahalar sassaka. Waɗannan kayan ba za su iya samar da sakamako bayyananne ba saboda abubuwan da suka ƙunsa da kuma yadda suke amsawa ga zafi.

Kammalawa

Domin samun sakamako mai kyau a fannin sassaka laser, a mai da hankali kan yadi masu amfani da polyester. Abubuwan da suke da shi ba wai kawai suna sauƙaƙa sassaka daidai ba ne, har ma suna ƙara juriya da aiki a aikace-aikace daban-daban.

Kayan Aiki Na Musamman Na Laser Engraving Fabric:

ulu, ji, kumfa, kayan ado na jeans,audugar neoprene, nailan, masana'anta na zane, karammiski, da sauransu.

Duk wani rikice-rikice da Tambayoyi don Yadda ake Saita Laser Yankan don Yadi

Lokacin Saƙo: Satumba-05-2023