Tips and Tricks for Achieving Perfect Results with a Fabric Laser Cutter

Laser cutting fabric is a game-changer for designers, offering a precise way to bring intricate ideas to life.

If you want to achieve flawless results, getting your settings and techniques just right is key.

In this article, we’ll walk you through everything you need to know about laser cutting fabric. From the best settings to tried-and-true techniques, we’ve got the tips to help you elevate your projects and achieve stunning results. Let’s dive in!

Table of Content:

What is Laser Cutting Fabric?

Laser cutting fabric is a revolutionary technology that's changing the game in textiles and design.

At its essence, it uses a high-powered laser beam to cut through different types of fabrics with incredible precision.

The benefits are impressive: you get clean, sealed edges that stop fraying in its tracks, the ability to create intricate and complex patterns, and the versatility to work with everything from delicate silk to durable canvas. It’s a fantastic way to bring your creative visions to life!

>> Crafting Precision with Light <<

Laser-cutting fabric is not limited by traditional cutting tools' constraints, allowing for the creation of intricate lace-like patterns.

Custom designs, and even personalized logos or monograms on clothing and accessories.

Additionally, it's a non-contact process, meaning there's no direct physical contact with the fabric, minimizing the risk of damage or distortion.

The Best Laser Settings for Laser Cut on Fabric

Getting the right laser settings is crucial for achieving top-notch results when cutting fabric. The optimal settings can vary based on several factors, including the thickness and type of fabric, your design, and the specific laser cutter you’re using.

Here are some general guidelines to help you set up your laser for fabric cutting:

▶ Laser Power for Laser Cut Fabric:

The laser power you choose should match the thickness of your fabric.

>> For thin and delicate fabrics, aim for a lower power setting of about 10-20%.

>> For thicker fabrics, increase the power to around 50-60%.

This way, you’ll ensure clean cuts without damaging your materials!

Laser Tube for Laser Cutter

CO2 laser cutting is a widely used and efficient method suitable for various fabrics, including polyester, cotton, nylon, felt, Cordura, silk, and more.

Typically, a 100W laser tube works well for most applications.

However, if you have specific needs—like cutting multiple layers of fabric or specialized composite materials—it’s essential to consider those requirements.

We always recommend conducting a laser test before starting actual fabric production. This helps ensure you achieve the desired results without any surprises!

Contact us for more professional advice if you have problems with laser cutting fabric.

▶ Speed of Laser Cutting Fabric:

The cutting speed of the laser is another critical factor that varies with fabric thickness:

>> For thin and delicate fabrics, use a slower speed of about 10-15 mm/s.

>> For thicker fabrics, you can increase the speed to around 20-25 mm/s.

Adjusting the speed appropriately ensures clean cuts while maintaining the integrity of the fabric!

▶ Frequency:

Set the laser frequency to a high value of 1000-2000 Hz.

This ensures clean and precise cuts, reducing the risk of rough edges.

▶ Air Assist:

Utilizing an air assist feature is beneficial.

It helps blow away debris from the cutting area, keeping it clean and preventing potential damage to the fabric during the cutting process.

▶ Fume Extractor:

Fume Extractor Laser Cleaning

When cutting certain composite materials, you may encounter unpleasant odors.

A fume extractor is essential for maintaining a clean environment, particularly for clients working on sensitive projects, such as airbags.

This helps ensure a safer and more pleasant working atmosphere.

The fume extractor can help you solve these.

Still Having no Idea about Laser Cutting Fabric Setting, Contact us for More Detailed Advice

Techniques and Tips for Laser Cutting Fabric

To achieve the best results when laser cutting fabric, consider the following techniques and tips:

1. Preparing the Fabric

Wash and Iron: Always wash and iron the fabric to remove any wrinkles and dirt.

Fusible Stabilizer: Apply a fusible stabilizer to the back of the fabric. This helps prevent shifting during the cutting process.

2. Design Considerations

Intricacy and Detail: Keep in mind the complexity of your design.

Avoid very small details or sharp corners, as these can be challenging to cut accurately with a fabric laser cutter.

3. Test Cuts

Do a Test Cut: Always perform a test cut on a scrap piece of fabric before cutting your final design.

This will help you identify the optimal laser settings for your specific fabric and design.

4. Cleaning the Fabric Laser Cutter Machine

Regular Maintenance: After cutting, clean the laser cutter to prevent debris from accumulating, which could potentially damage the machine.

Regular maintenance ensures optimal performance and longevity.

Video Display | How to Laser Cut Canvas Fabric

Video Display | Can Laser Cut Multi-layer Fabric?

Why a Fabric Laser Cutter is the Best Tool for Cutting Fabric

While various laser cutters can cut fabric, a dedicated fabric laser cutter is the optimal choice for several reasons:

1. Precision and Accuracy

Tailored Design: Fabric laser cutters are specifically designed for cutting fabric, featuring software that allows for precise control over the cutting process. This ensures that the fabric is cut to the exact specifications of your design.

2. Specialized Features

Air Assist: Many fabric laser cutters come equipped with air assist features that blow away debris from the cutting area. This keeps the fabric clean and minimizes the risk of damage during the cutting process.

3. Intricate Design Capability

Complex Patterns: The precision of fabric laser cutting enables designers to create intricate and detailed designs that would be difficult to achieve with traditional cutting methods.

In conclusion, laser cutting fabric is an innovative and precise way of cutting fabric that provides designers with the ability to create intricate designs with precision and accuracy.

By using the right laser settings, techniques.

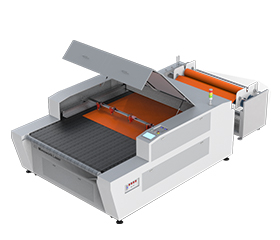

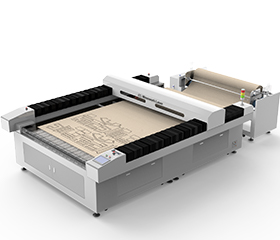

Glance | Fabric Laser Cutting Machine

Choose the One that Suits your Requirement

How to Laser Cut Fabric at Home or Factory?

Recently receiving many requirements about fabric laser cutters for home use or workshop, we decided to get things clear and straight.

Yes, laser cut fabric at home is feasible but you need to consider your fabric sizes and laser bed size.

Usually, a small laser cutter will be great like laser cutter 6040, and laser cutter 9060.

And the ventilation system is required, better if you have a ventilation tube or outlet.

For the factory, mass production is required, so we recommend the standard fabric laser cutter1610, and larger format laser cutting machine1630.

Auto-feeder and conveyor table can work together, realizing automatic fabric laser cutting.

Not only that, we have researched and developed versatile solutions for higher efficiency, less labor, and other special requirements.

Example: Multiple Laser Heads for Cutting Fabric

◼ Laser Head with Ink Marker: Marking and Cutting

Dual-layers Feeder: Laser Cut 2 Layers Fabric

How about Laser Engraving on Fabric?

At the core of CO2 laser engraving is the CO2 laser itself, which generates a highly concentrated beam of light at a specific wavelength. This wavelength is particularly effective for engraving and cutting a variety of materials, including fabric.

When the laser beam interacts with the fabric, it heats the surface, causing localized vaporization. This process creates precise and intricate patterns, allowing for detailed designs that are difficult to achieve through traditional methods.

Advantages of CO2 Laser Engraving:

1. Precision: The ability to create intricate and detailed patterns with high accuracy.

2. Versatility: Suitable for a wide range of fabrics, including cotton, polyester, and blends.

3. Sustainability: A cleaner method compared to traditional engraving, minimizing waste and chemical use.

Empowering Creativity

CO2 laser engraving is a revolutionary technology that transforms how textiles are designed and produced. It offers a powerful tool for artisans, entrepreneurs, and designers, enabling them to push the boundaries of creativity.

Explore Laser Engraving Fabric Setting

1. Choosing the Right Fabric

2. Design Engraving Pattern (Bitmap vs Vector)

3. Optimal Laser Parameters

4. Put on the Fabric and Start Engraving

Whether you’re a fashion enthusiast, a craftsperson, or an eco-conscious creator, CO2 laser engraving on fabric opens up a world of possibilities waiting to be explored. From unique, personalized fabric creations to innovative design applications, the potential is limitless!

Laser Engraving Fabric Samples

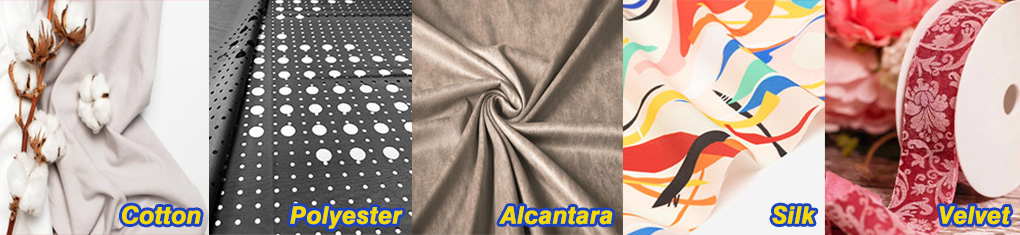

Not all fabrics are ideal for laser engraving. Here’s a breakdown of the types of fabrics that work best:

Best Fabrics for Laser Engraving

Polyester: Fabrics with a high polyester content are the best candidates for laser engraving. The polymer content interacts effectively with the laser's heat, allowing for precise and clear engravings. Polyester is commonly used in sportswear and activewear due to its durability and moisture-wicking properties.

Challenging Fabrics

Natural and Organic Materials: Fabrics primarily made of cotton, silk, wool, or other organic materials can be more difficult to engrave. These materials may not produce clear results due to their composition and the way they react to heat.

Conclusion

For optimal results in laser engraving, focus on polyester-based fabrics. Their properties not only facilitate precise engraving but also enhance durability and performance in various applications.

Common Materials of Laser Engraving Fabric:

fleece, felt, foam, denim, neoprene, nylon, canvas fabric, velvet, etc.

Any Confusions and Questions for How to Set Laser Cutting for Fabrics

Post time: Sep-05-2023