Laser acrylic yanke yana ba da hanya mai aminci, inganci, kuma madaidaiciya don ƙirƙirar samfura da ƙira iri-iri.Wannan jagorar ta zurfafa cikin ƙa'idodi, fa'idodi, ƙalubale, da dabarun amfani da laser acrylic., yana aiki a matsayin muhimmin tushe ga masu farawa da ƙwararru.

Abubuwan da ke ciki

1. Gabatarwa ga Laser Yanke na Acrylic

Menene Yanke acrylic

da laser?

Yanke acrylic tare da laserya ƙunshi amfani da hasken laser mai ƙarfi, wanda fayil ɗin CAD ke jagoranta, don yanke ko sassaka takamaiman ƙira a kan kayan acrylic.

Ba kamar hanyoyin gargajiya kamar haƙa ko yanke itace ba, wannan dabarar ta dogara ne akan ingantaccen fasahar laser don tururi kayan cikin tsafta da inganci, rage ɓarna da kuma samar da sakamako mai kyau.

Wannan hanyar ta dace musamman ga masana'antu waɗanda ke buƙatar cikakken daidaito, cikakkun bayanai masu rikitarwa, da kuma fitarwa mai ɗorewa, wanda hakan ya sa ya zama zaɓi mafi kyau fiye da hanyoyin yankewa na gargajiya.

▶ Me yasa ake yanke acrylic da laser?

Fasahar Laser tana ba da fa'idodi marasa misaltuwa ga yanke acrylic:

•Gefuna masu santsi:Yana samar da gefuna masu gogewa da harshen wuta akan acrylic da aka fitar, yana rage buƙatun bayan an sarrafa su.

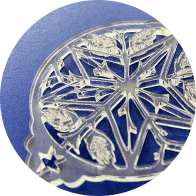

•Zaɓuɓɓukan sassaka:Yana ƙirƙirar zane-zanen fari masu sanyi akan acrylic na siminti don aikace-aikacen ado da aiki.

•Daidaito da Maimaitawa:Yana tabbatar da sakamako iri ɗaya don ƙira masu rikitarwa.

•Sauƙin amfani:Ya dace da ƙananan ayyuka na musamman da kuma samar da kayayyaki da yawa.

LED Acrylic Stand White

▶ Aikace-aikacen Injin Yanke Laser na Acrylic

Acrylic mai yanke laser yana da amfani iri-iri a fannoni daban-daban:

✔ Talla:Alamar musamman, tambarin da aka haskaka, da kuma nunin talla.

✔ Tsarin Gine-gine:Samfuran gini, allunan ado, da kuma sassan bango masu haske.

✔ Motoci:Abubuwan da ke cikin allon kwamfuta, murfin fitila, da gilashin gaba.

✔ Kayayyakin Gida:Masu shirya dafa abinci, masu dafa abinci, da kuma masu samar da akwatin kifaye.

✔ Lambobin yabo da karramawa:Kyaututtuka da alluna tare da zane-zane na musamman.

✔ Kayan Ado:'Yan kunne, abin wuya, da kuma brooches masu inganci.

✔ Marufi:Akwatuna da kwantena masu ɗorewa da kyau.

>> Duba bidiyon game da yanke acrylic da laser

Shin kuna da wasu ra'ayoyi game da yanke laser na acrylic?

▶ CO2 VS Fiber Laser: Wanne Ya Dace da Yanke Acrylic

Don yanke acrylic,Laser CO2 tabbas shine mafi kyawun zaɓisaboda kayan aikin gani da yake da su.

Kamar yadda kuke gani a cikin teburin, lasers na CO2 yawanci suna samar da haske mai haske a tsawon mita 10.6, wanda acrylic ke sha cikin sauƙi. Duk da haka, lasers na fiber suna aiki a tsawon mita 1, wanda itace ba ya sha sosai idan aka kwatanta da lasers na CO2. Don haka idan kuna son yankewa ko yi wa ƙarfe alama, laser ɗin fiber yana da kyau. Amma ga waɗannan waɗanda ba ƙarfe ba kamar itace, acrylic, yadi, tasirin yanke laser na CO2 ba shi da misaltuwa.

2. Amfani da rashin amfani da Laser Yanke Acrylic

▶ Fa'idodi

✔ Gefen Yankan Sanyi Mai Sanyi:

Ƙarfin laser mai ƙarfi zai iya yanke takardar acrylic nan take a tsaye. Zafin yana rufe kuma yana goge gefen ya zama santsi da tsabta.

✔ Yankewa Ba Tare Da Lalatawa Ba:

Injin yanke laser yana da tsarin sarrafawa mara taɓawa, yana kawar da damuwa game da karce da fashewa saboda babu damuwa ta injiniya. Babu buƙatar maye gurbin kayan aiki da guntu.

✔ Babban Daidaito:

Daidaitaccen tsari mai kyau yana sa acrylic laser cutter ya zama tsari mai rikitarwa bisa ga fayil ɗin da aka tsara. Ya dace da kayan adon acrylic na musamman da kayan masana'antu da na likita.

✔ Sauri da Inganci:

Ƙarfin ƙarfin laser, babu damuwa na injiniya, da kuma sarrafa kansa ta dijital, yana ƙara saurin yankewa da kuma ingancin samarwa gaba ɗaya.

✔ Sauƙin amfani:

Yanke laser na CO2 yana da sauƙin amfani don yanke zanen acrylic masu kauri daban-daban. Ya dace da kayan acrylic masu siriri da kauri, yana ba da sassauci a aikace-aikacen aikin.

✔ Ƙarancin Sharar Kayan Aiki:

Hasken da aka mayar da hankali a kai na laser CO2 yana rage sharar abu ta hanyar ƙirƙirar faɗin kerf mai kunkuntar. Idan kuna aiki tare da samar da taro, software na laser mai wayo zai iya inganta hanyar yankewa, da kuma haɓaka yawan amfani da kayan.

Gefen Crystal Clear

Tsarin Yanke Mai Tsauri

▶ Rashin amfani

Hotunan da aka sassaka a kan Acrylic

Duk da cewa fa'idodin yanke acrylic da laser suna da yawa, yana da mahimmanci a yi la'akari da rashin amfanin:

Yawan Samarwa Mai Canji:

Yawan samarwa lokacin yanke acrylic da laser wani lokacin yana iya zama ba daidai ba. Abubuwa kamar nau'in kayan acrylic, kauri, da takamaiman sigogin yanke laser suna taka rawa wajen tantance saurin da daidaiton samarwa. Waɗannan masu canji na iya shafar ingancin aikin gabaɗaya, musamman a manyan ayyuka.

3. Tsarin yanke acrylic da laser cutter

Acrylic na yanke laser hanya ce mai inganci da inganci don ƙirƙirar zane-zane masu cikakken bayani, amma samun sakamako mafi kyau yana buƙatar fahimtar kayan aiki da tsarin. Dangane da tsarin CNC da ainihin abubuwan da ke cikin injin, injin yanke laser na acrylic yana aiki ta atomatik kuma yana da sauƙin aiki.

Kawai kuna buƙatar loda fayil ɗin ƙira zuwa kwamfutar, kuma saita sigogi bisa ga fasalulluka na kayan aiki da buƙatun yankewa.

Ga jagorar mataki-mataki wanda ya haɗa da muhimman abubuwan da ake la'akari da su don aiki da acrylics.

Mataki na 1. Shirya Inji da Acrylic

Shiri na Acrylic:A ajiye acrylic a wuri mai faɗi kuma a tsaftace shi a kan teburin aiki, kuma ya fi kyau a gwada shi ta amfani da tarkace kafin a yanke ainihin laser.

Injin Laser:tantance girman acrylic, girman tsarin yankewa, da kauri acrylic, don zaɓar injin da ya dace.

Mataki na 2. Saita Software

Fayil ɗin Zane:shigo da fayil ɗin yankewa zuwa software.

Saitin Laser:Yi magana da ƙwararren laser ɗinmu don samun sigogin yankewa gabaɗaya. Amma kayayyaki daban-daban suna da kauri, tsarki, da yawa daban-daban, don haka gwadawa kafin shine mafi kyawun zaɓi.

Mataki na 3. Acrylic ɗin Yanke Laser

Fara Yanke Laser:Laser ɗin zai yanke tsarin ta atomatik bisa ga hanyar da aka bayar. Ku tuna ku buɗe hanyar samun iska don share hayakin, sannan ku rage iskar da ke hura don tabbatar da cewa gefen ya yi santsi.

Ta hanyar bin waɗannan matakai a hankali, za ku iya cimma sakamako mai kyau, mai inganci lokacin yanke acrylic na laser.

Tsarin shiri mai kyau, tsari, da matakan tsaro suna da mahimmanci don samun nasara, wanda ke ba ku damar amfani da fa'idodin wannan fasahar yankewa ta zamani gaba ɗaya.

Koyarwar Bidiyo: Yanke Laser & Zane Acrylic

4. Abubuwan da ke TasiriYankan Acrylic da Laser

Acrylic na yanke laser yana buƙatar daidaito da fahimtar abubuwa da dama da ke shafar inganci da ingancin aikin. A ƙasa, za mu bincikaMuhimman abubuwan da za a yi la'akari da su yayin yanke acrylic.

▶ Saitunan Injin Yanke Laser

Daidaita saitunan injin yanke laser ɗinku yadda ya kamata yana da mahimmanci don cimma sakamako mafi kyau. Injinan suna zuwa da fasaloli daban-daban waɗanda za a iya daidaitawa da su.shafi tsarin yankewa, ciki har da:

1. Ƙarfi

• Ka'ida ta gaba ɗaya ita ce a wareWatts 10 (W)ikon laser ga kowane mutum1 mmna kauri na acrylic.

• Ƙarfin da ya fi girma yana ba da damar yanke kayan da suka yi kauri cikin sauri kuma yana ba da ingantaccen ingancin yankewa ga kayan da suka yi kauri.

2. Yawan lokaci

Yana shafar adadin bugun laser a cikin daƙiƙa ɗaya, yana shafar daidaiton yankewa. Mafi kyawun mitar laser ya dogara da nau'in acrylic da ingancin yanke da ake so:

• Acrylic da aka yi da siminti:Yi amfani da mitoci masu yawa(20–25 kHz)don gefuna masu gogewa da harshen wuta.

• Acrylic da aka fitar:Ƙananan mitoci(2–5 kHz)aiki mafi kyau don tsaftace yanke.

3. Sauri

Saurin da ya dace ya bambanta dangane da ƙarfin laser da kauri kayan. Saurin sauri yana rage lokacin yankewa amma yana iya yin illa ga daidaiton kayan da suka kauri.

Teburan da ke bayanin matsakaicin gudu da mafi kyau ga matakan ƙarfi da kauri daban-daban na iya zama nassoshi masu amfani.

Tebur 1: Jadawalin Saitunan Yanke Laser na CO₂ don Matsakaicin Gudu

Daraja a Tebur:https://artizono.com/

Tebur na 2: Jadawalin Saitunan Yanke Laser na CO₂ don Ingantaccen Sauri

Daraja a Tebur:https://artizono.com/

▶Kauri na Acrylic

Kauri na takardar acrylic yana tasiri kai tsaye ga ƙarfin laser da ake buƙata.Gashinan da suka yi kauri suna buƙatar ƙarin kuzari don cimma kyakkyawan yankewa.

• A matsayin jagora na gabaɗaya, kusanWatts 10 (W)Ana buƙatar ƙarfin laser don kowane aiki1 mmna kauri na acrylic.

• Don kayan da suka fi siriri, zaku iya amfani da saitunan wutar lantarki masu ƙarancin ƙarfi da kuma saurin gudu mai jinkiri don tabbatar da isasshen shigarwar kuzari don yankewa.

• Idan wutar lantarki ta yi ƙasa sosai kuma ba za a iya rama ta hanyar rage gudu ba, ingancin yankewar na iya raguwa da buƙatun amfani.

Inganta saitunan wutar lantarki bisa ga kauri na kayan yana da mahimmanci don cimma yankewa mai santsi da inganci.

Ta hanyar la'akari da waɗannan abubuwan—saitunan injin, gudu, ƙarfi, da kauri kayan—zaka iya inganta inganci da daidaiton yanke laser na acrylic. Kowane abu yana taka muhimmiyar rawa wajen tabbatar da nasarar aikinka.

5. Injin Yanke Laser na Acrylic da aka Ba da Shawara

Jerin Laser na MimoWork

▶ Shahararrun Nau'ikan Yankan Laser na Acrylic

Buga Acrylic Laser Cutter: Ƙirƙirar Mai Kyau, An Ƙone

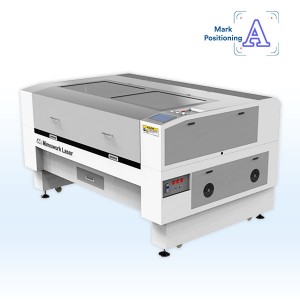

Domin biyan buƙatun yanke acrylic mai siffar UV da aka buga, MimoWork ya ƙera ƙwararren mai yanke laser na acrylic da aka buga.An sanye shi da kyamarar CCD, na'urar yanke laser ta kyamara za ta iya gane yanayin zane daidai kuma ta jagoranci kan laser ɗin zuwa yanke tare da kwane-kwane da aka buga. Na'urar yanke laser ta kyamarar CCD babban taimako ne ga acrylic da aka buga da laser, musamman tare da tallafin teburin yanke laser na zuma, ƙirar injin wucewa. Daga dandamalin aiki na musamman zuwa ƙwarewar sana'a mai kyau, Na'urar yanke laser ɗinmu ta yanke gefen ta wuce iyakoki. An ƙera ta musamman don Alamomi, kayan ado, sana'o'i da kyaututtuka a masana'antu, Yi amfani da ƙarfin fasahar kyamarar CCD mai ci gaba zuwa Acrylic da aka buga da kyau. Tare da watsa sikirin ƙwallon ƙafa da zaɓuɓɓukan injin Servo masu inganci, nutsar da kanka cikin daidaito mara daidaituwa da aiwatarwa mara aibi. Bari tunaninka ya tashi zuwa sabbin tsayi yayin da kake sake fasalta kyawun fasaha tare da fasaha mara misaltuwa.

Acrylic Sheet Laser Cutter, mafi kyawun kuInjin yanke laser na CNC na masana'antu

Ya dace da yanke laser mai girma da kauri acrylic zanen gado don saduwa da aikace-aikacen talla da masana'antu daban-daban.Teburin yanke laser mai girman 1300mm * 2500mm an tsara shi ne da hanyar shiga ta hanyoyi huɗu. Injin yanke laser ɗinmu na acrylic sheet laser zai iya kaiwa ga saurin yankewa na 36,000mm a minti ɗaya. Kuma tsarin watsa sikirin ƙwallon da injin servo yana tabbatar da kwanciyar hankali da daidaito ga motsi mai sauri na gantry, wanda ke ba da gudummawa ga yanke manyan kayan tsari na laser yayin da yake tabbatar da inganci da inganci. Ana amfani da zanen laser acrylic acrylic a masana'antar haske da kasuwanci, filin gini, masana'antar sinadarai, da sauran fannoni, kowace rana mun fi yawa a cikin kayan ado na talla, samfuran teburin yashi, da akwatunan nuni, kamar alamu, allon talla, allon akwatin haske, da allon haruffa na Ingilishi.

(Plexiglass/PMMA) AcrylicLaser Cutter, mafi kyawun kuInjin yanke laser na CNC na masana'antu

Ya dace da yanke laser mai girma da kauri acrylic zanen gado don saduwa da aikace-aikacen talla da masana'antu daban-daban.Teburin yanke laser mai girman 1300mm * 2500mm an tsara shi ne da hanyar shiga ta hanyoyi huɗu. Injin yanke laser na acrylic ɗinmu wanda aka nuna a babban gudu, zai iya kaiwa ga saurin yankewa na 36,000mm a minti ɗaya. Kuma tsarin watsa sikirin ƙwallon da injin servo yana tabbatar da kwanciyar hankali da daidaito ga motsi mai sauri na gantry, wanda ke ba da gudummawa ga yanke manyan kayan tsari na laser yayin da yake tabbatar da inganci da inganci. Ba wai kawai ba, ana iya yanke acrylic mai kauri ta hanyar bututun laser mai ƙarfi na 300W da 500W na zaɓi. Injin yanke laser na CO2 zai iya yanke manyan kayan ƙarfi masu kauri, kamar acrylic da itace.

Nemi Ƙarin Shawara game da Siyan Injin Yanke Acrylic Laser

6. Nasihu na Gabaɗaya don yanke acrylic da laser

Lokacin aiki tare da acrylic, dole ne a yi amfani da shi.Yana da mahimmanci a bi waɗannan jagororin don tabbatar da aminci da kuma cimma sakamako mafi kyau:

1. Kada Ka Bar Injin Ba Tare Da Kulawa Ba

• Acrylic yana da sauƙin ƙonewa idan aka yi amfani da shi wajen yankewa da laser, wanda hakan ke sa kulawa ta ci gaba da zama dole.

• A matsayin aikin tsaro gabaɗaya, kada a taɓa amfani da na'urar yanke laser—komai kayan—ba tare da an same ta ba.

2. Zaɓi Nau'in Acrylic Mai Dacewa

• Zaɓi nau'in acrylic da ya dace da takamaiman aikace-aikacenku:

o Simintin Acrylic: Ya dace da sassaka saboda launinsa mai launin fari.

o Acrylic da aka fitar: Ya fi dacewa da yankewa, samar da gefuna masu santsi, masu goge harshen wuta.

3. Ɗaga Acrylic

• Yi amfani da tallafi ko spacers don ɗaga acrylic daga teburin yankewa.

• Tsawaitawa yana taimakawa wajen kawar da tunani a bayan gida, wanda zai iya haifar da alamun da ba a so ko lalacewar kayan.

Laser Yankan Acrylic Sheet

7. Tambayoyin da ake yawan yi game da yankewar Laser na Acrylic

▶ Ta Yaya Laser Yanke Acrylic Ke Aiki?

Yankewar Laser ya ƙunshi mayar da hankali kan ƙarfin hasken laser a saman acrylic ɗin, wanda ke tururi kayan a kan hanyar yankewa da aka tsara.

Wannan tsari yana siffanta zanen acrylic zuwa siffar da ake so. Bugu da ƙari, ana iya amfani da irin wannan laser don sassaka ta hanyar daidaita saitunan don tururi kawai wani siririn Layer daga saman acrylic, ƙirƙirar zane-zanen saman dalla-dalla.

▶ Wane Nau'in Yankan Laser Zai Iya Yanka Acrylic?

Masu yanke laser na CO2 sune mafi inganci don yanke acrylic.

Waɗannan suna fitar da hasken laser a yankin infrared, wanda acrylic zai iya sha, ba tare da la'akari da launinsa ba.

Lasers masu ƙarfi na CO2 na iya yanke acrylic a cikin izinin tafiya ɗaya, ya danganta da kauri.

▶ Me Yasa Za Ku Zabi Mai Yanke Laser Don Acrylic

Maimakon Hanyoyin Gargajiya?

Tayin yanke Laserdaidai, santsi, da kuma gefuna masu kaifi ba tare da taɓawa da kayan ba, yana rage karyewar.

Yana da sassauƙa sosai, yana rage ɓarnar kayan aiki, kuma baya haifar da lalacewa ga kayan aiki.

Bugu da ƙari, yanke laser na iya haɗawa da lakabi da cikakkun bayanai masu kyau, yana ba da inganci mafi kyau idan aka kwatanta da hanyoyin gargajiya.

▶ Zan iya yanke Acrylic ta hanyar Laser da kaina?

Eh, za ka iyaacrylic ɗin laser ɗin da aka yanke matuƙar kuna da kayan aiki, kayan aiki, da ƙwarewa da suka dace.

Duk da haka, domin samun sakamako mai inganci a fannin ƙwararru, sau da yawa ana ba da shawarar ɗaukar ƙwararrun ƙwararru ko kamfanoni na musamman.

Waɗannan kasuwancin suna da kayan aiki da ƙwararrun ma'aikata don tabbatar da sakamako mai kyau.

▶ Menene Mafi Girman Acrylic da Yake

Za a iya yanke Laser?

Girman acrylic da za a iya yankewa ya dogara da girman gadon mai yanke laser.

Wasu injuna suna da ƙananan girman gado, yayin da wasu kuma za su iya ɗaukar manyan guntu, har zuwa1200mm x 2400mmko ma fiye da haka.

▶ Shin Acrylic Yana Ƙonewa Yayin Yanke Laser?

Ko acrylic yana ƙonewa yayin yankewa ya dogara da ƙarfin laser da saitunan saurinsa.

Yawanci, ƙaramin ƙonewa yana faruwa a gefuna, amma ta hanyar inganta saitunan wutar lantarki, zaku iya rage waɗannan ƙonewa kuma ku tabbatar da tsabtace yankewa.

▶ Shin Duk Acrylic Ya Dace Da Yanke Laser?

Yawancin nau'ikan acrylic sun dace da yanke laser, amma bambancin launi da nau'in kayan na iya yin tasiri ga tsarin.

Yana da mahimmanci a gwada acrylic ɗin da kake son amfani da shi don tabbatar da cewa ya dace da na'urar yanke laser ɗinka kuma ya samar da sakamakon da ake so.

Fara Mai Ba da Shawara Kan Laser Yanzu!

> Wane bayani kake buƙatar bayarwa?

| ✔ | Kayan aiki na musamman (kamar plywood, MDF) |

| ✔ | Girman Kayan Aiki da Kauri |

| ✔ | Me Kake Son Yi a Laser? (Yanke, Huda, ko sassaka) |

| ✔ | Matsakaicin Tsarin da za a sarrafa |

> Bayanin tuntuɓar mu

Za ku iya samun mu ta Facebook, YouTube, da Linkedin.

Nutsewa Mai Zurfi ▷

Kana iya sha'awar

# Nawa ne kudin na'urar yanke laser ta acrylic?

# yadda ake zaɓar teburin aiki don yanke laser acrylic?

# yadda ake samun madaidaicin tsawon hankali don yanke acrylic na laser?

# menene kuma kayan da laser zai iya yankewa?

Duk wani rudani ko tambayoyi game da Acrylic Laser Cutter, kawai ku tambaye mu a kowane lokaci

Lokacin Saƙo: Janairu-10-2025