I-acrylic yokusika nge-laser inikeza indlela ephephile, ephumelelayo, nenembile yokwakha imikhiqizo nemiklamo eyahlukahlukene.Lo mhlahlandlela uhlola ngokujulile izimiso, izinzuzo, izinselele, kanye namasu asebenzayo okusika i-acrylic nge-laser, esebenza njengomthombo obalulekile kwabaqalayo kanye nochwepheshe ngokufanayo.

Okuqukethwe

1. Isingeniso Sokusika Nge-Laser Kwe-Acrylic

Kuyini ukusika i-acrylic

nge-laser?

Ukusika i-acrylic nge-laserkuhilela ukusebenzisa umsebe we-laser onamandla amakhulu, oqondiswa ifayela le-CAD, ukusika noma ukuqopha imiklamo ethile ezintweni ze-acrylic.

Ngokungafani nezindlela zendabuko njengokubhoboza noma ukusaha, le ndlela incike kubuchwepheshe obuqondile be-laser ukuze iguqule izinto zibe nombala ohlanzekile futhi ophumelelayo, inciphise imfucuza futhi ilethe imiphumela emihle kakhulu.

Le ndlela ifaneleka kakhulu ezimbonini ezidinga ukunemba okuphezulu, imininingwane eyinkimbinkimbi, kanye nomkhiqizo ohambisanayo, okwenza kube ukukhetha okuthandwayo kunezindlela zokusika ezivamile.

▶ Kungani usika i-acrylic nge-laser?

Ubuchwepheshe be-laser bunikeza izinzuzo ezingenakuqhathaniswa zokusika i-acrylic:

•Imiphetho Ebushelelezi:Ikhiqiza imiphetho epholishwe ngomlilo ku-acrylic ekhishwe, okunciphisa izidingo zangemva kokucutshungulwa.

•Izinketho Zokuqopha:Idala ukuqoshwa okumhlophe okubandayo ku-acrylic ehlanganisiwe ukuze kusetshenziswe ukuhlobisa nokusebenzayo.

•Ukunemba Nokuphindeka:Iqinisekisa imiphumela efanayo yemiklamo eyinkimbinkimbi.

•Ukuguquguquka:Ifanele kokubili amaphrojekthi amancane angokwezifiso kanye nokukhiqizwa ngobuningi.

I-LED Acrylic Stand Emhlophe

▶ Ukusetshenziswa Komshini Wokusika we-Acrylic Laser

I-acrylic esikiwe nge-laser inezinhlobo eziningi zezicelo kuzo zonke izigaba:

✔ Ukukhangisa:Izimpawu ezenziwe ngokwezifiso, ama-logo akhanyayo, kanye nezibonisi zokukhangisa.

✔ Ukwakhiwa Kwezakhiwo:Amamodeli ezakhiwo, amaphaneli okuhlobisa, kanye nezingxenye ezibonakala obala.

✔ Izimoto:Izingxenye zedeshibhodi, izembozo zezibani, kanye namafasitela engaphambili.

✔ Izinto Zasekhaya:Abahleli bekhishi, ama-coasters, kanye nama-aquarium.

✔ Imiklomelo Nokuqashelwa:Izindebe nama-plaque anezithombe eziqoshwe ngendlela eyenzelwe wena.

✔ Ubucwebe:Amacici, imihlobiso elengayo, kanye nama-brooch anembile kakhulu.

✔ Ukupakisha:Amabhokisi nezitsha ezihlala isikhathi eside futhi ezibukeka kahle.

>> Buka amavidiyo mayelana nokusika i-acrylic nge-laser

Ingabe kukhona imibono mayelana nokusika i-acrylic nge-laser?

▶ I-CO2 VS I-Fiber Laser: Yikuphi Okufanela Ukusika I-Acrylic

Ukusika i-acrylic,I-CO2 Laser ngokuqinisekile iyisinqumo esingcono kakhulungenxa yempahla yayo ebonakalayo.

Njengoba ubona etafuleni, ama-laser e-CO2 ngokuvamile akhiqiza umsebe ogxilile kubude be-wavelength obungaba ama-micrometer ayi-10.6, obumuncwa kalula yi-acrylic. Kodwa-ke, ama-laser e-fiber asebenza kubude be-wavelength obungaba yi-micrometer eyi-1, obungamuncwa ngokugcwele yizinkuni uma kuqhathaniswa nama-laser e-CO2. Ngakho-ke uma ufuna ukusika noma ukumaka ensimbini, i-laser ye-fiber inhle kakhulu. Kodwa kulaba abangewona insimbi njengokhuni, i-acrylic, indwangu, nomphumela wokusika we-laser we-CO2 awunakuqhathaniswa.

2. Izinzuzo kanye nokubi kokusika i-Acrylic nge-laser

▶ Izinzuzo

✔ Unqenqema Olubushelelezi:

Amandla e-laser anamandla angasika ngokushesha ishidi le-acrylic ngendlela eqondile. Ukushisa kuvala futhi kupholishe umphetho ube bushelelezi futhi uhlanzekile.

✔ Ukusika Okungathintani:

Isisiki se-laser sinikeza ukucutshungulwa okungenakuthinta, okususa ukukhathazeka ngokuklwebheka kwezinto nokuqhekeka ngoba akukho ukucindezeleka komshini. Asikho isidingo sokushintsha amathuluzi nama-bits.

✔ Ukunemba Okuphezulu:

Ukunemba okuphezulu kakhulu kwenza i-acrylic laser cutter isikwe ibe amaphethini ayinkimbinkimbi ngokwefayela eliklanywe ngendlela efanele. Ifanelekela ukuhlobisa okuhle kwe-acrylic okwenziwe ngokwezifiso kanye nezinto zezimboni nezezokwelapha.

✔ Isivinini Nokusebenza Kahle:

Amandla e-laser aqinile, akukho ukucindezeleka komshini, kanye nokulawula okuzenzakalelayo kwedijithali, kukhulisa kakhulu isivinini sokusika kanye nokusebenza kahle kokukhiqiza konke.

✔ Ukuguquguquka:

Ukusika nge-laser ye-CO2 kuyasebenziseka kakhulu ekusikeni amashidi e-acrylic anobukhulu obuhlukahlukene. Kufanelekile kokubili ezintweni ezincane nezinkulu ze-acrylic, okunikeza ukuguquguquka ekusetshenzisweni kwephrojekthi.

✔ Ukungcola Okuncane Kwezinto Ezibalulekile:

Umugqa ogxilile we-laser ye-CO2 unciphisa imfucuza yezinto ezibonakalayo ngokudala ububanzi obuncane be-kerf. Uma usebenza ngokukhiqiza ngobuningi, isofthiwe ehlakaniphile yokufaka izidleke ze-laser ingenza ngcono indlela yokusika, futhi ikhulise izinga lokusetshenziswa kwezinto ezibonakalayo.

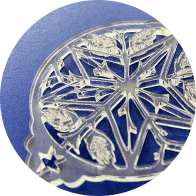

Umphetho Ocacile Wekristalu

Iphethini Yokusika Eyinkimbinkimbi

▶ Izinkinga

Izithombe Eziqoshiwe Ku-Acrylic

Nakuba izinzuzo zokusika i-acrylic nge-laser ziningi, kubaluleke ngokulinganayo ukucabangela ukushiyeka:

Amanani Okukhiqiza Aguquguqukayo:

Izinga lokukhiqiza lapho kusikwa i-acrylic nge-laser ngezinye izikhathi lingaguquguquki. Izici ezifana nohlobo lwezinto ze-acrylic, ukujiya kwazo, kanye nemingcele ethile yokusika i-laser idlala indima ekunqumeni isivinini kanye nokufana kokukhiqiza. Lezi ziguquguquki zingathinta ukusebenza kahle kwenqubo, ikakhulukazi emisebenzini emikhulu.

3. Inqubo yokusika i-acrylic nge-laser cutter

I-acrylic yokusika nge-laser iyindlela enembile nephumelelayo yokudala imiklamo enemininingwane, kodwa ukuthola imiphumela emihle kudinga ukuqonda izinto zokwakha kanye nenqubo. Kuye ngohlelo lwe-CNC kanye nezingxenye zomshini eziqondile, umshini wokusika nge-laser we-acrylic uyazenzakalela futhi kulula ukuwusebenzisa.

Udinga nje ukulayisha ifayela lokuklama kukhompyutha, bese usetha amapharamitha ngokuya ngezici zezinto kanye nezidingo zokusika.

Nasi umhlahlandlela wesinyathelo ngesinyathelo ohlanganisa izinto ezibalulekile okufanele uzicabangele uma usebenzisa ama-acrylic.

Isinyathelo 1. Lungisa Umshini Ne-Acrylic

Ukulungiswa kwe-Acrylic:gcina i-acrylic icwengekile futhi ihlanzekile etafuleni lokusebenza, futhi kungcono ukuhlola usebenzisa izingcezu ngaphambi kokusika nge-laser yangempela.

Umshini We-Laser:nquma usayizi we-acrylic, usayizi wephethini yokusika, kanye nobukhulu be-acrylic, ukuze ukhethe umshini ofanele.

Isinyathelo 2. Setha Isofthiwe

Ifayela Lokuklama:ngenisa ifayela lokusika kusofthiwe.

Ukusetha kwe-Laser:Khuluma nochwepheshe wethu we-laser ukuze uthole imingcele yokusika evamile. Kodwa izinto ezahlukene zinobukhulu obuhlukene, ubumsulwa, kanye nobuningi, ngakho ukuhlola ngaphambi kokusebenzisa kuyindlela engcono kakhulu.

Isinyathelo 3. I-Acrylic Esikiwe Nge-Laser

Qala Ukusika Nge-Laser:I-laser izosika ngokuzenzakalelayo iphethini ngokwendlela enikeziwe. Khumbula ukuvula umoya ukuze ususe intuthu, bese wehlisa umoya ovunguzayo ukuqinisekisa ukuthi unqenqema lubushelelezi.

Ngokulandela ngokucophelela lezi zinyathelo, ungafinyelela imiphumela eqondile nekhwalithi ephezulu lapho usika i-acrylic nge-laser.

Ukulungiselela okufanele, ukusetha, kanye nezinyathelo zokuphepha kubalulekile empumelelweni, okukuvumela ukuthi usebenzise ngokugcwele izinzuzo zalobu buchwepheshe bokusika obuthuthukisiwe.

Isifundo Sevidiyo: Ukusika Nokuqopha Nge-Laser Acrylic

4. Izici EzithonyayoUkusika i-Acrylic Nge-Laser

Ukusika i-acrylic nge-laser kudinga ukunemba nokuqonda izici eziningana ezithinta ikhwalithi kanye nokusebenza kahle kwenqubo. Ngezansi, sizohlolaizici ezibalulekile okufanele uzicabangele lapho usika i-acrylic.

▶ Izilungiselelo Zomshini Wokusika Nge-Laser

Ukulungisa kahle izilungiselelo zomshini wakho wokusika nge-laser kubalulekile ekufinyeleleni imiphumela emihle. Imishini iza nezici ezahlukahlukene ezilungisekayo ezithikuthinta inqubo yokusika, kufaka phakathi:

1. Amandla

• Umthetho ojwayelekile ukwabelaAma-watts ayi-10 (W)amandla e-laser kuwo wonke umuntu1 mmubukhulu be-acrylic.

• Amandla aphezulu aphezulu enza kube lula ukusika izinto ezincane ngokushesha futhi anikeze ikhwalithi engcono yokusika izinto ezijiyile.

2. Imvamisa

Ithonya inani lama-pulse e-laser ngomzuzwana, ithinta ukunemba kokusikwa. Imvamisa ye-laser efanele incike ohlotsheni lwe-acrylic kanye nekhwalithi yokusikwa oyifunayo:

• I-Acrylic Ehlanganisiwe:Sebenzisa imvamisa ephezulu(20–25 kHz)emaphethelweni acwebezelisiwe ngomlilo.

• I-Acrylic Ekhishwe:Imvamisa ephansi(2–5 kHz)isebenza kahle kakhulu ekusikeni okuhlanzekile.

3. Isivinini

Isivinini esifanele siyahlukahluka ngokusekelwe emandleni e-laser kanye nobukhulu bezinto. Isivinini esisheshayo sinciphisa isikhathi sokusika kodwa singalimaza ukunemba kwezinto ezijiyile.

Amathebula achaza isivinini esiphezulu nesifanele samazinga ahlukene wamandla kanye nobukhulu angasebenza njengezinkomba eziwusizo.

Ithebula 1: Ishadi Lezilungiselelo Zokusika Nge-Laser ze-CO₂ Lesivinini Esiphezulu

Ikhredithi Yethebula:https://artizono.com/

Ithebula 2: Ishadi Lezilungiselelo Zokusika Nge-Laser ze-CO₂ zesivinini esifanele

Ikhredithi Yethebula:https://artizono.com/

▶Ubukhulu be-Acrylic

Ubukhulu beshidi le-acrylic buthinta ngqo amandla e-laser adingekayo.Amashidi amakhulu adinga amandla engeziwe ukuze athole ukusika okuhlanzekile.

• Njengesiqondiso esijwayelekile, cisheAma-watts ayi-10 (W)amandla e-laser ayadingeka kuwo wonke umuntu1 mmubukhulu be-acrylic.

• Ngezinto ezincane, ungasebenzisa izilungiselelo zamandla aphansi kanye nesivinini esisheshayo ukuqinisekisa ukuthi kufakwe amandla anele okusika.

• Uma amandla ephansi kakhulu futhi engenakukhokhelwa ngokunciphisa isivinini, ikhwalithi yokusika ingase ingahlangabezani nezidingo zohlelo lokusebenza.

Ukuthuthukisa izilungiselelo zamandla ngokuya ngobukhulu bezinto kubalulekile ekufinyeleleni ukusika okubushelelezi nokusezingeni eliphezulu.

Ngokucabanga ngalezi zici—izilungiselelo zomshini, isivinini, amandla, kanye nobukhulu bezinto ezibonakalayo—ungathuthukisa ukusebenza kahle kanye nokunemba kokusika nge-laser ye-acrylic. Ingxenye ngayinye idlala indima ebalulekile ekuqinisekiseni impumelelo yephrojekthi yakho.

5. Umshini Wokusika we-Acrylic Laser Onconyiwe

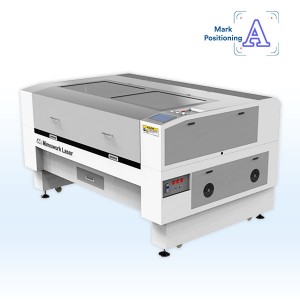

Uchungechunge lwe-MimoWork Laser

▶ Izinhlobo Ezidumile Zokusika I-Laser ye-Acrylic

Umsiki we-Laser we-Acrylic ophrintiwe: Ubuciko obunamandla, obuvuthayo

Ukuze kuhlangatshezwane nezidingo zokusika i-acrylic ephrintiwe nge-UV, i-MimoWork yaklama umsiki we-laser we-acrylic ophrintiwe ngobuchwepheshe.Ifakwe ikhamera ye-CCD, umsiki we-laser wekhamera angayibona ngokunembile indawo yephethini futhi aqondise ikhanda le-laser ukuthi lisike eceleni komugqa ophrintiwe. Umsiki we-laser wekhamera ye-CCD uwusizo olukhulu lwe-acrylic ephrintiwe nge-laser, ikakhulukazi ngokusekelwa kwetafula lokusika le-laser elinoju, umklamo womshini wokudlula. Kusukela kumapulatifomu okusebenza ngokwezifiso kuya kobuciko obuhle, umsiki wethu we-laser osezingeni eliphezulu udlula imingcele. Yakhelwe ngokukhethekile izimpawu, imihlobiso, imisebenzi yezandla kanye nezipho embonini, Sebenzisa amandla obuchwepheshe bekhamera ye-CCD ethuthukisiwe kuya ku-acrylic ephrintiwe enephethini eqoshiwe kahle. Nge-Ball Screw Transmission kanye nezinketho ze-High-Precision Servo Motor, Zicwilise ku-Unmatched Precision kanye nokusebenza okungenaphutha. Vumela ukucabanga kwakho kukhuphukele ezindaweni ezintsha njengoba uchaza kabusha ubuhle bobuciko ngobuhlakani obungenakuqhathaniswa.

Umsiki we-Laser weshidi le-Acrylic, okungcono kakhulu kuweumshini wokusika we-laser we-CNC wezimboni

Kuhle kakhulu ekusikeni nge-laser amashidi amakhulu kanye nama-acrylic aqinile ukuze kuhlangatshezwane nezikhangiso ezahlukahlukene kanye nezicelo zezimboni.Ithebula lokusika i-laser elingu-1300mm * 2500mm lenzelwe ukufinyelela ngezindlela ezine. Lifakwe ngesivinini esikhulu, umshini wethu wokusika i-laser weshidi le-acrylic ungafinyelela isivinini sokusika esingu-36,000mm ngomzuzu. Futhi uhlelo lokudlulisa i-ball screw kanye ne-servo motor luqinisekisa ukuzinza nokunemba kokunyakaza kwe-gantry ngesivinini esikhulu, okufaka isandla ekusikeni i-laser izinto ezinkulu ngenkathi kuqinisekiswa ukusebenza kahle kanye nekhwalithi. Amashidi e-acrylic okusika i-laser asetshenziswa kabanzi embonini yokukhanyisa neyezentengiselwano, insimu yokwakha, imboni yamakhemikhali, kanye neminye imikhakha, nsuku zonke sivame kakhulu ekuhlobiseni izikhangiso, amamodeli etafula lesihlabathi, namabhokisi okubonisa, njengezibonakaliso, amabhodi okukhangisa, iphaneli yebhokisi lokukhanya, kanye nephaneli yezinhlamvu zesiNgisi.

(I-Plexiglass/PMMA) I-AcrylicUmsiki we-Laser, okungcono kakhulu kuweumshini wokusika we-laser we-CNC wezimboni

Kuhle kakhulu ekusikeni nge-laser amashidi amakhulu kanye nama-acrylic aqinile ukuze kuhlangatshezwane nezikhangiso ezahlukahlukene kanye nezicelo zezimboni.Ithebula lokusika i-laser elingu-1300mm * 2500mm lenzelwe ukufinyelela ngezindlela ezine. Lifakwe ngesivinini esikhulu, umshini wethu wokusika i-laser we-acrylic ungafinyelela isivinini sokusika esingu-36,000mm ngomzuzu. Futhi uhlelo lokudlulisa i-ball screw kanye ne-servo motor luqinisekisa ukuzinza nokunemba kokunyakaza kwe-gantry ngesivinini esikhulu, okufaka isandla ekusikeni i-laser izinto ezinkulu ngenkathi kuqinisekiswa ukusebenza kahle kanye nekhwalithi. Akukhona lokho kuphela, i-acrylic ejiyile ingasikwa nge-laser tube enamandla aphezulu ye-300W kanye ne-500W yokuzikhethela. Umshini wokusika i-laser we-CO2 ungasika izinto eziqinile ezinkulu nezinkulu, njenge-acrylic kanye nokhuni.

Thola Iseluleko Esengeziwe mayelana Nokuthengwa Komshini Wokusika I-Acrylic Laser

6. Amathiphu Ajwayelekile Okusika i-acrylic nge-laser

Uma usebenza ne-acrylic,Kubalulekile ukulandela lezi ziqondiso ukuqinisekisa ukuphepha nokuthola imiphumela emihle kakhulu:

1. Ungalokothi Ushiye Umshini Unganakwa

• I-Acrylic ivutha kalula uma ivikelwe ekusikeni nge-laser, okwenza ukugadwa njalo kube yinto ebalulekile.

• Njengomkhuba ojwayelekile wokuphepha, ungalokothi usebenzise umshini wokusika nge-laser—kungakhathaliseki ukuthi uyini—ngaphandle kokuba khona.

2. Khetha Uhlobo Olufanele Lwe-Acrylic

• Khetha uhlobo lwe-acrylic olufanele lokusetshenziswa kwakho:

o I-Cast Acrylic: Ilungele ukuqoshwa ngenxa yokuphela kwayo okumhlophe okuqandisiwe.

o I-Acrylic Ekhishwe: Ifaneleka kangcono ukusika, ikhiqize imiphetho ebushelelezi, ecwebezelayo.

3. Phakamisa i-Acrylic

• Sebenzisa izisekelo noma ama-spacer ukuze uphakamise i-acrylic etafuleni lokusika.

• Ukuphakama kusiza ekususeni ukubonakaliswa kwangemuva, okungabangela amamaki angafuneki noma umonakalo ezintweni.

Ishidi le-Acrylic lokusika i-Laser

7. Ukusikwa kwe-Acrylic nge-Laser Imibuzo Evame Ukubuzwa

▶ Kusebenza Kanjani Ukusika I-Acrylic Nge-Laser?

Ukusika nge-laser kuhilela ukugxila umsebe we-laser onamandla phezu kobuso be-acrylic, okwenza izinto zibe nsundu ngendlela yokusika ekhethiwe.

Le nqubo ibumba ishidi le-acrylic libe yisimo esifunwayo. Ngaphezu kwalokho, i-laser efanayo ingasetshenziswa ekuqopheni ngokulungisa izilungiselelo ukuze kushiswe ungqimba oluncane kuphela ebusweni be-acrylic, kudale imiklamo eningiliziwe yobuso.

▶ Uhlobo Luni Lokusika Nge-Laser Olungasika I-Acrylic?

Izisiki ze-laser ze-CO2 zisebenza kahle kakhulu ekusikeni i-acrylic.

Lezi zikhipha imisebe ye-laser endaweni ye-infrared, engayimunca i-acrylic, kungakhathaliseki ukuthi inombala onjani.

Ama-laser e-CO2 anamandla amakhulu angasika i-acrylic ngephasi elilodwa, kuye ngokuthi ubukhulu buyini.

▶ Kungani Ukhetha Umsiki We-Laser We-Acrylic

Esikhundleni Sezindlela Ezivamile?

Izipesheli zokusika nge-laserimiphetho yokusika eqondile, ebushelelezi, futhi eqhubekayo ngaphandle kokuthintana nezinto zokwakha, okunciphisa ukuphuka.

Iguquguquka kakhulu, inciphisa ukungcola kwezinto ezibonakalayo, futhi ayibangeli ukuguguleka kwamathuluzi.

Ngaphezu kwalokho, ukusika nge-laser kungafaka phakathi ukulebula kanye nokubeka imininingwane emincane, okunikeza ikhwalithi ephezulu uma kuqhathaniswa nezindlela ezivamile.

▶ Ngingazisika Ngokwami I-Acrylic Nge-Laser?

Yebo, ungakwazii-acrylic esikiwe nge-laser inqobo nje uma unezinto zokwakha ezifanele, amathuluzi, kanye nolwazi.

Kodwa-ke, ukuze uthole imiphumela yekhwalithi yobungcweti, kuvame ukunconywa ukuqasha ochwepheshe abafanelekayo noma izinkampani ezikhethekile.

Lawa mabhizinisi anemishini edingekayo kanye nabasebenzi abanamakhono ukuqinisekisa imiphumela esezingeni eliphezulu.

▶ Yisiphi isayizi esikhulu kunazo zonke se-Acrylic

Ingabe Kungasikwa Nge-Laser?

Usayizi we-acrylic onganqunywa uncike kusayizi wombhede womsiki we-laser.

Eminye imishini inosayizi omncane wemibhede, kanti eminye ingathwala izingcezu ezinkulu, kuze kufike ku-1200mm x 2400mmnoma ngisho nangaphezulu.

▶ Ingabe i-Acrylic Iyashisa Ngesikhathi Sokusika Nge-Laser?

Ukuthi i-acrylic iyasha yini ngesikhathi sokusika kuncike emandleni kanye nezilungiselelo zesivinini se-laser.

Ngokuvamile, ukusha okuncane kwenzeka emaphethelweni, kodwa ngokwenza ngcono izilungiselelo zamandla, unganciphisa lokhu kusha futhi uqinisekise ukuthi ukuncishiswa kuhlanzekile.

▶ Ingabe Zonke Izinto Ezise-Acrylic Zilungele Ukusika Nge-Laser?

Izinhlobo eziningi ze-acrylic zifanelekela ukusika nge-laser, kodwa ukuhlukahluka kombala nohlobo lwezinto kungathinta inqubo.

Kubalulekile ukuhlola i-acrylic ohlose ukuyisebenzisa ukuqinisekisa ukuthi iyahambisana nesicuphi sakho se-laser futhi iveza imiphumela oyifunayo.

Qala Umeluleki We-Laser Manje!

> Yiluphi ulwazi okudingeka ulunikeze?

| ✔ | Izinto Ezithile (njenge-plywood, i-MDF) |

| ✔ | Usayizi Wezinto Nobukhulu |

| ✔ | Yini Ofuna Ukuyenza Nge-Laser? (ukusika, ukubhoboza, noma ukuqopha) |

| ✔ | Ifomethi ephezulu okufanele icutshungulwe |

> Ulwazi lwethu lokuxhumana

Ungasithola nge-Facebook, i-YouTube, kanye ne-Linkedin.

Gxila Kakhulu ▷

Ungase ube nentshisekelo ku-

# kubiza malini ukusika nge-laser ye-acrylic?

# ungayikhetha kanjani itafula lokusebenza le-acrylic yokusika i-laser?

# ungayithola kanjani ubude obufanele bokugxila be-acrylic yokusika nge-laser?

# yini enye into engasikwa nge-laser?

Ilebhu Yomshini We-Laser We-MimoWork

Noma yikuphi Ukudideka Noma Imibuzo Nge-Acrylic Laser Cutter, Vele Usibuze Noma Kunini

Isikhathi sokuthunyelwe: Jan-10-2025