Injin yanke laser na fiber laser yana ɗaya daga cikin injinan yanke laser da aka fi amfani da su. Ba kamar bututun laser na gas da watsa haske na injin laser na CO2 ba, injin yanke laser na fiber yana amfani da laser na fiber dakebuldon watsa hasken laser. Tsawon tsawon hasken laser ɗin fiber shine 1/10 kawai na tsawon tsayin da laser CO2 ke samarwa wanda ke ƙayyade bambancin amfani da su biyun. Babban bambanci tsakanin injin yanke laser na CO2 da injin yanke laser na fiber yana cikin waɗannan fannoni.

1. Injin samar da Laser

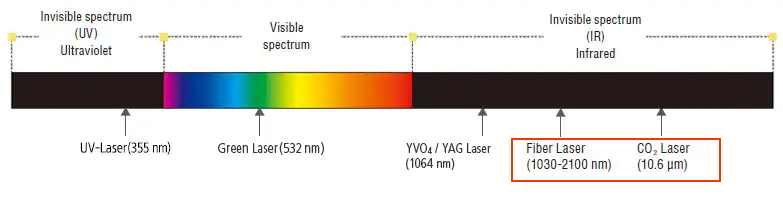

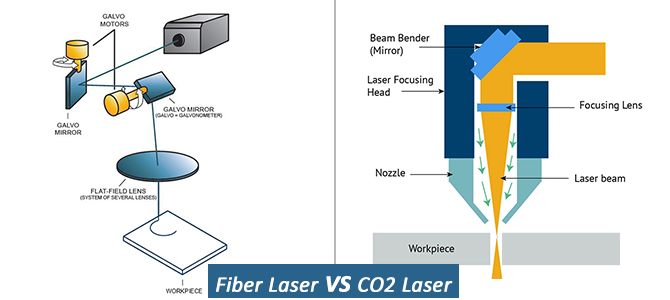

Injin alamar laser na CO2 yana amfani da laser CO2, kuma injin alamar laser na fiber yana amfani da laser fiber. Tsawon laser na carbon dioxide shine 10.64μm, kuma tsawon laser na fiber na optical shine 1064nm. Laser ɗin fiber na optical yana dogara ne akan fiber na optical don gudanar da laser, yayin da laser na CO2 yana buƙatar gudanar da laser ta hanyar tsarin hanyar gani ta waje. Saboda haka, ana buƙatar daidaita hanyar laser na CO2 kafin a yi amfani da kowace na'ura, yayin da laser ɗin fiber na optical ba ya buƙatar daidaitawa.

Mai sassaka laser na CO2 yana amfani da bututun laser na CO2 don samar da hasken laser. Babban hanyar aiki ita ce CO2, kuma O2, He, da Xe iskar gas ce mai taimako. Hasken laser na CO2 yana haskakawa ta hanyar ruwan tabarau mai haske da mai da hankali sannan a mayar da hankali kan kan abin yanka laser. Injin laser na fiber yana samar da hasken laser ta hanyar famfunan diode da yawa. Sannan ana aika hasken laser zuwa kan abin yanka laser, kan abin alama na laser da kan abin walda na laser ta hanyar kebul na fiber optic mai sassauƙa.

2. Kayan Aiki & Aikace-aikace

Tsawon tsayin hasken laser na CO2 shine 10.64um, wanda ya fi sauƙin sha ta kayan da ba na ƙarfe ba. Duk da haka, tsawon tsayin hasken laser na fiber shine 1.064um, wanda ya fi guntu sau 10. Saboda wannan ƙaramin tsayin haske, mai yanke laser na fiber ya fi ƙarfin mai yanke laser na CO2 kusan sau 100. Don haka injin yanke laser na fiber, wanda aka sani da injin yanke laser na ƙarfe, ya dace sosai don yanke kayan ƙarfe, kamar subakin karfe, ƙarfe mai carbon, ƙarfe mai galvanized, jan ƙarfe, aluminum, da sauransu.

Injin sassaka na laser CO2 zai iya yankewa da sassaka kayan ƙarfe, amma ba haka yake da inganci ba. Hakanan ya haɗa da yawan sha na kayan zuwa tsayi daban-daban na laser. Halayen kayan suna ƙayyade wane nau'in tushen laser ne mafi kyawun kayan aiki don sarrafawa. Injin laser CO2 galibi ana amfani da shi don yankewa da sassaka kayan da ba na ƙarfe ba. Misali,itace, acrylic, takarda, fata, masana'anta, da sauransu.

Nemi injin laser mai dacewa don aikace-aikacen ku

3. Sauran Kwatancen tsakanin laser CO2 da laser fiber

Tsawon rayuwar laser mai zare zai iya kaiwa awanni 100,000, tsawon rayuwar laser mai ƙarfi na CO2 zai iya kaiwa awanni 20,000, kuma tsawon bututun laser mai gilashi zai iya kaiwa awanni 3,000. Don haka kuna buƙatar maye gurbin bututun laser na CO2 bayan shekaru kaɗan.

Ƙara koyo game da fiber laser da CO2 laser da na'urar laser mai karɓa

Lokacin Saƙo: Agusta-31-2022