Ungayila njani ukusika kwe-laser okusemgangathweni ophezulu?

▶ Injongo Yakho:

Injongo yakho kukufumana imveliso ekumgangatho ophezulu ngokusebenzisa ngokupheleleyo amandla e-laser kunye nezixhobo ezichanekileyo. Oku kuthetha ukuqonda amandla e-laser kunye nezixhobo ezisetyenziswayo nokuqinisekisa ukuba azityhalelwa ngaphaya kwemida yazo.

I-laser echanekileyo kakhulu sisixhobo esinamandla esiphucula kakhulu inkqubo yemveliso. Ukuchaneka kwayo kunye nokuchaneka kwayo kwenza kube lula ukudala uyilo oluntsonkothileyo noluneenkcukacha. Ngokusebenzisa ngokupheleleyo i-laser, abavelisi banokuqinisekisa ukuba yonke into yemveliso yenziwe ngokuchanekileyo, nto leyo ephumela kwisiphumo esiphezulu.

Yintoni ekufuneka uyazi?

▶ Ubungakanani obuncinci beempawu:

Xa usebenza ngezinto ezincinci kune-0.040 intshi okanye i-1 millimeter, kubalulekile ukuqaphela ukuba zinokuba buthathaka okanye zibe buthathaka. Ezi milinganiselo zincinci zenza ukuba izinto okanye iinkcukacha zibe semngciphekweni wokwaphuka okanye wokonakala, ingakumbi ngexesha lokuphathwa okanye ukusetyenziswa.

Ukuqinisekisa ukuba usebenza ngaphakathi kwemida yezakhono zesixhobo ngasinye, kuyacetyiswa ukuba ubhekisele kumlinganiselo omncinci wobukhulu obubonelelwe kwiphepha lezinto kwikhathalogu yezinto. Ezi zilinganiso zisebenza njengesikhokelo sokumisela ubungakanani obuncinci obunokugcinwa ngokuthembekileyo yile nto ngaphandle kokubeka emngciphekweni ulwakhiwo lwayo.

Ngokujonga ubungakanani obuncinci bobukhulu, unokufumanisa ukuba uyilo okanye iinkcukacha ozifunayo zingena phantsi kwemida yezixhobo. Oku kuya kukunceda uphephe iingxaki ezinokubakho ezifana nokwaphuka okungalindelekanga, ukugqwetheka, okanye ezinye iindlela zokungaphumeleli ezinokuvela ngokutyhala izixhobo ngaphaya kwamandla azo.

Ukuqwalasela ubuthathaka beempawu ezincinci kune-0.040 intshi (1mm) kunye nokujonga ubungakanani obuncinci bekhathalogu yezinto eziphathekayo, ungenza izigqibo ezinolwazi kunye nohlengahlengiso ukuqinisekisa ukwenziwa ngempumelelo kunye nokusebenza kakuhle kwezinto ozifunayo.

▶Ubungakanani obuphantsi beCandelo:

Xa usebenza ngebhedi yelaser, kubalulekile ukuqaphela imida yobukhulu beendawo ezisetyenziswayo. Iindawo ezincinci kune-0.236 intshi okanye i-6mm ububanzi zinokuwela kwibhedi yelaser zize zilahleke. Oku kuthetha ukuba ukuba inxalenye incinci kakhulu, isenokungabanjwa ngokukhuselekileyo ngexesha lenkqubo yokusika okanye yokukrola ngelaser, kwaye inokutyibilika kwiindawo ezikwibhedi.

ToQinisekisa ukuba iindawo zakho zifanelekile ukusika okanye ukukrola nge-laser, kubalulekile ukujonga ubungakanani beendawo ezincinci zezinto ezithile. Ezi zilinganiso zingafumaneka kwiphepha lezinto kwikhathalogu yezinto. Ngokubhekisa kwezi nkcukacha, unokumisela iimfuno zobukhulu obuncinci kwiindawo zakho kwaye uphephe nayiphi na ilahleko okanye umonakalo onokubakho ngexesha lenkqubo yokusika okanye yokukrola nge-laser.

▶Ubuncinane bendawo yokuzoba:

Xa kufikwa kwi-raster area graving, ukucaca kwesicatshulwa kunye neendawo ezincinci ezingaphantsi kwe-0.040 intshi (1mm) akucaci kakhulu. Oku kungabikho kokucaca kubonakala ngakumbi njengoko ubungakanani bombhalo buncipha. Nangona kunjalo, kukho indlela yokuphucula umgangatho womzobo kunye nokwenza umbhalo okanye iimilo zakho zibonakale ngakumbi.

Enye indlela esebenzayo yokufezekisa oku kukudibanisa iindlela zokukrola indawo kunye nemigca. Ngokusebenzisa zombini ezi ndlela, ungenza ukukrola okubonakalayo nokubalaseleyo. Ukukrola indawo kubandakanya ukususa izinto kumphezulu ngendlela eqhubekayo, nto leyo ebangela ukubonakala okugudileyo nokungaguquguqukiyo. Kwelinye icala, ukukrola umgca kubandakanya ukukrola imigca emincinci kumphezulu, nto leyo eyongeza ubunzulu kunye nentsingiselo kuyilo.

Ukujonga ividiyo | Sika kwaye ukrole i-acrylic tutorial

Ukujonga ividiyo | ukusika iphepha

Utshintsho loBungqingqwa bezinto:

Igama elithi "ukunyamezelana kobukhulu" libhekisa kuluhlu olwamkelekileyo lokwahluka kubukhulu bezinto. Luphawu olubalulekileyo olunceda ukuqinisekisa umgangatho kunye nokuhambelana kwezinto. Olu linganiselo luhlala lubonelelwa ngezinto ezahlukeneyo kwaye lunokufumaneka kwiphepha lezinto ezifanelekileyo kwikhathalogu yezinto.

Ukunyamezelana kobukhulu kubonakaliswa njengoluhlu, olubonisa ubukhulu obuphezulu nobuncinci obuvumelekileyo bento ethile. Umzekelo, ukuba ukunyamezelana kobukhulu beshiti yesinyithi±0.1mm, oko kuthetha ukuba ubukhulu bokwenyani bephepha bunokwahluka ngaphakathi kolu luhlu. Umda ophezulu uya kuba bubukhulu obuqhelekileyo kunye ne-0.1mm, ngelixa umda ongezantsi uya kuba bubukhulu obuqhelekileyo ngaphandle kwe-0.1mm.

Kubalulekile ukuba abathengi baqwalasele ukunyamezelana kobukhulu xa bekhetha izinto ezihambelana neemfuno zabo ezithile. Ukuba iprojekthi ifuna ubungakanani obuchanekileyo, kuyacetyiswa ukuba bakhethe izinto ezinokunyamezelana kobukhulu obuqinileyo ukuqinisekisa iziphumo ezichanekileyo. Kwelinye icala, ukuba iprojekthi ivumela umahluko othile kubukhulu, izinto ezinokunyamezelana okukhululekileyo zinokuba neendleko ezingcono.

Ufuna Ukuqala Ikamva Elihle?

Kuthekani Ngezi Zikhetho Ezintle?

Ngaba ufuna ukuqalisa nge-Laser Cutter & Engraver kwangoko?

Qhagamshelana Nathi ukuze ubuze ukuze uqalise kwangoko!

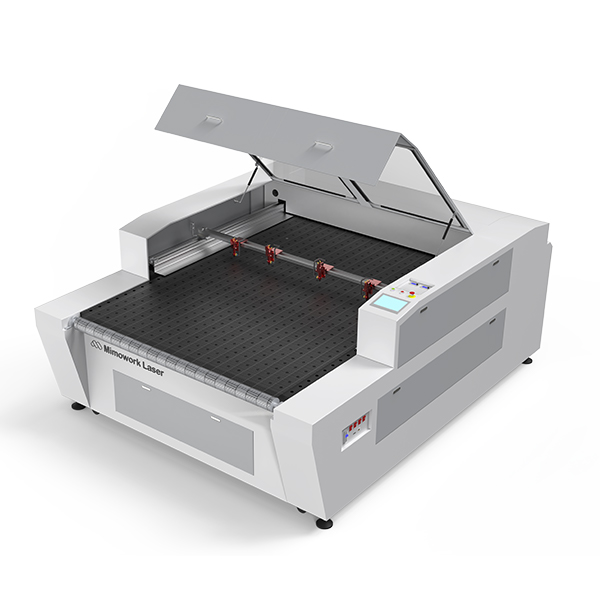

▶ Ngathi - I-MimoWork Laser

Asivumelani neziphumo eziphakathi

I-Mimowork ngumvelisi we-laser ojolise kwiziphumo, oseShanghai naseDongguan eTshayina, ozisa ubuchule bokusebenza obude beminyaka engama-20 ukuvelisa iinkqubo ze-laser nokubonelela ngezisombululo ezipheleleyo zokucubungula kunye nemveliso kwii-SME (amashishini amancinci naphakathi) kuluhlu olubanzi lwamashishini.

Amava ethu atyebileyo kwizisombululo ze-laser zokucubungula izinto zesinyithi nezingezizo ezesinyithi asekelwe nzulu kwiintengiso zehlabathi, iimoto kunye neenqwelomoya, izixhobo zesinyithi, usetyenziso lwe-dye sublimation, ishishini lelaphu kunye nelaphu.

Endaweni yokubonelela ngesisombululo esingaqinisekanga esifuna ukuthengwa kubavelisi abangafanelekanga, iMimoWork ilawula yonke inxalenye yekhonkco lemveliso ukuqinisekisa ukuba iimveliso zethu zisebenza kakuhle rhoqo.

I-MimoWork izibophelele ekudalweni nasekuphuculweni kwemveliso ye-laser kwaye iphuhlise iteknoloji ye-laser ephucukileyo emininzi ukuphucula ngakumbi amandla emveliso yabathengi kunye nokusebenza kakuhle okukhulu. Sifumana amalungelo obunikazi amaninzi eteknoloji ye-laser, sihlala sigxile kumgangatho kunye nokhuseleko lweenkqubo zomatshini we-laser ukuqinisekisa ukuveliswa kokucubungula okuqhubekayo nokuthembekileyo. Umgangatho womatshini we-laser uqinisekiswe yi-CE kunye ne-FDA.

Inkqubo yeLaser yeMimoWork ingasika iAcrylic nge-laser kwaye ikrole nge-laser ngeAcrylic, ekuvumela ukuba uqalise iimveliso ezintsha kwiindidi ezahlukeneyo zamashishini. Ngokungafaniyo nabasiki bokusika, ukukrola njengento yokuhombisa kunokufezekiswa kwimizuzwana embalwa ngokusebenzisa umkroli welaser. Ikwakunika ithuba lokuthatha iiodolo ezincinci njengemveliso enye eyenzelwe wena, kwaye ezinkulu njengeemveliso ezikhawulezayo ngamawaka, zonke zikwixabiso elifikelelekayo lotyalo-mali.

Fumana ezinye izimvo kwiSiteshi sethu seYouTube

Ixesha lokuthumela: Julayi-14-2023