How to design for the highest quality laser cutting?

▶ Your Goal:

Your goal is to achieve the highest quality product by fully utilizing the potential of high-precision laser and materials. This means understanding the capabilities of the laser and the materials being used and ensuring that they are not pushed beyond their limits.

High-precision laser is a powerful tool that greatly enhances the production process. Its accuracy and precision enable the creation of intricate and detailed designs with ease. By fully utilizing the laser, manufacturers can ensure that every aspect of the product is precisely crafted, resulting in a superior end result.

What you need to know?

▶ Minimum Feature Size:

When dealing with features smaller than 0.040 inches or 1 millimeter, it's important to note that they are likely to be delicate or fragile. These small dimensions make the components or details susceptible to breaking or damage, especially during handling or use.

To ensure that you work within the limits of each material's capabilities, it's advisable to refer to the minimum size measurements provided on the material page in the materials catalog. These measurements serve as guidelines to determine the smallest dimensions that the material can reliably accommodate without compromising its structural integrity.

By checking the minimum size measurements, you can determine whether your intended design or specifications fall within the material's limitations. This will help you avoid potential issues such as unexpected breakage, distortion, or other forms of failure that may arise from pushing the material beyond its capabilities.

Considering the fragility of features smaller than 0.040 inches (1mm) and referring to the material catalog's minimum size measurements, you can make informed decisions and adjustments to ensure the successful fabrication and functionality of your desired components.

▶Minimum Part Size:

When working with a laser bed, it's important to be aware of the size limitations of the parts being used. Parts that are smaller than 0.236 inches or 6mm in diameter can potentially fall through the laser bed and be lost. This means that if a part is too small, it may not be securely held in place during the laser cutting or engraving process, and it could slip through the gaps in the bed.

To ensure that your parts are suitable for laser cutting or engraving, it's crucial to check the minimum part size measurements for each specific material. These measurements can be found on the material page in the materials catalog. By referring to these specifications, you can determine the minimum size requirements for your parts and avoid any potential loss or damage during the laser cutting or engraving process.

▶Minimum Engraving Area:

When it comes to raster area engraving, the clarity of text and thin areas that are less than 0.040 inches (1mm) is not very sharp. This lack of crispness becomes even more apparent as the text size decreases. However, there is a way to enhance the quality of the engraving and make your text or shapes more prominent.

One effective method to achieve this is by combining area and line engraving techniques. By incorporating both approaches, you can create a more visually appealing and standout engraving. Area engraving involves removing material from the surface in a continuous manner, resulting in a smooth and consistent appearance. On the other hand, line engraving involves etching fine lines onto the surface, which adds depth and definition to the design.

Video Glance | Cut & Engrave Acrylic Tutorial

Video Glance | paper cutting

Material Thickness Variation:

The term "thickness tolerance" refers to the acceptable range of variation in the thickness of a material. It is an important specification that helps ensure the quality and consistency of the material. This measurement is typically provided for various materials and can be found on the respective material page in the materials catalog.

The thickness tolerance is expressed as a range, indicating the maximum and minimum allowable thickness for a particular material. For example, if the thickness tolerance for a sheet of metal is ±0.1mm, it means that the actual thickness of the sheet can vary within this range. The upper limit would be the nominal thickness plus 0.1mm, while the lower limit would be the nominal thickness minus 0.1mm.

It is important for customers to consider the thickness tolerance when selecting materials for their specific needs. If a project requires precise dimensions, it is advisable to choose materials with tighter thickness tolerances to ensure accurate results. On the other hand, if a project allows for some variation in thickness, materials with looser tolerances may be more cost-effective.

Want to Get a Head Start?

What About These Great Options?

Want to get Started with a Laser Cutter& Engraver Right Away?

Contact Us for Inquire to get Started Right Away!

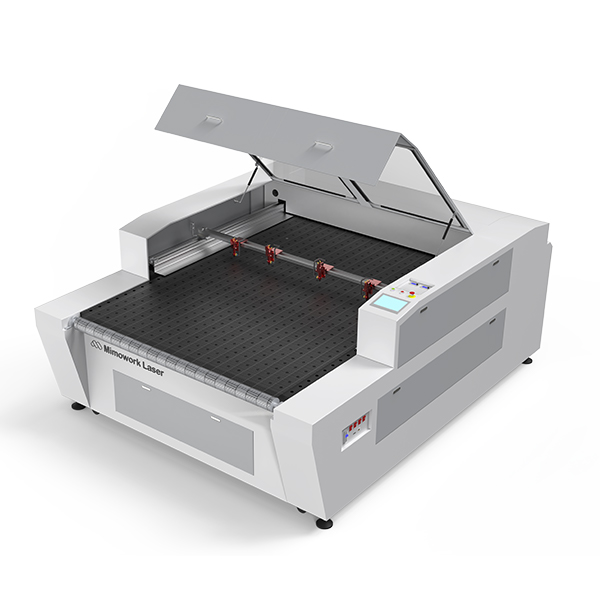

▶ About Us - MimoWork Laser

We Don't Settle for Mediocre Results

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20-year deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industry.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

MimoWork has been committed to the creation and upgrade of laser production and developed dozens of advanced laser technology to further improve clients' production capacity as well as great efficiency. Gaining many laser technology patents, we are always concentrating on the quality and safety of laser machine systems to ensure consistent and reliable processing production. The laser machine quality is certificated by CE and FDA.

MimoWork Laser System can laser cut Acrylic and laser engrave Acrylic, which allows you to launch new products for a wide variety of industries. Unlike milling cutters, engraving as a decorative element can be achieved within seconds by using a laser engraver. It also gives you the opportunity to take orders as small as one single unit customized product, and as large as thousands of rapid productions in batches, all within affordable investing prices.

Get More Ideas from Our YouTube Channel

Post time: Jul-14-2023