Indlela yokuklama ukusika kwekhwalithi ephezulu kakhulu ye-laser?

▶ Umgomo Wakho:

Umgomo wakho uwukuthola umkhiqizo wekhwalithi ephezulu kakhulu ngokusebenzisa ngokugcwele amandla e-laser enembe kakhulu nezinto zokwakha.Lokhu kusho ukuqonda amandla e-laser nezinto ezisetshenziswayo kanye nokuqinisekisa ukuthi aziphushwa zibe ngaphezu kwemikhawulo yazo.

I-laser enembe kakhulu iyithuluzi elinamandla elithuthukisa kakhulu inqubo yokukhiqiza.Ukunemba nokunemba kwayo kuvumela ukudalwa kwemiklamo eyinkimbinkimbi neningiliziwe kalula.Ngokusebenzisa i-laser ngokugcwele, abakhiqizi bangaqinisekisa ukuthi zonke izici zomkhiqizo zakhiwe ngokunembile, okuholela kumphumela wokugcina ophakeme.

Yini okudingeka ukwazi?

▶ Ubuncane Besici Besici:

Uma usebenza nezici ezincane kuno-0.040 amayintshi noma imilimitha engu-1, kubalulekile ukuqaphela ukuthi kungenzeka zintekenteke noma zintekenteke.Lezi zilinganiso ezincane zenza izingxenye noma imininingwane kube lula ukuphuka noma ukulimala, ikakhulukazi phakathi nokuphatha noma ukusetshenziswa.

Ukuqinisekisa ukuthi usebenza ngaphakathi kwemikhawulo yamakhono wento ngayinye, kuyancomeka ukuthi ubhekisele esilinganisweni esincane sikasayizi esinikezwe ekhasini lempahla kukhathalogi yezinto.Lezi zilinganiso zisebenza njengemihlahlandlela yokunquma ubukhulu obuncane kakhulu into engakwazi ukubamukela ngokuthembekile ngaphandle kokuphazamisa ubuqotho bayo besakhiwo.

Ngokuhlola izilinganiso zosayizi obuncane, ungakwazi ukunquma ukuthi idizayini oyihlosile noma imininingwane ebekiwe ingena ngaphakathi kwemikhawulo yokokusebenza.Lokhu kuzokusiza ukuthi ugweme izinkinga ezingase zibe khona njengokuphuka okungalindelekile, ukuhlanekezela, noma ezinye izinhlobo zokwehluleka okungase kuvele ngenxa yokuphusha okubalulekile okungaphezu kwamandla akho.

Uma ucabangela ubuthakathaka bezici ezincane kuno-0.040 amayintshi (1mm) futhi ubhekisela esilinganisweni sosayizi obuncane bekhathalogi, ungenza izinqumo ezinolwazi nokulungiswa ukuze uqinisekise ukwenziwa ngempumelelo nokusebenza kwezingxenye ozifisayo.

▶Usayizi Wengxenye Encane:

Lapho usebenza ngombhede we-laser, kubalulekile ukuqaphela ukulinganiselwa kosayizi wezingxenye ezisetshenziswayo.Izingxenye ezincane kuno-0.236 amayintshi noma 6mm ububanzi zingawela kumbhede we-laser futhi zilahleke.Lokhu kusho ukuthi uma ingxenye incane kakhulu, kungenzeka ingabambeki endaweni ngokuvikelekile ngesikhathi sokusika nge-laser noma inqubo yokuqopha, futhi ingase ishelele ezikhaleni zombhede.

Toqinisekisa ukuthi izingxenye zakho zifanele ukusika noma ukuqoshwa nge-laser, kubalulekile ukuhlola izilinganiso zosayizi wengxenye ngayinye yento ngayinye ethile.Lezi zilinganiso zingatholakala ekhasini lezinto kukhathalogi yezinto.Ngokubhekisela kulokhu kucaciswa, unganquma ubuncane bezidingo zosayizi wezingxenye zakho futhi ugweme noma yikuphi ukulahlekelwa okungaba khona noma ukulimala ngesikhathi sokusika noma inqubo yokuqopha nge-laser.

▶Indawo Eqoshiwe Encane:

Uma kukhulunywa ngokuqoshwa kwendawo e-raster, ukucaca kombhalo nezindawo ezizacile ezingaphansi kwamayintshi angu-0.040 (1mm) azicijile kakhulu.Lokhu kuntuleka kokucwazimula kuba sobala nakakhulu njengoba usayizi wombhalo uncipha.Nokho, kukhona indlela yokuthuthukisa ikhwalithi yokuqoshwa futhi wenze umbhalo wakho noma umumo ugqame kakhulu.

Enye indlela ephumelelayo yokufeza lokhu iwukuhlanganisa amasu okuqoshwa kwendawo kanye nemigqa.Ngokuhlanganisa zombili izindlela, ungakha umbhalo oqoshiwe obukeka kahle futhi ogqamayo.Ukuqoshwa kwendawo kuhilela ukususa izinto ezingaphezulu ngendlela eqhubekayo, okuholela ekubukekeni okubushelelezi nokungaguquguquki.Ngakolunye uhlangothi, ukuqoshwa komugqa kuhilela ukufaka imigqa emihle phezulu, okwengeza ukujula nencazelo eklanyweni.

Ukubuka Kwevidiyo |Sika futhi Uqophe Okokufundisa kwe-Acrylic

Ukubuka Kwevidiyo |ukusika iphepha

Ukuhlukahluka kokuqina kwempahla:

Igama elithi "ukujiya ukubekezelela" libhekisela kububanzi obamukelekayo bokuhlukahluka kobukhulu bento.Kuwukucaciswa okubalulekile okusiza ukuqinisekisa ikhwalithi nokuvumelana kwezinto.Lesi silinganiso ngokuvamile sihlinzekwa ngezinto ezihlukahlukene futhi singatholakala ekhasini lempahla elifanele kukhathalogi yezinto.

Ukubekezelela ukujiya kuvezwa njengobubanzi, okubonisa ubukhulu nobuncane bokujiya obuvunyelwe kokubalulekile okuthile.Ngokwesibonelo, uma ukujiya ukubekezelelana for ishidi lensimbi kuyinto±0.1mm, kusho ukuthi ukujiya kwangempela kweshidi kungahluka ngaphakathi kwalobu bubanzi.Umkhawulo ongaphezulu uzoba ukujiya okuzisholo kanye no-0.1mm, kuyilapho umkhawulo ophansi uzoba ukujiya okuzisholo kokususa u-0.1mm.

Kubalulekile kumakhasimende ukuthi acabangele ukubekezelela ukushuba lapho ekhetha izinto ezisetshenziswayo zezidingo zabo ezithile.Uma iphrojekthi idinga ubukhulu obunembile, kuhle ukukhetha izinto ezinokubekezelela ukushuba okuqinile ukuze kuqinisekiswe imiphumela enembile.Ngakolunye uhlangothi, uma iphrojekthi ivumela ukuhluka okuthile kogqinsi, izinto ezinokubekezelela okuxekethile zingase zingabizi kakhulu.

Uyafuna Ukuqala Ekhanda?

Kuthiwani Ngalezi Zikhetho Ezinhle?

Ufuna Ukuqalisa Nge-Laser Cutter & Engraver Khona Khona?

Xhumana Nathi Ukuze Ubuze Ukuze Uqalise Ngokushesha!

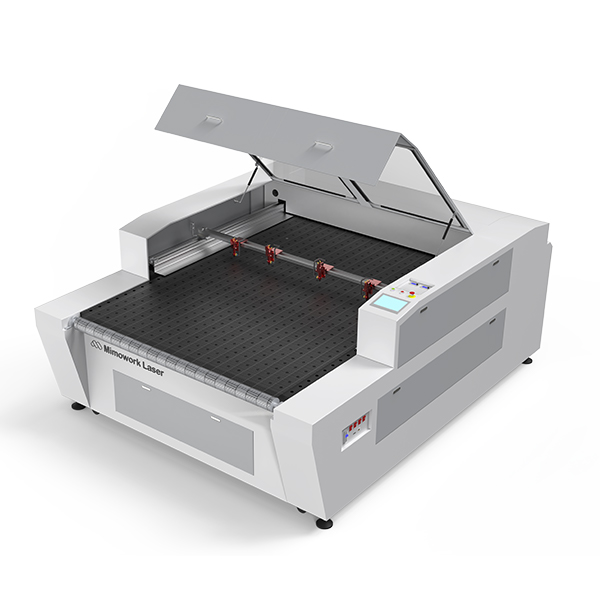

▶ Mayelana Nathi - I-MimoWork Laser

Asiyikhokhi imiphumela Emaphakathi

I-Mimowork ikhiqiza i-laser egxile emiphumeleni, ezinze e-Shanghai nase-Dongguan China, iletha ubuchwepheshe bokusebenza obujulile beminyaka engu-20 ukukhiqiza izinhlelo ze-laser futhi inikeze izixazululo eziphelele zokucubungula nokukhiqiza kuma-SME (amabhizinisi amancane naphakathi) ezinhlobonhlobo zezimboni. .

Umuzwa wethu ocebile wezixazululo ze-laser zokucubungula izinto zensimbi nezingezona ezensimbi ugxile kakhulu ekukhangiseni komhlaba wonke, ezezimoto & ezondiza, i-metalware, izinhlelo zokusebenza ze-sublimation kadayi, imboni yendwangu kanye nezindwangu.

Kunokuba inikeze isixazululo esingaqinisekile esidinga ukuthengwa kubakhiqizi abangafanelekile, iMimoWork ilawula yonke ingxenye yochungechunge lokukhiqiza ukuze iqinisekise ukuthi imikhiqizo yethu isebenza kahle kakhulu.

I-MimoWork izibophezele ekudaleni nasekuthuthukiseni ukukhiqizwa kwe-laser futhi yathuthukisa inqwaba yobuchwepheshe be-laser obuthuthukisiwe ukuze ithuthukise amandla okukhiqiza amaklayenti kanye nokusebenza kahle okukhulu.Ukuthola amalungelo obunikazi amaningi obuchwepheshe be-laser, sihlala sigxile kwikhwalithi nokuphepha kwezinhlelo zemishini ye-laser ukuze siqinisekise ukukhiqizwa kokucubungula okungaguquki nokuthembekile.Ikhwalithi yomshini we-laser iqinisekiswe yi-CE kanye ne-FDA.

I-MimoWork Laser System ingakwazi ukusika i-Acrylic ne-laser eqoshwe i-Acrylic, ekuvumela ukuthi uqalise imikhiqizo emisha yezimboni ezihlukahlukene.Ngokungafani nabasiki bokugaya, ukuqopha njengento yokuhlobisa kungafinyelelwa ngemizuzwana ngokusebenzisa umqophi we-laser.Kuphinde kukunike ithuba lokuthatha ama-oda abe mancane njengomkhiqizo owenziwe ngezifiso weyunithi eyodwa, futhi amakhulu njengezinkulungwane zemikhiqizo esheshayo ngamaqoqo, konke ngaphakathi kwamanani okutshala imali athengekayo.

Thola Imibono Eminye Esiteshini Sethu Se-YouTube

Isikhathi sokuthumela: Jul-14-2023