Uma usuqala ubuchwepheshe be-laser futhi ucabanga ukuthenga umshini wokusika nge-laser, kumele kube nemibuzo eminingi ofuna ukuyibuza.

I-MimoWorkiyajabula ukwabelana nawe ngolwazi olwengeziwe mayelana nemishini ye-laser ye-CO2 futhi ngethemba ukuthi ungathola idivayisi ekufanele ngempela, kungakhathaliseki ukuthi ivela kithi noma komunye umhlinzeki we-laser.

Kulesi sihloko, sizonikeza umbono omfushane wokucushwa komshini endaweni evamile futhi senze ukuhlaziywa okuqhathanisayo komkhakha ngamunye. Ngokuvamile, lesi sihloko sizohlanganisa amaphuzu njengoba ngezansi:

Ubuchwepheshe bomshini we-laser we-CO2

a. Imoto ye-DC engenamabhulashi, Imoto ye-Servo, Imoto Yesinyathelo

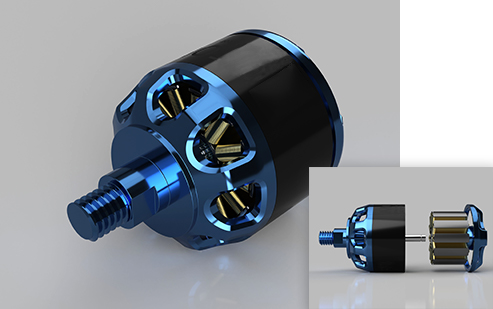

Injini ye-DC (yamanje eqondile) engenamabhulashi

Injini ye-DC engenamabhulashi ingasebenza nge-RPM ephezulu (ukujikeleza ngomzuzu). I-stator yenjini ye-DC inikeza insimu kazibuthe ejikelezayo eqhuba i-armature ukuthi ijikeleze. Phakathi kwazo zonke izinjini, imoto ye-DC engenamabhulashi inganikeza amandla e-kinetic anamandla kakhulu futhi iqhube ikhanda le-laser ukuthi lihambe ngesivinini esikhulu.Umshini wokuqopha we-CO2 laser ongcono kakhulu we-MimoWork ifakwe injini engenamabhulashi futhi ingafinyelela isivinini esiphezulu sokuqopha esingu-2000mm/s.Injini ye-dc engenamabhulashi ayibonakali kakhulu emshinini wokusika nge-laser we-CO2. Lokhu kungenxa yokuthi ijubane lokusika impahla linqunyelwe ubukhulu bezinto. Ngokuphambene nalokho, udinga amandla amancane kuphela ukuze uqophe ihluzo ezintweni zakho. Injini engenamabhulashi efakwe umqophi we-laser izokwenzanciphisa isikhathi sakho sokuqopha ngokunemba okukhulu.

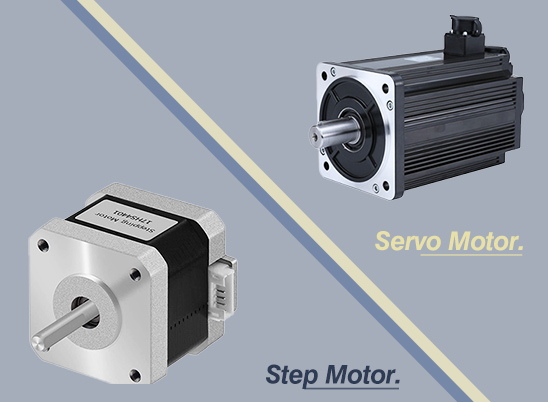

Injini ye-Servo kanye ne-Step motor

Uma zihlanganiswa netafula lokuqopha i-laser le-CO2, ama-servo motor anikeza i-torque ephezulu kanye nokunemba, ikakhulukazi emisebenzini yobuchwepheshe efana nokusika indwangu yokuhlunga noma izembozo zokufaka umswakama. Nakuba zibiza kakhulu futhi zidinga ama-encoder nama-gearbox—okwenza ukusethwa kube nzima kakhulu—zilungele izinhlelo zokusebenza ezidinga amandla. Nokho, uma wenza izipho ezilula zobuciko noma izibonakaliso, i-stepper motor etafuleni lakho lokuqopha i-laser ivame ukwenza umsebenzi kahle.

Injini ngayinye inezinzuzo nezinkinga zayo. Ekufanelekelayo iyona engcono kakhulu kuwe.

Ngokuqinisekile, i-MimoWork inganikezaUmqophi nomsiki we-laser we-CO2 enezinhlobo ezintathu zenjiningokusekelwe ezidingweni zakho kanye nesabelomali sakho.

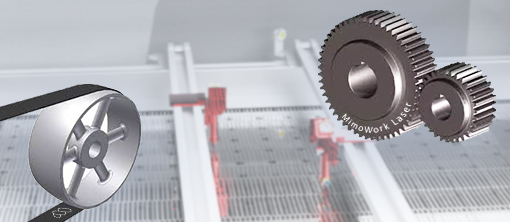

b. I-Belt Drive VS I-Gear Drive

I-belt drive isebenzisa ibhande ukuxhuma amasondo, kuyilapho i-gear drive ixhuma amagiya ngqo ngamazinyo axhumene. Emishinini ye-laser, zombili izinhlelo zisiza ukuhambisa i-gantry futhi zithinte ukuthi umshini ungaba unembe kangakanani.

Ake siqhathanise lokhu okubili nethebula elilandelayo:

| I-Belt Drive | I-Gear Drive |

| Izinto eziyinhloko: Ama-Pulleys kanye ne-Belt | Izinto eziyinhloko zamagiya |

| Kudingeka isikhala esengeziwe | Kudingeka isikhala esincane, ngakho-ke umshini we-laser ungaklanywa ube mncane |

| Ukulahlekelwa okukhulu kokungqubuzana, ngakho-ke ukudluliselwa okuphansi kanye nokusebenza kahle okuncane | Ukulahlekelwa okuphansi kokungqubuzana, ngakho-ke ukudluliselwa okuphezulu kanye nokusebenza kahle okwengeziwe |

| Isikhathi sokuphila esiphansi kunezinjini zokushayela, ngokuvamile siyashintsha njalo eminyakeni emi-3 | Isikhathi sokuphila sikhulu kakhulu kunezinqola zebhande, ngokuvamile ziyashintsha njalo eminyakeni eyishumi |

| Kudinga ukulungiswa okwengeziwe, kodwa izindleko zokulungisa zishibhile futhi zilula | Kudinga ukulungiswa okuncane, kodwa izindleko zokulungisa zibiza kakhulu futhi zinzima |

| Akudingeki ukuthambisa | Kudinga ukugcotshwa njalo |

| Kuthule kakhulu kuyasebenza | Kunomsindo osebenzayo |

Zombili izinhlelo zokushayela igiya kanye ne-belt drive zivame ukuklanywa emshinini wokusika nge-laser onezinzuzo kanye nokungalungi. Ngamafuphi,uhlelo lokushayela ibhande lunenzuzo kakhulu ezinhlotsheni zemishini ezincane, ezindizayongenxa yokudluliselwa okuphezulu nokuqina,i-gear drive ifaneleka kakhulu kumshini wokusika we-laser onefomethi enkulu, ngokuvamile onedizayini ye-hybrid optical.

c. Ithebula Lokusebenza Elingashintshi VS Ithebula Lokusebenza Lomthumeli

Ukuze kwenziwe ngcono ukucutshungulwa kwe-laser, udinga okungaphezu kokuhlinzekwa kwe-laser esezingeni eliphezulu kanye nohlelo lokushayela oluhle kakhulu ukuze uhambise ikhanda le-laser, itafula lokusekela lezinto ezibonakalayo elifanele nalo liyadingeka. Itafula elisebenzayo elenzelwe ukufanelana nezinto noma uhlelo lokusebenza lisho ukuthi ungakhulisa amandla omshini wakho we-laser.

Ngokuvamile, kunezinhlobo ezimbili zamapulatifomu okusebenza: Okungaguquki kanye Nokuselula.

(Ngezinhlelo zokusebenza ezahlukahlukene, ungagcina usebenzisa zonke izinhlobo zezinto zokwakha, nomaishidi noma izinto ezigoqiwe)

○Ithebula Lokusebenza Elingashintshiilungele ukubeka izinto zeshidi ezifana ne-acrylic, ukhuni, iphepha (ikhadibhodi).

• itafula lokususa imimese

• itafula lekamu loju

○Ithebula Lokusebenza Lomthuthiilungele ukubeka izinto zokugoqa ezifana nendwangu, isikhumba, igwebu.

• itafula le-shuttle

• itafula lokuhambisa

Izinzuzo zomklamo wetafula lokusebenza ofanele

✔Ukukhishwa okuhle kakhulu kokukhishwa komoya okusika

✔Qinisa izinto, akukho ukufuduka okwenzekayo lapho usika

✔Kulula ukulayisha nokulayisha izinto zokusebenza

✔Isiqondiso esihle kakhulu sokugxila ngenxa yezindawo ezisicaba

✔Ukunakekelwa okulula nokuhlanza

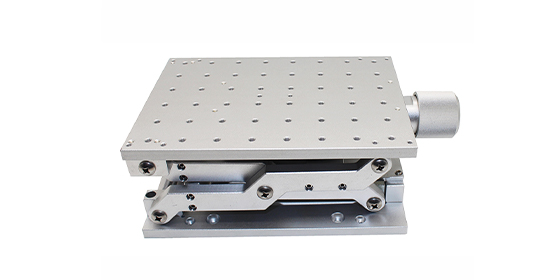

d. Ipulatifomu Yokuphakamisa Okuzenzakalelayo VS Yokuphakamisa Ngesandla

Uma uqopha izinto eziqinile, njengokuthii-acrylic (i-PMMA)futhiukhuni (i-MDF), izinto ziyahlukahluka ngobukhulu. Ukuphakama kokugxila okufanele kungathuthukisa umphumela wokuqopha. Ipulatifomu yokusebenza elungisekayo iyadingeka ukuthola iphuzu lokugxila elincane kakhulu. Kumshini wokuqopha we-laser we-CO2, amapulatifomu okuphakamisa okuzenzakalelayo kanye nokuphakamisa ngesandla avame ukuqhathaniswa. Uma isabelomali sakho sanele, khetha amapulatifomu okuphakamisa okuzenzakalelayo.Akugcini nje ngokuthuthukisa ukunemba kokusika nokuqopha, kodwa futhi kungakongela isikhathi esiningi nomzamo.

e. Uhlelo Lokungenisa Umoya Oluphezulu, Oluseceleni Nasezansi

Uhlelo lokungenisa umoya oluphansi luyindlela evame kakhulu yomshini we-laser we-CO2, kodwa i-MimoWork inezinye izinhlobo zokuklama ukuze ithuthukise lonke ulwazi lokucubungula i-laser.umshini wokusika we-laser omkhulu, i-MimoWork izosebenzisa i-uhlelo oluqeda amandla oluphezulu noluphansiukukhulisa umphumela wokukhipha ngenkathi kugcinwa imiphumela yokusika nge-laser esezingeni eliphezulu. Kwabaningi bethuumshini wokumaka we-galvo, sizofaka i-uhlelo lokungenisa umoya oluseceleniukukhipha umusi. Yonke imininingwane yomshini kufanele iqondiswe kangcono ukuze kuxazululwe izinkinga zomkhakha ngamunye.

An uhlelo lokukhiphakukhiqizwa ngaphansi kwezinto ezisetshenziswayo ngomshini. Akukhiphi nje kuphela intuthu ekhiqizwa ngokwelashwa ngokushisa kodwa futhi kuqinisa izinto, ikakhulukazi indwangu elula. Lapho ingxenye enkulu yendawo yokucubungula embozwe yizinto ezicutshungulwayo inkulu, umphumela wokumunca kanye ne-vacuum yokumunca ephumelayo iba phezulu.

Amashubhu e-laser engilazi ye-CO2 VS amashubhu e-laser e-CO2 RF

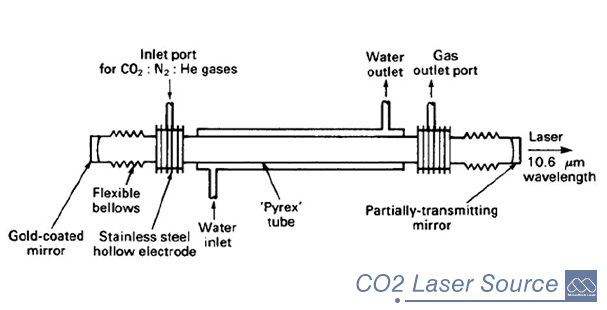

a. Isimiso sokuvusa inkanuko se-laser ye-CO2

I-laser ye-carbon dioxide yayingenye yama-laser egesi okuqala ukwakhiwa. Njengoba sekuthuthukiswe amashumi eminyaka, lobu buchwepheshe sebuvuthiwe kakhulu futhi banele ukusetshenziswa okuningi. Ishubhu ye-laser ye-CO2 ijabulisa i-laser ngesimiso se-ukukhishwa kokukhanyafuthikuguqula amandla kagesi abe amandla okukhanya agxilileNgokusebenzisa i-voltage ephezulu ku-carbon dioxide (i-laser medium esebenzayo) kanye nenye igesi ngaphakathi kwe-laser tube, igesi ikhiqiza ukukhishwa kokukhanya futhi iqhutshwa njalo esitsheni phakathi kwezibuko zokubonisa lapho izibuko zitholakala khona ezinhlangothini zombili zomkhumbi ukuze kukhiqizwe i-laser.

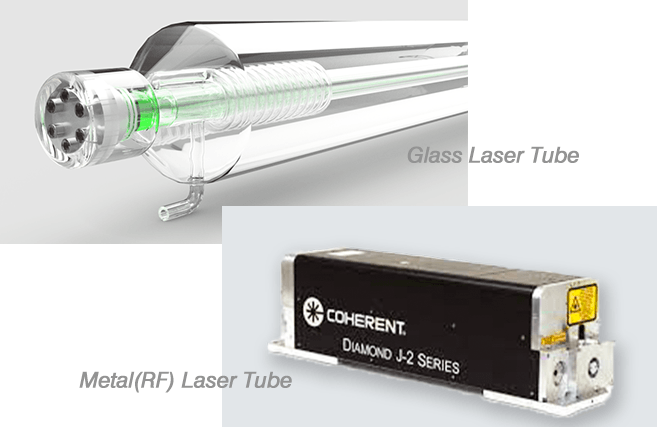

b. Umehluko we-CO2 glass laser tube kanye ne-CO2 RF laser tube

Uma ufuna ukuqonda okubanzi ngomshini we-laser we-CO2, kufanele ubheke imininingwane yalo mshini.umthombo we-laserNjengohlobo lwe-laser olufanele kakhulu ukucubungula izinto ezingezona ezensimbi, umthombo we-laser we-CO2 ungahlukaniswa ngobuchwepheshe obubili obuyinhloko:Ishubhu ye-Glass LaserfuthiIshubhu ye-RF Metal Laser.

(Ngendlela, i-laser ye-CO2 enamandla amakhulu okugeleza okusheshayo kwe-axial kanye ne-laser ye-CO2 ehamba kancane kwe-axial azikho engxoxweni yethu namuhla)

| Amashubhu e-Laser e-Glass (DC) | Amashubhu e-laser ensimbi (RF) | |

| Isikhathi Sokuphila | Amahora angu-2500-3500 | Amahora angu-20,000 |

| Umkhiqizo | IsiShayina | Okuvumelanayo |

| Indlela Yokupholisa | Ukupholisa Amanzi | Ukupholisa Amanzi |

| Ingashajwa kabusha | Cha, ukusetshenziswa kanye kuphela | Yebo |

| Iwaranti | Izinyanga ezi-6 | Izinyanga ezingu-12 |

Uhlelo Lokulawula kanye neSoftware

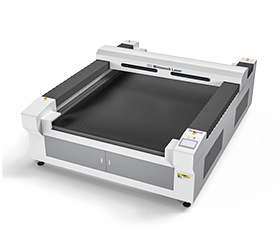

Isofthiwe yomshini wokusika nge-laser ye-CO2 isebenza njengobuchopho besistimu, isebenzisa uhlelo lwe-CNC ukuqondisa ukunyakaza nge-laser nokulungisa amazinga amandla. Ivumela ukukhiqizwa okuguquguqukayo ngokukuvumela ukuthi ushintshe imiklamo ngokushesha futhi uphathe izinto ezahlukene—ngokushintsha amandla nge-laser kanye nesivinini sokusika, akukho zinguquko zamathuluzi ezidingekayo.

Abaningi emakethe bazoqhathanisa ubuchwepheshe besofthiwe yaseShayina kanye nobuchwepheshe besofthiwe bezinkampani ze-laser zaseYurophu naseMelika. Ukuze uthole iphethini yokusika nokuqopha, ama-algorithms esofthiwe eminingi emakethe awafani kakhulu. Njengoba kuneminyaka eminingi yempendulo yedatha evela kubakhiqizi abaningi, isofthiwe yethu inezici ezilandelayo:

1. Kulula ukuyisebenzisa

2. Ukusebenza okuzinzile nokuphephile esikhathini eside

3. Hlola isikhathi sokukhiqiza kahle

4. Sekela i-DXF, i-AI, i-PLT namanye amafayela amaningi

5. Ngenisa amafayela amaningi okusika ngesikhathi esisodwa ngamathuba okuguqula

6. Hlela ngokuzenzakalelayo amaphethini okusika ngamaqoqo amakholomu nemigqa ene-I-Mimo-Nest

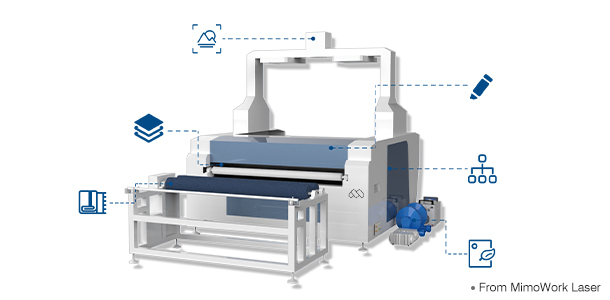

Ngaphandle kwesisekelo sesofthiwe yokusika evamile,Uhlelo Lokuqaphela Umbonoingathuthukisa izinga lokuzenzakalela ekukhiqizeni, inciphise umsebenzi futhi ithuthukise ukunemba kokusika. Kalula nje, i-CCD Camera noma i-HD Camera efakwe emshinini we-laser we-CO2 isebenza njengamehlo omuntu futhi iyala umshini we-laser ukuthi usike kuphi. Lobu buchwepheshe buvame ukusetshenziswa ezinhlelweni zokunyathelisa zedijithali kanye nezinkambu zokuhlobisa, njengezingubo zemidlalo zodayi-sublimation, amafulegi angaphandle, ama-embroidery patches kanye nezinye eziningi. Kunezinhlobo ezintathu zezindlela zokuqaphela umbono i-MimoWork engazinikeza:

▮ Ukuqashelwa Kwe-Contour

Ukuphrinta kwedijithali kanye ne-sublimation kuyanda, ikakhulukazi emikhiqizweni efana nezingubo zezemidlalo, amabhanela, kanye namaconsi ezinyembezi. Lezi zindwangu eziphrintiwe azikwazi ukunqunywa ngokunembile ngesikele noma ama-blade endabuko. Yilapho izinhlelo ze-laser ezisekelwe ekuboneni zikhanya khona. Usebenzisa ikhamera enesinqumo esiphezulu, umshini uthwebula iphethini bese usika ngokuzenzakalelayo eceleni kohlaka lwayo—akudingeki ifayela lokusika noma ukunqunywa ngesandla. Lokhu akugcini nje ngokuthuthukisa ukunemba kodwa futhi kusheshisa ukukhiqizwa.

Umhlahlandlela Wokusebenza:

1. Yondla imikhiqizo enamaphethini >

2. Thatha isithombe sephethini >

3. Qala ukusika nge-contour laser >

4. Qoqa okuqediwe >

▮ Iphuzu Lokumaka Lokubhalisa

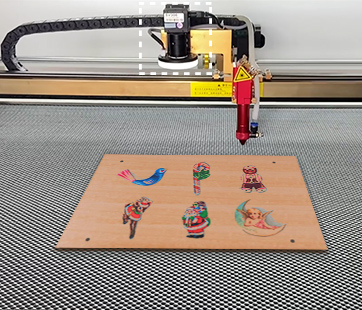

Ikhamera ye-CCDingabona futhi ithole iphethini ephrintiwe ebhodini lokhuni ukusiza i-laser ngokusika okunembile. Izimpawu zokhuni, ama-plaque, umsebenzi wobuciko kanye nesithombe sokhuni esenziwe ngokhuni oluphrintiwe kungacutshungulwa kalula.

Isinyathelo 1.

>> Phrinta ngqo iphethini yakho ebhodini lokhuni

Isinyathelo sesi-2.

>> Ikhamera ye-CCD isiza i-laser ukusika umklamo wakho

Isinyathelo sesi-3.

>> Qoqa izingcezu zakho eziqediwe

▮ Ukufaniswa Kwethempulethi

Kwamanye ama-patches, amalebula, ama-foil aphrintiwe anosayizi ofanayo kanye nephethini, i-Template Matching Vision System evela ku-MimoWork izoba usizo olukhulu. Uhlelo lwe-laser lungasika ngokunembile iphethini encane ngokuqaphela nokubeka ithempulethi elisethiwe eliyifayela lokusika lomklamo ukuze lifane nengxenye yesici sama-patches ahlukene. Noma yiliphi iphethini, ilogo, umbhalo noma enye ingxenye ebonakalayo ebonakalayo ingaba yingxenye yesici.

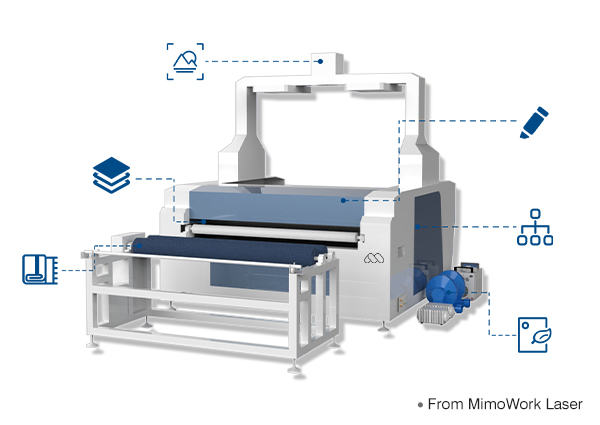

Izinketho ze-Laser

I-MimoWork inikeza izinketho eziningi ezengeziwe zazo zonke izicucu ze-laser eziyisisekelo ngokuhambisana nohlelo lokusebenza ngalunye. Enqubweni yokukhiqiza yansuku zonke, le miklamo eyenziwe ngokwezifiso emshinini we-laser ihlose ukwandisa ikhwalithi yomkhiqizo kanye nokuguquguquka ngokwezidingo zemakethe. Isixhumanisi esibaluleke kakhulu ekukhulumisaneni kwasekuqaleni nathi ukwazi isimo sakho sokukhiqiza, ukuthi yimaphi amathuluzi asetshenziswa njengamanje ekukhiqizeni, nokuthi yiziphi izinkinga ezihlangabezana nazo ekukhiqizeni. Ngakho-ke ake sethule izingxenye ezimbalwa ezivamile zokuzikhethela ezithandwa kakhulu.

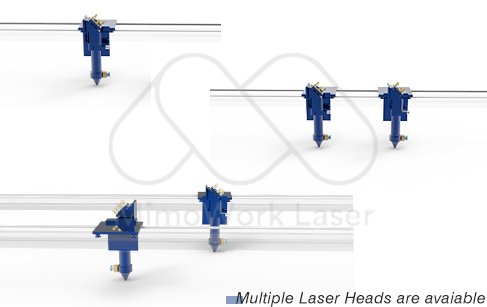

a. Amakhanda amaningi e-laser ongakhetha kuwo

Ukwengeza amakhanda namashubhu amaningi e-laser emshinini owodwa kuyindlela elula nengabizi yokukhulisa umkhiqizo. Kusindisa kokubili utshalomali kanye nendawo yephansi uma kuqhathaniswa nokuthenga imishini eminingana ehlukene. Kodwa akuyona njalo into efanelana kahle. Kuzodingeka ucabangele usayizi wetafula lakho lokusebenza kanye namaphethini okusika. Yingakho sivame ukucela amakhasimende ukuthi abelane ngemiklamo yesampula ngaphambi kokufaka i-oda.

Imibuzo eminingi mayelana nokugcinwa komshini we-laser noma i-laser

Isikhathi sokuthunyelwe: Okthoba-12-2021