Ke eng e etsang hore sehahi sa laser se fapane le sehahi sa laser?

Mokhoa oa ho khetha mochini oa laser bakeng sa ho seha le ho betla?

Haeba o na le dipotso tse jwalo, mohlomong o nahana ho tsetela sesebediswa sa laser bakeng sa mosebetsi wa hao wa ho sebetsa. Jwalo ka moqadi ya ithutang theknoloji ya laser, ho bohlokwa ho fumana phapang pakeng tsa tse pedi.

Sehloohong sena, re tla hlalosa ho tšoana le ho se tšoane pakeng tsa mefuta ena e 'meli ea mechini ea laser ho u fa setšoantšo se felletseng. Re tšepa hore u ka fumana mechini ea laser e fihlelang litlhoko tsa hau e le kannete 'me ea boloka tekanyetso ea hau matseteng.

Lethathamo la Dikahare(tobetsa ho fumana kapele ⇩)

Tlhaloso: Ho Seha le ho Ngola ka Laser

◼ Ho seha ka laser ke eng?

Ho seha ka laser ke mokhoa oa ho seha ka mocheso o sa amaneng le mocheso o sebelisang matla a khanya a matla ho thunya thepa, ebe e qhibiliha, e cha, e fetoha mouoane, kapa e fefoloa ke khase e thusang, e siea lehlakore le hloekileng ka ho nepahala ho hoholo. Ho latela thepa le botenya ba thepa, ho hlokahala li-laser tse fapaneng tsa matla ho phethela ho seha, e leng se boetse se hlalosang lebelo la ho seha.

/ Sheba livideo ho u thusa ho tseba haholoanyane /

◼Ho betla ka laser ke eng?

Ka lehlakoreng le leng, ho betla ka laser (e tsejoang hape e le ho betla ka laser, ho betla ka laser, ho hatisa ka laser), ke mokhoa oa ho sebelisa li-laser ho siea matšoao holim'a thepa ka ho e fetola mosi ka ho e etsa mouoane holim'a eona. Ho fapana le tšebeliso ea li-enke kapa li-bit tsa lisebelisoa tse amang bokaholimo ba thepa ka kotloloho, ho betla ka laser ho u bolokela nako ea ho nkela enke kapa lihlooho tsa li-bit sebaka khafetsa ha u ntse u boloka liphetho tsa ho betla ka boleng bo holimo kamehla. Motho a ka sebelisa mochini oa ho betla ka laser ho taka li-logo, likhoutu, litšoantšo tse phahameng tsa DPI holim'a lisebelisoa tse fapaneng tse "sebelisang laser".

Ho Tšoana: Laser Engraver le Laser Cutter

◼ Sebopeho sa Mechini

Pele re kena puisanong ea liphapang, ha re tsepamiseng maikutlo linthong tse tšoanang. Bakeng sa mechini ea laser e bataletseng, sebopeho sa mantlha sa mechini se tšoana har'a sehahi le sehahi sa laser, kaofela li tla le foreimi e matla ea mochini, jenereithara ea laser (tube ea laser ea CO2 DC/RF), likarolo tsa optical (lilense le liipone), sistimi ea taolo ea CNC, likarolo tsa elektrone, li-module tsa motsamao o otlolohileng, sistimi ea ho pholisa le moralo oa ho ntša mosi. Joalokaha ho hlalositsoe pejana, sehahi sa laser le sehahi ka bobeli li fetola matla a khanya a kopaneng a etsisitsoeng ke jenereithara ea laser ea CO2 ho ba matla a mocheso bakeng sa ho sebetsana le thepa ntle le ho ama.

◼ Phallo ea Ts'ebetso

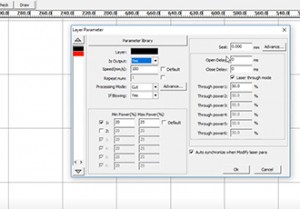

Mokhoa oa ho sebelisa sehahi sa laser kapa sehahi sa laser? Kaha tlhophiso ea mantlha e tšoana har'a sehahi le sehahi sa laser, melao-motheo ea ts'ebetso le eona e batla e tšoana. Ka tšehetso ea sistimi ea CNC le melemo ea ho etsa prototype ka potlako le ho nepahala ho phahameng, mochini oa laser o nolofatsa haholo mokhoa oa tlhahiso ha o bapisoa le lisebelisoa tsa setso. Sheba chate e latelang ea phallo:

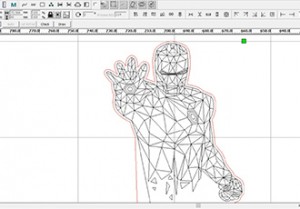

1. Beha taba >

2. Kenya faele ea litšoantšo >

3. Beha paramethara ea laser >

4. Qala ho seha ka laser (ho betla)

Mechini ea laser, ebang ke ea ho seha ka laser kapa ea ho betla ka laser, e tlisa boiketlo le tsela e khuts'oane bakeng sa tlhahiso e sebetsang le ho theha moralo. MimoWork e ikemiselitse ho nts'etsapele le ho ntlafatsa litsamaiso tsa mechini ea laser, 'me e lumellana le litlhoko tsa hau ka boleng bo holimo le ho nahanela.tšebeletso ea laser.

◼ Litšebeliso le Lisebelisoa

Haeba sehahi sa laser le sehahi sa laser li tšoana ka kakaretso, joale phapang ke efe? Mantsoe a bohlokoa mona ke "Ts'ebeliso le Thepa". Lintlha tsohle tse qaqileng moralong oa mochini li tsoa lits'ebetsong tse fapaneng. Ho na le mefuta e 'meli mabapi le thepa le lits'ebetso tse lumellanang le ho seha ha laser kapa ho betla ha laser. U ka li hlahloba ho khetha mochini o loketseng oa laser bakeng sa tlhahiso ea hau.

| Lehong | Acrylic | Lesela | Khalase | Plastiki | Letlalo | Delrin | Lesela | Seretse | 'Mabole | |

|

KHAOLA

| ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

|

NGOLA

| ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Chate ea Tafole ea 1

|

| Pampiri | Lebokose la khatiso | Veneer ea Lehong | Khalase ea Fiber | Thaele | Mylar | Cork | Rabara | 'Mè oa Perela | Tšepe tse koahetsoeng |

|

KHAOLA

| ✔ | ✔ | ✔ | ✔ |

| ✔ | ✔ | ✔ | ✔ |

|

|

NGOLA

| ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Chate ea 2

Jwalo ka ha bohle ba tseba hore jenereithara ya laser ya CO2 e sebediswa haholoholo bakeng sa ho seha le ho ntsha dintho tse seng tsa tshepe, empa ho na le dipharologanyo tse itseng thepang e ntseng e sebetswa (E thathamisitsoe ditafoleng tsa chate tse ka hodimo). Bakeng sa kutlwisiso e betere, re sebedisa thepa yaacryliclelehongho nka mohlala mme o ka bona phapang ka ho hlaka.

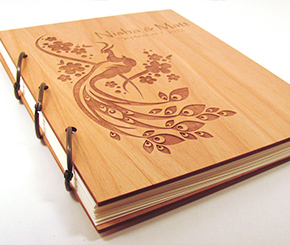

Pontšo ea disampole

Ho Seha ka Laser ea Lehong

Lehlasedi la laser le feta ka hara patsi mme le fetola ho tjheha ho eketsehileng hang-hang, le qete dipaterone tse hlwekileng tse sehilweng.

Ho betla ka Laser ea Lehong

Ho betla ka laser ho tsitsitseng ho hlahisa botebo bo itseng, ho etsa phetoho e bonolo le 'mala oa gradient. Haeba u batla ho betla ka botebo, fetola sekala se sootho feela.

Ho Seha ka Laser ea Acrylic

Matla a laser a loketseng le lebelo la laser li ka seha letlapa la acrylic ha li ntse li netefatsa hore kristale le lehlakore le bentšitsoeng lia tšoana.

Ho betla ka Laser ea Acrylic

Ho fumana lintlha tsa vector le ho betla ka pixel kaofela ho etsoa ke moetsi oa laser. Ho nepahala le ho rarahana ha paterone ho tla ba teng ka nako e le 'ngoe.

◼ Matla a Laser

Ha ho sehoa ka laser, mocheso oa laser o tla qhibilihisa thepa e hlokang tlhahiso e phahameng ea matla a laser.

Ha ho tluoa tabeng ea ho betla, lehlaseli la laser le tlosa bokaholimo ba thepa ho siea lesoba le senolang moralo oa hau, ha ho hlokahale hore u sebelise jenereithara ea laser e turang haholo e nang le matla a mangata.Ho tšoaea le ho betla ka laser ho hloka botebo bo fokolang boo laser e kenang ho bona. Sena ke 'nete hape ea hore thepa e mengata e ke keng ea sehoa ka laser e ka betloa ka laser. Ka lebaka leo,bataki ba laserhangata li hlomelloa ka matla a fokolangLiphaephe tsa laser tsa CO2ea ka tlase ho li-Watts tse 100. Ho sa le joalo, matla a manyane a laser a ka hlahisa lehlaseli le lenyenyane la ho thunya le ka fanang ka liphetho tse ngata tse inehetseng tsa ho betla.

Batla Keletso ea Setsebi ea Laser bakeng sa Khetho ea Hao

Boholo ba Tafole ea ho Sebetsa ka Laser

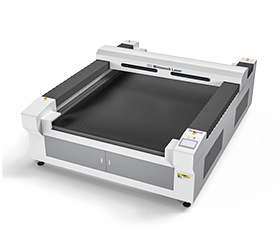

Ntle le phapang ea matla a laser,Mochini oa ho betla oa laser hangata o tla le boholo bo bonyenyane ba tafole ea ho sebetsa.Bongata ba baetsi ba thepa ba sebelisa mochini o betlang ka laser ho betla letshwao, khoutu, le moralo o inehetseng wa foto hodima thepa. Boholo ba setshwantsho se jwalo hangata bo ka hare ho 130cm*90cm (51in.*35in.). Bakeng sa ho betla dipalo tse kgolo tse sa hlokeng ho nepahala ho hoholo, CNC Router e ka ba le bokgoni bo eketsehileng.

Jwalo ka ha re buile serapeng se fetileng,Mechini ea ho seha ka laser hangata e tla le jenereithara e matla ea laser e phahameng. Ha matla a le holimo, boholo ba jenereithara ea matla a laser bo ba boholo.Lena ke lebaka le leng leo ka lona mochini oa ho seha oa laser oa CO2 o leng moholo ho feta mochini oa ho betla oa laser oa CO2.

◼ Liphapang tse ling

Liphapang tse ling tse teng sebopehong sa mochini li kenyelletsa khetho ealense e shebaneng.

Bakeng sa mechini e betlang ka laser, MimoWork e khetha lilense tse nyane tse bophara bo bonyenyane tse nang le libaka tse khutšoane tsa ho sheba bakeng sa ho fana ka mahlaseli a laser a manyane haholo, esita le litšoantšo tse nang le tlhaloso e phahameng li ka betloa joaloka tsa 'nete. Ho boetse ho na le liphapang tse ling tse nyane tseo re tla li akaretsa nakong e tlang.

Khothaletso ea Mochini oa Laser

Sehahi sa Laser sa CO2:

Moqomo oa Laser oa CO2 (le Seha):

Potso ea 1:

Na Mechini ea Laser ea MimoWork e ka khona ho seha le ho betla?

E. Ea ronamongolo oa laser o betliloeng ka sephara 130Ka jenereithara ea laser ea 100W e ka etsa lits'ebetso tsena ka bobeli. Ntle le ho khona ho etsa mekhoa e metle ea ho betla, e ka boela ea seha mefuta e fapaneng ea thepa. Ka kopo hlahloba liparamitha tse latelang tsa matla bakeng sa thepa e nang le botenya bo fapaneng.

U batla ho tseba lintlha tse ling u ka re sheba mahala!

Nako ea poso: Hlakubele-10-2022