What makes a laser engraver different from a laser cutter?

How to choose the laser machine for cutting and engraving?

If you have such questions, you are probably considering investing in a laser device for your workshop. As a beginner learning laser technology, it’s critical to figure out the distinction between the two.

In this article, we will explain the similarities and differences between these two types of laser machines to give you a fuller picture. Hopefully, you can find the laser machines that truly meet your requirements and save your budget on investment.

The Definition: Laser Cutting and Engraving

◼ What is laser cutting?

Laser cutting is a non-contact thermal cutting method that uses high-concentrated light energy to shoot at the material, which then either melts, burns, vaporizes away, or is blown away by auxiliary gas, leaving a clean edge with high accuracy. Depending on the properties and thickness of the material, different power lasers are required to complete the cutting, which also defines the cutting speed as well.

/ Check the videos to help you further know /

◼ What is laser engraving?

Laser engraving (aka laser marking, laser etching, laser printing), on the other hand, is the practice of using lasers to leave marks on the material permanently by vaporizing the surface into fumes. Unlike the use of inks or tool bits that contact the material surface directly, laser engraving saves your time on replacing inks or bit heads regularly while maintaining constantly high-quality engraving results. One can use a laser engraving machine to draw logos, codes, high DPI pictures onto a variety of “laserable” materials.

The Similarities: Laser Engraver and Laser Cutter

◼ Mechanical Structure

Before jumping into the discussion of differences, let’s focus on the things in common. For flatbed laser machines, the basic mechanical structure is the same among laser cutter and engraver, all come with a strong machine frame, laser generator (CO2 DC/RF laser tube), optical components (lenses and mirrors), CNC control system, electron components, linear motion modules, cooling system and fume extracting design. As described earlier, both laser engraver and cutter convert concentrated light energy which is simulated by the CO2 laser generator to thermal energy for processing material contactless.

◼ Operation Flow

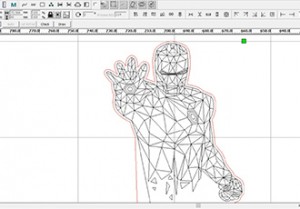

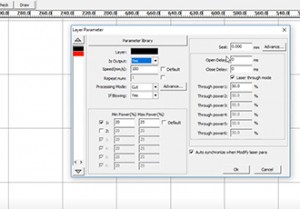

How to use a laser engraver or a laser cutter? As the basic configuration is similar among the laser cutter and engraver, the fundamental principles of the operation are also pretty much the same. With the support of CNC system and advantages of fast prototyping & high-precision, the laser machine greatly simplifys the production workflow compared with the traditional tools. Check the following flow chart:

1. Place the mateial >

2. Upload the graphic file >

3. Set the laser parameter >

4. Start the laser cutting (engraving)

The laser machines whether laser cutter or laser engraver bring the convenience and shortcut for practical production and design creation. MimoWork is committed to developing and improving the laser machine systems, and fit your demands with top quality and considerate laser service.

◼ Applications and Materials

If the laser cutter and the laser engraver are broadly the same, then what’s the difference? The keywords here are “Application and Material ”. All of the nuances in the machine design come from different uses. There are two forms about materials & applications compatibile with laser cutting or laser engraving. You can check them to choose suitable laser machine for your production.

|

Wood |

Acrylic |

Fabric |

Glass |

Plastic |

Leather |

Delrin |

Cloth |

Ceramic |

Marble |

|

|

CUT

|

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

|||

|

ENGRAVE

|

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

Chart Table 1

|

|

Paper |

Pressboard |

Wood Veneer |

Fiberglass |

Tile |

Mylar |

Cork |

Rubber |

Mother of Pearl |

Coated Metals |

|

CUT

|

✔ |

✔ |

✔ |

✔ |

|

✔ |

✔ |

✔ |

✔ |

|

|

ENGRAVE

|

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

✔ |

Chart Table 2

As everyone knows that CO2 laser generator is mainly used for cutting and etching non-metal materials, but there are some differences in the materials being processed (Listed in the chart tables above). For better understanding, we use the materials of acrylic and wood to take an example and you can see the contrast clearly.

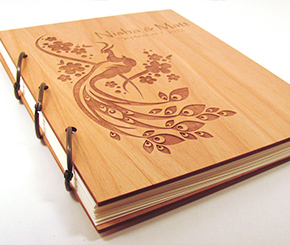

Samples display

Wood Laser Cutting

The laser beam pass through the wood and evaporate the extra chipping instantly, finishing the clean cut-out patterns.

Wood Laser Engraving

Consistent laser engraving produces a specific depth, making the delicate transition and gradient color. If you want the deep engraving, just adjust the gray scale.

Acrylic Laser Cutting

Appropriate laser power and laser speed can cut through the acrylic sheet while ensuring the crystal and polished edge.

Acrylic Laser Engraving

Vector scoring and pixel engraving all be realized by the laser engraver. Precision and intricacy on pattern will exist at the same time.

◼ Laser Powers

In laser cutting, the laser's heat will melt the material that requires high laser power output.

When it comes to engraving, the laser beam eliminates the surface of the material to leave a cavity that reveals your design, not necessary to adopt an expensive high power laser generator. Laser marking and engraving require less depth to which the laser penetrates. This is also the fact that many materials that can't be cut with lasers can be sculpted with lasers. As a result, the laser engravers are normally equipped with low-power CO2 laser tubes of less than 100Watts. Meanwhile, small laser power can produce a smaller shooting beam that can deliver many dedicated engraving results.

Seek for Professional Laser Advice for Your Choice

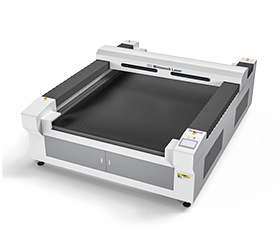

◼ Laser Working Table Sizes

In addition to the difference in laser power, the laser engraving machine normally comes with a smaller working table size. The majority of the fabricators use a laser engraving machine to carve logo, code, dedicated photo design on the materials. The size range of such a figure is generally within 130cm*90cm (51in.*35in.). For engraving larger figures that do not require high precision, the CNC Router can be more efficient.

As we discussed in the previous paragraph, laser cutting machines normally come with a high laser power generator. The higher the power, the larger the dimension of the laser power generator. This is also one reason that the CO2 laser cutting machine is larger than the CO2 laser engraving machine.

◼ Other Differences

Other differences in machine configuration include the choice of focusing lens.

For laser engraving machines, MimoWork chooses smaller diameter lenses with shorter focal distances for delivering much finer laser beams, even high-definition portraits can be sculpted lifelike. There are also other small differences we will cover next time.

Laser Machine Recommendation

CO2 Laser Cutter:

CO2 Laser Engraver (and Cutter):

Question 1:

Can MimoWork Laser Machines do both cutting and engraving?

Yes. Our flatbed laser engraver 130 with a 100W laser generator can perform both processes. Besides being able to do exquisite carving techniques, it can also cut different types of materials. Please check the following power parameters for materials with different thicknesses.

Want to know more details you can consult us for free!

Post time: Mar-10-2022