I-CO₂ Laser Plotter vs CO₂ Galvo:Yeyiphi Ehambelana Neemfuno Zakho Zokumakisha?

IiLaser Plotters (CO₂ Gantry) kunye neeGalvo Lasers ziinkqubo ezimbini ezidumileyo zokumakisha nokukrola. Nangona zombini zinokuvelisa iziphumo ezisemgangathweni ophezulu, zahlukile ngesantya, ukuchaneka, kunye nokusetyenziswa okufanelekileyo. Esi sikhokelo siza kukunceda uqonde umahluko wazo kwaye ukhethe inkqubo efanelekileyo kwiimfuno zakho.

1. Oomatshini beLaser Plotter (iNkqubo yeGantry)

Indlela ii-CO₂ Laser Plotters ezisingatha ngayo ukumakishwa kunye nokukrola

Iiplatter zeLaser zisebenzisa inkqubo yesitimela ye-XY ukuhambisa intloko yelaser phezu kwezinto. Oku kuvumela ukukrola kunye nokumakisha okuchanekileyo, okubanzi. Zilungele uyilo oluneenkcukacha ngomthi, i-acrylic, isikhumba, kunye nezinye izinto ezingezizo ezesinyithi.

Izixhobo Ezisebenza Kakuhle Ngee-Laser Plotters

Iiplati zeLaser ziyagqwesa ngezinto ezifanaumthi,i-acrylic,ulusu, iphepha, kwaye ezithile iiplastikiZiyakwazi ukusingatha amaphepha amakhulu kuneGalvo lasers kwaye zilungele ukukrolwa okunzulu okanye okubanzi.

Izicelo Eziqhelekileyo Zoomatshini Bokwenza I-Laser Plotter

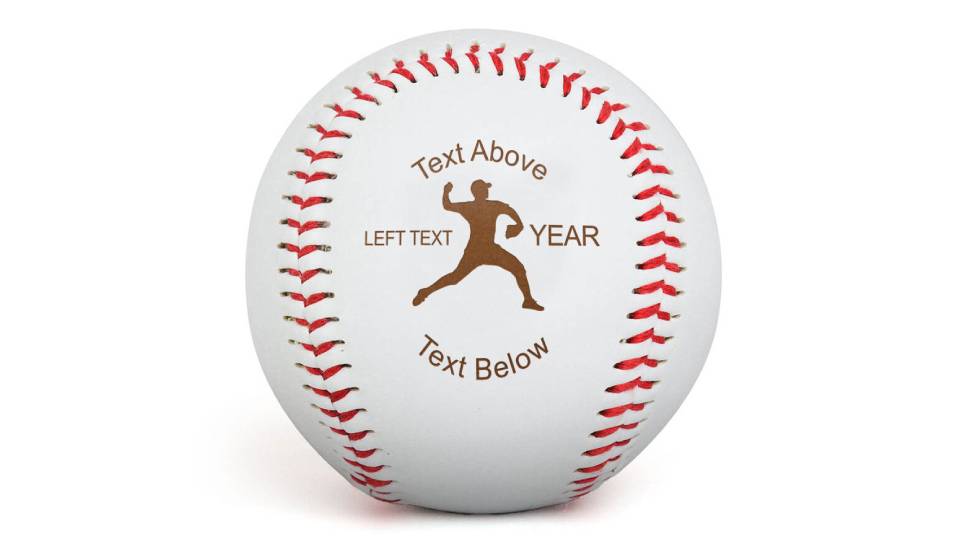

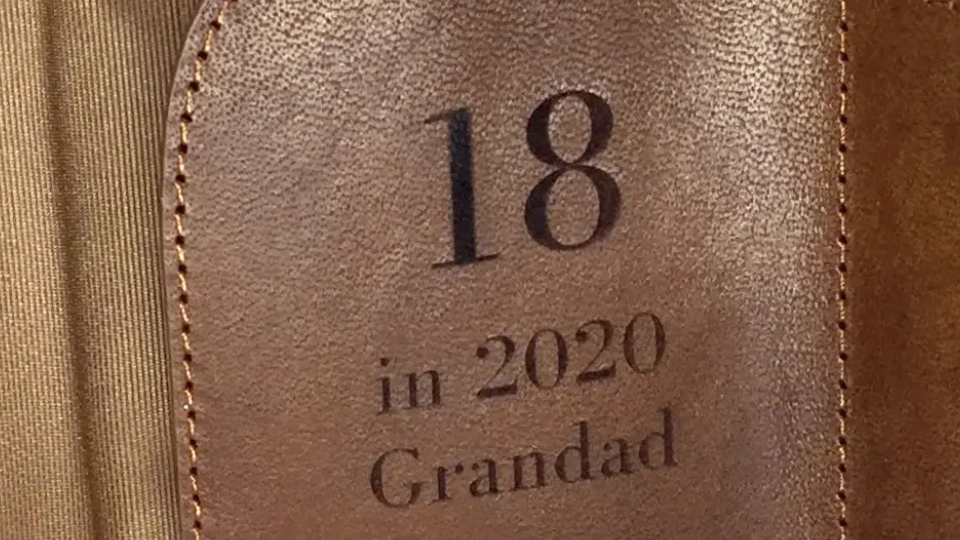

Ukusetyenziswa okuqhelekileyo kubandakanyaimiqondiso eyenziwe ngokwezifiso, izinto zobugcisa, imisebenzi yobugcisa emikhulu, ukupakisha, kunye nemveliso yomthamo ophakathi apho ukuchaneka kubalulekile khona.

Ezinye iiProjekthi zokuGqiba ngeLaser >>

2. Yintoni iGalvo Laser kwaye isebenza njani

Inkqubo yeGalvo Laser Mechanics kunye neVibrating Mirror

IiGalvo Lasers zisebenzisa izibuko ezibonisa ngokukhawuleza umqadi welaser ukuze zijolise kwiindawo ezikwizinto. Le nkqubo ivumela ukumakishwa nokukrolwa ngokukhawuleza kakhulu ngaphandle kokuhambisa izinto okanye intloko yelaser ngoomatshini.

Iingenelo zokuMakisha nokuGqoba ngesantya esiphezulu

IiGalvo Lasers zilungele iimpawu ezincinci nezineenkcukacha ezifana neelogo, iinombolo ze-serial, kunye neekhowudi ze-QR. Zifikelela ngokuchanekileyo okuphezulu ngesantya esiphezulu kakhulu, nto leyo ezenza zilungele ukusetyenziswa kwemizi-mveliso ngokuphindaphindiweyo.

Amatyala aqhelekileyo okusetyenziswa kwimizi-mveliso

Zisetyenziswa kakhulu kwizixhobo ze-elektroniki, ukupakisha, izinto zokwazisa, kunye nayo nayiphi na inkqubo apho kufuneka uphawu oluphindaphindwayo nolukhawulezayo.

3. I-Gantry vs Galvo: Uthelekiso lokuMakisha kunye nokuGqoba

Umahluko wesantya kunye nokusebenza kakuhle

IiGalvo Lasers zikhawuleza kakhulu kuneLaser Plotters kwiindawo ezincinci ngenxa yenkqubo yazo yokuskena isipili. IiLaser Plotters zihamba kancinci kodwa zinokugubungela iindawo ezinkulu ngokuchanekileyo okufanayo.

Umgangatho ochanekileyo kunye neenkcukacha

Zombini ezi nkqubo zibonelela ngocoselelo oluphezulu, kodwa iiLaser Plotters zibalasele ekukroleni kwindawo enkulu, ngelixa iiGalvo Lasers zingenakuthelekiswa nanto kwiimpawu ezincinci nezineenkcukacha.

Indawo Yokusebenza kunye Nokuguquguquka

Ii-Laser Plotters zinendawo enkulu yokusebenza, efanelekileyo kwiishiti ezinkulu kunye noyilo olubanzi. IiGalvo Lasers zinendawo encinci yokuskena, efanelekileyo kwiindawo ezincinci kunye nemisebenzi yokumakisha enomthamo omkhulu.

Ukukhetha Inkqubo Efanelekileyo Ngokusekelwe Kumsebenzi

Khetha i-Laser Plotter yeeprojekthi ezineenkcukacha, ezinkulu okanye ezenzelwe wena. Khetha i-Galvo Laser yokumakisha ngokukhawuleza, okuphindaphindiweyo kunye nokukrola kwindawo encinci.

4. Ukukhetha umatshini ofanelekileyo wokumakisha i-CO₂ Laser

Isishwankathelo seempawu eziphambili

Cinga ngesantya, ukuchaneka, indawo yokusebenza, kunye nokuhambelana kwezinto. Iiplatha zeLaser zilungele ukukrola okukhulu okanye okuntsonkothileyo, ngelixa iiGalvo Lasers zigqwesa ekuphawuleni ngesantya esiphezulu kwiidizayini ezincinci.

Iingcebiso zokukhetha eyona nkqubo ifanelekileyo kwiimfuno zakho

Vavanya iimfuno zeprojekthi yakho: izinto ezinkulu okanye ezincinci, ubunzulu bokukrola, ubungakanani bemveliso, kunye nohlahlo-lwabiwo mali. Oku kuya kunceda ekuqinisekiseni ukuba iLaser Plotter okanye iGalvo Laser iyahambelana na nomsebenzi wakho.

Awuqinisekanga ukuba iLaser Plotter okanye iGalvo Laser ziyahambelana neemfuno zakho? Masithethe.

• Indawo Yokusebenza: 1300mm * 900mm (51.2” * 35.4”)

• Amandla eLaser: 100W/150W/300W

• Isantya esiphezulu: 1~400mm/s

• Isantya sokukhawulezisa : 1000~4000mm/s2

• Umthombo weLaser: Ityhubhu yeLaser yeglasi yeCO2 okanye ityhubhu yeLaser yesinyithi yeCO2 RF

• Indawo Yokusebenza: 400mm * 400mm (15.7” * 15.7”)

• Amandla eLaser: 180W/250W/500W

• Ityhubhu yeLaser: Ityhubhu yeLaser yesinyithi yeCO2 RF

• Isantya Esiphezulu Sokusika: 1000mm/s

• Isantya esiphezulu sokukrola: 10,000mm/s

• Indawo Yokusebenza: 800mm * 800mm (31.4” * 31.4”)

• Amandla eLaser: 250W/500W

• Isantya Esiphezulu Sokusika: 1~1000mm/s

• Itheyibhile Yokusebenza: Itheyibhile Yokusebenza Yekama Lobusi

Ungayikhetha njani i-Laser Marking & Engraving Machine efanelekileyo?

Imibuzo ebuzwa rhoqo enxulumeneyo

Zombini iinkqubo zinokusebenza ngesoftware, kodwa iiGalvo Lasers zihlala zifuna ukuseta oomatshini abancinci ngenxa yendawo yazo yokusebenza encinci kunye nokuskena okukhawulezayo. IiLaser Plotters zinokufuna ixesha elingakumbi lokulungelelanisa kunye nokukrola kwindawo enkulu.

IiLaser Plotters (Gantry) zifuna ukucocwa rhoqo kweereyile, izibuko, kunye neelensi ukuze zihlale zichanekile. IiGalvo Lasers zifuna ukulinganiswa rhoqo kwezipili kunye nokucocwa kwezinto ezibonakalayo ukuqinisekisa uphawu oluchanekileyo.

Ngokubanzi, iiGalvo Lasers zibiza kakhulu ekuqaleni ngenxa yetekhnoloji yazo yokuskena ekhawulezayo. IiLaser Plotters zihlala zifikeleleka lula kwiindlela zokukrola kwiindawo ezinkulu kodwa zinokucotha.

IiGalvo Lasers zenzelwe ukuphawulwa ngokukhawuleza komphezulu kunye nokukrola okukhanyayo. Kwizicucu ezinzulu okanye ukukrola okuneenkcukacha kwindawo enkulu, iGantry Laser Plotter idla ngokufaneleka ngakumbi.

Ukuba iprojekthi yakho ibandakanya amaphepha amakhulu okanye uyilo olubanzi, i-Laser Plotter ifanelekile. Ukuba umsebenzi wakho ugxile kwizinto ezincinci, iilogo, okanye iinombolo ze-serial, i-Galvo Laser isebenza kakuhle ngakumbi.

Ewe. IiGalvo Lasers zibalasele kwimisebenzi yokumakisha ephindaphindwayo nenamandla aphezulu, ngelixa iiLaser Plotters zingcono kakhulu kwimveliso yokukrola eyenziwe ngokwezifiso, eneenkcukacha okanye enomthamo ophakathi apho ukuchaneka kubalulekile khona.

Ixesha leposi: Sep-25-2025