CO₂ Laser Plotter vs CO₂ Galvo: Which One Fits Your Marking Needs?

Laser Plotters (CO₂ Gantry) and Galvo Lasers are two popular systems for marking and engraving. While both can produce high-quality results, they differ in speed, precision, and ideal applications. This guide will help you understand their differences and choose the right system for your needs.

1. Laser Plotter Machines (Gantry System)

How CO₂ Laser Plotters Handle Marking and Engraving

Laser Plotters use an X-Y rail system to move the laser head over the material. This allows for precise, large-area engraving and marking. They are ideal for detailed designs on wood, acrylic, leather, and other non-metal materials.

Materials That Work Best with Laser Plotters

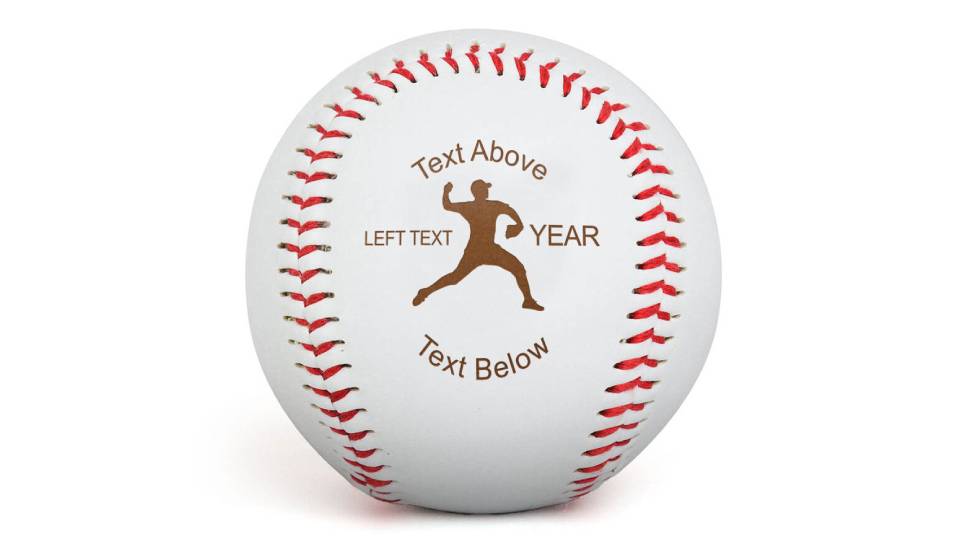

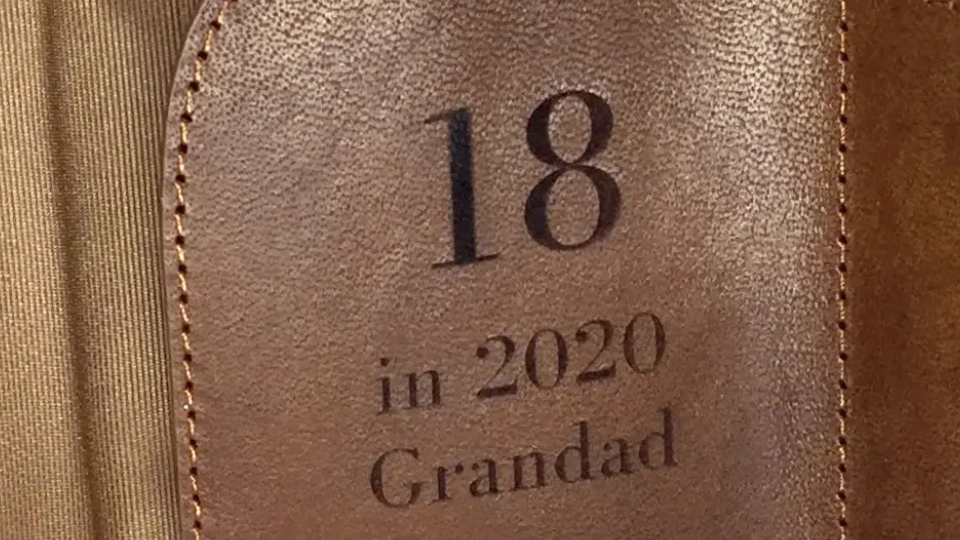

Common Applications for Laser Plotter Machines

Typical uses include custom signage, craft items, large-scale artwork, packaging, and medium-volume production where precision matters.

Some Laser Engraving Projects >>

2. What Is a Galvo Laser and How It Works

Galvo Laser Mechanics and Vibrating Mirror System

Galvo Lasers use mirrors that rapidly reflect the laser beam to target points on the material. This system allows extremely fast marking and engraving without moving the material or laser head mechanically.

Advantages for High-Speed Marking and Engraving

Galvo Lasers are ideal for small, detailed markings such as logos, serial numbers, and QR codes. They achieve high precision at very high speed, making them perfect for repetitive industrial applications.

Typical Industrial Use Cases

They are commonly used in electronics, packaging, promotional items, and any application where high-speed, repetitive marking is required.

3. Gantry vs Galvo: Marking & Engraving Comparison

Speed and Efficiency Differences

Galvo Lasers are much faster than Laser Plotters for small areas due to their mirror scanning system. Laser Plotters are slower but can cover large areas with consistent precision.

Precision and Detail Quality

Both systems offer high precision, but Laser Plotters excel at large-area engraving, while Galvo Lasers are unmatched for small, detailed marks.

Working Area and Flexibility

Laser Plotters have a larger working area, suitable for big sheets and wide designs. Galvo Lasers have a smaller scan area, ideal for small parts and high-volume marking tasks.

Choosing the Right System Based on Task

Choose a Laser Plotter for detailed, large-scale engraving or custom projects. Choose a Galvo Laser for fast, repetitive marking and small-area engraving.

4. Choosing the Right CO₂ Laser Marking Machine

Summary of Key Features

Consider speed, precision, working area, and material compatibility. Laser Plotters are best for large or complex engraving, while Galvo Lasers excel in high-speed marking of smaller designs.

Tips for Selecting the Best System for Your Needs

Evaluate your project requirements: large or small materials, depth of engraving, production volume, and budget. This will help determine whether a Laser Plotter or Galvo Laser fits your workflow.

Not sure whether a Laser Plotter or Galvo Laser fits your needs? Let’s talk.

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Max Speed: 1~400mm/s

• Acceleration Speed :1000~4000mm/s2

• Laser Source :CO2 Glass Laser Tube or CO2 RF Metal Laser Tube

• Working Area: 400mm * 400mm (15.7” * 15.7”)

• Laser Power: 180W/250W/500W

• Laser Tube: CO2 RF Metal Laser Tube

• Max Cutting Speed: 1000mm/s

• Max Engraving Speed: 10,000mm/s

• Working Area: 800mm * 800mm (31.4” * 31.4”)

• Laser Power: 250W/500W

• Max Cutting Speed: 1~1000mm/s

• Working Table: Honey Comb Working Table

How to Select a Suitable Laser Marking & Engraving Machine?

Additional Related FAQs

Both systems can be operated via software, but Galvo Lasers often require less mechanical setup due to their small working area and faster scanning. Laser Plotters may need more time for alignment and large-area engraving.

Laser Plotters (Gantry) need regular cleaning of rails, mirrors, and lenses to maintain precision. Galvo Lasers require periodic calibration of the mirrors and cleaning of optical components to ensure accurate marking.

Generally, Galvo Lasers are more expensive upfront due to their high-speed scanning technology. Laser Plotters are often more affordable for large-area engraving applications but may be slower.

Galvo Lasers are optimized for fast surface marking and light engraving. For deeper cuts or detailed large-area engraving, a Gantry Laser Plotter is usually more suitable.

If your project involves large sheets or wide-area designs, a Laser Plotter is ideal. If your work focuses on small items, logos, or serial numbers, a Galvo Laser is more efficient.

Yes. Galvo Lasers excel in high-volume, repetitive marking tasks, while Laser Plotters are better for custom, detailed engraving or medium-volume production where precision matters.

Post time: Sep-25-2025