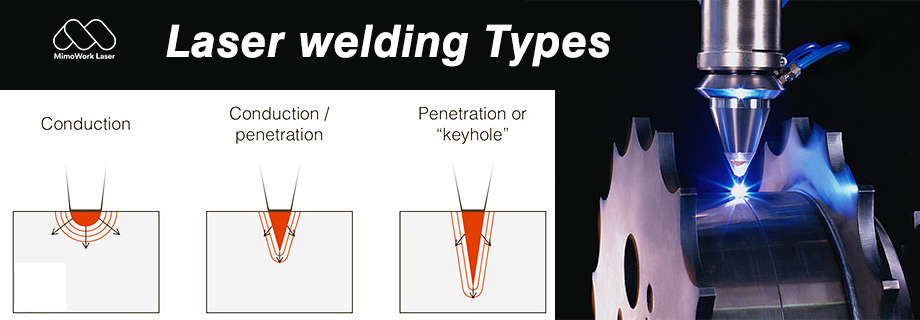

Ana iya cimma walda ta hanyar amfani da janareta mai ci gaba ko mai bugun zuciya. Ana iya raba ƙa'idar walda ta laser zuwa walda mai watsa zafi da walda mai zurfafa haɗuwa ta laser. Ƙarfin wutar lantarki ƙasa da 104~105 W/cm2 shine walda mai watsa zafi, a wannan lokacin, zurfin narkewa, da saurin walda yana raguwa; Lokacin da ƙarfin wutar ya fi 105~107 W/cm2, saman ƙarfe yana kwance cikin "ramukan maɓalli" ƙarƙashin aikin zafi, yana samar da walda mai haɗuwa mai zurfi, wanda ke da halaye na saurin walda mai sauri da babban rabo mai faɗi-zurfi.

A yau, za mu yi bayani ne kawai game da manyan abubuwan da ke shafar ingancin walda mai zurfi ta Laser.

1. Ƙarfin Laser

A cikin walda mai zurfin haɗa laser, ƙarfin laser yana sarrafa zurfin shiga da saurin walda. Zurfin walda yana da alaƙa kai tsaye da yawan ƙarfin hasken kuma yana da alaƙa da ƙarfin hasken da ya faru da kuma wurin da hasken ke mayar da hankali. Gabaɗaya, ga wani diamita na hasken laser, zurfin shigar yana ƙaruwa tare da ƙaruwar ƙarfin hasken.

2. Wurin da aka fi mayar da hankali

Girman tabo na katako yana ɗaya daga cikin mahimman abubuwan da ke canzawa a cikin walda ta laser domin yana ƙayyade yawan ƙarfin. Amma auna shi ƙalubale ne ga lasers masu ƙarfi, kodayake akwai dabarun aunawa kai tsaye da yawa da ake da su.

Ana iya ƙididdige girman tabo na nesa na hasken haske bisa ga ka'idar diffraction, amma ainihin girman tabo ya fi ƙimar da aka ƙididdige saboda rashin kyawun tunani mai zurfi. Hanya mafi sauƙi ta aunawa ita ce hanyar yanayin yanayin zafi na iso, wadda ke auna diamita na wurin da aka fi mayar da hankali da kuma rami bayan an ƙone takarda mai kauri kuma an ratsa ta cikin farantin polypropylene. Wannan hanyar ta hanyar aikin aunawa, tana da ƙwarewa a girman wutar lantarki ta laser da lokacin aikin haske.

3. Iskar Gas Mai Kariya

Tsarin walda na laser sau da yawa yana amfani da iskar gas mai kariya (helium, argon, nitrogen) don kare wurin narkakken najasa, yana hana aikin daga iskar shaka a cikin aikin walda. Dalili na biyu na amfani da iskar gas mai kariya shine don kare ruwan tabarau mai mai da hankali daga gurɓatawa ta tururin ƙarfe da kuma ɗigon ruwa. Musamman a cikin walda na laser mai ƙarfi, ejecta yana da ƙarfi sosai, yana da mahimmanci don kare ruwan tabarau. Tasiri na uku na iskar gas mai kariya shine yana da tasiri sosai wajen wargaza kariyar plasma da walda mai ƙarfi ta samar. Tururin ƙarfe yana shan hasken laser kuma yana ionize zuwa gajimare na plasma. Iskar gas mai kariya da ke kewaye da tururin ƙarfe shi ma yana ionizes saboda zafi. Idan akwai plasma da yawa, hasken laser yana cinye shi ta wata hanya ta plasma. A matsayin makamashi na biyu, plasma yana wanzuwa a saman aiki, wanda ke sa zurfin walda ya fi zurfi kuma saman wurin walda ya fi faɗi.

Yadda ake zaɓar iskar gas mai kariya mai kyau?

4. Yawan Sha

Shawarar laser na kayan ya dogara ne akan wasu muhimman halaye na kayan, kamar ƙimar sha, ƙarfin haske, ƙarfin watsa zafi, zafin narkewa, da zafin ƙafewar iska. Daga cikin dukkan abubuwan, mafi mahimmanci shine ƙimar sha.

Abubuwa biyu suna shafar yawan shan kayan zuwa ga hasken laser. Na farko shine yawan juriya na kayan. An gano cewa yawan shan kayan yana daidai da tushen murabba'in ma'aunin juriya, kuma ma'aunin juriya ya bambanta da zafin jiki. Na biyu, yanayin saman kayan (ko ƙarewa) yana da tasiri mai mahimmanci akan yawan sha na katako, wanda ke da tasiri mai mahimmanci akan tasirin walda.

5. Gudun Walda

Saurin walda yana da tasiri sosai kan zurfin shigar ciki. Ƙara saurin zai sa zurfin shigar ciki ya yi ƙasa, amma ƙasa da haka zai haifar da narkewar kayan aiki da walda ta hanyar aiki. Saboda haka, akwai kewayon saurin walda da ya dace don takamaiman kayan aiki tare da ƙarfin laser da wani kauri, kuma ana iya samun matsakaicin zurfin shigar ciki a ƙimar saurin da ta dace.

6. Tsawon Hasken Hasken Hasken Haske

Yawanci ana sanya ruwan tabarau mai mayar da hankali a kan bindigar walda, yawanci ana zaɓar tsawon haske mai tsawon 63 ~ 254mm (diamita 2.5 "~ 10"). Girman wurin da aka mayar da hankali ya yi daidai da tsawon haske, gajeriyar tsawon haske, ƙaramin wurin. Duk da haka, tsawon tsayin haske kuma yana shafar zurfin mayar da hankali, wato, zurfin mayar da hankali yana ƙaruwa tare da tsawon haske, don haka gajeren tsawon haske zai iya inganta yawan ƙarfi, amma saboda zurfin mayar da hankali ƙarami ne, dole ne a kiyaye nisa tsakanin ruwan tabarau da kayan aikin daidai, kuma zurfin shigar ba shi da girma. Saboda tasirin fashewar da yanayin laser yayin walda, mafi ƙarancin zurfin mayar da hankali da ake amfani da shi a walda na ainihi galibi shine 126mm (diamita 5"). Ana iya zaɓar ruwan tabarau mai tsawon haske na 254mm (diamita 10") lokacin da ɗinki ya yi girma ko kuma walda yana buƙatar ƙaruwa ta hanyar ƙara girman wurin. A wannan yanayin, ana buƙatar ƙarfin fitarwa na laser mafi girma (yawan ƙarfi) don cimma tasirin ramin shiga zurfin.

Ƙarin tambayoyi game da farashin injin walda na laser da aka yi amfani da shi da kuma tsari

Lokacin Saƙo: Satumba-27-2022