Laser ịgbado ọkụ bụ tumadi iji melite ịgbado ọkụ arụmọrụ na àgwà nke mkpa mgbidi ihe na nkenke akụkụ.Taa, anyị agaghị ekwu maka uru nke ịgbado ọkụ laser mana lekwasị anya na otu esi eji gas mkpuchi maka ịgbado ọkụ laser nke ọma.

Kedu ihe kpatara eji gas ọta maka ịgbado ọkụ laser?

Na laser ịgbado ọkụ, ọta gas ga-emetụta weld akpụ, weld àgwà, weld omimi, na weld obosara.N'ọtụtụ ọnọdụ, ịfụ gas na-enyere aka ga-enwe mmetụta dị mma na weld, ma ọ nwekwara ike ịkpata mmetụta ọjọọ.

Mgbe ị na-afụ gas ọta nke ọma, ọ ga-enyere gị aka:

✦Chebe ọdọ mmiri weld nke ọma iji belata ma ọ bụ ọbụna zere oxidation

✦Wedata nke ọma nfesa a na-emepụta na usoro ịgbado ọkụ

✦Ibelata weld pores nke ọma

✦Na-enyere ọdọ mmiri weld aka ịgbasa nke ọma mgbe ọ gbasiri ike, nke mere na eriri weld na-abịa na ọnụ dị ọcha ma dịkwa mma.

✦Mmetụta nchebe nke igwe vapor plume ma ọ bụ igwe ojii plasma na laser na-ebelata nke ọma, yana ọnụ ahịa ojiji nke laser na-abawanye.

Ogologo oge nkeụdị ọta gas, ọnụego nrịba gas, na nhọrọ ọnọdụ ịfụziri ezi, ị nwere ike nweta ezigbo mmetụta nke ịgbado ọkụ.Agbanyeghị, iji gas nchebe na-ezighi ezi nwekwara ike imetụta ịgbado ọkụ n'ụzọ dị njọ.Iji ụdị ọta gas na-ezighi ezi nwere ike iduga creaks na weld ma ọ bụ belata ihe eji arụ ọrụ nke ịgbado ọkụ.Oke gas na-eru oke ma ọ bụ dị ala nke ukwuu nwere ike iduga n'ịgba weld oxidation siri ike yana nnyonye anya mpụga nke ihe igwe dị n'ime ọdọ mmiri weld, na-ebute ọdịda weld ma ọ bụ na-akpụ akpụ.

Ụdị nke ọta gas

A na-ejikarị gas nchebe nke ịgbado ọkụ laser bụ N2, Ar, na He.Njirimara anụ ahụ na kemịkal ha dị iche, yabụ mmetụta ha na weld dịkwa iche iche.

Nitrogen (N2)

Ike ionization nke N2 dị oke oke, dị elu karịa nke Ar, na ala karịa nke Ya.N'okpuru radieshon nke laser, ogo ionization nke N2 na-anọ na keel ọbụna, nke nwere ike belata nguzobe nke ígwé ojii plasma ma mee ka ọnụọgụ laser dị irè.Nitrogen nwere ike meghachi omume na aluminom alloy na carbon ígwè na ụfọdụ okpomọkụ na-emepụta nitrides, nke ga-eme ka weld brittleness na ibelata siri ike, na-enwe oké oghom mmetụta na n'ibu Njirimara nke weld nkwonkwo.Ya mere, a naghị atụ aro iji nitrogen mgbe ị na-agbado aluminum alloy na carbon steel.

Otú ọ dị, mmeghachi omume kemịkalụ n'etiti nitrogen na igwe anaghị agba nchara nke nitrogen na-emepụta nwere ike ime ka ike nke nkwonkwo weld dịkwuo mma, nke ga-aba uru iji meziwanye ihe eji arụ ọrụ nke weld, ya mere ịgbado ọkụ nke igwe anaghị agba nchara nwere ike iji nitrogen dị ka ihe nchebe gas.

Argon (Ar)

Ike ionization nke Argon dị ntakịrị, na ogo ionization ya ga-adị elu n'okpuru ọrụ nke laser.Mgbe ahụ, Argon, dị ka gas na-echebe, enweghị ike ịchịkwa nguzobe nke ígwé ojii plasma nke ọma, nke ga-ebelata ọnụ ọgụgụ dị irè nke ịgbado ọkụ laser.Ajụjụ na-ebilite: argon ọ bụ onye na-adịghị mma maka ịgbado ọkụ dị ka gas na-echebe?Azịza ya bụ Mba. N'ịbụ gas inert, Argon siri ike meghachi omume na ọtụtụ ọla, na Ar dị ọnụ ala iji.Tụkwasị na nke ahụ, njupụta nke Ar dị ukwuu, ọ ga-adị mma maka ịmịnye n'elu ọdọ mmiri weld a wụrụ awụ ma nwee ike ichebe ọdọ mmiri weld, ya mere enwere ike iji Argon mee ihe dị ka gas nchebe nkịtị.

Helium (He)

N'adịghị ka Argon, Helium nwere ike ionization dị elu nke nwere ike ịchịkwa nhazi nke ígwé ojii plasma ngwa ngwa.N'otu oge ahụ, helium anaghị emeghachi omume na ọla ọ bụla.Ọ bụ ezigbo nhọrọ maka ịgbado ọkụ laser.Naanị nsogbu bụ na helium dị oke ọnụ.Maka ndị na-emepụta ihe na-enye ngwaahịa igwe na-emepụta oke, helium ga-agbakwunye nnukwu ego na ọnụahịa mmepụta.Ya mere, a na-ejikarị helium eme nchọpụta sayensị ma ọ bụ ngwaahịa nwere uru agbakwunyere nke ukwuu.

Kedu ka esi afụ gas ọta?

Nke mbụ, ọ ga-edo anya na ihe a na-akpọ "oxidation" nke weld bụ naanị aha a na-ahụkarị, nke na-ezo aka na mmeghachi omume kemịkal n'etiti weld na ihe ndị na-emerụ ahụ na ikuku, na-eduga ná mmebi nke weld. .Ọtụtụ mgbe, ígwè weld na-eji oxygen, nitrogen, na hydrogen emeghachi omume n'ikuku n'otu oge okpomọkụ.

Iji gbochie weld si ịbụ "oxidized" na-achọ ibelata ma ọ bụ na-ezere kọntaktị n'etiti ndị dị otú ahụ na-emerụ components na weld metal n'okpuru elu okpomọkụ, nke na-abụghị nanị na a wụrụ awụ ọdọ mmiri metal ma dum oge site na mgbe weld metal gbazee ruo mgbe weld metal gbazee ruo mgbe. Ọgba ọdọ mmiri a wụrụ awụ na-esiwanye ike na ọnọdụ okpomọkụ ya na-ajụkwa oyi ruo n'otu okpomọkụ.

Ụzọ abụọ bụ isi nke ịfụ ọta gas

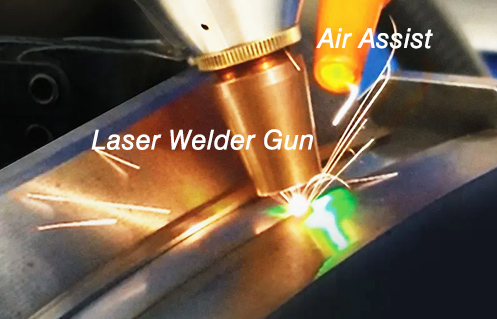

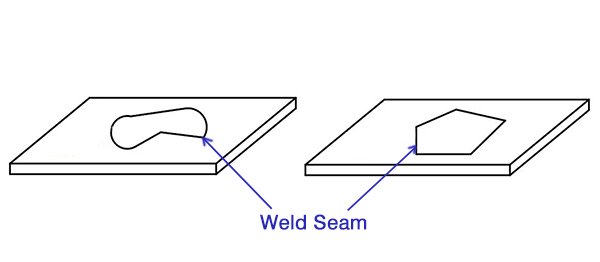

▶Otu na-afụ gas ọta n'akụkụ akụkụ, dị ka egosiri na foto 1.

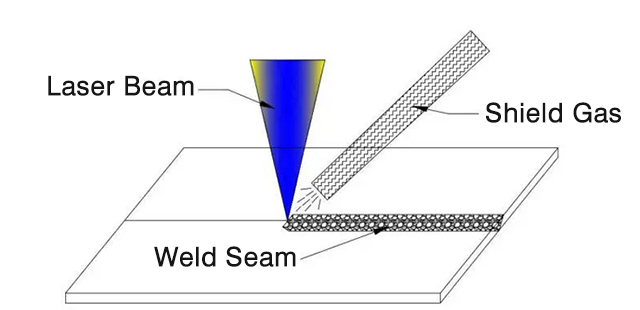

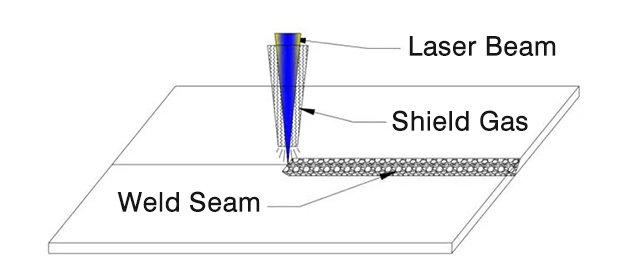

▶Nke ọzọ bụ usoro ịfụ coaxial, dị ka egosiri na foto 2.

Onyonyo 1.

Onyonyo 2.

Nhọrọ a kapịrị ọnụ nke ụzọ ịfụ abụọ bụ ntụle zuru oke nke ọtụtụ akụkụ.N'ozuzu, a na-atụ aro ka ị nweta ụzọ nke gas nchebe na-agbapụ n'akụkụ.

Ihe atụ ụfọdụ nke ịgbado ọkụ laser

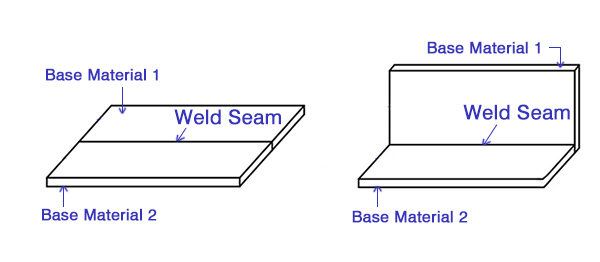

1. Ịgbado ọkụ kwụ ọtọ / ahịrị

Dị ka egosiri na eserese 3, ụdị weld nke ngwaahịa ahụ bụ ahịrị, na ụdị nkwonkwo nwere ike ịbụ nkwonkwo ụkwụ, nkwonkwo ụkwụ, nkwonkwo nkuku na-adịghị mma, ma ọ bụ nkwonkwo ịgbado ọkụ.Maka ụdị ngwaahịa a, ọ ka mma ịnakwere gas nchebe nke akụkụ-axis dị ka egosiri na foto 1.

2. Mechie ọnụ ọgụgụ ma ọ bụ ịgbado ọkụ mpaghara

Dị ka e gosiri na Figure 4, weld udi nke ngwaahịa bụ a mechiri emechi ụkpụrụ dị ka ụgbọelu gburugburu, ụgbọelu multilateral udi, ụgbọelu multi-segment linear udi, wdg The nkwonkwo ụdị nwere ike ịbụ butt nkwonkwo, n'apata nkwonkwo, overlapping ịgbado ọkụ, wdg. Ọ ka mma ịnakwere usoro mkpuchi mkpuchi coaxial dị ka egosiri na foto 2 maka ụdị ngwaahịa a.

Nhọrọ nke gas na-echebe ozugbo na-emetụta àgwà ịgbado ọkụ, arụmọrụ, na ọnụ ahịa nke mmepụta, ma n'ihi ụdị ihe dị iche iche nke ịgbado ọkụ, na usoro ịgbado ọkụ n'ezie, nhọrọ nke ịgbado ọkụ gas dị mgbagwoju anya ma na-achọ nleba anya zuru oke nke ihe ịgbado ọkụ, ịgbado ọkụ. usoro, ịgbado ọkụ ọnọdụ, nakwa dị ka chọrọ nke ịgbado ọkụ mmetụta.Site na ule ịgbado ọkụ, ị nwere ike họrọ gas ịgbado ọkụ ka mma iji nweta nsonaazụ kacha mma.

Nwere mmasị na ịgbado ọkụ laser na njikere ịmụta otú e si ahọrọ ọta gas

Njikọ ndị emetụtara:

Oge nzipu: Ọktoba 10-2022