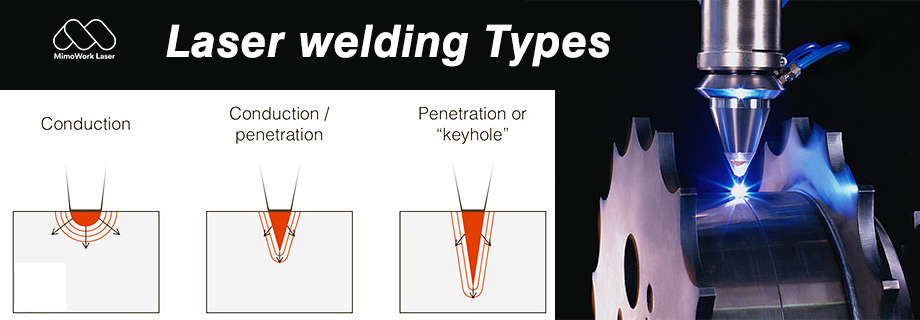

Ukuwelda nge-laser kunokufezekiswa yijenereyitha yelaser eqhubekayo okanye eshukumayo. Umgaqo wokuwelda nge-laser ungahlulwahlulwa ube kukuwelda kokuqhuba ubushushu kunye nokuwelda kwe-laser deep fusion. Uxinano lwamandla angaphantsi kwe-104 ~ 105 W / cm2 kukuwelda kokuqhuba ubushushu, ngeli xesha, ubunzulu bokunyibilika, kunye nesantya sokuwelda sicotha; Xa uxinano lwamandla lungaphezulu kwe-105 ~ 107 W / cm2, umphezulu wesinyithi ugobile ube "ziimbobo zesitshixo" phantsi kwesenzo sobushushu, okwenza ukuwelda kwe-deep fusion, eneempawu zesantya sokuwelda esikhawulezayo kunye nomlinganiselo omkhulu wobunzulu nobubanzi.

Namhlanje, siza kugubungela ulwazi oluphambili ngezinto eziphambili ezichaphazela umgangatho we-laser deep fusion welding.

1. Amandla eLaser

Kwi-laser deep fusion welding, amandla e-laser alawula ubunzulu bokungena kunye nesantya sokufaka i-welding. Ubunzulu be-weld bunxulumene ngokuthe ngqo noxinano lwamandla e-beam kwaye ngumsebenzi wamandla e-incident beam kunye nendawo egxile kwi-beam. Ngokubanzi, kwi-laser beam ethile enobubanzi, ubunzulu bokungena buyanda ngokonyuka kwamandla e-beam.

2. Indawo egxile kuyo

Ubungakanani bebala lemiqadi yenye yezona zinto zibalulekileyo ekudibaniseni nge-laser kuba imisela uxinano lwamandla. Kodwa ukuyilinganisa ngumceli mngeni kwii-laser ezinamandla aphezulu, nangona kukho iindlela ezininzi zokulinganisa ezingathanga ngqo ezikhoyo.

Ubungakanani bendawo yomda we-diffraction ye-beam focus bunokubalwa ngokwethiyori ye-diffraction, kodwa ubungakanani bendawo yokwenyani bukhulu kunexabiso elibaliweyo ngenxa yokuba kukho ukubonakaliswa okungalunganga kwe-focal. Eyona ndlela ilula yokulinganisa yindlela yeprofayili yobushushu be-iso, elinganisa ububanzi bendawo ye-focal kunye nokugqobhoka emva kokuba iphepha elingqindilili litshisiwe kwaye lingene kwi-polypropylene plate. Le ndlela ngokusebenzisa uqheliselo lokulinganisa, ilawula ubungakanani bamandla e-laser kunye nexesha lesenzo se-beam.

3. Igesi ekhuselayo

Inkqubo yokuwelda nge-laser idla ngokusebenzisa iigesi ezikhuselayo (i-helium, i-argon, i-nitrogen) ukukhusela ichibi elinyibilikisiweyo, ithintela isixhobo somsebenzi ekungcolisweni yi-oxidation kwinkqubo yokuwelda. Isizathu sesibini sokusebenzisa igesi ekhuselayo kukukhusela ilensi egxile ekungcolisweni ngumphunga wesinyithi kunye nokutshiza ngamaconsi olwelo. Ingakumbi kwi-laser welding enamandla aphezulu, i-ejecta iba namandla kakhulu, kuyimfuneko ukukhusela ilensi. Isiphumo sesithathu segesi ekhuselayo kukuba iyasebenza kakhulu ekusasazeni isikhuselo se-plasma esiveliswa yi-laser welding enamandla aphezulu. Umphunga wesinyithi ufunxa umqadi we-laser kwaye uyi-ionize kwilifu le-plasma. Igesi ekhuselayo ejikeleze umphunga wesinyithi nayo iyayi-ionize ngenxa yobushushu. Ukuba kukho i-plasma eninzi kakhulu, umqadi we-laser ngandlela thile utyiwa yi-plasma. Njengamandla esibini, i-plasma ikhona kumphezulu wokusebenza, nto leyo eyenza ubunzulu be-weld bube nzulu kwaye umphezulu we-weld pool ube banzi.

Ungayikhetha njani igesi yokukhusela efanelekileyo?

4. Izinga lokufunxa

Ukufunxwa kwezinto nge-laser kuxhomekeke kwiimpawu ezibalulekileyo zezinto, ezinje ngesantya sokufunxwa, ukubonakalisa ukukhanya, ukuqhuba kobushushu, ubushushu bokunyibilika, kunye nobushushu bokufuma. Phakathi kwazo zonke ezi zinto, eyona ibalulekileyo yisantya sokufunxwa.

Izinto ezimbini zichaphazela izinga lokufunxwa kwezinto ukuya kumqadi welaser. Eyokuqala yi-resistance coefficient yezinto. Kufunyaniswe ukuba izinga lokufunxwa kwezinto lilingana nengcambu yesikwere ye-resistance coefficient, kwaye i-resistance coefficient iyahluka ngokweqondo lobushushu. Okwesibini, imeko yomphezulu (okanye ukugqitywa) kwezinto inempembelelo ebalulekileyo kwizinga lokufunxwa kwe-beam, enempembelelo ebalulekileyo kwisiphumo se-welding.

5. Isantya sokuWelda

Isantya sokuwelda sinempembelelo enkulu kubunzulu bokungena. Ukwandisa isantya kuya kwenza ubunzulu bokungena bube nzulu, kodwa bube sezantsi kakhulu kuya kukhokelela ekunyibilikeni kakhulu kwezinto kunye nokuwelda kwezinto zokusebenza. Ke ngoko, kukho uluhlu lwesantya sokuwelda olufanelekileyo kwisixhobo esithile esinamandla athile e-laser kunye nobukhulu obuthile, kwaye ubunzulu bokungena bunokufunyanwa ngexabiso lesantya elihambelanayo.

6. Ubude beFocal yeLensi yoGxilo

Ilensi yokugxila idla ngokufakwa entlokweni yesibhamu sokufaka intsimbi, ngokubanzi, kukhethwa ubude be-focal obuyi-63 ~ 254mm (ububanzi obuyi-2.5 "~ 10"). Ubungakanani bendawo yokugxila buhambelana nobude be-focal, okukhona ubude be-focal bufutshane, kokukhona indawo incinci. Nangona kunjalo, ubude be-focal buchaphazela ubunzulu be-focal, oko kukuthi, ubunzulu be-focal buyanda ngokulandelelana nobude be-focal, ngoko ke ubude be-focal obufutshane bunokuphucula uxinano lwamandla, kodwa ngenxa yokuba ubunzulu be-focal buncinci, umgama phakathi kwelensi kunye ne-workpiece kufuneka ugcinwe ngokuchanekileyo, kwaye ubunzulu bokungena abubukhulu. Ngenxa yempembelelo ye-splashes kunye ne-laser mode ngexesha lokufaka intsimbi, ubunzulu be-focal obufutshane obusetyenziswa kwi-welding yokwenyani buyi-126mm (ububanzi obuyi-5 "). Ilensi enobude be-focal obuyi-254mm (ububanzi obuyi-10") inokukhethwa xa umthungo mkhulu okanye i-weld kufuneka yonyuswe ngokwandisa ubungakanani be-focal. Kule meko, kufuneka amandla aphezulu okukhupha i-laser (uxinano lwamandla) ukuze kufezekiswe isiphumo somngxuma wokungena nzulu.

Imibuzo engakumbi malunga nexabiso kunye noqwalaselo lomatshini wokuwelda we-laser ophathwa ngesandla

Ixesha lokuthumela: Sep-27-2022