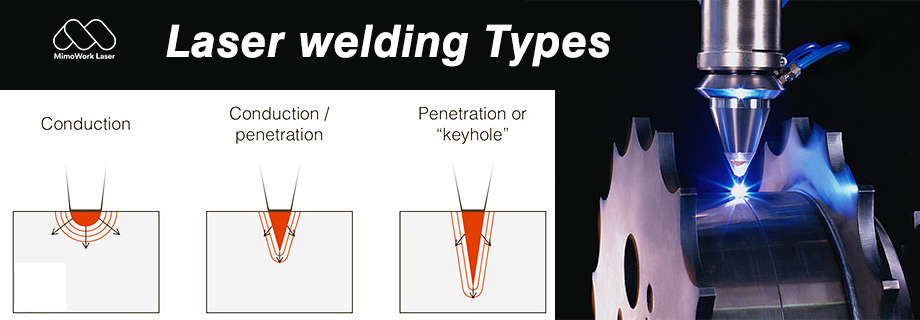

Ukushisela nge-laser kungabonakala ngejeneretha ye-laser eqhubekayo noma eqhutshwa yi-pulsed. Isimiso sokushisela nge-laser singahlukaniswa sibe ukushisela kokushisa kanye nokushisela kwe-laser deep fusion. Ubuningi bamandla obungaphansi kuka-104 ~ 105 W/cm2 ukushisela kokushisa, ngalesi sikhathi, ukujula kokuncibilika, kanye nesivinini sokushisela kuhamba kancane; Lapho ubukhulu bamandla bungaphezu kuka-105 ~ 107 W/cm2, ubuso bensimbi bugobekile bube "yimigodi yokhiye" ngaphansi kwesenzo sokushisa, kwakha ukushisela okujulile, okunezici zesivinini sokushisela esisheshayo kanye nesilinganiso esikhulu sobubanzi bokujula.

Namuhla, sizokhuluma kakhulu ngolwazi lwezinto ezibalulekile ezithinta ikhwalithi yokushisela i-laser deep fusion.

1. Amandla e-Laser

Ekushiseni okujulile kwe-laser fusion, amandla e-laser alawula kokubili ukujula kokungena kanye nesivinini sokushisela. Ukujula kokushisela kuhlobene ngqo nobuningi bamandla e-beam futhi kuwumsebenzi wamandla e-incident beam kanye nendawo egxile ku-beam. Ngokuvamile, ngomsebe we-laser obubanzi obuthile, ukujula kokungena kuyanda ngokwanda kwamandla e-beam.

2. Indawo Egxile Kuyo

Usayizi we-beam spot ungenye yezinto ezibaluleke kakhulu ekushiseni nge-laser ngoba inquma ubuningi bamandla. Kodwa ukuyilinganisa kuyinselele kuma-laser anamandla amakhulu, yize kunezindlela eziningi zokulinganisa ezingaqondile ezitholakalayo.

Usayizi wendawo yomkhawulo we-diffraction wokugxila kwe-beam ungabalwa ngokuya ngethiyori ye-diffraction, kodwa usayizi wendawo wangempela mkhulu kunenani elibalwe ngenxa yokuba khona kokubonakaliswa okungekuhle kwe-focal. Indlela elula yokulinganisa indlela yephrofayili ye-iso-temperature, elinganisa ububanzi bendawo yokugxila kanye nokubhoboka ngemva kokuba iphepha elijiyile lishisiwe futhi lingene ngepuleti le-polypropylene. Le ndlela ngokusebenzisa umkhuba wokulinganisa, ilawula usayizi wamandla we-laser kanye nesikhathi sesenzo se-beam.

3. Igesi Evikelayo

Inqubo yokushisela nge-laser ivame ukusebenzisa amagesi avikelayo (i-helium, i-argon, i-nitrogen) ukuvikela ichibi elincibilikisiwe, ukuvimbela umsebenzi ukuthi ungashisi enkambisweni yokushisela. Isizathu sesibili sokusebenzisa igesi evikelayo ukuvikela ilensi egxilile ekungcolisweni yimisi yensimbi kanye nokuchitheka ngamaconsi amanzi. Ikakhulukazi ekushiseleni nge-laser enamandla amakhulu, i-ejecta iba namandla kakhulu, kuyadingeka ukuvikela ilensi. Umphumela wesithathu wegesi evikelayo ukuthi iyasebenza kakhulu ekusakazeni isivikelo se-plasma esikhiqizwa yi-laser eqinisayo enamandla amakhulu. Umhwamuko wensimbi umunca umhwamuko we-laser bese uyifaka efwini le-plasma. Igesi evikelayo ezungeze umhwamuko wensimbi nayo iyayifaka ngenxa yokushisa. Uma kune-plasma eningi kakhulu, umhwamuko we-laser ngandlela thile udliwa yi-plasma. Njengamandla esibili, i-plasma ikhona endaweni yokusebenza, okwenza ukujula kokushisela kube kuncane kakhulu futhi indawo yokushisela ibe banzi.

Ungayikhetha kanjani igesi yokuvikela efanele?

4. Izinga Lokumunca

Ukumuncwa kwezinto nge-laser kuncike kwezinye izakhiwo ezibalulekile zezinto, njengezinga lokumuncwa, ukubuyisa ukukhanya, ukuhanjiswa kokushisa, izinga lokushisa lokuncibilika, kanye nokushisa kokuhwamuka. Phakathi kwazo zonke izici, okubaluleke kakhulu izinga lokumuncwa.

Izici ezimbili zithinta izinga lokumuncwa kwezinto kuya emsebeni we-laser. Eyokuqala yi-coefficient yokumelana kwezinto. Kutholakale ukuthi izinga lokumuncwa kwezinto lilingana nomsuka wesikwele we-coefficient yokumelana, futhi i-coefficient yokumelana iyahlukahluka ngokushisa. Okwesibili, isimo sobuso (noma ukuphela) kwezinto kunethonya elibalulekile ezingeni lokumuncwa kwe-bore, elinomthelela omkhulu emphumeleni wokushisela.

5. Isivinini Sokushisela

Ijubane lokushisela linethonya elikhulu ekujuleni kokungena. Ukwandisa ijubane kuzokwenza ukujula kokungena kube kuncane kakhulu, kodwa okuphansi kakhulu kuzoholela ekuncibilikeni ngokweqile kwezinto kanye nokushisela kwezinto zokusebenza. Ngakho-ke, kunebanga lejubane lokushisela elifanele lezinto ezithile ezinamandla athile e-laser kanye nobukhulu obuthile, futhi ukujula kokungena okuphezulu kungatholakala ngenani lejubane elihambisanayo.

6. Ubude Bokugxila Kwelensi Yokugxila

Ilensi yokugxila ivame ukufakwa ekhanda lesibhamu sokushisela, ngokuvamile, kukhethwa ubude bokugxila obungu-63 ~ 254mm (ububanzi obungu-2.5 "~ 10"). Usayizi wendawo yokugxila ulingana nobude bokugxila, uma ubude bokugxila bufushane, indawo iba ncane. Kodwa-ke, ubude bobude bokugxila buthinta nokujula kokugxila, okungukuthi, ukujula kokugxila kuyanda ngokuvumelana nobude bokugxila, ngakho-ke ubude obufushane bokugxila bungathuthukisa ubuningi bamandla, kodwa ngenxa yokuthi ukujula kokugxila kuncane, ibanga phakathi kwelensi nendawo yokusebenza kumele ligcinwe kahle, futhi ukujula kokungena akukukhulu. Ngenxa yethonya le-splashes kanye nemodi ye-laser ngesikhathi sokushisela, ukujula okufushane kakhulu kokugxila okusetshenziswe ekushiseleni kwangempela kungama-126mm (ububanzi obungu-5"). Ilensi enobude bokugxila obungu-254mm (ububanzi obungu-10") ingakhethwa lapho umthungo mkhulu noma i-weld idinga ukukhushulwa ngokwandisa usayizi wendawo. Kulokhu, kudingeka amandla aphezulu okukhipha i-laser (ubuningi bamandla) ukuze kufezwe umphumela womgodi wokungena ojulile.

Imibuzo eminingi mayelana nentengo yomshini wokuwelda we-laser ophathwa ngesandla kanye nokucushwa kwawo

Isikhathi sokuthunyelwe: Septhemba-27-2022