Ukushisela nge-laser kuhloselwe kakhulu ukuthuthukisa ukusebenza kahle kokushisela kanye nekhwalithi yezinto zodonga oluncane kanye nezingxenye ezinembile. Namuhla ngeke sikhulume ngezinzuzo zokushisela nge-laser kodwa sizogxila endleleni yokusebenzisa amagesi okuvikela ukushisela nge-laser ngendlela efanele.

Kungani usebenzisa igesi yokuvikela ukushisela nge-laser?

Ekushiseni nge-laser, igesi yokuvikela izothinta ukwakheka kwe-weld, ikhwalithi ye-weld, ukujula kwe-weld, kanye nobubanzi be-weld. Ezimweni eziningi, ukuqhuma kwegesi esizwayo kuzoba nomthelela omuhle ku-weld, kodwa futhi kungaletha imiphumela emibi.

Uma uphefumula igesi yokuvikela kahle, izokusiza:

✦Vikela ngempumelelo ichibi lokushisela ukuze unciphise noma ugweme ukushiswa kwe-oxidation

✦Nciphisa ngempumelelo ukuchaphaza okukhiqizwa enqubweni yokushisela

✦Yehlisa ngempumelelo ama-weld pores

✦Siza ichibi lokushisela lisabalale ngokulinganayo lapho liqina, ukuze umthungo wokushisela ube nomphetho ohlanzekile nobushelelezi

✦Umphumela wokuvikela we-plume yensimbi noma ifu le-plasma ku-laser uncishiswa ngempumelelo, futhi izinga lokusetshenziswa ngempumelelo kwe-laser liyakhuphuka.

Uma njeuhlobo lwegesi yesivikelo, izinga lokugeleza kwegesi, kanye nokukhetha imodi yokuqhumaUma zilungile, ungathola umphumela omuhle wokushisela. Kodwa-ke, ukusetshenziswa okungalungile kwegesi evikelayo nakho kungathinta kabi ukushisela. Ukusebenzisa uhlobo olungalungile lwegesi evikelayo kungaholela ekuqhekekeni kwe-weld noma kunciphise izakhiwo zemishini zokushisela. Isivinini sokugeleza kwegesi esiphezulu kakhulu noma esiphansi kakhulu singaholela ekuqhekekeni kwe-weld okukhulu kanye nokuphazamiseka okukhulu kwangaphandle kwezinto zensimbi ngaphakathi kwechibi lokushisela, okuholela ekuweni kwe-weld noma ukwakheka okungalingani.

Izinhlobo zegesi yokuvikela

Amagesi avikelayo asetshenziswa kakhulu ekushiseni nge-laser ikakhulukazi yi-N2, Ar, kanye ne-He. Izakhiwo zawo zomzimba nezamakhemikhali zihlukile, ngakho-ke imiphumela yawo kuma-weld nayo ihlukile.

I-nitrogen (N2)

Amandla e-ionization e-N2 aphakathi nendawo, aphezulu kune-Ar, futhi aphansi kune-He. Ngaphansi kwemisebe ye-laser, izinga le-ionization le-N2 lihlala lilingana, okunganciphisa kangcono ukwakheka kwefu le-plasma futhi kwandise izinga lokusetshenziswa okusebenzayo kwe-laser. I-nitrogen ingasabela nge-aluminium alloy kanye ne-carbon steel ekushiseni okuthile ukuze ikhiqize ama-nitride, okuzothuthukisa ukuqhekeka kwe-weld futhi kunciphise ukuqina, futhi kube nomthelela omubi kakhulu ezimpahleni zemishini yamajoyinti e-weld. Ngakho-ke, akukhuthazwa ukusebenzisa i-nitrogen lapho kushintshwa i-aluminium alloy kanye ne-carbon steel.

Kodwa-ke, ukusabela kwamakhemikhali phakathi kwe-nitrogen nensimbi engagqwali okukhiqizwa yi-nitrogen kungathuthukisa amandla e-weld joint, okuzoba wusizo ekuthuthukiseni izakhiwo zemishini ze-weld, ngakho-ke ukushisela insimbi engagqwali kungasebenzisa i-nitrogen njengegesi yokuvikela.

I-Argon (i-Ar)

Amandla e-ionization e-Argon aphansi kakhulu, futhi izinga lawo le-ionization lizophakama ngaphansi kwesenzo se-laser. Ngemuva kwalokho, i-Argon, njengegesi yokuvikela, ayikwazi ukulawula ngempumelelo ukwakheka kwamafu e-plasma, okuzonciphisa izinga lokusetshenziswa okusebenzayo kwe-laser welding. Umbuzo uphakama: ingabe i-argon iyindlela embi yokusetshenziswa kwe-welding njengegesi yokuvikela? Impendulo inguCha. Njengoba iyigesi engasebenzi, i-Argon kunzima ukusabela ngezinsimbi eziningi, futhi i-Ar ishibhile ukuyisebenzisa. Ngaphezu kwalokho, ubuningi be-Ar bukhulu, buzoba nomthelela wokucwila ebusweni bechibi elincibilikisiwe le-weld futhi bungavikela kangcono ichibi le-weld, ngakho-ke i-Argon ingasetshenziswa njengegesi yokuvikela evamile.

I-Helium (He)

Ngokungafani ne-Argon, i-Helium inamandla aphezulu e-ionization angalawula ukwakheka kwamafu e-plasma kalula. Ngesikhathi esifanayo, i-Helium ayisabelani nanoma yiziphi izinsimbi. Kuyisinqumo esihle ngempela sokushisela nge-laser. Inkinga kuphela ukuthi i-Helium ibiza kakhulu. Kwabakhiqizi abahlinzeka ngemikhiqizo yensimbi ekhiqizwa ngobuningi, i-helium izokwengeza inani elikhulu ezindlekweni zokukhiqiza. Ngakho-ke i-helium ivame ukusetshenziswa ocwaningweni lwesayensi noma emikhiqizweni enenani eliphezulu kakhulu.

Ungawuphehla kanjani umoya ovikelayo?

Okokuqala, kufanele kucace ukuthi lokho okubizwa ngokuthi "i-oxidation" ye-weld kuyigama elivamile nje, elibhekisela ngokwengqondo ekusabeleni kwamakhemikhali phakathi kwe-weld kanye nezingxenye eziyingozi emoyeni, okuholela ekuwohlokeni kwe-weld. Ngokuvamile, insimbi ye-weld isabela nomoya-mpilo, i-nitrogen, kanye ne-hydrogen emoyeni ekushiseni okuthile.

Ukuvimbela i-weld ukuthi "ingangcoliswa" kudinga ukunciphisa noma ukugwema ukuxhumana phakathi kwezingxenye ezinjalo eziyingozi nensimbi ye-weld ngaphansi kokushisa okuphezulu, okungekona nje kuphela ensimbini yechibi encibilikisiwe kodwa sonke isikhathi kusukela ngesikhathi insimbi ye-weld incibilikisiwe kuze kube yilapho insimbi yechibi encibilikisiwe iqina futhi izinga lokushisa layo liphola liye ezingeni lokushisa elithile.

Izindlela ezimbili eziyinhloko zokushaya igesi yokuvikela

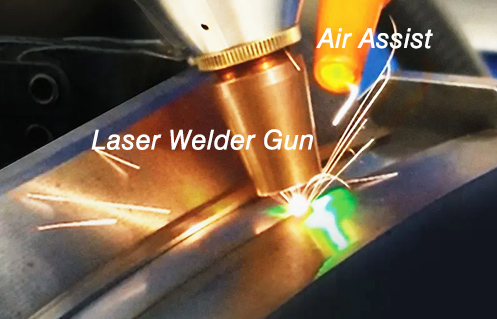

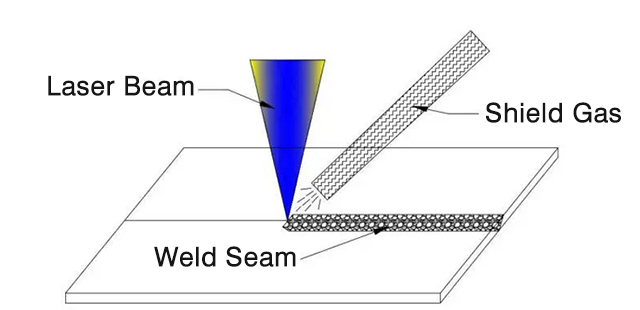

▶Omunye uvuthela igesi yokuvikela ohlangothini, njengoba kuboniswe kuMfanekiso 1.

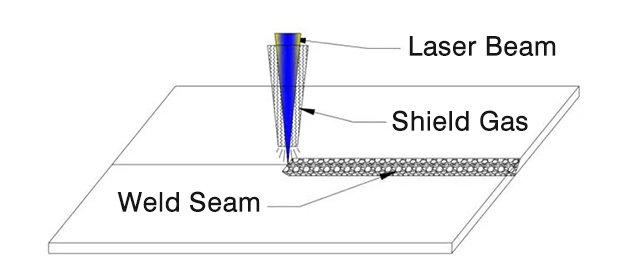

▶Enye indlela yokuvuthela nge-coaxial, njengoba kuboniswe kuMfanekiso 2.

Umfanekiso 1.

Umfanekiso 2.

Ukukhetha okuqondile kwezindlela ezimbili zokuvuthela kuyindaba ebanzi yezici eziningi. Ngokuvamile, kunconywa ukusebenzisa indlela yegesi evikelayo evuthela eceleni.

Ezinye izibonelo zokushisela nge-laser

1. Ukushisela okuqondile kobuhlalu/umugqa

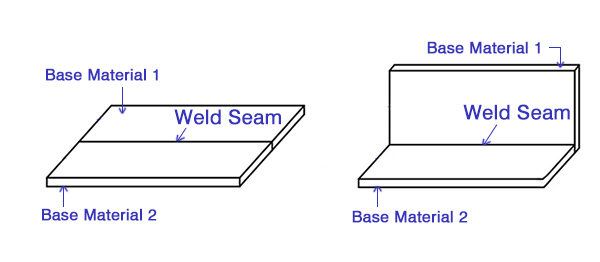

Njengoba kuboniswe kuMfanekiso 3, ukuma kwe-weld komkhiqizo kuqondile, futhi isimo se-joint singaba yi-butt joint, i-lap joint, i-negative corner joint, noma i-welding joint ehlanganisiwe. Kulolu hlobo lomkhiqizo, kungcono ukusebenzisa igesi evikelayo evunguzayo eseceleni njengoba kuboniswe kuMfanekiso 1.

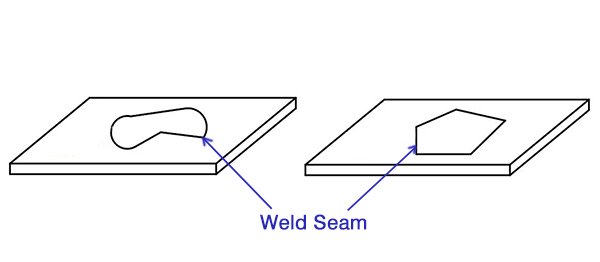

2. Ukushisela okuseduze noma indawo

Njengoba kuboniswe kuMfanekiso 4, ukuma kokushisela komkhiqizo kuyiphethini evaliwe njengendilinga, ukuma kwendilinga enezinhlangothi eziningi, ukuma kwendilinga enezingxenye eziningi, njll. Ifomu lokuhlangana lingaba yi-butt joint, i-lap joint, i-overlapping welding, njll. Kungcono ukusebenzisa indlela yegesi evikelayo ye-coaxial njengoba kuboniswe kuMfanekiso 2 kulolu hlobo lomkhiqizo.

Ukukhethwa kwegesi evikelayo kuthinta ngqo ikhwalithi yokushisela, ukusebenza kahle, kanye nezindleko zokukhiqiza, kodwa ngenxa yokwehlukahluka kwezinto zokushisela, enkambisweni yangempela yokushisela, ukukhethwa kwegesi yokushisela kuyinkimbinkimbi kakhulu futhi kudinga ukucatshangelwa okubanzi kwezinto zokushisela, indlela yokushisela, indawo yokushisela, kanye nezidingo zomphumela wokushisela. Ngokuhlolwa kokushisela, ungakhetha igesi yokushisela efaneleka kakhulu ukuze uthole imiphumela engcono.

Unentshisekelo ekushiseni nge-laser futhi uzimisele ukufunda ukuthi ungayikhetha kanjani igesi yokuvikela

Izixhumanisi Ezihlobene:

Isikhathi sokuthunyelwe: Okthoba-10-2022