Kuyini Ukushisela Nge-Laser?

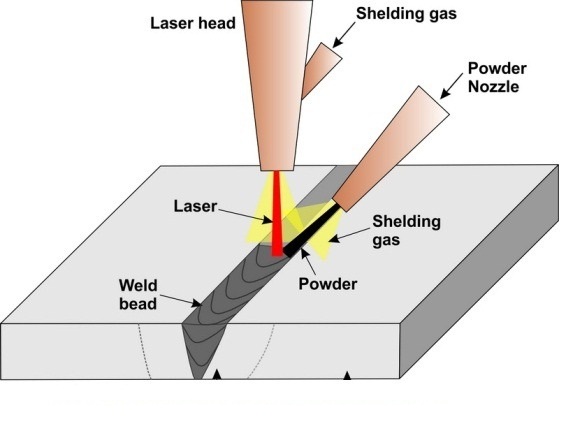

Ukusetshenziswa komshini wokuwelda we-laser welding metal workpiece, lo msebenzi umunca i-laser ngokushesha ngemva kokuncibilika nokufaka igesi, insimbi encibilikisiwe ngaphansi kwesenzo sokucindezela komusi ukuze kwakheke umgodi omncane ukuze umsebe we-laser uvezwe ngqo phansi komgodi ukuze umgodi uqhubeke nokwelulwa kuze kube yilapho umfutho womusi ngaphakathi komgodi kanye nokucindezeleka kobuso bensimbi ewuketshezi kanye namandla adonsela phansi kufinyelela ibhalansi.

Le ndlela yokushisela inobubanzi obukhulu bokungena kanye nesilinganiso esikhulu sokujula nobubanzi. Lapho imbobo ilandela umsebe we-laser eceleni kwendlela yokushisela, insimbi encibilikisiwe ephambi komshini wokushisela we-laser idlula imbobo bese igeleza iye ngemuva, bese i-weld yakhiwa ngemuva kokuqina.

Umhlahlandlela Wokusebenza mayelana Nokushisela Nge-Laser

▶ Ukulungiselela ngaphambi kokuqala umshini wokushisela nge-laser

1. Hlola ukunikezwa kwamandla nge-laser kanye nomthombo kagesi womshini wokushisela nge-laser

2. Hlola ukuthi i-chiller yamanzi yezimboni esebenza njalo isebenza kahle

3. Hlola ukuthi ipayipi legesi elisizayo elingaphakathi komshini wokushisela livamile yini

4. Hlola ubuso bomshini ngaphandle kothuli, amabala, uwoyela, njll.

▶ Ukuqala umshini wokushisela nge-laser

1. Vula ugesi bese uvula iswishi yamandla eyinhloko

2. Vula i-cooler yamanzi yezimboni engaguquki kanye ne-fiber laser generator

3. Vula i-argon valve bese ulungisa ukugeleza kwegesi kube sezingeni lokugeleza elifanele

4. Khetha amapharamitha agcinwe ohlelweni lokusebenza

5. Yenza ukushisela nge-laser

▶ Ukuvula umshini wokushisela nge-laser

1. Phuma ohlelweni lokusebenza bese ucima ijeneretha yelaser

2. Cima umshini wokupholisa amanzi, umshini wokukhipha intuthu, kanye neminye imishini yokusiza ngokulandelana

3. Vala umnyango wevalvu wesilinda se-argon

4. Cima iswishi yamandla eyinhloko

Ukunaka kwe-Laser Welder

Ukusebenza Kokushisela Nge-Laser Ephathwayo

1. Ngesikhathi sokusebenza komshini wokushisela nge-laser, njengesimo esiphuthumayo (ukuvuza kwamanzi, umsindo ongajwayelekile, njll.) kudingeka ucindezele ngokushesha isitobhi esiphuthumayo bese unqamula ngokushesha ugesi.

2. Iswishi yamanzi ejikelezayo yangaphandle yokushisela nge-laser kumele ivulwe ngaphambi kokusebenza.

3. Ngenxa yokuthi uhlelo lwe-laser lupholisiwe ngamanzi futhi ugesi we-laser upholisiwe ngomoya uma uhlelo lokupholisa luhluleka, akuvunyelwe ngokuphelele ukuqala umsebenzi.

4. Ungaqaqi noma yiziphi izingxenye emshinini, ungashiseli lapho umnyango wokuphepha komshini uvuliwe, futhi ungabheki ngqo ku-laser noma ubonise i-laser lapho i-laser isebenza ukuze ungalimazi amehlo.

5. Izinto ezivuthayo neziqhumayo akufanele zibekwe endleleni yelaser noma endaweni lapho umsebe welaser ungakhanyiswa khona, ukuze zingabangeli umlilo nokuqhuma.

6. Ngesikhathi sokusebenza, isekethe isesimweni se-voltage ephezulu kanye nogesi oqinile. Akuvunyelwe ukuthinta izingxenye zesekethe emshinini lapho usebenza.

Imibuzo Evame Ukubuzwa

Ukulungiswa okufanele kuqinisekisa ukushisela nge-laser okuphephile nokubushelelezi. Nakhu okufanele ukuhlole:

Amandla Nokupholisa:Hlola ukunikezwa kwamandla nge-laser, ukuxhumeka kukagesi, kanye ne-water filler (i-coolant kumele igeleze).

Igesi Nokugeleza Komoya:Hlola amashubhu egesi ye-argon ukuze ubone ukuthi avimbekile; setha ukugeleza kufike emazingeni anconyiwe.

Ukuhlanzeka Komshini:Sula uthuli/uwoyela emshinini—imfucumfucu ingase ibangele ukukhubazeka noma ukushisa ngokweqile.

Cha—izinhlelo zokupholisa zibalulekile ekuphepheni nasekusebenzeni kahle kwe-laser welder.

Ingozi Yokushisa Okudlulele:Ama-laser akhiqiza ukushisa okukhulu; izinhlelo zokupholisa (amanzi/igesi) zivimbela ukusha.

Ukuthembela Kwesistimu:Izinsiza zikagesi ze-laser zithembele ekupholiseni—ukwehluleka kubangela ukuvala noma umonakalo.

Ukuphepha Kuqala:Ngisho “nokushisela okusheshayo” kudinga ukupholisa—ukungakunaki kuqeda iziqinisekiso futhi kubeka engcupheni izingozi.

Izivikelo zegesi ze-Argon zithungatha ukungcola, okuqinisekisa ikhwalithi.

Umphumela Wokuvikela:I-Argon isusa umoya-mpilo, ivimbele ukushintshwa kwe-welds ekugqwaleni noma ekukhuleni kwemiphetho enezimbobo.

Ukuzinza kwe-Arc:Ukugeleza kwegesi kuzinzisa umsebe we-laser, kunciphisa ukuchitheka kanye nokuncibilika okungalingani.

Ukuhambisana kwezinto ezibonakalayo:Kubalulekile ezinsimbini (isb., insimbi engagqwali, i-aluminium) ezivame ukushiswa yi-oxidation.

Funda kabanzi mayelana nesakhiwo kanye nesimiso somshini wokushisela we-laser ophathwa ngesandla

Isikhathi sokuthunyelwe: Agasti-11-2022