What is Laser Welding?

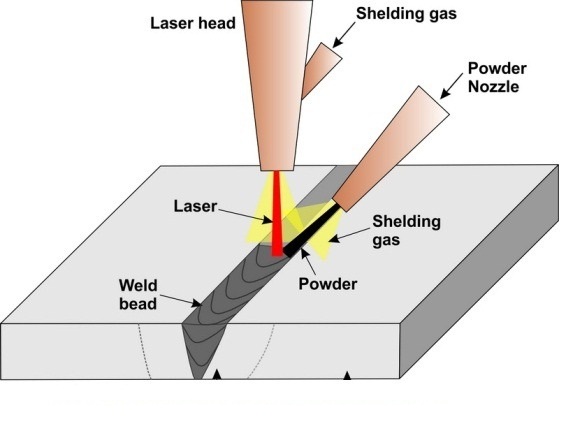

The use of a laser welding machine welding metal workpiece, the workpiece absorbs the laser quickly after melting and gasification, molten metal under the action of steam pressure to form a small hole so that the laser beam can be exposed directly at the bottom of the hole so that the hole continues to extend until the steam pressure inside the hole and liquid metal surface tension and gravity reach balance.

This welding mode has a large penetration depth and a large depth-width ratio. When the hole follows the laser beam along the welding direction, the molten metal in front of the laser welding machine bypasses the hole and flows to the rear, and the weld is formed after solidification.

Operation Guide about Laser Welding

▶ Preparation before starting up the laser welder

1. Check the laser power supply and electrical source of the laser welding machine

2. Check the constant industrial water chiller works normally

3. Check whether the auxiliary gas tube inside the welding machine is normal

4. Check the machine surface without dust, speckle, oil, etc

▶ Starting the laser welder machine

1. Switch on the power supply and turn on the main power switch

2. Turn on the constant industrial water cooler and fiber laser generator

3. Open the argon valve and adjust the gas flow to the appropriate flow level

4. Choose the parameters saved in the operating system

5. Perform laser welding

▶ Powering off the laser welder machine

1. Exit the operation program and turn off the laser generator

2. Turn off the water chiller, fume extractor, and other auxiliary equipment in sequence

3. Close the valve door of the argon cylinder

4. Turn off the main power switch

Attentions for the Laser Welder

Handheld Laser Welding Operation

1. During the operation of a laser welding machine, such as an emergency (water leakage, abnormal sound, etc.) need to immediately press the emergency stop and quickly cut off the power supply.

2. The external circulating water switch of laser welding must be opened before operation.

3. Because the laser system is water-cooled and the laser power supply is air-cooled if the cooling system fails, it is strictly prohibited to start the work.

4. Do not disassemble any parts in the machine, do not weld when the machine safety door is opened, and do not look directly at the laser or reflect the laser when the laser is working so as not to harm the eyes.

5. Inflammable and explosive materials shall not be placed on the laser path or the place where the laser beam can be illuminated, so as not to cause fire and explosion.

6. During the operation, the circuit is in a state of high voltage and strong current. It is forbidden to touch the circuit components in the machine when working.

FAQs

Proper prep ensures safe, smooth laser welding. Here’s what to check:

Power & Cooling: Check laser power supply, electrical connections, and water chiller (coolant must flow).

Gas & Airflow: Inspect argon gas tubes for blockages; set flow to recommended levels.

Machine Cleanliness: Wipe dust/oil from the machine—debris risks defects or overheating.

No—cooling systems are critical for laser welder safety and performance.

Overheating Risk: Lasers generate extreme heat; cooling systems (water/gas) prevent burnout.

System Dependencies: Laser power supplies rely on cooling—failures trigger shutdowns or damage.

Safety First: Even “quick welds” need cooling—ignoring it voids warranties and risks accidents.

Argon gas shields welds from contamination, ensuring quality.

Shielding Effect: Argon displaces oxygen, stopping welds from rusting or developing porous edges.

Arc Stability: Gas flow stabilizes the laser beam, reducing spatter and uneven melts.

Material Compatibility: Essential for metals (e.g., stainless steel, aluminum) prone to oxidation.

Learn more about the structure and principle of handheld laser welder

Post time: Aug-11-2022