I-foam, into elula futhi enezimbobo ngokuvamile eyenziwe ngepulasitiki noma irabha, iyaziswa ngezakhiwo zayo ezinhle kakhulu zokumunca ukushaqeka nokuvikela uthuli. Isetshenziswa kabanzi ezinhlotsheni ezahlukene zokusebenza, okuhlanganisa ukupakisha, ukuthungela, ukuvikela uthuli, kanye nobuciko bokudala kanye nemisebenzi yezandla.

Kusukela ezintweni ezenziwe ngokwezifiso zokuthumela nokukhiqiza ifenisha kuya ekufakweni kodonga kanye nokupakishwa kwezimboni, i-foam iyingxenye ebalulekile yokukhiqiza kwesimanje. Njengoba isidingo sezingxenye ze-foam siqhubeka sikhula, amasu okukhiqiza kumele azivumelanise ukuze ahlangabezane nalezi zidingo ngempumelelo. Ukusika i-foam nge-laser kuvele njengesixazululo esisebenza kahle kakhulu, okwenza amabhizinisi akwazi ukufeza ikhwalithi yomkhiqizo ephezulu ngenkathi ekhulisa kakhulu amandla okukhiqiza.

Kulo mhlahlandlela, sizohlola inqubo ye-laser cutting foam, ukuhambisana kwayo nezinto ezibonakalayo, kanye nezinzuzo ezinikezayo kunezindlela zokusika zendabuko.

kusukela

Ilebhu ye-Laser Cut Foam

UKUBUKELA OKUQUKETHWE

Izinto Ezihlobene

Ukubuka Konke Kokusika I-Laser Foam

▶ Kuyini ukusika nge-laser?

Ukusika nge-laser kuyinqubo yokukhiqiza esezingeni eliphezulu esebenzisa ubuchwepheshe be-CNC (okulawulwa ngezinombolo yikhompyutha) ukuqondisa umsebe we-laser ngokunemba.

Le ndlela ifaka ukushisa okukhulu endaweni encane, egxilile, incibilikisa ngokushesha izinto ngendlela ethile.

Ukuze usike izinto ezijiyile noma eziqinile, ukunciphisa isivinini sokunyakaza kwe-laser kuvumela ukushisa okwengeziwe ukuthi kudluliselwe endaweni yokusebenza.

Ngaphandle kwalokho, umthombo we-laser onamandla aphezulu, okwazi ukukhiqiza amandla engeziwe ngomzuzwana, ungasetshenziswa ukufeza umphumela ofanayo.

▶ Isebenza Kanjani Igwebu Lokusika Nge-Laser?

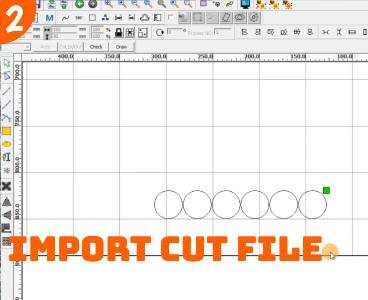

Ukusika ifoam ye-laser kuncike emisebeni ye-laser egxilile ukuze kushiswe ifoam ngokunembile, kususwe izinto ezindleleni ezinqunyiwe. Inqubo iqala ngokulungiselela ifayela lokusika le-laser kusetshenziswa isofthiwe yokuklama. Izilungiselelo zokusika ifoam ye-laser zibe sezilungiswa ngokuya ngobukhulu kanye nobukhulu befoam.

Okulandelayo, ishidi le-foam libekwa ngokuphephile embhedeni we-laser ukuvimbela ukunyakaza. Ikhanda le-laser lomshini ligxile ebusweni be-foam, futhi inqubo yokusika ilandela umklamo ngokunemba okumangalisayo. I-foam yokusika nge-laser inikeza ukunemba okungenakuqhathaniswa, okwenza kube ukukhetha okuhle kakhulu kokudala izimo nemiklamo eyinkimbinkimbi.

▶ Izinzuzo ezivela ku-Laser Cutting Foam

Igwebu nezinto ezifanayo ziyinselele ezindleleni zokusika zendabuko. Ukusika ngesandla kudinga abasebenzi abanekhono futhi kuthatha isikhathi, kuyilapho ukusetha ngokushaya nokubulala kungabiza kakhulu futhi kungaguquguquki. Izicucu zegwebu ze-laser zinikeza izinzuzo ezahlukahlukene, okwenza zibe inketho engcono kakhulu yokucubungula igwebu.

✔ Ukukhiqizwa Okusheshayo

Ifoam yokusika nge-laser ikhulisa kakhulu ukusebenza kahle kokukhiqiza. Nakuba izinto eziqinile zidinga isivinini sokusika esihamba kancane, izinto ezithambile njengefoam, ipulasitiki, kanye ne-plywood zingacutshungulwa ngokushesha okukhulu. Isibonelo, ukufakwa kwefoam okungathatha amahora amaningi ukusika ngesandla manje kungakhiqizwa ngemizuzwana nje kusetshenziswa i-laser foam cutter.

✔ Ukunciphisa Ukungcola Kwezinto Ezibalulekile

Izindlela zokusika zendabuko zingadala imfucuza ebalulekile yezinto ezibonakalayo, ikakhulukazi kumadizayini ayinkimbinkimbi. Ukusika i-laser foam kunciphisa imfucuza ngokunika amandla ukwakheka kwedijithali ngesofthiwe ye-CAD (umklamo osizwa yikhompyutha). Lokhu kuqinisekisa ukusika okunembile emzamweni wokuqala, konga kokubili izinto kanye nesikhathi.

✔ Imiphetho Ehlanzekile

Igwebu elithambile livame ukugoba futhi liphendukezeleke ngaphansi kwengcindezi, okwenza ukusika okuhlanzekile kube nzima ngamathuluzi endabuko. Ukusika nge-laser, nokho, kusebenzisa ukushisa ukuncibilikisa igwebu ngendlela yokusika, okuholela emaphethelweni abushelelezi futhi anembile. Ngokungafani nemimese noma ama-blade, i-laser ayithinti ngokoqobo izinto ezibonakalayo, isusa izinkinga ezifana nokusika okugobile noma amaphethelo angalingani.

✔ Ukuguquguquka Nokuguquguquka

Abasiki be-laser basebenza kahle kakhulu ekusetshenzisweni okuhlukahlukene, okuvumela ukusetshenziswa okuhlukahlukene kokusika i-laser foam. Kusukela ekudaleni izinto zokufaka ezimbonini kuya ekuklameni izinto eziyinkimbinkimbi nezingubo zokugqoka zemboni yamafilimu, amathuba maningi kakhulu. Ngaphezu kwalokho, imishini ye-laser ayigcini nje nge-foam; ingaphatha izinto ezifana nensimbi, ipulasitiki kanye nendwangu ngempumelelo efanayo.

Umphetho Oqinile Nohlanzekile

Ukusika Okunezimo Eziningi Okuguquguqukayo

Ukusika Okuqondile

Indlela Yokusika I-Laser Foam?

▶ Inqubo Ye-Laser Cutting Foam

I-laser cutting foam iyinqubo engenamthungo futhi ezenzakalelayo. Usebenzisa uhlelo lwe-CNC, ifayela lakho lokusika elingenisiwe liqondisa ikhanda le-laser endleleni yokusika ekhethiwe ngokunemba. Mane ubeke i-foam yakho etafuleni lokusebenzela, ungenise ifayela lokusika, bese uvumela i-laser ukuthi ilithathe lapho.

Ukulungiselela igwebu:gcina igwebu liphansi futhi liqinile etafuleni.

Umshini We-Laser:khetha amandla e-laser kanye nosayizi womshini ngokuya ngobukhulu be-foam kanye nosayizi.

▶

Ifayela Lokuklama:ngenisa ifayela lokusika kusofthiwe.

Ukusetha kwe-Laser:hlola ukusika igwebu ngeukusetha isivinini namandla ahlukene

▶

Qala Ukusika Nge-Laser:I-laser cutting foam iyazisebenzela futhi inembe kakhulu, idala imikhiqizo ye-foam esezingeni eliphezulu engaguquki.

Isiguqo Sesihlalo Esisikiwe Esine-Foam Laser Cutter

▶ Amanye Amathiphu Uma Usebenzisa I-Laser Cutting Foam

Ukulungiswa Kwezinto:Sebenzisa itheyiphu, i-magnet, noma i-vacuum table ukuze ugcine igwebu lakho liphansi etafuleni lokusebenza.

Umoya opholile:Umoya ofanele ungena uphuma ...

Ukugxila: Qinisekisa ukuthi umsebe we-laser ugxile kahle.

Ukuhlola kanye Nokwenza Izibonelo:Njalo yenza ukusika kokuhlola ezintweni ezifanayo ze-foam ukuze ulungise izilungiselelo zakho ngaphambi kokuqala iphrojekthi yangempela.

Unemibuzo ngalokho?

Xhumana Nochwepheshe Wethu We-Laser!

Izinkinga Ezivamile Lapho I-Laser Cut Foam Isetshenziswa Nge-Laser

Ukusika ifoam nge-laser kuyindlela ephumelelayo nephumelelayo yokucubungula izinto zefoam. Kodwa-ke, ngenxa yemvelo ethambile nenezimbobo zefoam, kungavela izinselele ngesikhathi senqubo yokusika.Ngezansi kunezinkinga ezivamile ezitholakala lapho usebenzisa i-laser foam cutter kanye nezixazululo zazo ezihambisanayo.

1. Ukuncibilikisa Nokushisa Izinto

Imbangela: Amandla e-laser amaningi noma isivinini sokusika esihamba kancane kuholela ekufakweni kwamandla ngokweqile, okubangela ukuthi igwebu lincibilike noma lishise.

Isixazululo:

1. Yehlisa amandla okukhipha i-laser.

2. Khulisa isivinini sokusika ukuze unciphise ukuvezwa ukushisa isikhathi eside.

3. Hlola ukulungiswa kwe-foam eqoshiwe ngaphambi kokuqhubeka nengxenye yokugcina.

2. Ukuvutha kwezinto

ImbangelaIzinto ze-foam ezivuthayo, njenge-polystyrene ne-polyethylene, zingavutha ngaphansi kwamandla aphezulu e-laser.

Isixazululo:

Ukwenziwa Kwe-Carbon Kwe-Foam Ngenxa Yamandla Aphezulu

1. Nciphisa amandla e-laser futhi wandise isivinini sokusika ukuze uvimbele ukushisa ngokweqile.

2. Khetha amagwebu angashi njenge-EVA noma i-polyurethane, okuyizindlela eziphephile zokusebenzisa igwebu lokusika nge-laser.

I-Dirty Optics Eholela Ekhwalithini Embi Yomphetho

3. Intuthu Namaphunga

ImbangelaIzinto ezenziwe nge-foam, ngokuvamile ezisekelwe epulasitikini, zikhipha umusi oyingozi nongathandeki uma uncibilikisiwe.

Isixazululo:

1. Sebenzisa umshini wakho wokusika nge-laser endaweni enomoya omuhle.

2. Faka i-fume hood noma uhlelo lokukhipha umoya ukuze ususe ukukhishwa okuyingozi.

3. Cabanga ukusebenzisa uhlelo lokuhlunga umoya ukuze unciphise kakhulu ukuchayeka entuthwini.

4. Ikhwalithi Embi Yomphetho

Imbangela: Ama-optics angcolile noma umsebe we-laser ongagxilile ungalimaza ikhwalithi yokusika kwe-foam, okuholela emaphethelweni angalingani noma acijile.

Isixazululo:

1. Hlanza njalo i-laser optics, ikakhulukazi ngemva kwezikhathi zokusika ezinde.

2. Qinisekisa ukuthi umsebe we-laser ugxile kahle ezintweni ze-foam.

5. Ukujula Kokusika Okungaguquguquki

Imbangela: Ubuso be-foam obungalingani noma ukungalingani ekubunjweni kwe-foam kungaphazamisa ukujula kokungena kwe-laser.

Isixazululo:

1. Qinisekisa ukuthi ishidi le-foam lilele kahle ebhentshini lokusebenza ngaphambi kokusika.

2. Sebenzisa igwebu elisezingeni eliphezulu elinobukhulu obufanayo ukuze uthole imiphumela engcono.

6. Ukubekezelela Okubi Kokusika

Imbangela: Izindawo ezikhanyayo noma okunamathelayo okusele ku-foam kungaphazamisa ukugxila kanye nokunemba kwe-laser.

Isixazululo:

1. Sika amashidi e-foam akhanyayo ngaphansi okungakhanyi.

2. Faka i-masking tape endaweni yokusika ukuze unciphise ukubonakaliswa futhi ubheke ukujiya kwe-tape.

Izinhlobo Nokusetshenziswa Kwe-Laser Cutting Foam

▶ Izinhlobo Zegwebu Ezingasikwa Nge-Laser

Ifoam yokusika nge-laser isekela izinto ezahlukahlukene, kusukela kokuthambile kuya kokuqinile. Uhlobo ngalunye lwefoam lunezakhiwo ezihlukile ezifanela izinhlelo zokusebenza ezithile, okwenza kube lula inqubo yokwenza izinqumo zamaphrojekthi okusika nge-laser. Nazi izinhlobo zefoam ezithandwa kakhulu zokusika nge-laser foam:

1. Igwebu le-Ethylene-Vinyl Acetate (EVA)

I-foam ye-EVA iyinto ebanzi kakhulu, enwebeka kakhulu. Ilungele ukwakheka kwangaphakathi kanye nokufakwa kokuvikela udonga. I-foam ye-EVA igcina isimo sayo kahle futhi kulula ukuyinamathelisa, okwenza kube ukukhetha okuhle kakhulu kumaphrojekthi okuklama okudala nokuhlobisa. Izicucu ze-foam ze-laser ziphatha i-foam ye-EVA ngokunemba, ziqinisekisa imiphetho ehlanzekile namaphethini ayinkimbinkimbi.

2. Igwebu le-Polyethylene(PE)

I-PE foam iyinto ephansi enokuqina okuhle, okwenza ifaneleke kakhulu ekupakisheni nasekumunceni ukushaqeka. Ukukhanya kwayo okulula kuyasiza ekunciphiseni izindleko zokuthumela. Ngaphezu kwalokho, i-PE foam ivame ukunqunywa nge-laser ukuze kusetshenziswe izinhlelo zokusebenza ezidinga ukunemba okuphezulu, njengama-gaskets kanye nezingxenye zokuvala.

3. Igwebu le-Polypropylene(PP)

I-polypropylene foam, eyaziwa ngezakhiwo zayo ezilula nezimelana nomswakama, isetshenziswa kabanzi embonini yezimoto ukunciphisa umsindo nokulawula ukudlidliza. Ukusika i-laser foam kuqinisekisa imiphumela efanayo, ebalulekile ekukhiqizweni kwezingxenye zezimoto ezenziwe ngokwezifiso.

4. Igwebu le-Polyurethane(PU)

I-polyurethane foam iyatholakala ngezinhlobo eziguquguqukayo neziqinile futhi inikeza ukuguquguquka okukhulu. I-soft PU foam isetshenziselwa izihlalo zemoto, kuyilapho i-rigid PU isetshenziswa njengokuvikela ezindongeni zesiqandisi. I-custom PU foam insulation ivame ukutholakala ezindaweni ezivalekile zikagesi ukuze kuvalwe izingxenye ezibucayi, kuvinjelwe umonakalo wokushaqeka, futhi kuvinjelwe ukungena kwamanzi.

>> Buka amavidiyo: I-Laser Cutting PU Foam

Sisebenzise

Izinto: I-Memory Foam (i-PU foam)

Ubukhulu bezinto: 10mm, 20mm

Umshini We-Laser:Umsiki we-Laser we-Foam 130

Ungenza

Isicelo Esibanzi: I-Foam Core, i-Padding, i-Car Seat Cushion, i-Insulation, i-Acoustic Panel, i-Interior Decor, ama-Crats, i-Toolbox kanye ne-Insert, njll.

▶ Ukusetshenziswa kwe-Laser Cut Foam

Yini ongayenza nge-laser foam?

Izicelo Ze-Laser Foam

Uma unemibuzo mayelana nendlela i-lase cutting foam esebenza ngayo, Xhumana Nathi!

Imibuzo Evame Ukubuzwa ye-Laser Cutting Foam

▶ Iyiphi i-laser engcono kakhulu yokusika igwebu?

▶ I-Laser Cut Foam ingakanani ubukhulu?

▶ Ungakwazi yini ukusika i-EVA Foam nge-laser?

▶ Ingabe Igwebu Eline-Adhesive Backup Lingasikwa Nge-Laser?

▶ Ingabe i-Laser Cutter Engrave Foam ingakwazi ukuqopha?

▶ Hlobo Luni Lwegwebu Olungcono Kakhulu Lokusika Nge-Laser?

写文章时,先搜索关键词读一下其他网站上传的文章。其次在考虑中文搜索引擎)读完10-15篇文章后可能大概就有思路了,可以先列一个大纲 (明确各级标题)出來。然后根据大纲写好文章(ai生成或复制别人的内容再用a i转写.xxxx

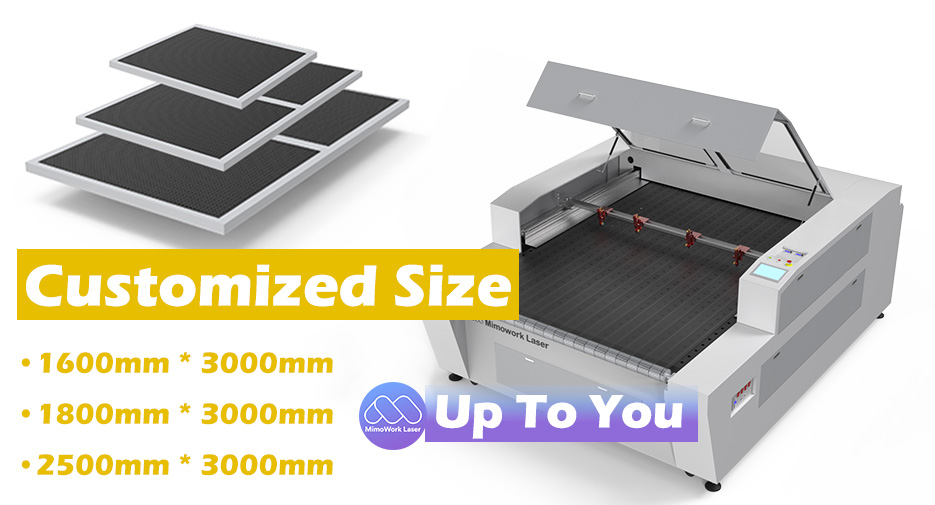

Isisiki Se-Laser Foam Esinconyiwe

Usayizi Wethebula Lokusebenza:1300mm * 900mm (51.2” * 35.4”)

Izinketho Zamandla E-Laser:100W/150W/300W

Ukubuka konke kwe-Flatbed Laser Cutter 130

Ngemikhiqizo ejwayelekile ye-foam efana namabhokisi amathuluzi, imihlobiso, kanye nemisebenzi yezandla, i-Flatbed Laser Cutter 130 iyindlela ethandwa kakhulu yokusika nokuqopha i-foam. Usayizi namandla kuyahlangabezana nezidingo eziningi, futhi intengo iyathengeka. Dlula ekwakhiweni, uhlelo lwekhamera oluthuthukisiwe, itafula lokusebenza lokuzikhethela, kanye nokucushwa okwengeziwe komshini ongakhetha kukho.

Usayizi Wethebula Lokusebenza:1600mm * 1000mm (62.9” * 39.3”)

Izinketho Zamandla E-Laser:100W/150W/300W

Ukubuka konke kwe-Flatbed Laser Cutter 160

I-Flatbed Laser Cutter 160 ingumshini onefomethi enkulu. Nge-auto feeder kanye netafula lokuhambisa, ungafeza izinto zokugoqa ezisebenza ngokuzenzakalela. Indawo yokusebenza engu-1600mm *1000mm ifanelekela iningi le-yoga mat, i-marine mat, i-seat cushion, i-industrial gasket nokuningi. Amakhanda amaningi e-laser angakhethwa ukuthuthukisa umkhiqizo.

Thumela Izidingo Zakho Kithi, Sizokunikeza Isixazululo Se-Laser Esingochwepheshe

Qala Umeluleki We-Laser Manje!

> Yiluphi ulwazi okudingeka ulunikeze?

> Ulwazi lwethu lokuxhumana

Gxila Kakhulu ▷

Ungase ube nentshisekelo ku-

Noma yikuphi Ukudideka Noma Imibuzo Yomsiki We-Laser We-Foam, Vele Usibuze Noma Kunini

Noma yikuphi Ukudideka Noma Imibuzo Yomsiki We-Laser We-Foam, Vele Usibuze Noma Kunini

Isikhathi sokuthunyelwe: Jan-14-2025