Hordhac

Laser-ka diode-ka ah wuxuu shaqeeyaa isagoo soo saarayalaambad cidhiidhi ahiftiinka iyada oo loo marayo semiconductor.

Tiknoolajiyaddani waxay bixisaaIsha tamarta ee xooggantaas oo diiradda lagu saari karo walxaha sida acrylic.

Si ka duwan kuwa caadiga ahlaysarka CO2, laser-ka diode-ka badanaa waa kuwo aad u badanyar oo kharash-ool ah, taas oo ka dhigaysa gaar ahaansoo jiidasho lehaqoon-is-weydaarsiyo yaryar iyo isticmaalka guriga.

Faa'iidooyinka

Goynta saxda ah: Laydhka xooggan wuxuu suurtogal ka dhigayaa qaabab jilicsan iyo geeso nadiif ah, oo muhiim u ah hawlaha faahfaahsan ee fiican.

Qashinka walxaha hoose: Habka jarista wax ku oolka ah wuxuu keenaa in walxaha harsan ay yaraadaan.

Isticmaale - saaxiibtinimo: Nidaamyo badan oo laysarka diode ah ayaa ku qalabaysan software fudud oo fududeeya habka naqshadeynta iyo jarista.

Waxtarka kharashka hawlgalka: Laysarrada diode-ka waxay isticmaalaan koronto yar waxayna leeyihiin baahiyo dayactir oo hooseeya marka loo eego noocyada kale ee laysarka.

Geedi-socodka Tallaabo-tallaabo

1. Diyaarinta Naqshadeynta: Isticmaal software-ka ku habboon laysarka (tusaale ahaan, Adobe Illustrator, AutoCAD) si aad u abuurto ama u soo dejiso naqshad ku salaysan vector (SVG, DXF). Hagaaji xuduudaha jarista (xawaaraha, awoodda, baasaska, dhererka diiradda) iyadoo lagu saleynayo nooca acrylic, dhumucda, iyo awoodaha laysarka.

2. Diyaarinta Acrylic: Dooro xaashiyo akrilik ah oo siman oo aan duubnayn. Ku nadiifi saabuun khafiif ah, si fiican u qalaji, oo mari cajalad ama warqad si aad u ilaaliso dusha sare.

3. Dejinta laysarka: Ku kululee laysarka, hubi in si sax ah loo waafajiyo iftiinka, oo nadiifi muraayadaha indhaha. Samee jarista tijaabada ah ee walxaha qashinka ah si aad u hagaajiso dejimaha.

Badeecada Acrylic

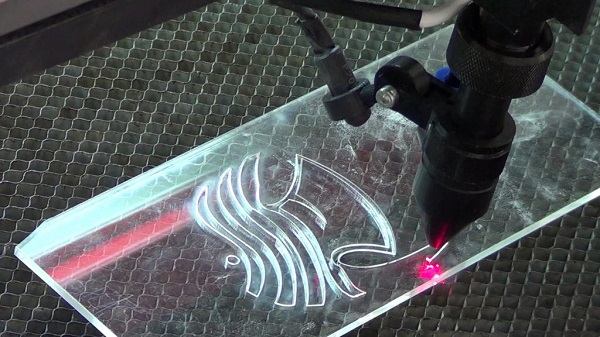

Habka looxa goynta laser

4. Meelaynta Acrylic: Ku dheji xaashida akrilik-ka sariirta laysarka leh cajalad maaskaro ah, taasoo hubinaysa meel bannaan oo loogu talagalay dhaqdhaqaaqa madaxa goynta.

5. Habka Jarida: Ku bilow jarista laysarka iyada oo loo marayo kontaroolada software-ka, si dhow ula soco hawsha, oo hagaaji dejimaha sida loogu baahdo. Jooji haddii ay jiraan dhibaatooyin oo wax ka qabso ka hor intaadan sii wadin.

6. Kadib-HagaajintaKa dib marka la jaro, ku nadiifi acrylic-ga burush jilicsan ama hawo la cadaadiyey. Ka saar walxaha maaskarada oo mari daawaynta dhammaystirka (isku-darka dhalaalinta, dhalaalinta ololka) haddii loo baahdo.

Fiidiyowyada La Xiriira

Sida loo jaro looxa daabacan

Mashiinka jarista laser-ka araggaKamarada CCDnidaamka aqoonsiga wuxuu bixiyaakharash-ool ahbeddel u ah daabacaha UV si loo jaro farshaxanka acrylic ee daabacan.

Habkanwaxay fududeysaa hawsha, baabi'inta baahidahagaajinta laysarka gacanta lagu sameeyo.

Waa ku habboon tahay labadabahirgelinta mashruuca degdega ahiyo wax soo saarka warshadaha ee heer-warshadeedagab kala duwan.

Ma rabtaa inaad wax badan ka ogaatoJarida laysarka?

Bilow Wadahadal Hadda!

Talooyin

Talooyinka Diyaarinta

Dooro akrilik-ka ku habboonAkrilikyada cad iyo buluugga ah waxay caqabado ku noqon karaan laysarka diode-ka maadaama aysan si wax ku ool ah u nuugin iftiinka. Si kastaba ha ahaatee, akrilikyada madow waxay u muuqdaan inay si fudud u gooyaan.

Hagaaji Diiradda: Si sax ah u diiradda saarista iftiinka laysarka dusha sare ee walaxda waa muhiim. Hubi in dhererka diiradda la hagaajiyay si waafaqsan dhumucda acrylic-ga.

Dooro Dejinta Awoodda iyo Xawaaraha ee Ku HabboonMarka la jarayo acrylic, laysarka diode guud ahaan si fiican ayay u shaqeeyaan iyagoo leh heerar awood hooseeya iyo xawaare hooseeya.

Talooyinka Hawlgalka

Jaritaanka tijaabadaKahor intaadan samayn badeecada kama dambaysta ah, had iyo jeer tijaabi jarista qashinka si aad u hesho meesha ugu habboon.

Isticmaalka qalabka kaabayaasha ah: Isticmaalka koolada dabka waxay yarayn kartaa ololka iyo qiiqa, taasoo keenta geeso nadiif ah.

Nadiifi muraayadda laysarka: Hubi in muraayadda laysarka ay ka xor tahay qashinka, maadaama caqabad kasta ay saameyn xun ku yeelan karto tayada jarista.

Talooyinka Badbaadada

Indhaha Ilaalinta: Had iyo jeer xidho muraayadaha badbaadada laysarka ee ku habboon si aad indhahaaga uga ilaaliso iftiinka soo ifbaxaya.

Badbaadada Dabka: Ku hay dab-damiye meel kuu dhow, maadaama qalabka acrylic-ga ee la jaray uu soo saari karo qiiq dab-damis ah.

Badbaadada Korontada: Hubi in laysarka diode-kaaga si habboon loo dhigay si looga fogaado khataraha korontada.

Jar Xaashida Cad ee Acrylic-ka ah

Su'aalaha Badiya La Weydiiyo

Inta badan akrilik-ka waxaa laga jari karaa laysarka. Si kastaba ha ahaatee, arrimo sidamidabka iyo noocawaxay saameyn kartaa habka.

Tusaale ahaan, laysarka diode-ka ee iftiinka buluugga ah ma awoodaan inay jaraan acrylic buluug ama hufan.

Waxaa muhiim ah intijaabi waxyaabaha gaarka ahacrylic-ga aad qorsheyneyso inaad isticmaasho.

Tani waxay hubineysaa inay la jaanqaadi karto qalabkaaga laser-ka oo ay gaari karto natiijooyinka la rabo.

Si laysarka loo xardho ama loo jaro walxaha, walaxdu waa inay nuugtaa tamarta iftiinka laysarka.

Tamartan ayaa uumi nuugtaagab, taasoo suurtogalinaysa in la jaro.

Si kastaba ha ahaatee, laser-ka diode-ka wuxuu iftiimiyaa iftiinka mowjadda hirarka oo dhan.450nm, kaas oo acrylic cad iyo walxo kale oo hufan aan nuugi karin.

Sidaas darteed, iftiinka laysarka wuxuu dhex maraa acrylic cad isagoon saameyn ku yeelan.

Dhanka kale, walxaha mugdiga ah waxay nuugaan iftiinka laysarka ee ka yimaada goynta laysarka diode-kasi aad uga fudud.

Tani waa sababta laser-ka diode-ka uu u jari karo walxo acrylic ah oo mugdi ah oo aan caddayn.

Inta badan laser-yada diode-ka waxay xamili karaan xaashida acrylic-ga oo dhumucdiisu tahay ilaa6 mm.

Go'yaal dhumuc weyn leh,baasas badan ama laysar awood badan lehlaga yaabaa in loo baahdo.

Mashiinnada lagu taliyay

Goobta Shaqada (W *L)Cabbirka: 600mm * 400mm (23.6” * 15.7”)

Awoodda Laydhka: 60W

Goobta Shaqada (W *L)Cabbirka: 1300mm * 900mm (51.2” * 35.4”)

Awoodda Laydhka: 100W/150W/300W

Waqtiga boostada: Abriil-30-2025