Intshayelelo

Iilaser zediode zisebenza ngokuvelisaumqadi omxinwayokukhanya ngesixhobo sokulinganisa ukukhanya.

Le teknoloji inikaumthombo wamandla aqinileyoezinokuthi zigxile ekusikeni izinto ezifana ne-acrylic.

Ngokungafaniyo nesiqheloIileyiza ze-CO2, ii-diode lasers zihlala zininziincinci kwaye iyasebenza ngexabiso eliphantsi, nto leyo ebenza bakhetheke ngakumbinomtsalanekwiindawo zokusebenzela ezincinci nokusetyenziswa ekhaya.

Iingenelo

Ukusika ngokuchanekileyo: Umqadi oqinileyo wenza iipatheni ezithambileyo kunye nemiphetho ecocekileyo, nto leyo ebalulekileyo kwimisebenzi eneenkcukacha ezincinci.

Inkunkuma yezinto ezisezantsi: Inkqubo yokusika esebenzayo ibangela ukuba izinto eziseleyo zingabi nanto ingako.

Ubuhlobo bomsebenzisiIinkqubo ezininzi ze-diode laser zixhotyiswe ngesoftware elula ukuyisebenzisa eyenza kube lula ukuyila kunye neenkqubo zokusika.

Ukusebenza kakuhle kweendleko: Iilaser zeDiode zisebenzisa umbane omncinci kwaye azidingi kulungiswa kakhulu xa kuthelekiswa nezinye iintlobo zeelaser.

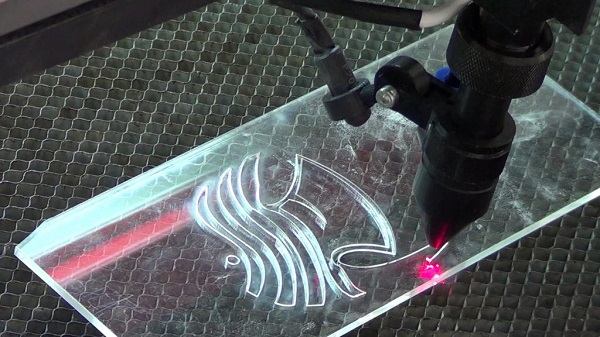

Inkqubo yeNyathelo ngeNyathelo

1. Ukulungiselela Uyilo: Sebenzisa isoftware ehambelana nelaser (umz., iAdobe Illustrator, iAutoCAD) ukwenza okanye ukungenisa uyilo olusekelwe kwivektha (SVG, DXF). Lungisa iiparameter zokusika (isantya, amandla, iipasi, ubude befocal) ngokusekelwe kuhlobo lwe-acrylic, ubukhulu, kunye nobuchule belaser.

2. Ukulungiswa kwe-Acrylic: Khetha amaphepha e-acrylic acwebezelayo, angasongwanga. Coca ngesepha ethambileyo, womise kakuhle, uze ufake iteyiphu yokufihla okanye iphepha ukukhusela iindawo eziphezulu.

3. Ukuseta iLaser: Fudumeza i-laser, qinisekisa ukuba imisebe ilungelelaniswe kakuhle, kwaye ucoce i-optics. Yenza uvavanyo lokusika izinto ezilahliweyo ukuze ulinganise useto.

Imveliso ye-Acrylic

Inkqubo ye-Acrylic yokusika i-Laser

4. Ukubekwa kwe-Acrylic: Nxibelela ishiti le-acrylic kwibhedi yelaser ngeteyipu yokufihla, uqinisekise indawo yokuhamba kwentloko yokusika.

5. Inkqubo yokusika: Qala ukusika nge-laser usebenzisa ulawulo lwesoftware, jonga inkqubo ngokusondeleyo, kwaye ulungise useto njengoko kufuneka. Misa kancinci ukuba kuvela iingxaki uze uzilungise ngaphambi kokuba uqhubeke.

6. Ukucutshungulwa emva: Emva kokusika, coca i-acrylic ngebrashi ethambileyo okanye ngomoya ocinezelweyo. Susa izinto zokufihla kwaye ufake unyango lokugqiba (i-polish compound, i-flame polishing) ukuba kuyimfuneko.

Iividiyo Ezinxulumeneyo

Indlela yokusika i-Acrylic eprintiweyo

Umatshini wokusika nge-laser yombonoIkhamera yeCCDinkqubo yokuqaphela inikaisebenza kakuhle emalinienye indlela yokushicilela i-UV yokusika izinto zobugcisa ze-acrylic eziprintiweyo.

Le ndlelayenza lula inkqubo, ukuphelisa imfunekoukuze kulungiswe umsiki we-laser ngesandla.

Ifanelekile kuzo zombiniukuphunyezwa kweprojekthi ngokukhawulezakunye nemveliso yemizi-mvelisoizixhobo ezahlukeneyo.

Ufuna Ukwazi Okungakumbi MalungaUkusika ngeLaser?

Qala Incoko Ngoku!

Iingcebiso

Iingcebiso Zokulungiselela

Khetha i-Acrylic efanelekileyo: Ii-acrylics ezicacileyo neziluhlaza okwesibhakabhaka zinokuba yingxaki kwii-diode lasers kuba azikwazi ukufunxa ukukhanya ngokufanelekileyo. Nangona kunjalo, i-acrylic emnyama idla ngokusika ngokulula.

Lungisa kakuhle i-Focus: Kubalulekile ukujolisa ngokuchanekileyo umqadi welaser kumphezulu wento leyo. Qinisekisa ukuba ubude befocal buhlengahlengiswa ngokuhambelana nobukhulu be-acrylic.

Khetha Useto lwaMandla kunye neSisantya esifanelekileyo: Xa kusikwa i-acrylic, ii-diode lasers zihlala zisebenza kakuhle ngamanqanaba aphantsi ombane kunye nesantya esinciphileyo.

Iingcebiso Zokusebenza

Ukusika uvavanyo: Ngaphambi kokuba wenze imveliso yokugqibela, soloko uvavanya izinto ezilahliweyo ukuze ufumane indawo efanelekileyo.

Ukusebenzisa izixhobo ezincedisayoUkusebenzisa i-range hood kunokunciphisa amalangatye nomsi, nto leyo ebangela ukuba imiphetho icoceke ngakumbi.

Coca ilensi yelaser: Qinisekisa ukuba ilensi yelaser ayinazo iingceba, njengoko nayiphi na imiqobo inokuba nefuthe elibi kumgangatho wokusika.

Iingcebiso zoKhuseleko

Izihlangu zamehlo ezikhuselayo: Soloko unxibe iiglasi zokhuseleko ze-laser ezifanelekileyo ukukhusela amehlo akho ekukhanyeni okukhanyayo.

Ukhuseleko loMlilo: Yiba nesicima-mlilo esikufutshane, njengoko ukusika i-acrylic kunokuvelisa umsi ovuthayo.

Ukhuseleko loMbane: Qinisekisa ukuba i-diode laser yakho isekelwe kakuhle ukuze uphephe iingozi zombane.

Sika kwiPhepha eliMhlophe le-Acrylic

Imibuzo ebuzwa rhoqo

Uninzi lwe-acrylic lunokunqunyulwa nge-laser. Nangona kunjalo, izinto ezifanaumbala kunye nohloboinokuchaphazela inkqubo.

Umzekelo, ii-laser ze-diode ezikhanyayo eziluhlaza okwesibhakabhaka azikwazi ukusika i-acrylic eluhlaza okwesibhakabhaka okanye ecacileyo.

Kubalulekile ukubavavanya into ethilei-acrylic oceba ukuyisebenzisa.

Oku kuqinisekisa ukuba iyahambelana nomsiki wakho we-laser kwaye inokufezekisa iziphumo ezinqwenelekayo.

Ukuze i-laser ikwazi ukukrola okanye ukusika izinto, izinto kufuneka zifunxe amandla okukhanya e-laser.

La mandla aphehla umphungaizinto, okwenza ukuba inqunyulwe.

Nangona kunjalo, ii-diode lasers zikhupha ukukhanya kwi-wavelength ye450nm, ecacileyo i-acrylic kunye nezinye izinto ezibonakalayo ezingenako ukufunxwa.

Ngaloo ndlela, ukukhanya kwelaser kudlula kwi-acrylic ecacileyo ngaphandle kokuyichaphazela.

Kwelinye icala, izinto ezimnyama zifunxa ukukhanya kwelaser kwi-diode laser cutterslula kakhulu.

Yiyo le nto ii-diode lasers zinokusika ezinye izinto ze-acrylic ezimnyama nezingabonakaliyo.

Uninzi lweelaser zediode zinokuphatha amaphepha e-acrylic anobukhulu obufikelela kwi6 mm.

Kwiphepha elityebileyo,iipasi ezininzi okanye ii-laser ezinamandla ngakumbikunokufuneka.

Ncoma oomatshini

Indawo Yokusebenza (W *L): 600mm * 400mm (23.6” * 15.7”)

Amandla eLaser: 60W

Indawo Yokusebenza (W *L): 1300mm * 900mm (51.2” * 35.4”)

Amandla eLaser: 100W/150W/300W

Ixesha leposi: Epreli-30-2025